The global brushless motor market is experiencing robust growth, driven by rising demand for energy-efficient and high-performance motors across industries such as electric vehicles, drones, industrial automation, and consumer electronics. According to a report by Mordor Intelligence, the global brushless DC motor market was valued at USD 18.65 billion in 2023 and is projected to reach USD 29.34 billion by 2029, growing at a CAGR of 7.8% during the forecast period. This expansion is fueled by technological advancements, increasing adoption of electric mobility, and the shift toward automation in manufacturing. Outrunner brushless motors, known for their superior torque, cooling efficiency, and direct-drive capabilities, are particularly gaining traction in UAVs, electric skateboards, and lightweight EVs. As demand intensifies, a core group of manufacturers has emerged as leaders in innovation, scalability, and product reliability. Below are the top 8 outrunner brushless motor manufacturers shaping the future of motion control and electrification.

Top 8 Outrunner Brushless Motor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Lin Engineering

Domain Est. 1998

Website: linengineering.com

Key Highlights: We engineer and manufacture a variety of precision DC motors and motion control components. We have the capability, capacity, and expertise to supply a small ……

#2 Outrunner Motors for Groud Vehicles

Domain Est. 2007

Website: maytech.cn

Key Highlights: 4–12 day deliveryOver 16 years Manufacturer of brushless motor, ESCs/VESCs, remote, electric … © 2026, Maytech.cn–Maytech official website Powered by Shopify….

#3 Outrunner Brushless DC Motor, Outer Rotor BLDC Motor Manufacturer

Domain Est. 2018

Website: leili-motor.net

Key Highlights: Our outrunner brushless DC motor features high efficiency, torque, and low noise, using permanent magnets for optimal performance….

#4 Manufacturer & supplier of frameless motors and motion control …

Domain Est. 2019

Website: mosrac.com

Key Highlights: Mosrac offers standard and custom frameless motors, encoders, and robot joint modules for industries worldwide, focusing on cutting-edge precision ……

#5 outrunner brushless motors

Domain Est. 2004

Website: neumotors.com

Key Highlights: Brushless motor (BLDC motors) from 50 watts to 50kW. Choose Inrunner or Outrunner format, then choose power level needed for the application….

#6 HOBBYWING

Domain Est. 2005

Website: hobbywing.com

Key Highlights: Explore HOBBYWING’s full range of brushless ESCs and motors for drones/FPV, RC cars, airplanes, and boats. Professional performance for RC enthusiasts ……

#7 Brushless Outrunner Motors

Domain Est. 2006

Website: scorpionsystem.com

Key Highlights: Scorpion Power Systems specializes in the design, development and production of premium Brushless Outrunner Motors….

#8 Plettenberg

Domain Est. 2022

Website: plettenbergmotors.com

Key Highlights: We are the global leader in ultra-rugged high-performance inrunner BLDC motors. Our portfolio also includes outrunner BLDC motors, brushed DC motors, ESCs, ……

Expert Sourcing Insights for Outrunner Brushless Motor

H2: 2026 Market Trends for Outrunner Brushless Motors

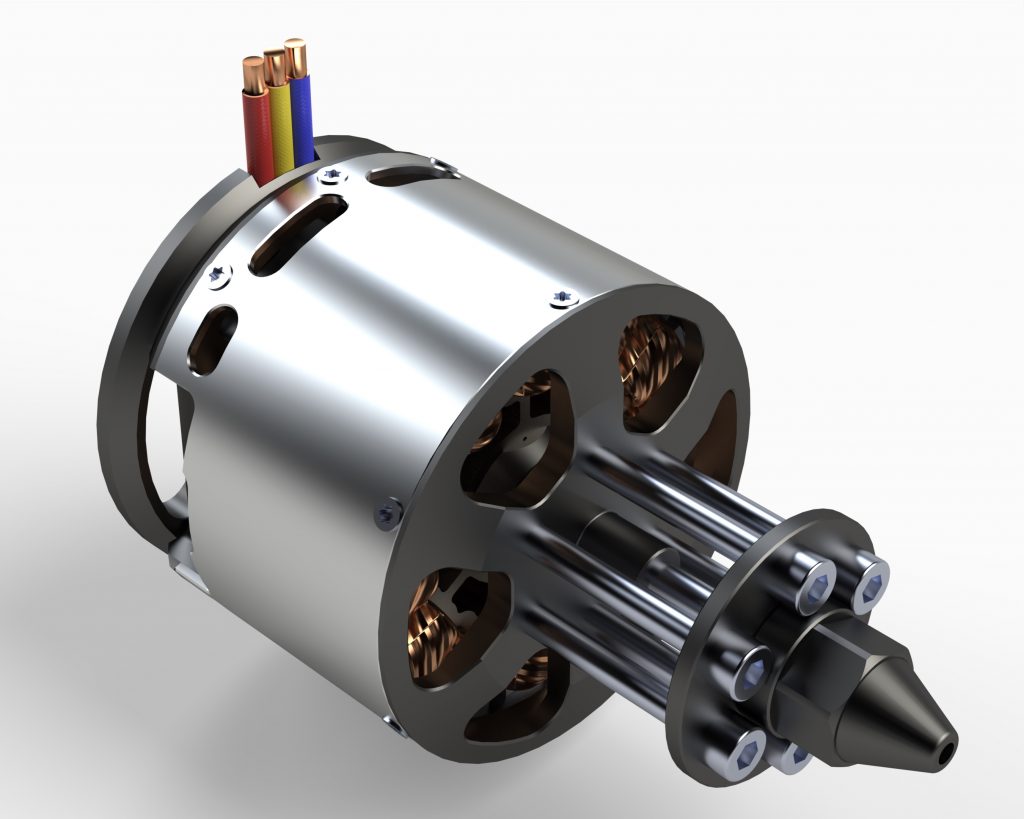

The global market for outrunner brushless motors is poised for significant transformation by 2026, driven by technological advancements, rising demand across key industries, and a shift toward energy-efficient and high-performance electromechanical systems. Outrunner motors—characterized by a rotating outer shell with permanent magnets surrounding a stationary core—offer advantages such as high torque at low speeds, excellent heat dissipation, and compact design, making them ideal for applications in drones, electric vehicles (EVs), robotics, and industrial automation.

-

Expansion in the Drone and UAV Sector

The commercial and consumer drone market remains a primary growth driver for outrunner brushless motors. By 2026, increasing adoption of drones for delivery services, aerial photography, agriculture, and surveillance is expected to boost demand. Outrunner motors are preferred in multirotor drones due to their high torque-to-weight ratio and efficiency, enabling longer flight times and improved payload capacity. Regulatory support and investment in drone infrastructure across North America, Europe, and Asia-Pacific will further fuel market expansion. -

Growth in Electric Mobility Applications

While inrunner motors dominate many EV drivetrains, outrunner motors are gaining traction in niche electric mobility applications, such as electric bicycles, scooters, and personal mobility devices. Their ability to deliver direct drive capabilities without gearboxes reduces mechanical complexity and maintenance needs. As urban electrification and micro-mobility solutions proliferate, especially in densely populated regions like China and India, demand for compact and efficient outrunners will rise. -

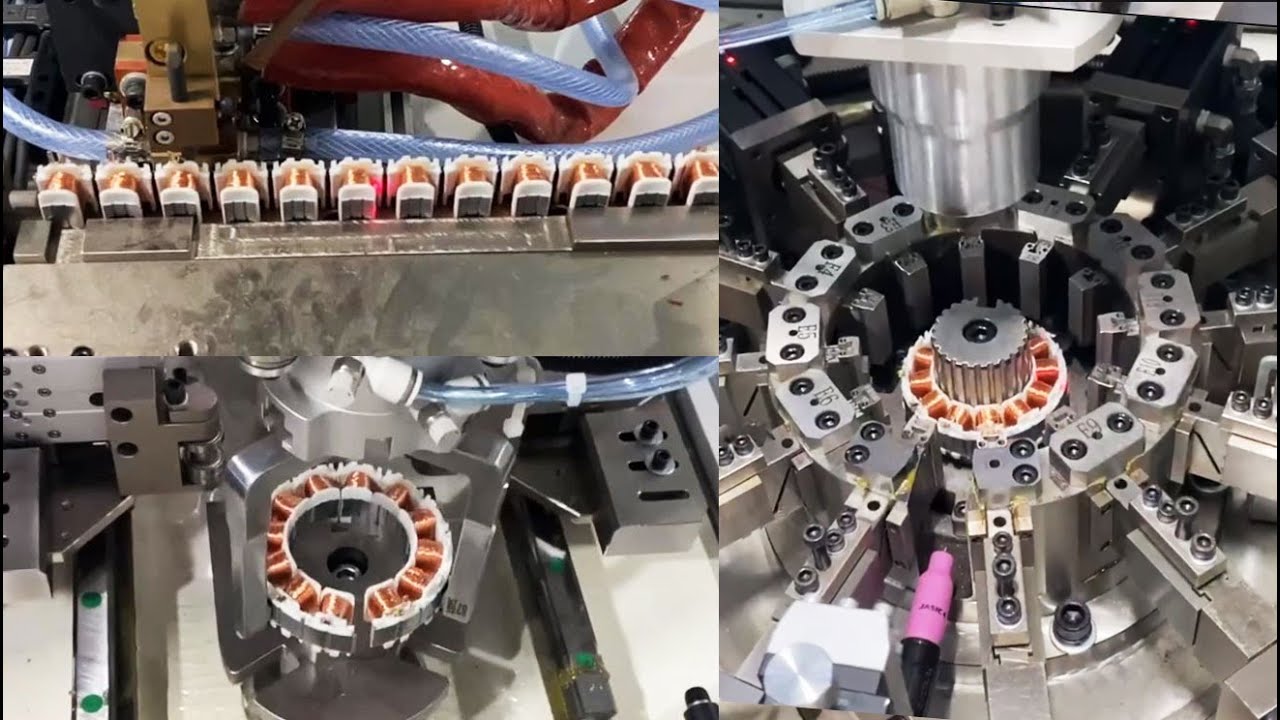

Advancements in Motor Design and Materials

By 2026, innovations in magnet materials (e.g., neodymium-iron-boron), improved winding techniques, and integration with sensorless control algorithms will enhance the performance and reliability of outrunner motors. Manufacturers are focusing on lightweight composite housings and better thermal management to improve power density. These improvements are expected to lower production costs and expand application reach into more demanding environments. -

Integration with Smart Control Systems

The convergence of outrunner motors with advanced electronic speed controllers (ESCs) and IoT-enabled monitoring systems is a key trend. Smart motor systems capable of real-time performance optimization, predictive maintenance, and remote diagnostics will become standard, particularly in industrial and commercial applications. This integration supports the broader Industry 4.0 movement and enhances operational efficiency. -

Regional Market Dynamics

Asia-Pacific is projected to dominate the outrunner motor market by 2026, led by China’s robust manufacturing ecosystem and strong domestic demand in drones and e-mobility. Europe and North America will follow, driven by innovation in automation, aerospace, and defense sectors. Increasing R&D investments and government incentives for green technologies will further stimulate growth. -

Sustainability and Environmental Regulations

Stringent emissions standards and global decarbonization goals are accelerating the shift from brushed to brushless motors. Outrunner designs, with higher efficiency and longer lifespan, align with sustainability objectives. Recycling initiatives for rare-earth magnets and efforts to develop alternative magnet-free designs may also influence long-term market trajectories.

In conclusion, the 2026 outlook for outrunner brushless motors is highly positive, with robust growth anticipated across diverse sectors. Continued innovation, supportive regulatory frameworks, and expanding application ecosystems will solidify their role as critical components in next-generation electric systems.

Common Pitfalls When Sourcing Outrunner Brushless Motors (Quality & IP)

Sourcing Outrunner Brushless Motors can be challenging, especially when balancing performance, durability, and cost. Overlooking key aspects related to quality and intellectual property (IP) can lead to significant issues down the line. Here are common pitfalls to avoid:

Poor Build Quality and Inconsistent Manufacturing

Many low-cost or unverified suppliers offer motors that appear identical on paper but suffer from substandard materials and inconsistent assembly. This can manifest as unbalanced rotors, poor winding quality, inadequate bearing lubrication, and inconsistent air gaps—leading to excessive vibration, heat buildup, reduced efficiency, shorter lifespan, and potential in-field failures.

Misrepresented or Inflated Specifications

Suppliers—particularly on open marketplaces—often exaggerate motor performance metrics such as Kv (RPM per volt), torque, power output, and efficiency. Without independent verification or standardized testing protocols, buyers may receive motors that fail to meet required performance thresholds, resulting in underperforming systems and rework costs.

Lack of Environmental Protection (IP Rating Misrepresentation)

Outrunner motors used in drones, electric vehicles, or outdoor equipment require appropriate Ingress Protection (IP) ratings to withstand dust, moisture, and environmental contaminants. A common pitfall is sourcing motors advertised with high IP ratings (e.g., IP67) that lack proper sealing, gaskets, or conformal coatings. This can lead to internal corrosion, winding damage, and premature motor failure when exposed to real-world conditions.

Inadequate Thermal Management Design

High-performance outrunners generate significant heat, especially under sustained loads. Poorly designed motors may lack sufficient thermal pathways or use low-grade materials that degrade at elevated temperatures. This results in thermal runaway, demagnetization of permanent magnets, and insulation breakdown—issues that are often not evident during initial testing but emerge over time.

Counterfeit or Unlicensed Designs (IP Infringement Risk)

Some manufacturers reverse-engineer popular motor designs from reputable brands (e.g., T-Motor, DJI, or RC-specific OEMs) without licensing. While these clones may offer similar specs at lower prices, they pose intellectual property risks, especially for commercial integrators. Using such motors in mass-produced products can expose companies to legal liability, product recalls, or reputational damage.

Absence of Traceability and Certification

Reputable motors should come with clear documentation, batch traceability, and compliance certifications (e.g., RoHS, REACH, or CE). Sourcing from suppliers without these can complicate quality control, regulatory approvals, and warranty claims. It also increases the risk of receiving non-compliant components, especially in safety-critical or regulated applications.

Insufficient Supplier Vetting and Long-Term Support

Relying on suppliers with no proven track record, poor communication, or limited technical support can be a major pitfall. Issues such as inconsistent supply, lack of firmware or documentation updates (for integrated sensors), and difficulty resolving quality disputes can severely impact production timelines and product reliability.

Avoiding these pitfalls requires due diligence: request sample testing, verify IP ratings through third-party reports, audit manufacturing practices, and ensure legal compliance with IP rights—especially when scaling to commercial production.

Logistics & Compliance Guide for Outrunner Brushless Motors

Overview of Outrunner Brushless Motors

Outrunner brushless motors are widely used in drones, electric vehicles, and industrial applications due to their high torque, efficiency, and reliability. Proper logistics and compliance management are essential to ensure safe transportation, regulatory adherence, and smooth market entry. This guide outlines key considerations for shipping, handling, and regulatory compliance of outrunner brushless motors globally.

Classification and HS Code

Outrunner brushless motors typically fall under the Harmonized System (HS) code 8501.31 or 8501.32, depending on power output:

– 8501.31: Motors with output ≤ 750 watts

– 8501.32: Motors with output > 750 watts

Accurate classification is critical for import/export declarations, duty assessment, and customs clearance. Always verify local tariff schedules, as classifications may vary by country.

Export Controls and Licensing

Brushless motors may be subject to export control regulations, especially if used in defense, aerospace, or dual-use applications. Key considerations include:

– ITAR (International Traffic in Arms Regulations): May apply if the motor is designed for military drones or aerospace systems.

– EAR (Export Administration Regulations): Most commercial outrunner motors fall under EAR99. However, high-performance motors may require a license if exported to restricted destinations.

– Dual-Use Concerns: Verify if the motor meets performance thresholds (e.g., power density, RPM) that could trigger licensing requirements under the Wassenaar Arrangement.

Always conduct an export classification review and consult legal counsel when exporting to sensitive regions.

Packaging and Handling Requirements

Proper packaging ensures product integrity and safety during transport:

– Use anti-static and moisture-resistant materials to protect electronic components.

– Secure motors in rigid containers with cushioning to prevent mechanical damage.

– Label packages with “Fragile,” “This Side Up,” and “Do Not Stack” as appropriate.

– Include desiccant packs in sealed packaging to prevent corrosion during maritime shipments.

Avoid exposing motors to extreme temperatures or humidity during storage and transit.

Shipping and Transportation Regulations

Outrunner motors are generally not classified as hazardous materials. However, compliance with transportation standards is required:

– IATA/ICAO: For air freight, motors must not contain magnetic components exceeding limits (check for strong permanent magnets). If necessary, perform a magnetic field test (IATA Special Provision A48).

– IMDG Code: For sea freight, declare motors as non-hazardous unless equipped with lithium components (e.g., integrated ESC with battery).

– Road/Rail (ADR/RID): No special restrictions apply if motors are standalone units without batteries.

Ensure motors are completely de-energized and disconnected from any power source before shipment.

Import Compliance and Documentation

Successful customs clearance requires accurate documentation:

– Commercial Invoice: Include HS code, value, origin, and detailed product description.

– Packing List: Specify quantities, weights, and dimensions.

– Certificate of Origin: May be required for preferential tariff treatment (e.g., under USMCA, RCEP).

– Import Permits: Some countries require approval for electrical equipment (e.g., India’s BIS, China’s CCC).

Verify local conformity requirements before shipping.

Electromagnetic Compatibility (EMC) and Safety Standards

Ensure motors comply with regional EMC and safety regulations:

– CE Marking (EU): Compliance with EMC Directive 2014/30/EU and RoHS Directive 2011/65/EU is mandatory.

– FCC (USA): Motors may need to meet FCC Part 15 for unintentional radiators.

– UKCA (UK): Required for sale in the United Kingdom post-Brexit.

– Other Regions: Check for PSE (Japan), KC (South Korea), and CCC (China) certifications if applicable.

Maintain test reports and technical documentation for audit purposes.

Environmental and RoHS Compliance

Outrunner motors must comply with environmental directives restricting hazardous substances:

– RoHS (EU/UK/China): Limits on lead, cadmium, mercury, and certain flame retardants.

– REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals.

– WEEE (EU): Producers may be responsible for end-of-life recycling.

Ensure all components (e.g., wiring, coatings) meet material restrictions.

Battery Integration Warnings

If motors are shipped with integrated controllers or batteries:

– Lithium batteries are subject to UN 38.3 testing and must be shipped under IATA PI 965–970.

– Declare battery type, watt-hour rating, and packaging instructions clearly.

– Standalone motors without batteries are not subject to these rules.

Recordkeeping and Audit Readiness

Maintain records for at least 5 years, including:

– Export classifications

– Test reports (EMC, safety, environmental)

– Certificates of compliance

– Shipping documentation

This supports audit readiness and regulatory defense.

Conclusion

Compliance and logistics for outrunner brushless motors involve precise classification, adherence to export controls, proper packaging, and conformity with regional regulations. Proactive planning, accurate documentation, and staying updated on regulatory changes are essential for global distribution success. Consult with logistics providers and compliance experts to ensure full adherence to international standards.

Conclusion: Sourcing Outrunner Brushless Motors

In conclusion, sourcing outrunner brushless motors requires a strategic approach that balances performance requirements, cost, reliability, and supplier capability. These motors are ideal for applications demanding high torque at low speeds, efficient thermal performance, and compact design—commonly used in drones, electric propulsion systems, RC vehicles, and various industrial applications.

Through careful evaluation of key parameters such as KV rating, power output, physical dimensions, efficiency, and cooling requirements, organizations can identify motors that best suit their technical needs. Additionally, assessing supplier reputation, manufacturing quality, lead times, and after-sales support is crucial to ensuring consistent supply and long-term operational success.

Opting for established manufacturers or reputable distributors often ensures compliance with industry standards and provides access to technical support and warranties. However, cost-effective alternatives from emerging markets may be viable with proper due diligence and sample testing.

Ultimately, a well-informed sourcing decision—based on thorough technical analysis, application-specific requirements, and supply chain considerations—will lead to improved system performance, reliability, and cost efficiency. Regular review of market developments and technological advancements will also enable continuous optimization of the sourcing strategy for outrunner brushless motors.