The global oyster farming industry is experiencing steady growth, driven by rising demand for sustainable seafood and advancements in aquaculture technology. According to Grand View Research, the global aquaculture equipment market was valued at USD 14.9 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030. A significant segment of this growth is attributed to shellfish cultivation, particularly oyster farming, which benefits from innovations in growing equipment designed to improve yield, reduce labor costs, and enhance environmental sustainability. As oyster producers scale operations and adopt modern farming techniques, demand for reliable, high-performance equipment—from oyster tumbler machines and nursery systems to longline and rack-and-bag solutions—has surged. In this evolving landscape, key manufacturers are emerging as leaders through technological innovation, durability, and scalability. Below, we spotlight the top 8 oyster growing equipment manufacturers shaping the future of efficient and sustainable oyster aquaculture.

Top 8 Oyster Growing Equipment Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Oyster Culture Gear and Supplies

Domain Est. 1986

Website: shellfish.ifas.ufl.edu

Key Highlights: ShouAn Aquaculture Cage is a manufacturer and distributor of a variety of oyster culture equipment including mesh, growing bags, foam float bags, and farm ……

#2 Outlaw Oysters

Domain Est. 2017

Website: outlawoysters.com

Key Highlights: Outlaw Oyster Co. is proudly serving as the premier equipment retail distributor in the Southeast. If you’re interested in buying your own oyster farming …Missing: growing manuf…

#3 About Us – ACO Farming Systems

Domain Est. 2021

Website: sustainableoysterfarming.com

Key Highlights: Submürge is the only manufacturer of oyster growing equipment to provide everything you need for your farm. Whether it is a single spat trap or an entire ……

#4 Innovative Floating Oyster Farming Systems

Domain Est. 2006

Website: oystergro.com

Key Highlights: OysterGro® specializes in innovative oyster farming equipment, offering a comprehensive range of floating cage, bottom cage and storage pod systems. Our durable ……

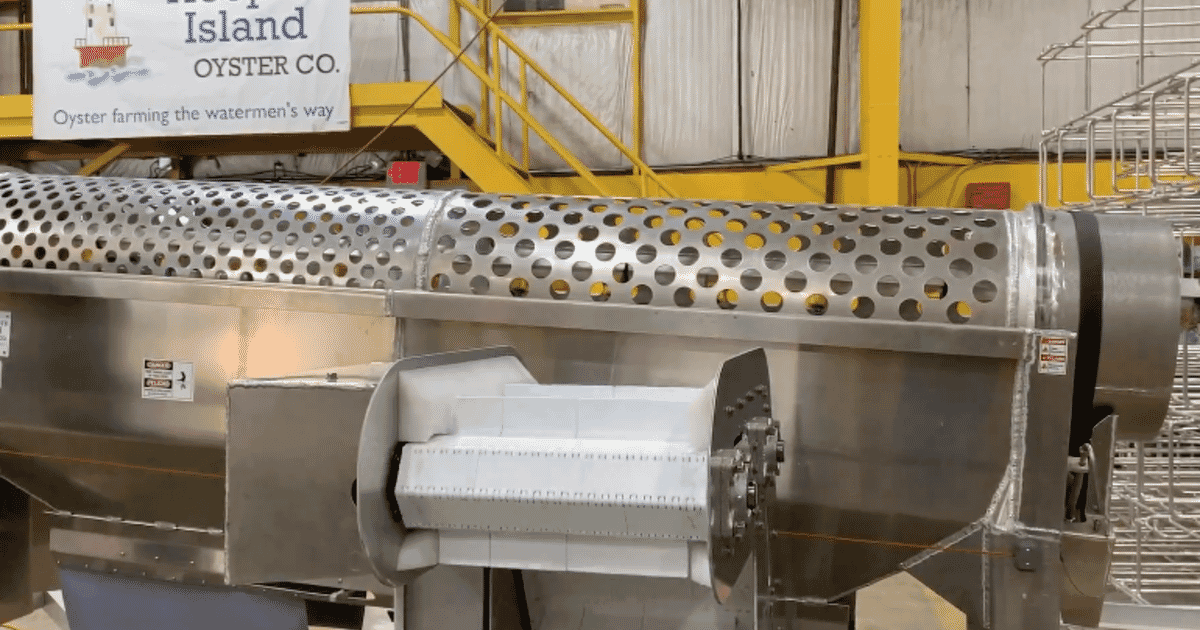

#5 Hoopers Island Oysters

Domain Est. 2008

Website: hoopersisland.com

Key Highlights: The Hoopers Island Oyster Co. offers a fully integrated system for oyster production. We spawn disease-resistant seed, build and distribute grow-out gear….

#6 Zapco Aquaculture Oyster Farming Equipment

Domain Est. 2010

Website: zapcoaquaculture.com

Key Highlights: Zapco Aquaculture has created the first cost-effective commercially available floating mesh bag system designed for farming of single seeded oysters….

#7 OUR AQUACULTURE OYSTER FARM

Domain Est. 2011

Website: wardoyster.com

Key Highlights: Our Aquaculture Oyster Farm is located in Gloucester Virginia. Ward Oyster Company grows & sells oysters at our online store. Largest in VA….

#8 Oyster Farming Equipment

Domain Est. 2020

Website: flipfarmusa.com

Key Highlights: FlipFarm is a re-invention of oyster aquaculture by semi-automating farming, reducing labor and injuries, and allowing you to scale your farm profitably….

Expert Sourcing Insights for Oyster Growing Equipment

2026 Market Trends for Oyster Growing Equipment

The global oyster growing equipment market is poised for significant transformation by 2026, driven by rising consumer demand for sustainable seafood, technological advancements, and increasing aquaculture intensification. This analysis explores the key trends shaping the industry in the lead-up to and during 2026.

1. Automation and Smart Technology Integration Dominates

By 2026, automation will be a defining feature of oyster farms, particularly in developed markets. Expect widespread adoption of:

* Automated Sorting and Grading Systems: Robotic arms and AI-powered vision systems will drastically reduce labor costs and improve consistency in size grading, a critical factor for market value.

* Remote Monitoring & IoT Sensors: Networks of sensors tracking water quality (temperature, salinity, dissolved oxygen, pH), equipment status (buoy integrity, line tension), and even oyster growth rates in real-time will become standard. This enables predictive maintenance and optimized feeding/growing cycles.

* Automated Feeding and Harvesting Aids: While full automation of harvesting remains complex, equipment for automated seed distribution and partial harvesting assistance will gain traction, improving efficiency and reducing physical strain on workers.

2. Sustainability and Eco-Engineering Drive Equipment Design

Environmental responsibility is no longer optional. Equipment manufacturers will prioritize:

* Biodegradable and Non-Toxic Materials: Replacement of traditional plastics (especially in longlines and bags) with bio-based polymers or recycled materials to minimize marine plastic pollution will accelerate.

* Energy-Efficient Operations: Equipment powered by renewable sources (solar, wind) for monitoring systems and on-site operations will become more common, reducing the carbon footprint.

* Low-Impact Design: Innovations focusing on minimizing seabed disturbance, reducing bycatch during handling, and enhancing integration with natural ecosystems (e.g., designs promoting beneficial biofouling control) will be key selling points. Focus will be on equipment facilitating multi-trophic aquaculture (IMTA) integration.

3. Expansion of Offshore and Deep-Water Oyster Farming

As coastal space becomes constrained and demand grows, 2026 will see a notable push into deeper, more exposed waters. This necessitates:

* Robust and Submersible Systems: Development of stronger, more durable longline, raft, and cage systems designed to withstand harsher offshore conditions (stronger currents, waves, storms). Submersible cages to protect oysters from surface icing, predators, or extreme weather events will become more prevalent.

* Advanced Mooring and Anchoring Solutions: Enhanced mooring technology (e.g., dynamic positioning aids, improved anchor designs) will be critical for securing large-scale offshore operations safely and reliably.

* Larger-Scale Deployment Equipment: Specialized vessels and handling systems designed for the efficient deployment, maintenance, and retrieval of equipment in challenging offshore environments will be in higher demand.

4. Consolidation and Vertical Integration Reshapes the Supply Chain

The market will likely see increased consolidation among equipment manufacturers and stronger vertical integration by large oyster producers:

* Acquisition of Niche Innovators: Larger established players may acquire smaller companies specializing in automation, sensors, or sustainable materials to rapidly expand their technological portfolios.

* Producer-Owned Solutions: Some major oyster farming companies may develop or co-develop proprietary equipment tailored to their specific needs, reducing reliance on external suppliers and optimizing for their unique farm conditions and processes.

* Focus on Service & Data Platforms: Equipment sales will increasingly bundle with data analytics platforms and service contracts (maintenance, monitoring support), creating recurring revenue streams and deeper customer relationships.

5. Regional Growth Diversification and Policy Influence

While established markets (North America, Europe, Japan) lead in technology adoption, significant growth will come from emerging regions:

* Asia-Pacific Expansion: Countries like China, South Korea, and Southeast Asian nations will drive volume growth, adopting both traditional and increasingly modernized equipment. Government support for sustainable aquaculture will be a key catalyst.

* Latin America & Africa Potential: Emerging oyster farming industries in countries like Chile, Mexico, and South Africa will create new markets for cost-effective, durable equipment, potentially leapfrogging to newer technologies.

* Regulatory Drivers: Stricter environmental regulations globally will mandate the use of less polluting equipment and better monitoring systems, directly influencing purchasing decisions and accelerating the adoption of sustainable technologies by 2026.

In conclusion, the 2026 oyster growing equipment market will be characterized by a convergence of high-tech automation, deep commitment to environmental sustainability, expansion into new farming frontiers, and evolving market structures. Success will belong to manufacturers and producers who embrace innovation, prioritize eco-efficiency, and adapt to the demands of a more data-driven and regulated global aquaculture landscape.

Common Pitfalls When Sourcing Oyster Growing Equipment: Quality and Intellectual Property Concerns

When sourcing oyster growing equipment, producers must navigate several critical challenges related to both quality assurance and intellectual property (IP) protection. Overlooking these aspects can lead to operational inefficiencies, financial losses, and legal complications. Below are key pitfalls to avoid:

Poor Equipment Quality and Durability

One of the most frequent issues is acquiring substandard equipment that fails to withstand the harsh marine environment. Low-quality materials—such as inferior plastics, weak ropes, or corrosion-prone metals—can degrade rapidly, leading to frequent replacements, oyster loss, and increased labor costs. Equipment not designed for local water conditions (e.g., strong currents, temperature extremes, or biofouling pressure) may also underperform or fail entirely. Buyers often prioritize low upfront costs over long-term durability, resulting in higher total cost of ownership.

Lack of Standardization and Compatibility

Sourcing from multiple vendors without attention to compatibility can lead to equipment mismatches. Trestles, bags, cages, and floats may not interlock or function together efficiently, complicating farm operations and reducing scalability. Inconsistent dimensions or connection mechanisms can hinder automation and increase labor requirements during deployment and maintenance.

Inadequate Testing and Certification

Many suppliers, especially new or offshore manufacturers, may not provide verifiable testing data or certifications (e.g., UV resistance, load capacity, or marine safety standards). Without third-party validation, producers risk deploying unproven equipment that may fail under real-world conditions, potentially endangering both oyster stock and workers.

Intellectual Property Infringement

Using or sourcing equipment that replicates patented designs—such as specialized oyster tongs, grading systems, or grow-out bags—without proper licensing exposes farmers and suppliers to legal action. Some overseas manufacturers produce counterfeit or “knock-off” versions of innovative, patented gear. Purchasing such equipment may lead to cease-and-desist orders, financial penalties, or forced equipment removal, disrupting farm operations.

Limited Access to Technical Support and Innovation

Sourcing from generic suppliers or low-cost manufacturers often means minimal access to technical support, training, or updates on design improvements. This can hinder troubleshooting and limit a farm’s ability to adopt advancements in oyster cultivation technology. Moreover, reliance on unoriginal equipment may prevent producers from differentiating their operations through innovative growing practices.

Supply Chain and After-Sales Risks

Many low-cost suppliers lack reliable after-sales service, spare parts availability, or clear warranty terms. If equipment fails, delays in support or replacement can halt production during critical growing periods. Long lead times or communication barriers with international suppliers further compound these risks.

To mitigate these pitfalls, oyster farmers should conduct thorough due diligence on suppliers, prioritize quality and durability over cost, verify IP rights, and seek equipment backed by performance data and strong warranties. Engaging with reputable manufacturers and consulting industry networks can also help ensure long-term success and compliance.

Logistics & Compliance Guide for Oyster Growing Equipment

This guide outlines key logistics and compliance considerations for transporting and using oyster farming equipment to ensure legal, safe, and sustainable operations.

Equipment Classification and Regulatory Oversight

Oyster growing equipment—including longlines, cages, trays, bags, seed stockings, and monitoring tools—is subject to agricultural, environmental, and maritime regulations. Classification may vary by region, but equipment used in aquaculture is typically regulated under fisheries or coastal zone management authorities. It is essential to confirm whether your equipment falls under agricultural machinery, marine infrastructure, or specialty aquaculture gear, as this affects permitting, safety standards, and transport regulations.

Import and Export Compliance

When shipping oyster farming equipment across international borders, compliance with customs regulations is required. Key steps include:

– Harmonized System (HS) Code Classification: Identify the correct HS code for each equipment type (e.g., aquaculture cages may fall under 8436.80 or similar agricultural machinery codes).

– Phytosanitary and Biosecurity Requirements: Ensure equipment is clean and free of organic material to prevent the spread of invasive species or pathogens. Some countries require disinfection certificates.

– Import Permits: Certain regions require advance permits for aquaculture-related imports, especially if equipment will contact seawater or shellfish.

Domestic Transportation Logistics

Transporting oyster farming equipment domestically involves considerations for size, weight, and material durability:

– Freight Mode Selection: Choose between road, sea, or rail based on equipment size and delivery location. Oversized loads (e.g., longline reels or large cages) may require special permits and pilot vehicles.

– Packaging and Protection: Use weather-resistant packaging and secure fastenings to prevent damage during transit. Label fragile or sharp components clearly.

– Last-Mile Delivery: Coordinate with local transporters familiar with coastal access routes and tidal schedules to ensure timely delivery to remote farms.

Environmental and Site-Specific Regulations

Before deploying equipment, verify compliance with local environmental standards:

– Coastal Zone Permits: Most oyster farms require permits from coastal management agencies, specifying allowable equipment types and placement.

– Marine Spatial Planning: Ensure equipment does not interfere with navigation, fishing zones, or protected habitats.

– Material Restrictions: Some regions prohibit non-biodegradable or toxic materials (e.g., certain plastics or treated wood) in marine environments.

Safety and Operational Standards

Oyster farming equipment must meet safety and operational guidelines:

– Structural Integrity: Equipment should withstand local marine conditions (currents, storms, biofouling).

– Worker Safety: Provide training on safe handling, especially for heavy lifting and deployment in tidal areas.

– Monitoring and Maintenance: Implement regular inspections to comply with operational standards and prevent equipment loss or environmental harm.

Recordkeeping and Traceability

Maintain detailed records to demonstrate compliance:

– Equipment Inventory: Track model numbers, purchase dates, and maintenance logs.

– Permit Documentation: Keep copies of all permits, environmental assessments, and inspection reports.

– Deployment Logs: Record installation dates, locations, and modifications for audit purposes.

Sustainability and End-of-Life Management

Plan for responsible disposal or recycling:

– Recycling Programs: Partner with suppliers offering take-back programs for worn nets or plastic components.

– Avoid Marine Debris: Retrieve and dispose of damaged equipment promptly to prevent pollution.

– Eco-Design: Opt for durable, recyclable, or biodegradable materials where feasible.

Adhering to this logistics and compliance framework supports efficient operations, minimizes legal risks, and promotes environmentally responsible oyster aquaculture.

In conclusion, sourcing oyster growing equipment requires careful consideration of several key factors, including the type of oyster farming method (e.g., rack and bag, longline, bottom culture), the environmental conditions of the cultivation site, equipment durability, cost-efficiency, and sustainability. It is essential to partner with reliable suppliers who offer quality materials that withstand marine conditions and comply with local regulations. Additionally, investing in scalable and low-maintenance equipment supports long-term productivity and operational resilience. By conducting thorough research, evaluating multiple vendors, and prioritizing both performance and environmental impact, oyster farmers can make informed sourcing decisions that enhance growth yields, reduce operational risks, and contribute to a sustainable aquaculture industry.