The global oriented strand board (OSB) market has experienced steady expansion, driven by growing demand in residential construction and favorable material properties such as strength, cost-efficiency, and sustainability. According to Grand View Research, the global OSB market was valued at USD 23.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth trajectory reflects increasing adoption of engineered wood products in North America and Europe, where 7/16-inch OSB remains a standard thickness for roofing and wall sheathing due to its optimal balance of performance and load-bearing capacity.

As demand rises, manufacturers are scaling production and improving product consistency, particularly for mid-thickness panels like 7/16-inch OSB. Supply chain dynamics, raw material availability, and regional construction activity heavily influence output and pricing. To identify the leading producers of 7/16-inch OSB, a data-driven analysis of production capacity, market presence, quality standards, and geographic reach is essential. Based on industry reports and performance metrics, the following seven manufacturers have emerged as top suppliers in this segment.

Top 7 Osb Weight 7 16 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 OSB

Domain Est. 1997

Website: westfraser.com

Key Highlights: West Fraser’s oriented strand board (OSB) is a strong, durable option for residential, commercial and industrial construction. Made from cross-oriented ……

#2 1/2 ” x 4 x 8′ Osb (7/16) Sheating Panel

Domain Est. 2003

Website: dbmlumber.com

Key Highlights: In stock $65 delivery1/2″ x 4′ x 8′ OSB (7/16) Sheathing Panel ; Material: Oriented Strand Board (OSB) ; Weight: Approximately 45-50 lbs per panel (varies by manufacturer) ; Edge T…

#3 OSB & Panels

Domain Est. 1995

Website: weyerhaeuser.com

Key Highlights: A versatile engineered structural panel often used for floor decking and wall/roof sheathing. Quality builders rely on Weyerhaeuser OSB panels for good reason….

#4 Standard OSB Sheathing

Domain Est. 1996

Website: lpcorp.com

Key Highlights: OSB sheathing products, offered in a variety of panel sizes and performance categories. All are APA-rated and backed by a 20-year transferable limited warranty….

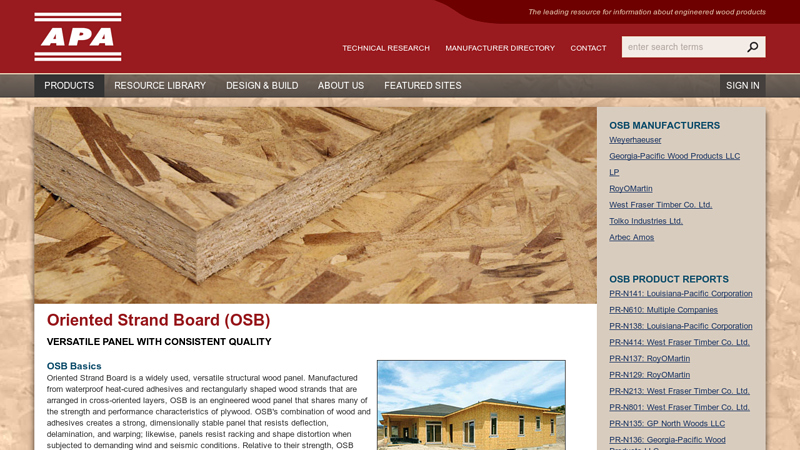

#5 Oriented Strand Board (OSB)

Domain Est. 1996

Website: apawood.org

Key Highlights: Oriented Strand Board is a widely used, versatile structural wood panel. Manufactured from waterproof heat-cured adhesives and rectangularly shaped wood ……

#6 OSB 7/16

Domain Est. 1999

Website: plywoodcompany.com

Key Highlights: 30-day returnsSKU# 5OSB. OSB – 7/16″ – SOUTHERN YELLOW PINE. Size: 4×8 Weight: 49.5 Piece OSB 7/16″-4×8 Oriented Strand Board. QTY: Decrement Increment. 861 Available….

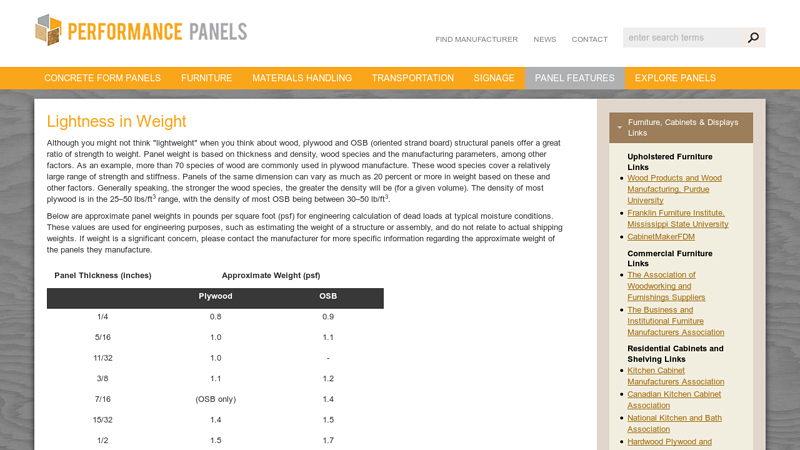

#7 Lightness in Weight

Domain Est. 2005

Website: performancepanels.com

Key Highlights: The density of most plywood is in the 25–50 lbs/ft3 range, with the density of most OSB being between 30–50 lb/ft3. Below are approximate panel weights in ……

Expert Sourcing Insights for Osb Weight 7 16

H2: Projected 2026 Market Trends for OSB Weight 7/16

The market for 7/16-inch oriented strand board (OSB), a standard thickness widely used in residential roofing and sheathing applications, is expected to experience notable shifts by 2026 driven by housing demand, material costs, supply chain dynamics, and sustainability trends.

1. Housing Market Influence

The demand for 7/16-inch OSB is closely tied to new residential construction and repair, renovation, and remodeling (R&R) activity. In 2026, housing starts in North America—particularly the U.S., the largest consumer of OSB—are projected to stabilize or slightly increase compared to recent volatile years. As mortgage rates potentially ease from 2023–2024 peaks, homebuilding activity is expected to rebound, boosting OSB demand. Since 7/16-inch OSB is commonly used as roof sheathing (often as a cost-effective alternative to 1/2-inch panels), roofing-intensive housing designs and re-roofing projects will drive volume.

2. Price Volatility and Cost Pressures

OSB pricing has historically been cyclical, and 2026 may see moderate price stability compared to the extreme swings of 2020–2022. However, input costs—including wood fiber, resins, and energy—will remain key factors. Rising environmental regulations on forestry practices and emissions could increase production costs. Additionally, labor and transportation expenses, especially in remote mill regions, may exert upward pressure on OSB prices. Buyers of 7/16-inch OSB are likely to seek long-term supply contracts to hedge against volatility.

3. Supply Chain Resilience and Production Capacity

By 2026, North American OSB producers are expected to operate at high capacity utilization, with few new greenfield mills planned. Instead, manufacturers are investing in efficiency upgrades and sustainability certifications. This constrained supply growth could limit oversupply risks, supporting balanced market conditions. Regional supply imbalances may persist, particularly in the Western U.S. and Canada, where wildfire disruptions and timber access issues could affect mill operations.

4. Competition with Plywood and Alternative Materials

Although 7/16-inch OSB maintains a cost advantage over plywood (typically 15–30% cheaper), concerns over moisture resistance and edge swelling may push some builders toward treated OSB or plywood in high-humidity regions. Innovations in resin technology—such as moisture-resistant and formaldehyde-free binders—are expected to enhance OSB’s performance, improving its competitiveness. Additionally, engineered wood products and advanced composites may begin to encroach on traditional OSB applications, though likely at a slow pace by 2026.

5. Sustainability and Green Building Trends

Environmental considerations are gaining influence in building material selection. OSB manufacturers are responding by increasing the use of smaller-diameter trees and recycled wood, reducing waste, and obtaining certifications like FSC or SFI. In 2026, green building standards (e.g., LEED, ENERGY STAR) and consumer preference for sustainable materials may favor OSB if producers can demonstrate lower carbon footprints and responsible sourcing—boosting demand for certified 7/16-inch panels.

6. Technological and Logistical Advancements

Digital procurement platforms and just-in-time inventory systems are streamlining distribution. By 2026, more builders and distributors will likely use data analytics to forecast OSB needs and reduce waste. Pre-cut and precision-fabricated OSB panels may gain traction in modular and panelized home construction, improving efficiency and reducing labor costs—particularly beneficial for standardized 7/16-inch applications.

Conclusion

The 2026 market for 7/16-inch OSB is projected to be characterized by steady demand, controlled pricing, and incremental innovation. While challenges related to raw materials and climate policy persist, the product’s cost-effectiveness and adaptability will sustain its dominant role in residential construction. Producers who invest in sustainability, supply chain resilience, and product performance enhancements are best positioned to capture market share in this maturing yet vital segment.

Common Pitfalls When Sourcing OSB Weight 7/16 (Quality and Performance)

Sourcing 7/16-inch OSB (Oriented Strand Board) for structural applications requires careful attention to quality and performance standards to avoid costly mistakes. Below are key pitfalls to watch for:

Inadequate Verification of Structural Grade and Exposure Rating

One of the most common errors is assuming all 7/16-inch OSB is suitable for structural use. Not all OSB panels meet load-bearing requirements or environmental exposure standards. Buyers must confirm the panel is rated as Structural I and has the correct Exposure 1 or Exterior bond classification. Using interior-grade or non-structural OSB in roofing or sheathing can lead to premature failure, especially in humid or wet conditions.

Ignoring Manufacturer Specifications and Third-Party Certification

Relying solely on supplier claims without checking third-party certification (e.g., APA – The Engineered Wood Association) can result in substandard material. Always verify that the OSB carries an APA stamp or equivalent certification, ensuring it meets PS 2 (Performance Standard 2) requirements for strength, stiffness, and durability. Panels without such certification may not perform as expected under load or over time.

Overlooking Span and Load Capacity Mismatch

7/16-inch OSB has specific span ratings based on joist spacing and expected loads. A frequent pitfall is using 7/16-inch panels in applications that require thicker or stronger sheathing (e.g., wide rafter spacing or high snow loads). This can cause sagging, noise, or structural compromise. Always cross-reference the manufacturer’s span charts and ensure the OSB meets local building code requirements for the intended application.

Poor Quality Control During Delivery and Handling

Even high-quality OSB can be compromised by improper handling. Panels exposed to rain or ground moisture during transport or storage may swell or delaminate, reducing performance. Inspect shipments upon arrival for warping, edge damage, or moisture exposure. Store panels flat, elevated off the ground, and covered to maintain integrity before installation.

Confusing OSB with Particleboard or MDF

Some suppliers may mislabel or substitute lower-density panels such as particleboard or MDF as OSB. These materials lack the structural integrity and moisture resistance needed for roofing or wall sheathing. Visually inspect the panel edges: true OSB shows distinct wood strands, while particleboard has a finer, more uniform texture. Always confirm product type with documentation.

Failing to Address Regional Climate and Building Code Requirements

Performance needs vary by region. In high-humidity or coastal areas, standard OSB may be prone to edge swelling or fungal growth if not treated or properly installed. Ensure the OSB meets regional codes for moisture resistance and thermal performance. Some projects may require Zero-Added Formaldehyde (NAF) or low-emitting panels for indoor air quality compliance.

By avoiding these common pitfalls, buyers can ensure they source 7/16-inch OSB that delivers the necessary structural performance, durability, and compliance for their project.

Logistics & Compliance Guide for OSB Weight 7/16

Product Overview

Oriented Strand Board (OSB) with a thickness of 7/16 inch is a widely used engineered wood panel in residential and light commercial construction. It is commonly used for roof sheathing, sidewall bracing, and flooring underlayment. Understanding the logistics and compliance aspects of handling and using 7/16-inch OSB is essential for project efficiency and regulatory adherence.

Weight Specifications

- Average Panel Weight: A standard 4′ x 8′ sheet of 7/16-inch OSB weighs approximately 46–50 pounds (20.9–22.7 kg).

- Weight per Square Foot: Roughly 1.4 to 1.6 pounds per square foot.

- Pallet Weight: A full pallet typically holds 40–50 sheets, resulting in a total weight of 1,840 to 2,500 pounds (835–1,134 kg), depending on packaging and moisture content.

Handling & Storage Logistics

- Manual Handling: Use proper lifting techniques or mechanical aids (e.g., panel lifters) to reduce worker strain and injury risk.

- Storage Conditions:

- Store panels flat on a level, dry surface.

- Elevate pallets at least 4 inches off the ground using stringers.

- Cover with waterproof tarp to prevent moisture absorption; avoid plastic sheeting that can trap moisture.

- Stacking Limits: Do not stack more than two pallets high unless designed for it; ensure stability and prevent tipping.

Transportation Requirements

- Truck Loading: Secure loads with straps or load bars to prevent shifting during transit.

- Weight Considerations: Account for total load weight when planning deliveries. Confirm vehicle weight limits, especially for local or urban routes with restrictions.

- Weather Protection: Use tarps or enclosed trailers to protect OSB from rain and snow during transport.

Compliance & Regulatory Standards

- APA Certification: Ensure 7/16-inch OSB panels are APA (The Engineered Wood Association) rated and marked (e.g., APA PRP-108). Look for grade stamps indicating compliance.

- Building Codes: Complies with IBC (International Building Code) and IRC (International Residential Code) for structural sheathing when used in approved applications.

- Exposure Rating: Most 7/16-inch OSB is rated for Exposure 1, allowing temporary moisture exposure during construction but not intended for long-term outdoor use without protection.

- Formaldehyde Emissions: Must meet CARB ATCM Phase 2 and HUD/US EPA TSCA Title VI standards for formaldehyde emissions, especially in indoor applications.

Installation Best Practices

- Edge Support: Ensure all panel edges are supported by framing members to prevent sagging.

- Spacing: Leave a 1/8-inch gap between panels to allow for expansion due to moisture.

- Fastening: Use appropriate nails or screws as specified by code or manufacturer (e.g., 8d common nails at 6″ on edges, 12″ in the field for roof sheathing).

- Orientation: Install panels with the graded side facing outward (typically marked “This Side Down” or with exposure rating).

Environmental & Safety Considerations

- Dust Control: Use PPE (respirators, eye protection) during cutting; use dust collection tools to minimize airborne particles.

- Recycling & Disposal: OSB can often be recycled at wood waste facilities. Check local regulations for disposal of treated or coated panels.

- Sustainability: Many OSB products use sustainably harvested wood strands and low-emission resins. Verify FSC or SFI certification if required.

Documentation & Traceability

- Maintain records of:

- Mill certificates and grade stamps.

- Delivery receipts with lot numbers.

- Compliance documentation (CARB, APA, TSCA).

- Ensure traceability from supplier to jobsite for quality assurance and audit readiness.

Conclusion

Proper logistics planning and adherence to compliance standards are critical when working with 7/16-inch OSB. By following this guide, contractors, suppliers, and builders can ensure safe handling, regulatory compliance, and optimal performance in construction applications.

In conclusion, when sourcing OSB (Oriented Strand Board) with a thickness of 7/16 inch, it’s essential to consider its weight for transportation, handling, and structural requirements. A standard 4′ x 8′ sheet of 7/16″ OSB typically weighs between 45 to 50 pounds, depending on the manufacturer, resin content, and moisture level. Accurate weight estimation helps in planning logistics, ensuring safety during installation, and verifying compliance with load specifications in construction projects. Always confirm the exact weight with the supplier or product datasheet, as variations can occur between brands and product lines. Proper sourcing should balance weight considerations with performance, cost, and availability to meet project needs effectively.