The global paint booth ventilation market is experiencing steady growth, driven by increasing demand from automotive, aerospace, and industrial manufacturing sectors for efficient air quality control and regulatory compliance. According to Grand View Research, the global industrial ventilation market was valued at USD 47.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030, with paint booth systems representing a significant segment due to stringent environmental and safety regulations. Similarly, Mordor Intelligence projects a CAGR of over 5.8% for the industrial ventilation systems market through 2028, citing rising investments in manufacturing infrastructure and the growing emphasis on worker health and energy-efficient solutions. As facilities prioritize emission control and optimal airflow performance, the need for reliable ventilation technology has intensified—elevating the role of key manufacturers in shaping safer, compliant, and sustainable painting environments.

Top 10 Paint Booth Ventilation Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Painting Equipment

Domain Est. 2013

Website: bzbspraybooth.com

Key Highlights: Jingzhongjing is a specialist manufacturer of industrial paint booths and finishing equipment for a variety of industries, such as automotive spray booth, ……

#2 Spray Systems, Inc.: Spray Booths

Domain Est. 1997

Website: spraysystems.com

Key Highlights: With over 40 years of expertise, Spray Systems offers custom spray booths and finishing systems for aerospace, automotive, and equipment manufacturers….

#3 Industrial Paint Booths

Domain Est. 2010

Website: blowtherm-usa.com

Key Highlights: Blowtherm USA Automotive Spray Booths offers the best in class, most advanced technology for Automotive Spray Booth companies today….

#4 Paint Booth, Industrial Spray Booths Installation

Domain Est. 2000

Website: paintbooth.com

Key Highlights: We can professionally install your paint booth, spray booth, prep station, paint mixing room, finishing system, industrial paint booth or heated make-up air ……

#5 Paint Booths & Industrial Spray Application Systems

Domain Est. 2002

#6 Paint Booths, Spray Booths, Finishing Systems

Domain Est. 2011

Website: zparint.com

Key Highlights: Each booth is custom-built according to your business solutions, with proper ventilation and appropriate fixtures. We deliver powder coating ovens, industrial ……

#7 Paint booth odor removal exhaust fans

Domain Est. 2012

Website: aeib.fr

Key Highlights: Take a look at our range of industrial fans that are specially adapted to provide ventilation in professional paint booths….

#8 Spray & Paint Booth Exhaust Fans

Domain Est. 1996

Website: nyb.com

Key Highlights: The New York Blower fans used for this application are designed and manufactured for removing paint fumes and paint over-spray. Request a quote or call us ……

#9 Blowtherm: Spray booths, Thermo

Domain Est. 1997

Website: blowtherm.it

Key Highlights: Spray booths and paint systems. Tailor-made solutions for maximum results. We assess your goals and design the perfect paint system for your company….

#10 Spray Booths And Finishing Solutions

Domain Est. 2016

Website: rttsolutions.com

Key Highlights: RTT Finishing Solutions by Clean Air Industries has emerged as a market leader in paint booths, powder booths, ovens, washers, AMU’s, and other finishing ……

Expert Sourcing Insights for Paint Booth Ventilation

H2: 2026 Market Trends for Paint Booth Ventilation

The global paint booth ventilation market is poised for significant transformation by 2026, driven by tightening environmental regulations, advancements in energy-efficient technologies, and growing demand from automotive, aerospace, and industrial manufacturing sectors. Key trends shaping the market include:

-

Increased Regulatory Pressure and Emission Standards

By 2026, stringent environmental regulations—especially from the EPA in the U.S., the European Union’s REACH and VOC directives, and emerging standards in Asia-Pacific—will continue to compel manufacturers to adopt high-efficiency ventilation systems. Paint booths must increasingly integrate advanced filtration and air purification technologies to meet VOC (volatile organic compound) and particulate emission limits, driving innovation and market growth. -

Rise of Energy-Efficient and Sustainable Systems

Energy consumption is a major operational cost in paint booth operations. As sustainability becomes a core business priority, demand is growing for energy recovery systems, variable frequency drives (VFDs), and low-energy fan designs. By 2026, energy recovery ventilators (ERVs) and regenerative thermal oxidizers (RTOs) are expected to gain wider adoption, especially in regions with high energy costs. -

Adoption of Smart Ventilation and IoT Integration

The integration of IoT (Internet of Things) sensors and smart controls will be a defining trend. Paint booths equipped with real-time air quality monitoring, predictive maintenance alerts, and automated airflow adjustment will enhance efficiency and reduce downtime. By 2026, smart ventilation systems are projected to become standard in new installations, particularly in high-end manufacturing facilities. -

Growth in the Automotive and Aerospace Sectors

The global push toward electric vehicles (EVs) is expected to increase demand for precision paint finishes, necessitating advanced ventilation to maintain cleanroom-level environments. Similarly, aerospace manufacturing requires strict contamination control. These sectors will drive demand for downdraft and semi-downdraft paint booths with superior airflow management. -

Expansion in Emerging Markets

Rapid industrialization in countries such as India, Vietnam, and Brazil is leading to new manufacturing facilities and repair centers, boosting the need for compliant and efficient paint booth systems. Local manufacturers are beginning to adopt international standards, creating opportunities for global ventilation system providers. -

Shift Toward Modular and Portable Solutions

Demand for prefabricated, modular paint booths with integrated ventilation is rising, especially in the automotive refinish and field service sectors. These systems offer faster installation, scalability, and compliance with environmental codes—making them ideal for small to mid-sized operations. -

Focus on Worker Health and Safety

Enhanced awareness of occupational health is pushing companies to invest in ventilation systems that ensure optimal air quality inside paint booths. By 2026, systems featuring HEPA filters, carbon adsorption, and real-time contaminant detection will be increasingly mandated to protect workers from hazardous fumes and overspray.

In conclusion, the 2026 paint booth ventilation market will be defined by innovation, regulatory alignment, and sustainability. Companies that prioritize energy efficiency, digital integration, and compliance will be best positioned to capture growth across both mature and emerging markets.

Common Pitfalls Sourcing Paint Booth Ventilation (Quality, IP)

Inadequate IP Rating for Harsh Environments

A frequent oversight is selecting ventilation systems with an insufficient Ingress Protection (IP) rating. Paint booths expose equipment to overspray, solvents, moisture, and dust. Opting for fans or motors with low IP ratings (e.g., IP54 instead of IP55 or higher) risks internal contamination, leading to premature motor failure, fire hazards, and costly downtime. Always verify that all electrical components, especially motors and control boxes, meet or exceed IP55 standards to ensure protection against dust and water jets.

Compromising on Material Quality and Corrosion Resistance

Sourcing low-cost ventilation units made from substandard materials—such as non-galvanized steel or inadequate powder coatings—leads to rapid corrosion from chemical exposure and humidity. This compromises structural integrity and air quality, increasing maintenance costs and safety risks. Ensure fan housings, blades, and ductwork are constructed from corrosion-resistant materials like galvanized steel with protective coatings or stainless steel, especially in high-solvent environments.

Overlooking Airflow and Filtration Performance Specifications

Buyers often focus on upfront cost while neglecting critical performance metrics like CFM (cubic feet per minute), static pressure tolerance, and filtration efficiency. Undersized or poorly designed systems result in inadequate airflow, poor paint finish quality, and buildup of hazardous fumes. Confirm that the ventilation system meets or exceeds industry standards (e.g., NFPA 33, OSHA) for airflow velocity (typically 100 ft/min across the booth face) and includes multi-stage filtration (e.g., pre-filters and final filters) to capture overspray effectively.

Ignoring Compliance with Safety and Environmental Regulations

Sourcing ventilation equipment without verifying compliance with local and international safety standards (e.g., ATEX for explosive atmospheres, UL certification, CE marking) can lead to regulatory violations, failed inspections, and operational shutdowns. Additionally, non-compliant systems may lack spark-resistant construction or explosion relief panels, creating serious fire and health hazards in flammable environments.

Failing to Verify Manufacturer Credentials and After-Sales Support

Procuring from unverified suppliers or third-party resellers without direct access to technical support increases the risk of counterfeit or non-genuine parts. Lack of warranty, poor documentation, and limited availability of replacement parts hinder maintenance and reduce system longevity. Always source from reputable manufacturers with proven industry experience, comprehensive technical documentation, and responsive after-sales service to ensure long-term reliability and compliance.

Logistics & Compliance Guide for Paint Booth Ventivation

Regulatory Framework and Standards

Paint booth ventilation systems are subject to a range of federal, state, and local regulations designed to ensure worker safety, environmental protection, and air quality. Key regulatory bodies include the Environmental Protection Agency (EPA), Occupational Safety and Health Administration (OSHA), National Fire Protection Association (NFPA), and local air quality management districts. Compliance with standards such as NFPA 33 (Standard for Spray Application Using Flammable and Combustible Materials), OSHA 29 CFR 1910.94 (Ventilation), and EPA National Emission Standards for Hazardous Air Pollutants (NESHAP) for surface coating operations is mandatory. Facilities must stay current with updates to these regulations to avoid penalties and ensure operational legality.

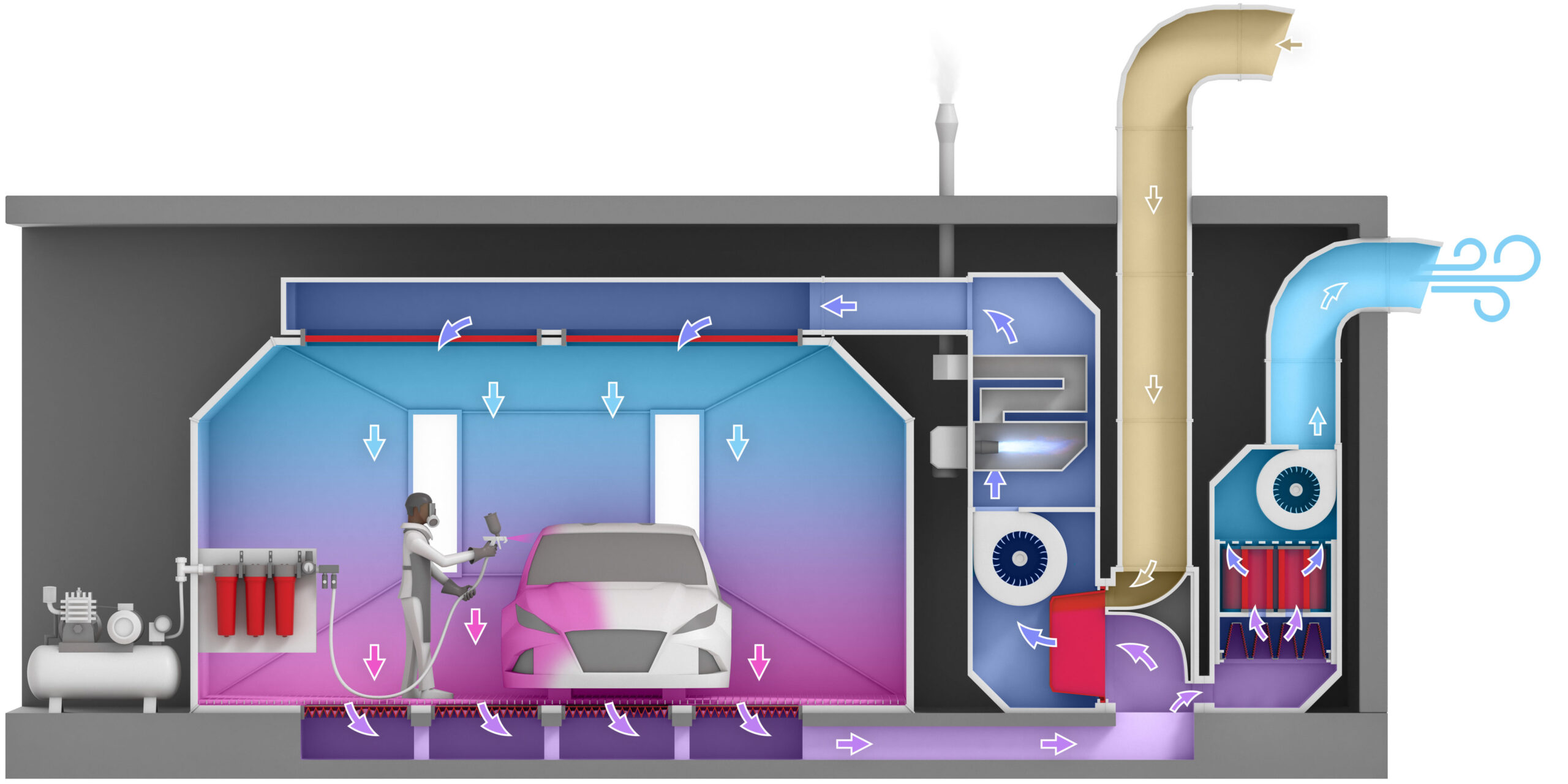

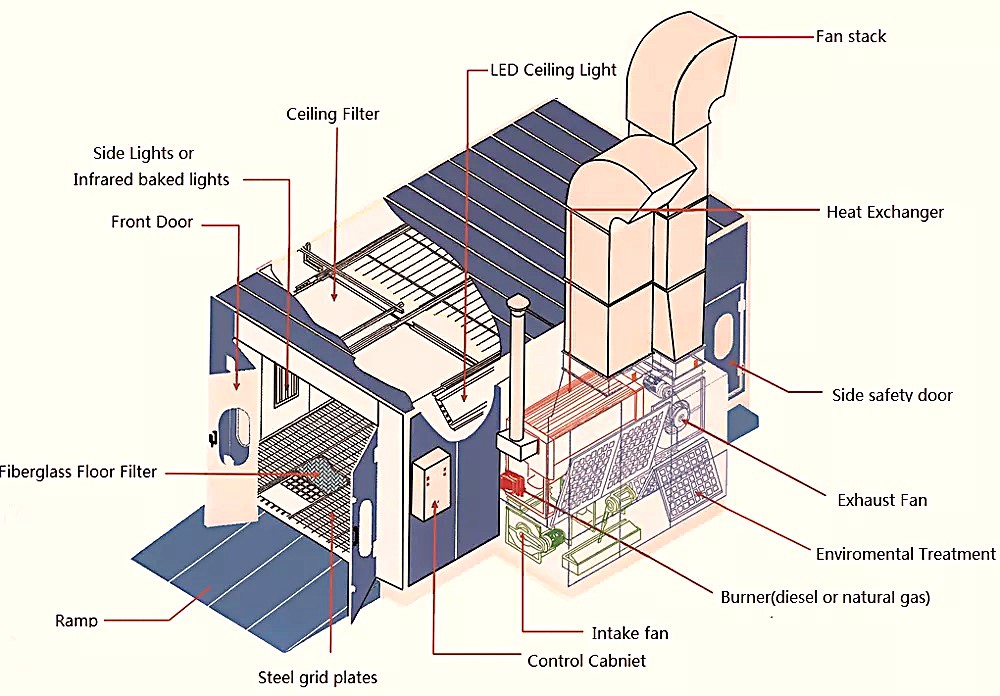

Ventilation System Design Requirements

Effective paint booth ventilation must provide adequate airflow to capture and remove overspray, solvents, and hazardous fumes. Key design considerations include:

– Airflow velocity: Maintain a minimum face velocity of 100 feet per minute (fpm) across the booth opening.

– Airflow pattern: Ensure a unidirectional airflow (typically downward or cross-draft) to carry contaminants away from operators.

– Exhaust filtration: Implement primary (e.g., fiberglass filters) and secondary (e.g., charcoal or HEPA) filtration to capture particulates and volatile organic compounds (VOCs).

– Explosion protection: Install flame arrestors, spark-resistant construction, and explosion-relief panels where required by NFPA 33.

Permitting and Environmental Compliance

Prior to installation or modification, facilities must obtain necessary environmental permits, including:

– Air quality permits: Required by state or local air districts for emissions of VOCs and hazardous air pollutants (HAPs).

– Title V operating permits: For larger facilities emitting regulated pollutants above threshold levels.

Documentation must include emission estimates, control equipment specifications, and compliance monitoring plans. Regular reporting and recordkeeping are essential for ongoing compliance.

Monitoring and Maintenance Protocols

To remain compliant and ensure system efficacy, implement a structured maintenance program:

– Daily checks: Inspect filters, airflow, and alarms.

– Weekly/monthly tasks: Clean filters, check fan belts, and verify exhaust rates.

– Annual certification: Conduct airflow velocity tests and duct integrity inspections by a qualified technician.

Keep detailed logs of all maintenance, filter changes, and repairs for audit readiness.

Worker Safety and Training

Personnel working near or operating paint booths must be trained on:

– Proper use of ventilation systems and personal protective equipment (PPE).

– Emergency procedures for fire, chemical exposure, or system failure.

– Recognition of symptoms related to solvent overexposure.

OSHA requires hazard communication (HazCom) training for all employees handling hazardous chemicals used in spray operations.

Waste Handling and Disposal

Used filters, overspray residue, and cleaning solvents are often classified as hazardous waste under RCRA (Resource Conservation and Recovery Act). Facilities must:

– Characterize waste materials properly.

– Store waste in labeled, closed containers.

– Use licensed hazardous waste transporters and treatment facilities.

Maintain manifests and disposal records for at least three years.

Inspection and Audit Preparedness

Prepare for regulatory inspections by:

– Maintaining up-to-date compliance documentation, including permits, monitoring results, and training records.

– Conducting internal audits at least annually.

– Ensuring all safety signage is visible and equipment is in proper working order.

Immediate corrective actions should be documented and implemented for any non-conformities.

Conclusion

Proper logistics and compliance for paint booth ventilation require proactive planning, regular maintenance, and adherence to evolving regulations. By integrating robust design, continuous monitoring, and comprehensive training, facilities can ensure a safe working environment, minimize environmental impact, and maintain regulatory compliance.

In conclusion, sourcing a paint booth ventilation system requires careful evaluation of several critical factors including airflow efficiency, compliance with environmental and safety regulations (such as OSHA and EPA standards), energy consumption, and the specific requirements of your painting operations. Selecting the right system not only ensures optimal operator health and safety but also enhances finish quality, reduces paint overspray, and supports regulatory compliance. It is essential to partner with reputable suppliers who offer reliable equipment, proper technical support, and systems tailored to your operational scale and paint types. Investing in a high-quality ventilation system ultimately leads to long-term cost savings, improved productivity, and a safer working environment.