The global overhead and gantry crane market is experiencing robust growth, driven by increasing industrial automation, expanding infrastructure projects, and rising demand from sectors such as manufacturing, automotive, and logistics. According to a report by Mordor Intelligence, the global overhead cranes market was valued at USD 6.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. Similarly, Grand View Research estimates that the global gantry crane market size reached USD 3.1 billion in 2022 and is expected to expand at a CAGR of 5.8% from 2023 to 2030, fueled by adoption in shipbuilding, ports, and heavy industries. With such steady market expansion, identifying leading manufacturers becomes critical for businesses seeking reliable, high-performance material handling solutions. The following list highlights the top 10 overhead and gantry crane manufacturers recognized for innovation, global reach, quality engineering, and strong after-sales support—key factors that align with the evolving demands of modern industrial operations.

Top 10 Overhead Crane Gantry Crane Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Spanco, Inc.

Domain Est. 1997

Website: spanco.com

Key Highlights: As a leading manufacturer of material handling cranes, Spanco designs and builds overhead systems that make material movement safer, faster, and more efficient ……

#2 American Crane & Equipment Corporation

Domain Est. 1996

Website: americancrane.com

Key Highlights: As a member of the Crane Manufacturers Association of America (CMAA), our crane experts can help find the right solution for your project’s specifications….

#3 Cranes, Ergonomic Lifting, Fall Protection, & Warehouse Solutions …

Domain Est. 1996

Website: gorbel.com

Key Highlights: Shop Crane is a non-industrial overhead bridge crane system that uses two parallel steel tracks, or runways, to guide a steel bridge over your work space….

#4 Ace World Companies

Domain Est. 1998

Website: aceworldcompanies.com

Key Highlights: Ace World Companies manufactures overhead cranes, electric wire rope hoists, and end trucks both standard and custom. Find the right crane and components ……

#5 Industrial Overhead Gantry Cranes for Any Industry

Domain Est. 1999

Website: konecranes.com

Key Highlights: Konecranes industrial gantry cranes provide versatile lifting solutions for industries, delivering reliability and performance in tough work environments….

#6 Crane Manufacturer UK & Global Supplier

Domain Est. 2001

Website: streetcrane.com

Key Highlights: We specialise in the design, manufacture, and supply of overhead cranes and hoists. 79 years of experience designing and manufacturing cranes, hoists and ……

#7 GH crane and hoist manufacturer.

Domain Est. 2005

Website: ghcranes.com

Key Highlights: Manufacturer of lifting systems. Overhead cranes (bridge cranes), gantry cranes, semi-gantry cranes, automotive gantry cranes, jib cranes, cantilever cranes ……

#8 Nante Crane

Domain Est. 2014

Website: nantecrane.com

Key Highlights: Explore Nante Crane, a leading Chinese manufacturer of various types of cranes including overhead cranes, gantry cranes, construction cranes, and mobile ……

#9 ProservCrane Group

Domain Est. 1996

Website: proservcrane.com

Key Highlights: ProservCrane Group, Inc manufactures overhead cranes and offers quality overhead crane parts for all makes and models of cranes….

#10 Mi-Jack:

Domain Est. 1997

Website: mi-jack.com

Key Highlights: Mi-Jack provides American-Made rubber tired gantry cranes, parts, service, and automation. Industry leaders for 60+ years. Learn More….

Expert Sourcing Insights for Overhead Crane Gantry Crane

H2: 2026 Market Trends for Overhead Crane and Gantry Crane

The global market for overhead cranes and gantry cranes is poised for significant transformation by 2026, driven by evolving industrial demands, technological advancements, and regional economic developments. Key trends shaping the industry include automation and digitalization, sustainability initiatives, growth in infrastructure and manufacturing, and increasing demand from emerging economies.

1. Automation and Smart Crane Technologies

By 2026, the integration of automation, Internet of Things (IoT), and artificial intelligence (AI) into overhead and gantry cranes is expected to accelerate. Smart cranes equipped with real-time monitoring, predictive maintenance, and remote operation capabilities are becoming standard in advanced manufacturing and logistics facilities. This shift enhances operational efficiency, reduces downtime, and improves worker safety—key priorities for industrial end-users.

2. Rising Infrastructure and Construction Activities

Government-led infrastructure projects in Asia-Pacific, North America, and the Middle East are major growth drivers. Gantry cranes, in particular, are in high demand for port terminals, shipyards, and rail yards due to their versatility in outdoor and heavy-load applications. The expansion of smart ports and intermodal logistics hubs will further boost the need for high-capacity, energy-efficient gantry systems.

3. Growth in Manufacturing and Automotive Sectors

The automotive, aerospace, and heavy machinery industries continue to rely on overhead cranes for precise material handling. As electric vehicle (EV) production scales globally, new manufacturing plants will require customized crane solutions capable of handling battery packs and large components. This trend is expected to fuel demand for modular and adaptable overhead crane systems.

4. Emphasis on Energy Efficiency and Sustainability

Environmental regulations and corporate sustainability goals are pushing manufacturers to adopt energy-efficient crane designs. By 2026, cranes with regenerative drives, lightweight materials, and low-power components will gain market share. Additionally, the use of green manufacturing practices in crane production is expected to become a competitive differentiator.

5. Expansion in Emerging Markets

Countries in Southeast Asia, India, and Africa are witnessing rapid industrialization and urban development. These regions are investing heavily in industrial parks, steel plants, and logistics infrastructure—all of which require robust material handling solutions. Local manufacturing of cranes, supported by government incentives, is also expected to increase, reducing reliance on imports.

6. Supply Chain Resilience and Regionalization

Post-pandemic supply chain disruptions have prompted companies to reevaluate sourcing strategies. In response, crane manufacturers are localizing production and building regional supply chains to improve delivery times and reduce costs. This trend supports faster customization and after-sales service, enhancing customer satisfaction.

7. Competitive Landscape and Mergers & Acquisitions

The market is seeing increased consolidation, with major players acquiring niche technology firms to enhance their digital offerings. Companies such as Konecranes, Terex, and Zoomlion are investing in R&D to stay ahead in smart crane innovation, while smaller manufacturers focus on cost-effective, specialized solutions.

In conclusion, the 2026 outlook for overhead and gantry cranes is positive, marked by technological innovation, infrastructure growth, and geographic expansion. Stakeholders who embrace digital transformation and sustainability will be best positioned to capture emerging opportunities in this dynamic market.

Common Pitfalls When Sourcing Overhead Crane and Gantry Crane: Quality and IP Concerns

Poor Quality Control and Substandard Materials

One of the most frequent issues when sourcing overhead and gantry cranes is receiving equipment made with substandard materials or inadequate manufacturing practices. Suppliers—especially in low-cost regions—may cut corners by using inferior steel, undersized components, or outdated welding techniques. These compromises can lead to structural weaknesses, reduced load capacity, and premature failure. Buyers often discover these flaws only after installation, when safety hazards or performance issues emerge. It’s essential to verify supplier certifications (such as ISO 9001), conduct factory audits, and require third-party inspections before shipment.

Lack of Compliance with International Standards

Many sourced cranes fail to meet recognized international standards such as FEM (European), CMAA (American), or ASME B30. Cranes that don’t comply with these specifications may not be legally permitted for operation in certain countries or industrial environments. Non-compliant cranes also pose safety risks and can expose the buyer to liability. Always confirm that the crane design and manufacturing process adhere to the required standards for your region and application.

Inadequate or Missing Documentation

Reliable crane suppliers provide comprehensive technical documentation, including load charts, assembly manuals, electrical schematics, and maintenance guides. However, low-cost suppliers often omit or provide incomplete documentation, making installation, operation, and regulatory compliance difficult. Missing documentation can also hinder troubleshooting and servicing, increasing downtime and repair costs.

Intellectual Property (IP) Infringement Risks

Sourcing cranes from certain regions may expose buyers to intellectual property risks. Some suppliers replicate patented designs, control systems, or safety mechanisms from reputable manufacturers without authorization. Purchasing such equipment can inadvertently involve your organization in IP violations, leading to legal action, seizure of equipment, or reputational damage. Always vet suppliers for original design capabilities and request proof of IP ownership or licensing for critical components.

Misrepresentation of Crane Specifications

Some suppliers exaggerate crane performance metrics such as lifting capacity, duty cycle (e.g., class A, B, C, etc.), or span length to win contracts. These misrepresentations can result in cranes that cannot handle intended workloads, leading to safety incidents or operational inefficiencies. Buyers should demand performance testing reports and, if possible, witness load tests before final acceptance.

Inconsistent After-Sales Support and Spare Parts Availability

Even if the initial crane meets quality standards, sourcing from unreliable suppliers often leads to long-term operational challenges. Poor after-sales support, delayed response times, and unavailability of spare parts can result in extended downtime. This is particularly problematic for businesses relying on continuous operation. Confirm the supplier’s service network, warranty terms, and spare parts inventory before purchase.

Counterfeit or Reconditioned Components

Some suppliers integrate used, refurbished, or counterfeit components—such as motors, brakes, or hoists—into new cranes without disclosure. These parts may not meet required safety or performance standards and can fail unexpectedly. Conducting component-level inspections and requiring genuine manufacturer certifications for key parts is crucial to avoid this pitfall.

Conclusion

To avoid these common pitfalls, due diligence is essential. Engage reputable suppliers with verifiable track records, demand compliance certifications, conduct on-site audits, and consider working with third-party inspection agencies. Prioritizing quality and IP integrity during sourcing protects your investment, ensures regulatory compliance, and safeguards worker safety.

Logistics & Compliance Guide for Overhead Crane and Gantry Crane

Overview of Overhead and Gantry Cranes

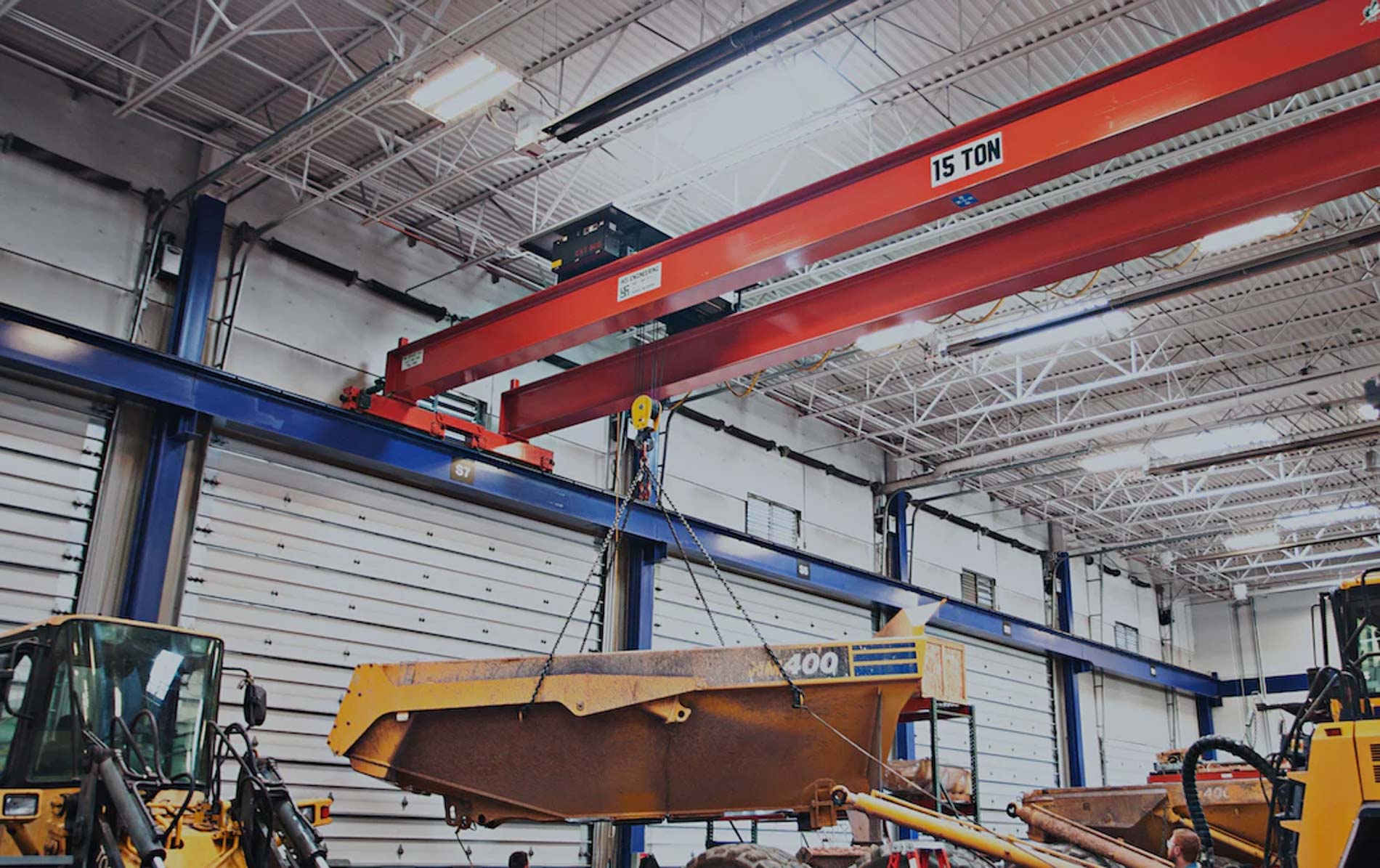

Overhead cranes and gantry cranes are essential material handling systems used across industries such as manufacturing, construction, shipping, and warehousing. Overhead cranes are typically mounted to a building’s runway beams, while gantry cranes are supported by legs that run on tracks or wheels along the ground. Both types must be transported, installed, operated, and maintained in compliance with strict safety and regulatory standards.

Transportation and Delivery Logistics

- Pre-Shipment Planning: Coordinate with the manufacturer or supplier to confirm crane dimensions, weight, and disassembly requirements. Ensure delivery routes accommodate oversized loads, particularly for large gantry cranes.

- Packaging and Protection: Components should be securely crated or bundled to prevent damage during transit. Critical parts such as motors, control panels, and hoists must be weather-protected and shock-absorbed.

- Shipping Method Selection: Use flatbed trucks or specialized heavy-haul transporters. For international shipments, comply with INCOTERMS and coordinate customs clearance in advance.

- Site Accessibility: Verify on-site access for delivery vehicles, including gate width, ground load capacity, and overhead clearance. Temporary road reinforcements may be required for heavy gantry systems.

Installation and Site Preparation

- Foundation and Support Requirements: Gantry cranes require level, load-bearing ground or rail systems. Overhead cranes depend on structurally sound runway beams and building support columns. Conduct site surveys and engineering assessments prior to installation.

- Assembly Procedures: Follow the manufacturer’s assembly manual. Use certified rigging and lifting equipment. Ensure all bolted and welded connections meet design specifications.

- Electrical and Control Integration: Coordinate with licensed electricians to connect power supply, control circuits, and safety devices. Verify voltage compatibility and grounding requirements.

Regulatory and Safety Compliance

- OSHA Standards (U.S.): Comply with OSHA 29 CFR 1910.179 (Overhead and Gantry Cranes) and 1926 Subpart N (Construction). Requirements include load testing, operator certification, and routine inspections.

- ASME B30.2 Standards: Adhere to ASME B30.2 guidelines for design, construction, inspection, testing, maintenance, and operation of overhead and gantry cranes.

- Load Testing and Certification: Perform initial and periodic load tests at 125% of the rated capacity. Document results and obtain certification from a qualified engineer or inspector.

- Operator Training and Certification: Operators must be trained and certified per OSHA and company safety programs. Training should include crane controls, load handling, emergency procedures, and hazard recognition.

Routine Inspection and Maintenance

- Daily Pre-Use Inspections: Operators must inspect hooks, wire ropes, brakes, limit switches, and control systems before each shift.

- Periodic Inspections:

- Frequent (Monthly): Check for wear, damage, and lubrication needs.

- Periodic (Quarterly to Annually): Conduct thorough examinations by a qualified person; include structural integrity, electrical systems, and safety devices.

- Maintenance Records: Maintain detailed logs of inspections, repairs, modifications, and load tests. Retain records for compliance audits and accident investigations.

Environmental and Operational Considerations

- Indoor vs. Outdoor Use: Outdoor gantry cranes must be designed for weather resistance (e.g., corrosion protection, wind load ratings). Indoor overhead cranes should account for temperature, dust, and fume exposure.

- Hazardous Locations: In explosive or flammable environments, use explosion-proof components and comply with NFPA 70 (NEC) and ATEX/IECEx standards where applicable.

- Load Handling Safety: Ensure clear load paths, marked exclusion zones, and use of proper rigging hardware. Never exceed rated load capacity.

Documentation and Compliance Audits

- Required Documentation:

- Crane design and capacity charts

- Inspection and maintenance records

- Operator certification files

- Load test reports

- Compliance certificates (ASME, OSHA, etc.)

- Audit Preparedness: Regular internal audits help identify gaps. Maintain an organized compliance folder accessible to safety officers and regulatory inspectors.

Decommissioning and Relocation

- Safe Dismantling: Follow reverse installation procedures using qualified personnel. De-energize all electrical systems before disassembly.

- Relocation Logistics: Recompile shipping documentation and re-evaluate site conditions at the new location. Perform full inspection and re-certification after reinstallation.

- End-of-Life Disposal: Recycle metal components responsibly. Dispose of electrical and hydraulic parts per environmental regulations (e.g., EPA, WEEE).

Conclusion

Proper logistics and compliance are critical for the safe and efficient operation of overhead and gantry cranes. By following transportation best practices, adhering to regulatory standards, conducting regular maintenance, and maintaining complete documentation, organizations can minimize risks, ensure operational continuity, and achieve full regulatory compliance.

Conclusion on Sourcing Overhead and Gantry Cranes

Sourcing overhead and gantry cranes is a critical decision that significantly impacts operational efficiency, safety, and long-term productivity in industrial and manufacturing environments. A well-informed procurement process must consider several key factors including load capacity, span, lift height, duty cycle, environmental conditions, and compliance with safety standards such as OSHA, CMAA, or FEM.

When selecting a supplier, it is essential to evaluate not only the initial purchase price but also the total cost of ownership—factoring in installation, maintenance, spare parts availability, and after-sales support. Partnering with reputable manufacturers or distributors who offer customized solutions, proven engineering expertise, and comprehensive service networks ensures reliable performance and reduces downtime.

Additionally, advancements in automation, variable frequency drives (VFD), and remote monitoring systems present opportunities to enhance crane functionality and integrate seamlessly with modern material handling workflows. Therefore, investing in cranes with future-ready features can yield long-term operational benefits.

In conclusion, successful sourcing of overhead and gantry cranes requires a strategic approach that balances technical requirements, safety, scalability, and lifecycle costs. By conducting thorough due diligence and aligning procurement with both current needs and future growth plans, organizations can ensure a safe, efficient, and cost-effective material handling infrastructure.