The global paint spray equipment market is experiencing robust growth, driven by rising demand across automotive, industrial, and architectural applications. According to Grand View Research, the global paint spraying equipment market size was valued at USD 3.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This expansion is fueled by increasing construction activities, technological advancements in spray efficiency, and a growing emphasis on precision coating in manufacturing. As industries strive for higher finish quality and reduced material waste, the role of advanced paint gun manufacturers becomes increasingly pivotal. In this evolving landscape, nine key manufacturers stand out for their innovation, product breadth, and global market presence—shaping the future of spray application technology.

Top 9 Paint Gun Types Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Paint Sprayers

Domain Est. 1994

Website: graco.com

Key Highlights: All Graco sprayers are 100% factory-tested and field-proven so you can be sure your money is going toward the best professional paint sprayer you can purchase….

#2 Sames

Domain Est. 1999

Website: sames.com

Key Highlights: Sames offers a wide range of products to meet your industrial needs, including: -Automatic and manual guns: For precise and efficient spraying. -Pumps: For the ……

#3 Pittsburgh Spray Equipment Company

Domain Est. 2015

Website: pittsburghsprayequip.com

Key Highlights: From manufacturers to contractors to individuals we have a variety of options to help with your painting, sandblasting, powder coating, and safety equipment ……

#4 3M Spray Guns

Domain Est. 1988

Website: 3m.com

Key Highlights: Devices that utilize pressure to apply paint or coatings onto a work surface. The head of a spray gun dictates the spray pattern when dispensed….

#5 Apollo Sprayers

Domain Est. 1995

Website: hvlp.com

Key Highlights: Spray Your Way to the Perfect Finish. Apollo Sprayers is the global home of the most advanced High Volume, Low Pressure HVLP paint sprayers. Learn More ……

#6 DeVilbiss Automotive Refinishing

Domain Est. 1995

Website: binks.com

Key Highlights: We have years of experience developing professional spray guns and equipment designed to easily integrate into your overall automotive refinishing operations….

#7 Spray Guns by Sharpe

Domain Est. 1997

Website: sharpe1.com

Key Highlights: Sharpe manufactures a complete line of paint spray guns that cover a wide variety of application needs. From our newest and most advanced RAZOR Spray Guns to ……

#8 Buy Paint Spray Guns

Domain Est. 2019

Website: pilotsprayguns.com

Key Highlights: Available in HVLP, HP & LEGACY series, optimized to ensure the right spray painting tool for every job. Low Maintenance. Low Maintenance….

#9 Ranox

Domain Est. 2024

Website: ranoxspray.com

Key Highlights: Ranox keeps manufacturing high-quality air paint spray guns under strict production standards and has been widely favored by many customers….

Expert Sourcing Insights for Paint Gun Types

H2: 2026 Market Trends for Paint Gun Types

The global paint gun market is poised for significant transformation by 2026, driven by technological innovation, sustainability demands, and evolving end-user requirements across industries such as automotive, construction, and manufacturing. Key trends shaping the landscape of paint gun types include the rising adoption of electrostatic and HVLP (High Volume Low Pressure) systems, increased automation, and a growing emphasis on eco-friendly application methods.

1. Dominance of HVLP and LVLP (Low Volume Low Pressure) Systems

HVLP and LVLP paint guns are expected to maintain strong market growth through 2026 due to their superior transfer efficiency and reduced overspray. These systems align with tightening environmental regulations, particularly in North America and Europe, where VOC (volatile organic compound) emissions are strictly monitored. Their popularity in automotive refinishing and woodworking applications continues to boost demand.

2. Surge in Electrostatic Paint Guns

Electrostatic paint guns are gaining traction, especially in industrial coating applications. By electrically charging paint particles, these systems ensure uniform coverage and high material utilization—critical for mass production in aerospace, appliances, and metal fabrication. As manufacturers prioritize cost-efficiency and waste reduction, the adoption of electrostatic technology is projected to grow at a CAGR of over 6% through 2026.

3. Automation and Integration with Robotics

The integration of paint guns with robotic systems is a defining trend in industrial settings. Automated spray solutions offer precision, consistency, and reduced labor costs. By 2026, demand for robotic-compatible paint guns—particularly in automotive OEM plants and large-scale manufacturing—is expected to rise significantly, with companies investing in smart factories and Industry 4.0 technologies.

4. Growth in Cordless and Portable Spray Systems

In the DIY and small commercial sectors, cordless and portable paint guns are gaining popularity. Advances in battery technology have improved runtime and performance, making these tools ideal for on-site jobs in construction and home improvement. This segment is forecasted to expand rapidly, especially in emerging markets with growing urbanization and infrastructure development.

5. Sustainability and Water-Based Coatings Compatibility

With a global push toward greener practices, paint gun manufacturers are redesigning equipment to handle water-based and low-VOC coatings effectively. Traditional air spray guns are being adapted or replaced to prevent clogging and ensure smooth application of eco-friendly paints, positioning sustainability as a core design criterion.

6. Regional Market Dynamics

Asia-Pacific is expected to lead market growth by 2026, fueled by expanding automotive and construction industries in China, India, and Southeast Asia. Meanwhile, North America and Europe will emphasize high-efficiency and compliant systems due to stringent environmental standards.

In summary, the 2026 paint gun market will be characterized by technological sophistication, automation, and sustainability. HVLP, electrostatic, and robotic-integrated systems are set to dominate, while regional demand patterns and environmental policies will continue to shape innovation and adoption across paint gun types.

Common Pitfalls When Sourcing Paint Gun Types (Quality, IP)

When sourcing paint guns—especially considering quality and Ingress Protection (IP) ratings—several common pitfalls can lead to suboptimal performance, safety risks, or increased long-term costs. Being aware of these issues helps ensure you select the right equipment for your application.

Overlooking IP Rating Requirements

One of the most frequent mistakes is ignoring or misunderstanding the importance of Ingress Protection (IP) ratings. Paint environments often involve moisture, dust, solvents, and fine particulates. Selecting a paint gun with an insufficient IP rating (e.g., IP40 instead of IP54 or higher) can lead to internal component failure, electrical hazards, or reduced lifespan—especially in humid or outdoor conditions.

Prioritizing Low Cost Over Build Quality

Choosing a lower-cost paint gun without evaluating material quality and manufacturing standards often results in poor durability, inconsistent spray patterns, and frequent maintenance. Cheap models may use inferior seals, nozzles, and trigger mechanisms that degrade quickly when exposed to aggressive coatings or continuous use.

Ignoring Compatibility with Coating Materials

Different paint guns are designed for specific types of coatings (e.g., water-based, solvent-based, high-viscosity paints). Sourcing a gun not chemically compatible with your materials can lead to clogging, corrosion, or degradation of internal components—even if the IP rating is sufficient for the environment.

Assuming All HVLP Guns Are Equal

High Volume Low Pressure (HVLP) guns vary significantly in quality and design. Some budget models may claim HVLP compliance but fail to deliver proper atomization or transfer efficiency. This leads to overspray, wasted material, and poor finish quality—undermining the primary benefits of HVLP technology.

Neglecting Certification and Standards Compliance

In industrial or regulated environments, using uncertified equipment can pose safety and compliance risks. Failing to verify that a paint gun meets relevant standards (e.g., ATEX for explosive environments, CE marking, or UL certification) may result in unsafe operation or non-compliance with workplace regulations.

Overlooking Service and Spare Parts Availability

Even high-quality paint guns require maintenance. Sourcing from suppliers or brands with limited support, unavailable spare parts, or long lead times can cause extended downtime. This is especially critical in production environments where uptime is essential.

Misjudging Air Supply and Pressure Requirements

Some paint guns, particularly HVLP or LVLP (Low Volume Low Pressure) models, require specific air delivery rates and pressure stability. Using a gun that exceeds your compressor’s capacity leads to poor atomization and inconsistent finishes. Always match the gun’s specifications with your existing air system capabilities.

Failing to Verify Real-World Performance Claims

Manufacturers may exaggerate performance metrics like transfer efficiency, airflow requirements, or durability. Without testing or verified user reviews, you risk investing in a paint gun that underperforms in actual operating conditions.

Avoiding these pitfalls requires due diligence: evaluate IP ratings for your environment, prioritize build quality and compatibility, verify certifications, and ensure long-term support and performance reliability.

Logistics & Compliance Guide for Paint Gun Types

Understanding Paint Gun Classifications for Shipping and Regulation

When transporting or using paint guns across different regions, it is essential to understand how various types are classified under logistics and compliance frameworks. These classifications influence packaging, transportation, import/export regulations, safety data sheets (SDS), and environmental compliance.

Common Paint Gun Types and Regulatory Considerations

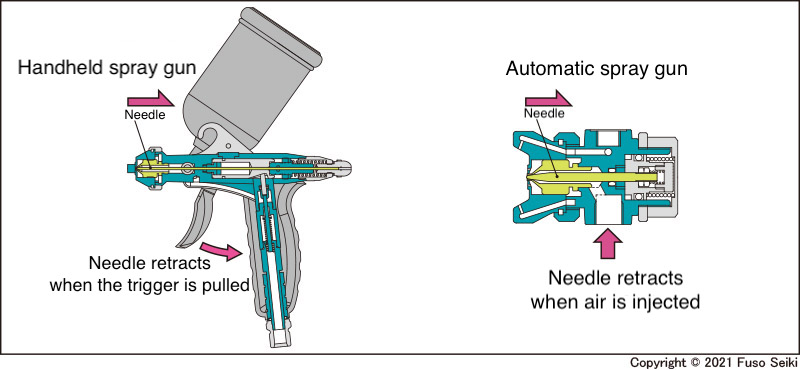

Air Spray Paint Guns

Air spray guns use compressed air to atomize paint. These are widely used in automotive and industrial applications. From a compliance standpoint, they are generally considered general industrial equipment. However, if shipped with solvent-based coatings or cleaning agents, they may fall under hazardous materials (HAZMAT) regulations due to residue. Ensure thorough cleaning and declaration of any residual chemicals per DOT (Department of Transportation) and IATA guidelines.

HVLP (High Volume Low Pressure) Paint Guns

HVLP guns are favored for reduced overspray and improved transfer efficiency. Many regions promote HVLP use due to environmental regulations targeting volatile organic compound (VOC) emissions. When shipping internationally, verify local air quality standards (e.g., EPA in the U.S., REACH in the EU), as HVLP systems may be subject to specific VOC control requirements depending on application.

Airless Paint Guns

Common in construction and large surface coating, airless paint guns operate under high pressure. Logistics considerations include securing moving parts and depressurizing units before transport. Safety compliance must address high-pressure hazards—ensure compliance with OSHA (U.S.) or equivalent workplace safety standards. Units with electric components may also require adherence to electrical safety certifications (e.g., CE, UL).

Electrostatic Paint Guns

These use electric charge to attract paint particles to grounded surfaces, improving efficiency. Electrostatic guns often contain electronic circuitry and high-voltage components, requiring compliance with electromagnetic compatibility (EMC) and electrical safety standards (e.g., IEC 60204). When shipping, classify under appropriate HS codes for electrical industrial equipment and ensure packaging prevents electrostatic discharge (ESD) damage.

Pressure Feed and Siphon Feed Paint Guns

Feed mechanism type affects portability and application, but regulatory differences are minimal. However, if the gun is part of a complete system including solvent reservoirs, evaluate whether the assembled unit contains hazardous residues. Clean and dry units appropriately; otherwise, they may be classified as contaminated equipment under environmental disposal laws (e.g., RCRA in the U.S.).

Packaging and Transportation Compliance

All paint guns should be cleaned, dried, and disassembled if necessary to remove flammable or toxic residues before shipping. Declare contents accurately on shipping manifests. For international transport, follow:

– IATA (air freight): Classify under UN 3499 (Equipment, self-contained, non-dangerous) if clean and dry.

– IMDG Code (sea freight): Similar classification; ensure no hazardous residues.

– ADR (road transport in Europe): Comply with packaging group standards if any hazardous materials are involved.

Import/Export Documentation

Common documentation includes:

– Commercial invoice specifying HS code (e.g., 8424.20 for mechanical appliances for projecting, dispersing or spraying liquids)

– Packing list

– Certificate of origin

– SDS for accompanying materials (e.g., cleaners, lubricants)

Verify country-specific import regulations—some nations may impose VOC restrictions or require product certification (e.g., UKCA, CCC for China).

Environmental and Workplace Safety Compliance

Ensure paint gun use complies with:

– EPA NESHAP (U.S.) for surface coating operations

– EU Solvents Directive (2004/42/EC) limiting solvent emissions

– Local worker protection laws requiring respiratory protection, ventilation, and training when using hazardous coatings

Regular maintenance and proper disposal of cleaning solvents are also compliance-critical.

Conclusion

Selecting and shipping paint guns requires attention to type-specific regulatory profiles. Always clean equipment thoroughly, classify correctly under HAZMAT rules if needed, and maintain documentation for smooth logistics and compliance across jurisdictions. Stay updated on regional environmental and safety standards to avoid delays or penalties.

In conclusion, selecting the appropriate paint gun type depends on a variety of factors including the nature of the project, desired finish quality, material viscosity, production efficiency, and budget constraints. Air spray guns offer excellent finish quality and are ideal for detailed work, while HVLP (High Volume, Low Pressure) guns provide high transfer efficiency and reduced overspray, making them more environmentally friendly and suitable for smaller or sensitive jobs. For higher productivity and thick coatings, airless spray guns are optimal, especially in large-scale industrial or construction applications. Meanwhile, electrostatic paint guns enhance coating adhesion and efficiency, particularly on conductive surfaces, reducing waste and improving finish uniformity.

Ultimately, evaluating the specific requirements of each application—such as material type, coverage area, portability, and regulatory standards—will guide the most effective sourcing decision. Investing in the right paint gun technology not only improves finish quality and operational efficiency but also reduces material waste and long-term costs. Therefore, a strategic, application-specific approach to sourcing paint guns ensures optimal performance and return on investment across diverse painting operations.