The global pad printing machine market is experiencing steady growth, driven by increasing demand for high-precision printing across industries such as automotive, medical devices, electronics, and consumer goods. According to a report by Mordor Intelligence, the pad printing machine market was valued at approximately USD 560 million in 2023 and is projected to grow at a CAGR of 4.2% from 2024 to 2029. This expansion is fueled by ongoing advancements in printing technology, rising industrial automation, and the need for durable, high-resolution graphics on complex surfaces. As manufacturers seek greater efficiency, consistency, and customization, leading pad printing machine suppliers are responding with innovative, digitally integrated solutions. In this evolving landscape, nine key manufacturers stand out for their technological leadership, global reach, and robust product portfolios—shaping the future of industrial pad printing.

Top 9 Pad Printing Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Leading Manufacturer of Pad Printing Equipment Solutions

Domain Est. 1997

Website: printinginternational.com

Key Highlights: Explore top-tier pad printing equipment for medical, pharmaceutical, and industrial needs, featuring both manual and automatic options….

#2 Kent Pad Printer Canada Inc.

Domain Est. 1997

Website: kentpp.com

Key Highlights: Kent is the worldwide manufacturer and supplier of high-quality pad and screen-printing systems. We provide complete decorating solutions from single colour to ……

#3 Deco Tech

Domain Est. 1999

Website: decotechgroup.com

Key Highlights: Deco Tech is the leading pad printing supplier & manufacturer in North America (United States & Canada). We provide pad printing machines, silicone pads, ……

#4 TAMPOPRINT

Domain Est. 1996

Website: tampoprint.com

Key Highlights: Industrial product marking and labeling using pad printing and lasers – that is our profession and our passion. TAMPOPRINT develops a perfectly coordinated ……

#5 Pad Printing Equipment Manufacturer And Supplies in USA

Domain Est. 1997

Website: itwtranstech.com

Key Highlights: We are a global pad print equipment manufacturer, specialized in machines, fixtures and consumables for automated and manual pad print solutions….

#6 Inkcups

Domain Est. 1999

Website: inkcups.com

Key Highlights: Inkcups is a leading supplier and manufacturer of digital inkjet equipment, pad printing equipment, laser plate makers and corresponding supplies, with ……

#7 Teca

Domain Est. 2009

Website: tecaprintusa.com

Key Highlights: Teca-Print USA is a top producer of the world’s finest and most sophisticated pad printing machines and consumables like pads, inks and cliché plates….

#8 Pad Printing Machines

Website: epsvt.com

Key Highlights: EPS sells industrial pad printing machines for all applications. Print on glass, print on metal, print on plastic. Competitive prices ensure quick ROI….

#9 FINECAUSE

Domain Est. 2012

Website: finecause.com

Key Highlights: From compact pad printing machines to advanced screen printing equipment, we design and manufacture reliable printing solutions for diverse industries….

Expert Sourcing Insights for Pad Printing Machine

2026 Market Trends for Pad Printing Machines

The pad printing machine market is poised for significant evolution by 2026, driven by technological advancements, shifting industrial demands, and sustainability imperatives. Key trends shaping the landscape include:

Automation and Smart Manufacturing Integration

By 2026, automation will be a dominant force in the pad printing sector. Manufacturers are increasingly adopting semi- and fully automated pad printing systems integrated with Industry 4.0 technologies. These machines feature IoT connectivity, real-time monitoring, predictive maintenance, and seamless compatibility with robotic arms and conveyor systems. This integration enhances production efficiency, reduces human error, and enables remote diagnostics, making pad printing more scalable and reliable—especially in high-volume industries like automotive and consumer electronics.

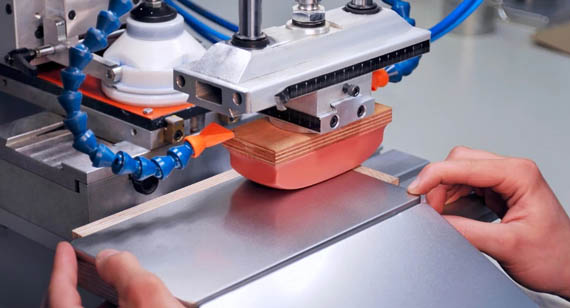

Demand for High-Precision and Micro-Printing Capabilities

As consumer products become smaller and more complex, there is growing demand for ultra-high precision pad printing. The 2026 market will see increased adoption of machines capable of micro-printing on intricate components such as medical devices, wearable electronics, and miniature sensors. Advancements in silicone pad technology and digital control systems allow for finer detail reproduction, tighter registration, and improved ink transfer on irregular 3D surfaces.

Sustainable and Eco-Friendly Printing Solutions

Environmental regulations and corporate sustainability goals are pushing the adoption of eco-friendly inks and energy-efficient machines. By 2026, pad printing equipment manufacturers are expected to prioritize low-VOC (volatile organic compound) inks, solvent recovery systems, and energy-saving designs. Water-based and UV-curable inks are gaining market share, particularly in food packaging and medical applications, where safety and compliance are critical.

Customization and Short-Run Flexibility

The rise of mass customization and on-demand manufacturing is influencing pad printing machine design. Equipment with quick-change tooling, modular configurations, and user-friendly digital interfaces will be in higher demand. These features enable manufacturers to switch between jobs rapidly, making pad printing economically viable for small batch and personalized production—especially in promotional goods, cosmetics, and specialty electronics.

Expansion in Emerging Applications

While traditional sectors like automotive and electronics remain core markets, pad printing is expanding into new domains. In 2026, growth is expected in medical device labeling, smart packaging, and renewable energy components (e.g., solar panel markings). The ability of pad printing to adhere to diverse substrates—including plastics, metals, glass, and composites—will drive its adoption across these emerging industries.

Regional Market Shifts and Supply Chain Localization

Asia-Pacific, particularly China and India, will continue to lead in both production and consumption due to robust manufacturing ecosystems. However, geopolitical factors and supply chain resilience concerns are prompting companies in North America and Europe to localize production. This shift may increase demand for compact, high-efficiency pad printing machines suitable for nearshoring and regional manufacturing hubs.

In summary, the 2026 pad printing machine market will be characterized by smarter, greener, and more adaptable technologies, catering to a broader range of precision-driven and sustainable industrial applications.

Common Pitfalls When Sourcing Pad Printing Machines (Quality & Intellectual Property)

Sourcing a pad printing machine—especially from international suppliers—can be fraught with risks related to both product quality and intellectual property (IP) protection. Being aware of these pitfalls helps buyers make informed decisions and avoid costly mistakes.

Poor Build Quality and Component Selection

Many low-cost pad printing machines, particularly from less reputable suppliers, use substandard materials and components. This includes weak mechanical frames, low-precision alignment systems, and unreliable pneumatic or electrical parts. These flaws lead to inconsistent print registration, frequent breakdowns, and shorter machine lifespans, ultimately increasing total cost of ownership despite a lower initial price.

Inaccurate or Misrepresented Technical Specifications

Some suppliers exaggerate machine capabilities, such as print accuracy, speed, or compatibility with substrates. For example, a machine may claim ±0.05 mm repeatability but fail to achieve it under real production conditions. Buyers should demand third-party test reports or conduct on-site trials before finalizing purchases.

Lack of Compliance with International Safety and Environmental Standards

Non-compliant machines may lack essential safety features (e.g., emergency stops, proper guarding) or fail to meet regional electrical and emissions standards (e.g., CE, UL, RoHS). This can result in regulatory penalties, workplace hazards, or import delays.

Inadequate After-Sales Support and Spare Parts Availability

Many overseas suppliers offer limited technical support, slow response times, and difficulty sourcing spare parts. This leads to extended downtime and production delays. Machines with proprietary components can be especially problematic if the supplier goes out of business or refuses to supply parts.

Use of Counterfeit or Unlicensed Control Systems and Software

Some manufacturers integrate cloned or pirated PLCs, touchscreens, or software into their machines to cut costs. This not only violates intellectual property rights but also introduces cybersecurity risks, lack of updates, and potential legal liability for the end user.

Risk of IP Infringement Through Machine Design

Certain pad printing machines may copy patented mechanical designs, motion systems, or software algorithms from established brands. Purchasing such machines—even unknowingly—can expose the buyer to legal risks, especially if the machine is deployed in jurisdictions with strong IP enforcement.

Insufficient Documentation and Lack of Traceability

Poorly documented machines often lack manuals, wiring diagrams, or component lists. This complicates installation, maintenance, and troubleshooting. Additionally, the absence of serial numbers or manufacturing traceability makes warranty claims and recalls difficult.

Hidden Costs from Integration and Calibration

Low upfront pricing may not reflect the true cost of integrating the machine into existing production lines. Additional expenses can arise from custom tooling, substrate testing, calibration services, or retrofitting to meet quality standards.

How to Mitigate These Risks

Conduct thorough due diligence: request references, perform factory audits, verify certifications, and use escrow services for payment. Engage legal counsel to review contracts and IP clauses. Insist on machine trials with your actual products and inks before full acceptance.

Logistics & Compliance Guide for Pad Printing Machine

Shipping and Handling Procedures

Ensure the pad printing machine is securely packed using a robust wooden crate or heavy-duty cardboard box with sufficient internal bracing. Use foam padding or anti-vibration materials to protect delicate components such as the printing plate holder, silicone pad, and control panel. Always position the machine upright during transport to prevent fluid leakage from ink cups or solvent reservoirs. Clearly label the package with “Fragile,” “This Side Up,” and “Do Not Stack” indicators. Utilize a logistics provider experienced in handling industrial printing equipment, and consider shipping insurance for added protection.

Import and Export Regulations

Verify the Harmonized System (HS) code for pad printing machines in both the exporting and importing countries—common classifications include 8443.19 (other printing machinery). Obtain necessary export documentation such as a commercial invoice, packing list, bill of lading, and certificate of origin. Ensure compliance with destination country regulations, which may require conformity assessments, CE marking (for EU), or FCC certification (for U.S. if the machine includes electronic controls). Check for any import restrictions, tariffs, or licensing requirements related to industrial machinery.

Safety and Electrical Compliance

Confirm that the pad printing machine meets regional electrical standards such as CE (Europe), UL/CSA (North America), or PSE (Japan). Ensure voltage and frequency compatibility with the destination’s power supply (e.g., 220V/50Hz vs. 110V/60Hz). Include grounding and circuit protection features as required. Equip the machine with emergency stop buttons, protective guards, and proper ventilation if solvent-based inks are used. Provide multilingual safety labels and instructions for safe operation and maintenance.

Environmental and Chemical Regulations

Pad printing often involves inks and cleaning solvents subject to environmental and hazardous materials regulations. If shipping with inks or solvents, classify them under the appropriate UN numbers (e.g., UN1263 for flammable liquids) and package according to IATA/IMDG/ADR standards for dangerous goods. Provide Safety Data Sheets (SDS) for all chemicals included. Ensure compliance with REACH (EU), TSCA (U.S.), or other local chemical control regulations. Recommend proper waste disposal procedures for ink residues and solvent-contaminated materials.

Installation and Operational Compliance

Upon delivery, ensure installation is performed by qualified personnel in accordance with local building, fire, and occupational safety codes. Verify compliance with OSHA (U.S.) or equivalent workplace safety standards regarding machine guarding, ventilation, and operator training. Maintain records of equipment maintenance, calibration, and safety inspections. Retain all compliance documentation—including conformity certificates and user manuals—for audit purposes and warranty claims.

Conclusion for Sourcing a Pad Printing Machine

After a thorough evaluation of technical requirements, production capacity, customization needs, and budget considerations, sourcing a pad printing machine is a strategic decision that can significantly enhance product branding and manufacturing efficiency. The selected machine should align with the specific substrates, print complexity, and volume demands of the operation. Whether opting for a manual, semi-automatic, or fully automatic model, key factors such as precision, durability, ease of maintenance, and supplier support are critical to long-term success.

Additionally, considering total cost of ownership—including initial investment, training, spare parts, and consumables—ensures sustainable operation. Partnering with a reputable supplier offering technical assistance and training further minimizes downtime and optimizes print quality.

In conclusion, carefully sourcing the right pad printing machine not only improves product aesthetics and consistency but also strengthens competitiveness in the market by enabling high-quality, cost-effective, and scalable printing solutions.