The global automotive suspension systems market is undergoing significant transformation, driven by rising consumer demand for enhanced ride comfort, vehicle safety, and performance—particularly in electric and premium vehicles. According to Grand View Research, the global automotive suspension system market was valued at USD 67.9 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This expansion is fueled by the increasing adoption of advanced suspension technologies, including active and semi-active systems, as well as the integration of lightweight materials to improve fuel efficiency and handling.

Within this evolving landscape, pad set suspension systems—critical components that contribute to noise reduction, vibration dampening, and structural integrity—have gained prominence among OEMs and Tier-1 suppliers. The surge in vehicle production, especially in Asia-Pacific and North America, alongside stringent regulations on vehicle safety and comfort, has intensified competition among manufacturers to innovate and scale production. As demand for higher-performance suspension solutions grows, a select group of manufacturers has emerged as leaders in developing and supplying technologically advanced pad set systems. These companies are not only investing heavily in R&D but are also expanding their global footprint to meet the needs of a rapidly advancing automotive industry.

Top 8 Pad Set Suspension System Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Delta Retention and RPS® Helmet Padding Liner System

Domain Est. 1995

Website: safariland.com

Key Highlights: This system is made up of a lightweight Polyamide build with a leather-lined chinstrap for all-day comfortable fit. Hardened injection molded plastic buckles ……

#2 Products

Domain Est. 1997

Website: teamwendy.com

Key Highlights: Team Wendy is an Avon Technologies company providing exceptional head protection systems for those who risk their lives every day….

#3 Fas-Trac III Hard Hat Suspension

Domain Est. 2004

Website: us.msasafety.com

Key Highlights: No more pulled hair. No more falling off. No more sacrificing worker comfort for safety. Market-leading MSA helmets now have a comfort-leading suspension!…

#4 AireSupport

Domain Est. 2004

Website: armorsource.com

Key Highlights: ArmorSource’s AireSupport pad system is a lightweight solution that provides protection and the ability to customize pad placement within the shell for a ……

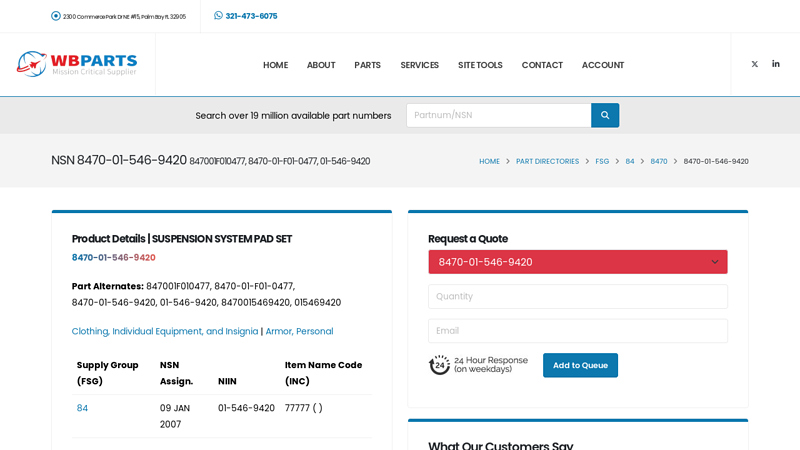

#5 8470-01-546-9420 – SUSPENSION SYSTEM PAD SET

Domain Est. 2006

Website: wbparts.com

Key Highlights: Product Details | SUSPENSION SYSTEM PAD SET 8470-01-546-9420. Part Alternates: 847001F010477, 8470-01-F01-0477,…

#6 Sports Gear Store & Sporting Goods Company

Domain Est. 2009

Website: force3progear.com

Key Highlights: We design and manufacture some of the worlds top safety equipment to protect athletes and officials around the world. Our Patented S3 Shock suspension system ……

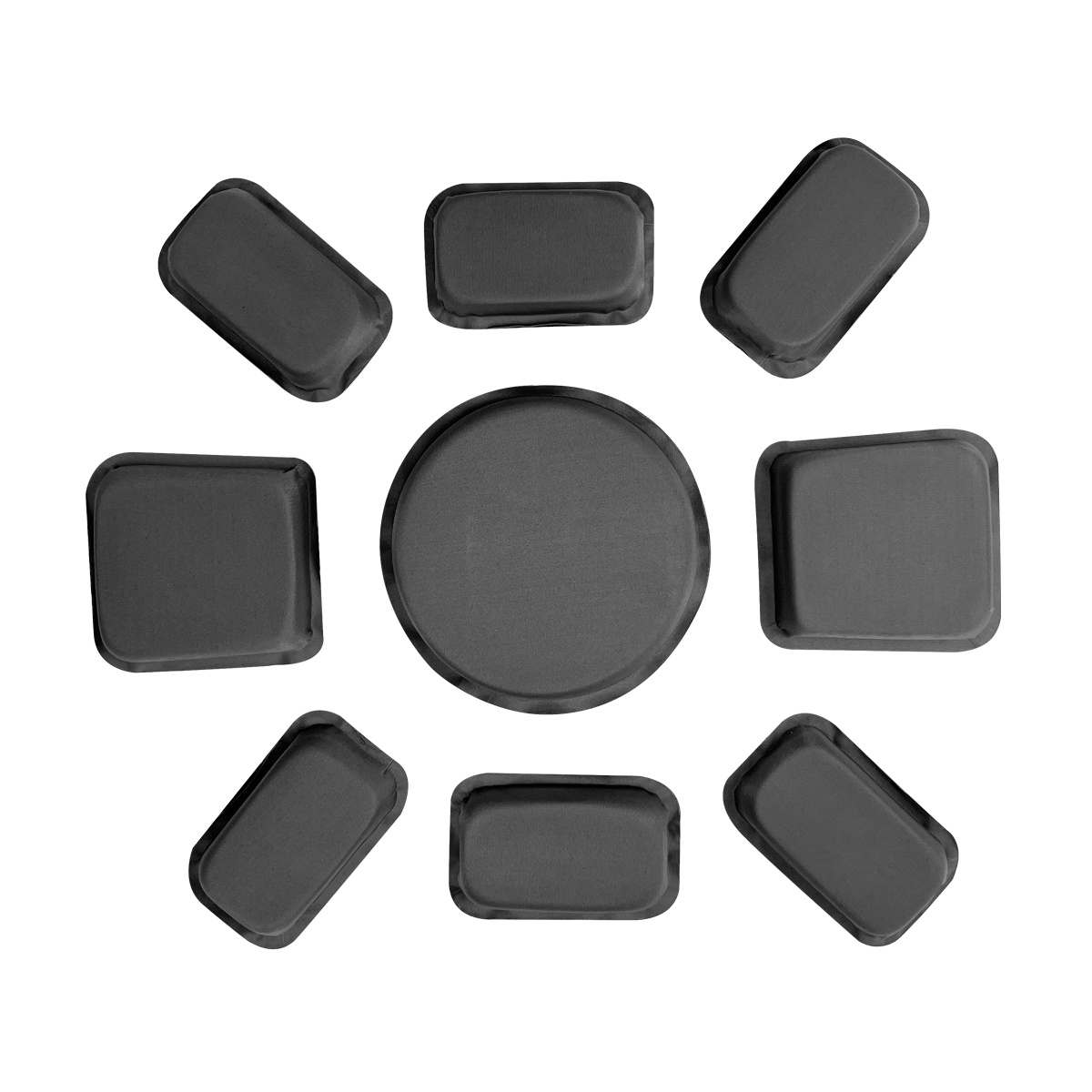

#7 ECH Helmet Suspension System (9

Domain Est. 2010

Website: g-form.com

Key Highlights: Experience superior protection and comfort with our advanced helmet suspension system for ACH and ECH Ballistic Helmets. Available in 7- and 9-pad ……

#8 Safariland PROTECH Delta Retention System and RPS Helmet …

Domain Est. 2014

Website: curtisblueline.com

Key Highlights: This system is made up of a lightweight Polyamide build with a leather-lined chinstrap for an all-day comfortable fit….

Expert Sourcing Insights for Pad Set Suspension System

H2: Projected Market Trends for Pad Set Suspension Systems in 2026

The global market for pad set suspension systems is poised for significant evolution by 2026, driven by technological advancements, increasing demand across automotive and industrial sectors, and a shift toward enhanced vehicle performance and comfort. These systems—critical components in vehicle suspension that utilize rubber or elastomeric pads to absorb shocks and reduce vibrations—are experiencing a transformation due to changing regulatory standards, material innovations, and evolving consumer expectations.

-

Rising Demand in Electric Vehicles (EVs)

With the global push toward electrification, the EV market is expected to account for a substantial share of pad set suspension system demand by 2026. Electric vehicles, which are generally heavier due to battery packs, require more robust suspension solutions. Pad sets that offer improved vibration damping and noise isolation are becoming essential to maintain ride comfort and structural integrity. As automakers expand their EV lineups, the integration of advanced pad set suspension components will grow in parallel. -

Material Innovation and Lightweighting

A key trend shaping the 2026 outlook is the development of high-performance elastomers and composite materials. Manufacturers are investing in thermoplastic polyurethanes (TPU), silicone-based compounds, and nano-reinforced rubbers that offer better durability, temperature resistance, and longevity. These materials not only enhance performance but also contribute to vehicle lightweighting—improving energy efficiency, especially in EVs. -

Growth in Aftermarket and Replacement Demand

The aftermarket segment for pad set suspension systems is projected to expand significantly by 2026. As vehicle fleets age globally, especially in emerging markets, the need for maintenance and replacement of worn suspension components increases. Coupled with longer vehicle usage lifespans and rising consumer awareness about ride safety, the aftermarket presents a lucrative opportunity for suppliers. -

Stringent Regulatory and Safety Standards

Governments worldwide are tightening vehicle safety and emissions regulations, indirectly influencing suspension system design. Noise, vibration, and harshness (NVH) reduction has become a compliance and competitive differentiator. Pad set suspension systems are being optimized to meet these standards, leading to more sophisticated designs and higher quality control requirements across the supply chain. -

Asia-Pacific as a Growth Hub

The Asia-Pacific region, particularly China, India, and Southeast Asia, is expected to dominate market growth by 2026. Rapid urbanization, rising disposable incomes, and expanding automotive production are key drivers. Local manufacturers are increasingly adopting global quality standards, fostering domestic innovation and supply chain integration in pad set suspension technologies. -

Integration with Smart Suspension Systems

While pad sets are traditionally passive components, future trends indicate integration with semi-active and active suspension systems. By 2026, hybrid designs that combine traditional pad sets with sensors and adaptive materials may begin to emerge, especially in premium and commercial vehicle segments, enabling real-time response to road conditions.

In conclusion, the pad set suspension system market in 2026 will be shaped by electrification, material science advancements, regulatory dynamics, and regional industrial growth. Companies that invest in R&D, sustainability, and strategic partnerships are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls Sourcing a Pad Set Suspension System (Quality, IP)

Sourcing a Pad Set Suspension System—critical for vibration isolation in sensitive equipment like semiconductor tools or precision instruments—requires careful attention to both quality and intellectual property (IP) concerns. Overlooking these aspects can lead to performance failures, legal risks, and costly downtime.

Poor Quality Control and Inconsistent Performance

Suppliers may offer lower-cost systems that lack rigorous quality assurance, leading to inconsistent damping characteristics, premature wear, or failure under load. These issues compromise equipment stability, potentially damaging high-value machinery or disrupting production. Always verify adherence to industry standards (e.g., ISO 9001), request test reports, and conduct factory audits to ensure manufacturing consistency and material integrity.

Inadequate Intellectual Property Protection

Many advanced suspension systems incorporate proprietary designs, damping technologies, or patented materials. Sourcing from suppliers without proper IP clearance risks infringement lawsuits, shipment seizures, or forced redesigns. Ensure suppliers provide IP indemnification and confirm that the design does not violate existing patents—particularly those held by major OEMs in the semiconductor or precision engineering sectors.

Lack of Traceability and Documentation

A frequent quality oversight is insufficient component traceability. Without lot tracking, material certifications, and detailed assembly records, diagnosing field failures becomes difficult, and compliance with regulatory or customer requirements (e.g., in cleanroom environments) may be compromised. Demand full documentation packages, including RoHS/REACH compliance and material test reports.

Counterfeit or Reverse-Engineered Components

In cost-driven markets, some suppliers may offer systems that mimic original equipment but use inferior or unauthorized copies of patented technologies. These counterfeit products often fail under real-world conditions and expose the buyer to legal liability. Work only with authorized distributors or suppliers with verifiable OEM partnerships.

Insufficient Environmental and Compliance Validation

Pad set systems used in controlled environments must meet strict outgassing, particle emission, and chemical resistance standards. Sourcing systems without proper validation (e.g., ASTM E595 for outgassing) can contaminate cleanrooms or degrade in harsh conditions. Confirm compliance with relevant environmental standards prior to procurement.

Avoiding these pitfalls requires due diligence in supplier qualification, thorough contract terms covering quality and IP, and ongoing performance monitoring. Engaging technical experts during the sourcing process can mitigate risks and ensure long-term system reliability.

Logistics & Compliance Guide for Pad Set Suspension System

Product Overview

The Pad Set Suspension System is a critical component designed to enhance vehicle ride comfort, stability, and safety by absorbing shocks and supporting the vehicle’s weight. This guide outlines the logistics handling, transportation, storage, and regulatory compliance requirements essential for the safe and legal distribution and use of the system.

Packaging Requirements

- Use manufacturer-approved packaging designed to protect suspension components from impact, moisture, and contamination.

- Include moisture-resistant wrapping and desiccants in sealed containers to prevent corrosion during transit.

- Clearly label each package with product name, part number, batch/lot number, and handling instructions (e.g., “Fragile – Handle with Care,” “Do Not Stack”).

- Ensure packaging complies with international shipping standards (e.g., ISTA 3A) for durability.

Storage Conditions

- Store in a dry, climate-controlled environment with temperatures between 10°C and 30°C (50°F to 86°F) and relative humidity below 60%.

- Keep away from direct sunlight, heat sources, and corrosive chemicals.

- Store on pallets off the floor to prevent moisture absorption and pest infestation.

- Follow FIFO (First In, First Out) inventory practices to minimize aging of rubber and elastomeric components.

Transportation Guidelines

- Use enclosed and secure vehicles to protect against weather exposure and theft.

- Secure loads with straps or braces to prevent shifting during transit.

- Avoid extreme temperature exposure; do not leave cargo in vehicles for prolonged periods in hot or freezing conditions.

- Comply with hazardous materials regulations if packaging includes desiccants or other regulated substances (typically non-hazardous; confirm with MSDS/SDS).

Import/Export Compliance

- Verify Harmonized System (HS) Code: 8708.80.xx (Suspension Parts) for accurate customs classification.

- Prepare complete documentation: Commercial Invoice, Packing List, Bill of Lading/Air Waybill, Certificate of Origin.

- Confirm compliance with destination country standards (e.g., FMVSS in the U.S., ECE Regulations in Europe, ADR in Australia).

- Obtain necessary import permits or conformity assessment certificates where required (e.g., GCC Certificate for Gulf countries).

Regulatory & Safety Compliance

- Ensure product meets ISO 9001 (Quality Management) and IATF 16949 (Automotive Quality) standards.

- Confirm compliance with vehicle safety standards such as FMVSS 126 (ESC) and applicable parts of FMVSS 105/135 (Braking Systems), where the suspension system interacts with vehicle dynamics.

- Maintain full traceability through batch/lot tracking and component serialization.

- Provide technical documentation and installation instructions in local languages for target markets.

Environmental & RoHS Compliance

- Confirm the Pad Set Suspension System complies with RoHS (Restriction of Hazardous Substances) directives, particularly for any electronic or coated components.

- Ensure packaging materials are recyclable and符合 EU Packaging Waste Directive or equivalent local regulations.

- Provide disposal guidelines for end-of-life components, especially rubber and metal parts.

After-Sales & Recall Preparedness

- Maintain a product traceability system capable of supporting recalls if non-conformance or safety issues arise.

- Provide a clear warranty policy and process for reporting defects.

- Train logistics partners and distributors on handling, storage, and compliance procedures.

Contact & Support

For compliance documentation, safety data sheets (SDS), or logistical support, contact:

Global Compliance Team

Email: [email protected]

Phone: +1 (800) XXX-XXXX

Website: www.yourcompany.com/compliance

Conclusion for Sourcing Pad Set Suspension System:

After a thorough evaluation of technical specifications, supplier capabilities, cost considerations, quality standards, and lead time requirements, the sourcing strategy for the pad set suspension system should focus on selecting a reliable supplier that ensures consistent product quality, compliance with industry standards (such as ISO/TS certifications), and the ability to support future scalability.

The chosen pad set suspension components must deliver optimal vibration damping, durability under operational stress, and compatibility with existing vehicle or machinery systems. Close collaboration with suppliers for just-in-time delivery, long-term service agreements, and performance monitoring will further enhance supply chain efficiency and system reliability.

In conclusion, a strategic, partnership-driven sourcing approach—balancing cost-effectiveness with engineering excellence—will ensure the pad set suspension system contributes to improved ride comfort, safety, and overall performance of the final product. Continuous supplier assessment and technological advancements integration should remain priorities for long-term success.