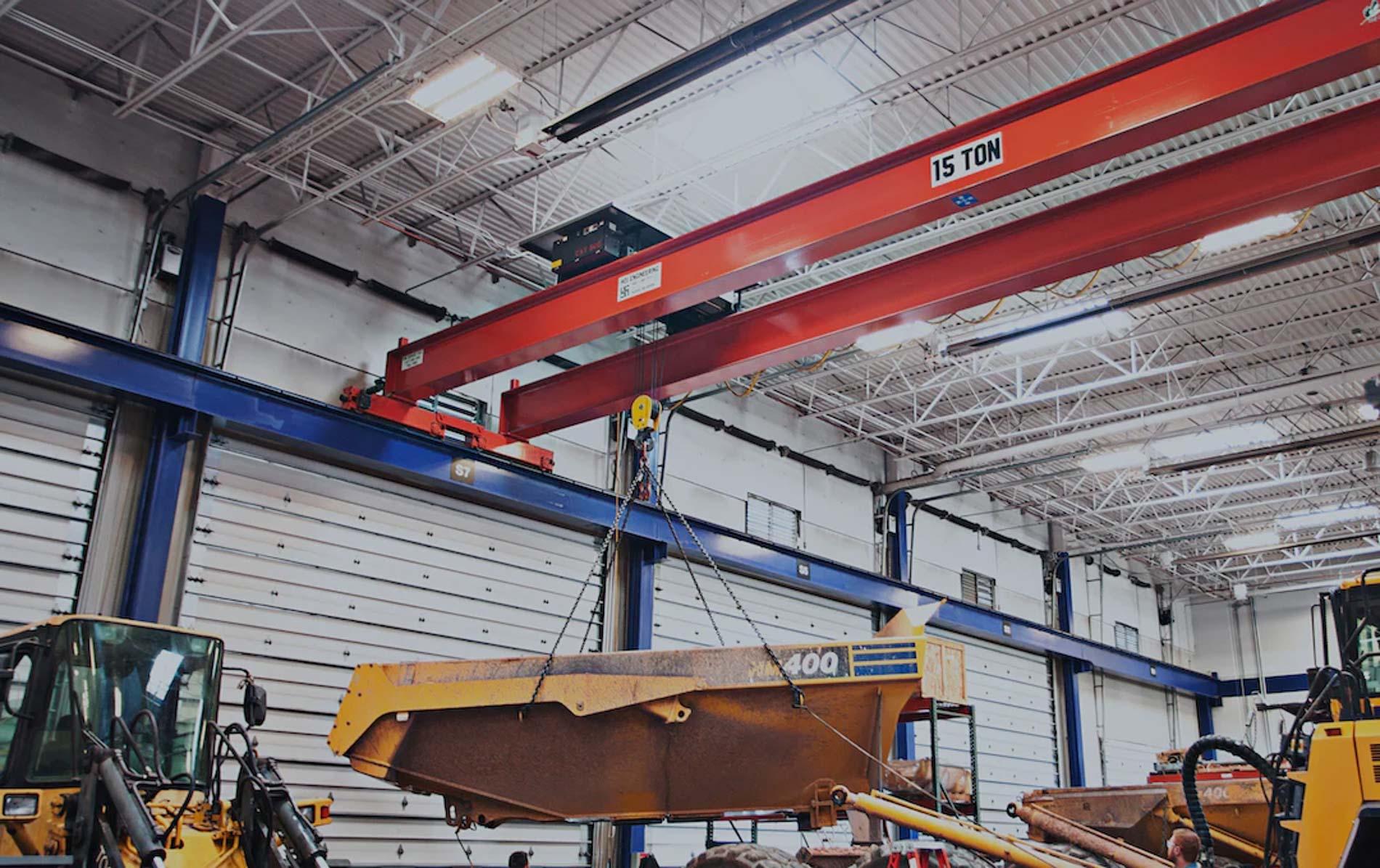

The global overhead crane hoist market is experiencing robust growth, driven by increasing industrialization, infrastructure development, and automation across manufacturing, construction, and logistics sectors. According to a report by Mordor Intelligence, the global industrial crane market was valued at USD 33.6 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. Similarly, Grand View Research estimates the global overhead cranes market size at USD 18.3 billion in 2023, forecasting a CAGR of 4.6% through 2030, with hoist components representing a critical segment due to rising demand for reliable lifting solutions and stringent safety standards. As industries prioritize efficiency and uptime, the need for high-quality, durable hoist parts—from motors and gearboxes to brakes and wire ropes—has intensified. This demand has positioned leading manufacturers at the forefront of innovation, driving advancements in load capacity, energy efficiency, and smart monitoring capabilities. In this evolving landscape, selecting the right supplier for overhead crane hoist parts is not just a maintenance decision—it’s a strategic imperative for operational excellence.

Top 10 Overhead Crane Hoist Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Ace World Companies

Domain Est. 1998

Website: aceworldcompanies.com

Key Highlights: Ace World Companies manufactures overhead cranes, electric wire rope hoists, and end trucks both standard and custom. Find the right crane and components ……

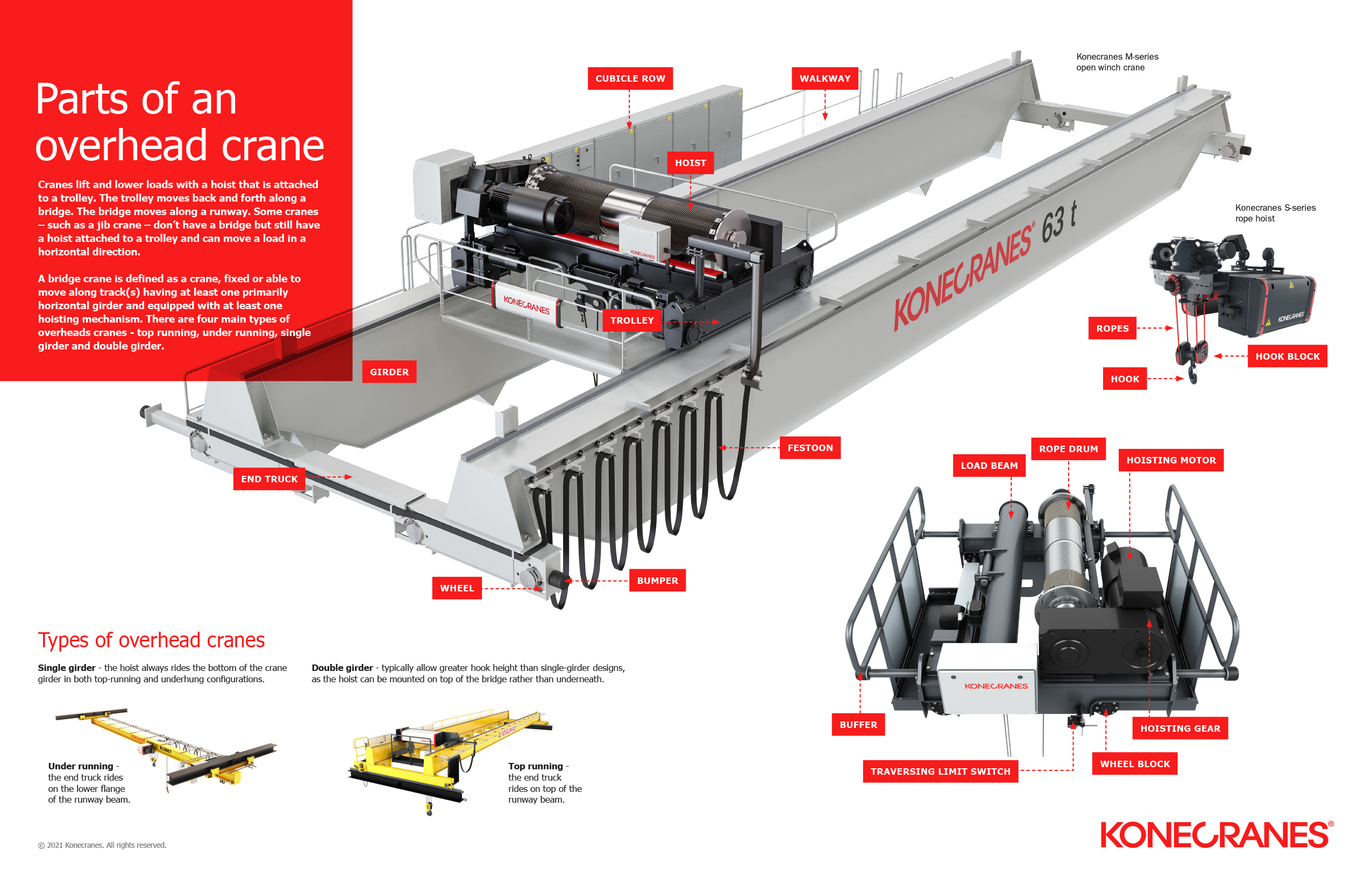

#2 Parts and Support for Konecranes Family of Brands

Domain Est. 1999

Website: konecranes.com

Key Highlights: Access parts and support for the entire Konecranes family of brands. As an OEM, we provide expert service and quality components for over 40 crane brands….

#3 Industrial Lifting Solutions by R&M Materials Handling

Domain Est. 2000

Website: rmhoist.com

Key Highlights: With over 90 years of experience in the overhead crane, electric chain hoist and wire rope hoist industries, we have the experience to help you improve the flow ……

#4 Overhead Crane & Hoist Replacement Parts

Domain Est. 2003

Website: hoistsdirect.com

Key Highlights: Overhead Crane & Hoist Replacement Parts. Hoists Direct stocks a variety of overhead crane and hoist parts from original equipment manufacturers….

#5 GH crane and hoist manufacturer.

Domain Est. 2005 | Founded: 1958

Website: ghcranes.com

Key Highlights: A family owned business since 1958. Overhead material handling experts, manufacturing hoists, overhead cranes, gantry cranes and a wide range of lifting ……

#6 ProservCrane Group

Domain Est. 1996

Website: proservcrane.com

Key Highlights: ProservCrane Group, Inc manufactures overhead cranes and offers quality overhead crane parts for all makes and models of cranes….

#7 American Crane & Equipment Corporation

Domain Est. 1996

Website: americancrane.com

Key Highlights: Our comprehensive inventory of replacement parts and components for cranes, hoists, and trolleys includes our manufactured parts and other well-known brands. We ……

#8 Harrington Hoists

Domain Est. 1998

Website: harringtonhoists.com

Key Highlights: Mix and match our manual hoists and trolleys to solve lifting and moving needs. Learn more How to Buy · Manual Trolleys & Beam Clamps….

#9 Spare Parts

Domain Est. 1998

Website: demagcranes.com

Key Highlights: At Demag Cranes and Components, our spare parts reduce maintenance requirements and ensure reliability. Check out our reliable spare part supply today!…

#10 Crane Hoist Solutions & Services

Domain Est. 2001

Website: hoj.net

Key Highlights: Genuine Crane Hoist Parts & Components. Access genuine crane hoist parts through our extensive inventory and supplier network. We stock critical components ……

Expert Sourcing Insights for Overhead Crane Hoist Parts

H2: 2026 Market Trends for Overhead Crane Hoist Parts

The global market for overhead crane hoist parts is poised for steady growth and transformation by 2026, driven by industrial modernization, increased automation, and rising demand across key sectors such as manufacturing, logistics, and infrastructure. Below is an analysis of the major trends shaping the overhead crane hoist parts market in 2026.

1. Rising Industrial Automation and Smart Manufacturing

The integration of Industry 4.0 technologies is significantly influencing the design and functionality of hoist components. By 2026, demand is expected to shift toward smart hoist parts equipped with IoT sensors, predictive maintenance capabilities, and real-time monitoring systems. These intelligent components enhance operational efficiency, reduce downtime, and improve safety—making them essential in automated production environments.

2. Growth in Heavy Industry and Infrastructure Development

Emerging economies in Asia-Pacific, Latin America, and Africa are investing heavily in infrastructure, energy, and heavy manufacturing, which directly boosts the need for reliable overhead cranes and their replacement parts. Countries like India, Vietnam, and Brazil are expanding steel plants, ports, and logistics hubs, driving sustained demand for hoist components such as brakes, motors, drums, and wire ropes.

3. Emphasis on Safety and Regulatory Compliance

Stringent safety regulations from OSHA (U.S.), EU Machinery Directive, and other global bodies are compelling industries to upgrade aging hoist systems. In 2026, there will be heightened demand for safety-certified hoist parts, including overload protection devices, emergency stop mechanisms, and fail-safe brakes. Manufacturers are increasingly aligning with ISO and CMAA standards to meet compliance requirements.

4. Replacement and Aftermarket Expansion

A significant portion of the market growth will come from the aftermarket segment. Aging crane fleets in developed regions like North America and Western Europe require retrofitting and maintenance, leading to robust demand for replacement hoist parts. OEMs and third-party suppliers are expanding their service networks and inventory to support this growing after-sales market.

5. Adoption of Energy-Efficient and Lightweight Components

Energy efficiency is a growing priority. Hoist parts manufacturers are innovating with high-efficiency motors, regenerative drives, and lightweight yet durable materials (e.g., high-strength alloys and composite components). These advancements reduce energy consumption and extend service life, appealing to environmentally conscious and cost-sensitive industries.

6. Supply Chain Resilience and Localization

Post-pandemic disruptions have prompted companies to reevaluate supply chain dependencies. By 2026, there is a noticeable trend toward regionalizing production and sourcing of hoist parts to mitigate risks. This includes localized manufacturing hubs and strategic stockpiling of critical components to ensure supply continuity.

7. Digital Platforms and E-Commerce Growth

Digital marketplaces for industrial parts are gaining traction. By 2026, B2B e-commerce platforms are expected to play a major role in the distribution of hoist components, offering faster procurement, transparent pricing, and digital inventory management tools. This shift improves accessibility, especially for small and medium-sized enterprises (SMEs).

8. Sustainability and Circular Economy Initiatives

Environmental concerns are pushing the industry toward sustainable manufacturing and end-of-life part recycling. Leading suppliers are introducing remanufactured hoist components and closed-loop recycling programs. These initiatives not only reduce waste but also lower costs for end users, supporting long-term market viability.

Conclusion

The 2026 outlook for overhead crane hoist parts is characterized by technological innovation, regulatory evolution, and regional market diversification. Companies that embrace digitalization, sustainability, and regional supply strategies will be best positioned to capitalize on emerging opportunities in this dynamic sector.

Common Pitfalls Sourcing Overhead Crane Hoist Parts (Quality, IP)

Sourcing overhead crane hoist parts involves critical considerations around quality and intellectual property (IP) that, if overlooked, can lead to safety hazards, downtime, legal issues, and increased costs. Below are key pitfalls to avoid:

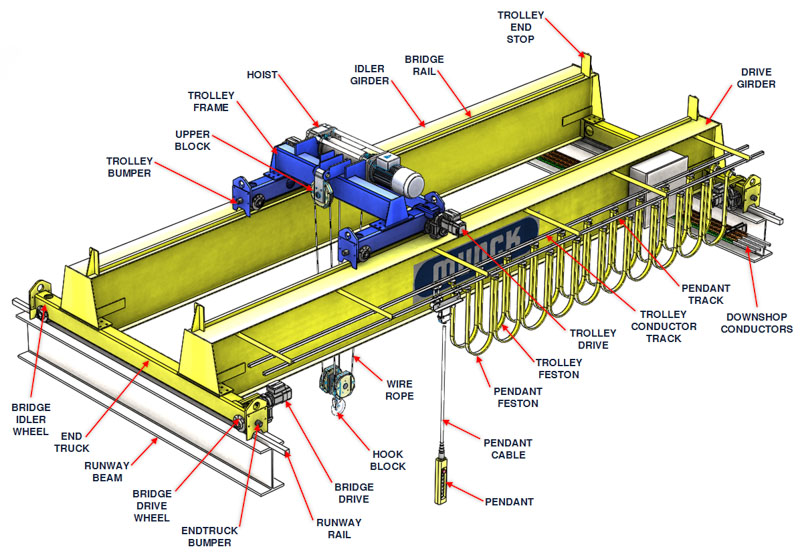

Poor Quality Components

One of the most significant risks when sourcing hoist parts is receiving substandard components that fail to meet safety and performance standards. Low-quality parts—such as worn gears, weak wire ropes, or poorly machined brake systems—can lead to catastrophic equipment failure, endangering personnel and operations. Parts sourced from unreliable suppliers may lack proper material certifications, dimensional accuracy, or heat treatment, compromising the integrity of the entire hoisting system.

Counterfeit or Non-OEM Parts

Using counterfeit or imitation parts presents both quality and IP concerns. These parts often mimic genuine OEM (Original Equipment Manufacturer) designs but are manufactured without proper engineering specifications or quality control. Not only do they pose safety risks, but they may also infringe on the OEM’s intellectual property rights, exposing the buyer to legal liability. Additionally, counterfeit parts typically void equipment warranties and are not supported by technical documentation or service networks.

Lack of Traceability and Certification

Reputable hoist parts should come with full traceability, including material test reports (MTRs), heat numbers, and compliance certifications (e.g., ISO, CE, ASME). Sourcing parts without proper documentation makes it difficult to verify quality and regulatory compliance. In safety-critical applications like overhead cranes, missing certifications can lead to failed inspections, regulatory penalties, or liability in the event of an accident.

Ignoring Intellectual Property Rights

Using reverse-engineered or cloned parts without proper licensing infringes on patents, trademarks, and design rights held by OEMs. Many crane manufacturers protect their components through IP laws, and unauthorized replication—even for replacement purposes—can result in cease-and-desist orders, fines, or lawsuits. Sourcing from suppliers who respect IP ensures both legal compliance and access to proven, tested designs.

Inadequate Supplier Vetting

Choosing suppliers based solely on price or availability without evaluating their reputation, manufacturing capabilities, or compliance history increases the risk of receiving defective or non-compliant parts. Reliable suppliers should demonstrate quality management systems (e.g., ISO 9001), offer technical support, and provide warranties. Skipping due diligence can result in repeated failures, unplanned downtime, and higher total cost of ownership.

Mismatched Specifications and Compatibility

Even genuine-looking parts may not be compatible with specific crane models or configurations. Variations in load capacity, duty cycle ratings, mounting dimensions, or control systems can lead to improper operation or premature wear. Always verify that replacement parts match the original equipment specifications and are approved for use in your crane model.

Overlooking After-Sales Support and Warranty

Parts sourced from unauthorized or offshore suppliers may come with limited or no warranty and minimal technical support. In the event of a failure, obtaining replacements or troubleshooting assistance can be difficult and time-consuming. This lack of support increases operational risk and can extend downtime significantly.

Avoiding these pitfalls requires diligence in selecting reputable suppliers, verifying part authenticity and certifications, and respecting intellectual property rights—all essential for maintaining safe, reliable, and compliant overhead crane operations.

Logistics & Compliance Guide for Overhead Crane Hoist Parts

Introduction

Overhead crane hoist parts are critical components in material handling systems across industries such as manufacturing, construction, and logistics. Ensuring proper logistics planning and compliance with regulatory standards is essential for safety, efficiency, and legal operation. This guide outlines key considerations for transporting, storing, and maintaining compliance for hoist components.

Regulatory Compliance Standards

All overhead crane hoist parts must comply with applicable international, national, and local regulations. Key standards include:

– OSHA 29 CFR 1910.179 (U.S. Occupational Safety and Health Administration) for overhead and gantry cranes.

– ASME B30.16 (American Society of Mechanical Engineers) covering below-the-hook lifting devices and hoists.

– EU Machinery Directive 2006/42/EC for equipment placed on the European market.

– ISO 4301-6 for classification and performance of hoisting machinery.

Ensure all parts are certified and accompanied by documentation such as CE marking, test certificates, and conformity declarations.

Safe Packaging and Handling

Proper packaging prevents damage during transit and ensures part integrity.

– Use moisture-resistant, shock-absorbent materials for sensitive components (e.g., motors, brakes, control units).

– Secure heavy parts (e.g., drums, gearboxes) with bracing and skids to prevent shifting.

– Label packages clearly with part numbers, weight, handling instructions (e.g., “Fragile,” “Do Not Invert”), and hazard symbols if applicable.

– Follow manufacturer-recommended handling procedures—use lifting points and avoid dragging or dropping parts.

Transportation Requirements

Transport logistics must account for size, weight, and destination.

– Select carriers experienced in handling industrial equipment.

– Ensure compliance with DOT (Department of Transportation) or ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road) regulations if applicable.

– Use enclosed trailers for protection against weather and theft.

– For oversized or heavy components, obtain necessary permits and plan routes accordingly.

Import/Export Compliance

International shipments require additional documentation and adherence to customs regulations.

– Prepare accurate commercial invoices, packing lists, and certificates of origin.

– Verify tariff classifications (HS Codes) for hoist parts (e.g., 8425.31 for electric hoists).

– Comply with export controls such as EAR (Export Administration Regulations) if technology is sensitive.

– Confirm destination country’s import restrictions or conformity assessment requirements (e.g., UKCA, CCC in China).

Storage and Inventory Management

Proper storage preserves part quality and ensures traceability.

– Store in a dry, temperature-controlled environment to prevent corrosion and damage to electrical components.

– Keep parts on elevated pallets and away from high-traffic areas.

– Implement a first-in, first-out (FIFO) inventory system for replacement parts.

– Maintain digital records of batch numbers, inspection dates, and warranty information.

Quality Assurance and Traceability

Each hoist part should be traceable to ensure compliance and facilitate recalls if needed.

– Use serialized part numbering and barcodes for tracking.

– Retain inspection reports, load test certifications, and maintenance logs.

– Conduct incoming inspections upon delivery to verify conformity with purchase specifications.

Maintenance and Lifecycle Compliance

Regular maintenance ensures ongoing compliance and operational safety.

– Follow manufacturer-recommended maintenance intervals for hoist components.

– Document all inspections, repairs, and part replacements per OSHA and ASME requirements.

– Replace worn or outdated parts with compliant, certified equivalents.

– Train personnel on proper handling, installation, and safety protocols.

Conclusion

Effective logistics and compliance management for overhead crane hoist parts minimizes risk, ensures regulatory adherence, and supports uninterrupted operations. By following industry standards, implementing secure handling practices, and maintaining accurate documentation, organizations can ensure the safety and reliability of their lifting equipment.

Conclusion: Sourcing Overhead Crane Hoist Parts

In conclusion, sourcing overhead crane hoist parts requires a strategic approach that balances quality, reliability, cost-effectiveness, and timely delivery. It is essential to partner with reputable suppliers or manufacturers who adhere to industry standards and provide certified components to ensure operational safety and compliance. Evaluating factors such as part compatibility, availability of technical support, warranty offerings, and after-sales service further enhances the procurement process. Additionally, maintaining a proactive maintenance and inventory strategy—potentially including critical spare parts—helps minimize downtime and extends the lifespan of the hoisting equipment. By implementing a well-structured sourcing plan, organizations can ensure the safe, efficient, and continuous operation of their overhead cranes, ultimately supporting productivity and workplace safety.