The global organochlorine pesticides market continues to experience measured growth despite increasing regulatory scrutiny and environmental concerns, driven largely by persistent demand in select agricultural sectors and public health applications such as vector control. According to Grand View Research, the global pesticides market was valued at USD 220.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.9% from 2023 to 2030. While organochlorines represent a declining segment due to bans and restrictions under international agreements like the Stockholm Convention, niche usage in malaria-endemic regions and stockpile management sustains limited production. Mordor Intelligence reports that vector-borne disease outbreaks and ongoing needs in subsistence farming contribute to continued, albeit regulated, demand in certain geographies. As a result, a small cohort of manufacturers—primarily based in Asia and focused on DDT and related compounds for disease vector control—remain active. The following analysis identifies the top six organochlorine pesticide manufacturers operating in this highly regulated and evolving landscape, based on historical production capacity, regional influence, and compliance with international regulatory standards.

Top 6 Organochlorine Pesticides Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Download Organochlorine Pesticides

Domain Est. 1996

Website: leco.com

Key Highlights: Download the latest document fromLECO Corporation….

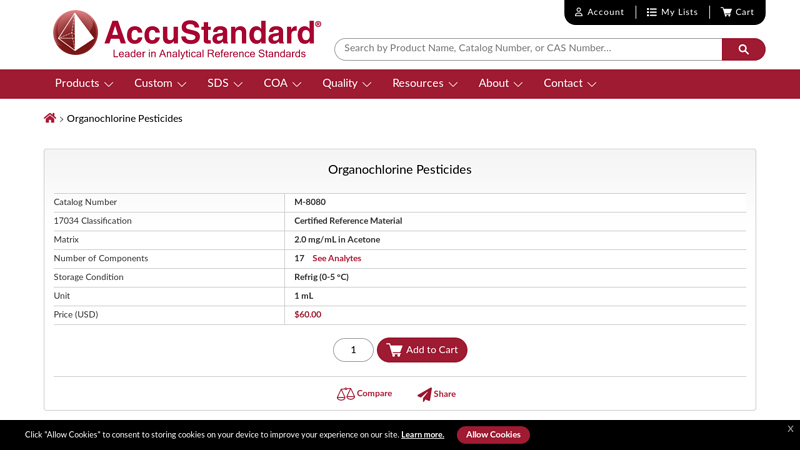

#2 Organochlorine Pesticides

Domain Est. 1996

Website: accustandard.com

Key Highlights: Purchase Organochlorine Pesticides at 2.0 mg/mL in Acetone – Certified Reference Standard from AccuStandard, Catalog No. M-8080….

#3 EPA 8081: Organochlorine Pesticides on ZB-MR2

Domain Est. 1997

Website: phenomenex.com

Key Highlights: Discover a wide range of chromatography applications tailored to your analytical needs, powered by innovative solutions from Phenomenex….

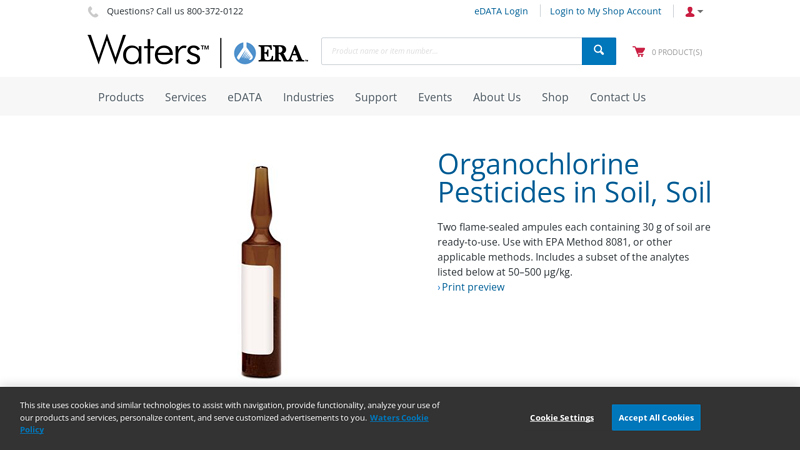

#4 Organochlorine Pesticides in Soil

Domain Est. 1997

Website: eraqc.com

Key Highlights: Assess performance with this Organochlorine Pesticides in Soil standard. This comes as two 30 g flame-sealed ampules of soil, ready to use….

#5 OCP, Native Organochlorine Pesticides

Domain Est. 2009

Website: bcp-instruments.com

Key Highlights: Our range of native organochlorine pesticide standards (OCPs) for your environmental analyses. Discover our native standards, individually or in mixtures: OCPs, ……

#6 George AFB’s Organochlorine Pesticides Contamination

Website: georgeafb.info

Key Highlights: In 2002, aldrin, chlordane, DDT, dieldrin, endrin, heptachlor, and lindane were detected in the surface soil at the George AFB Family Housing….

Expert Sourcing Insights for Organochlorine Pesticides

H2: Market Trends for Organochlorine Pesticides in 2026

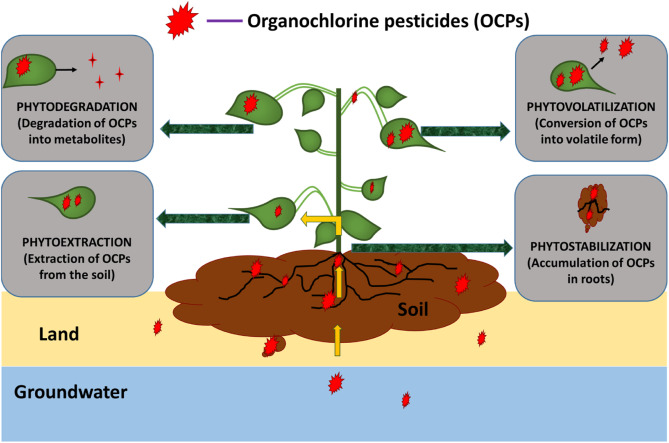

As of 2026, the global market for organochlorine pesticides continues to reflect a legacy of historical usage amid increasingly stringent regulatory environments and a strong shift toward sustainable agriculture. Once widely used for their effectiveness against a broad spectrum of pests, organochlorine compounds such as DDT, lindane, and endosulfan are now heavily restricted or banned in most countries under international agreements like the Stockholm Convention on Persistent Organic Pollutants (POPs).

Despite their decline, limited use of certain organochlorine pesticides persists in specific regions, primarily in vector control programs for malaria prevention—where DDT is still employed under World Health Organization (WHO) guidelines in selected indoor residual spraying (IRS) operations. This niche application supports a minimal but stable segment of the market, particularly in parts of sub-Saharan Africa and South Asia. However, even in these contexts, pressure to transition to safer, more environmentally friendly alternatives is growing.

The 2026 market is characterized by:

-

Declining Production and Trade: Global manufacturing of organochlorine pesticides has significantly diminished. Few chemical producers continue to synthesize these compounds, and international trade is closely monitored under the Prior Informed Consent (PIC) procedure of the Rotterdam Convention.

-

Environmental and Health Concerns: Persistent organic pollution, bioaccumulation in food chains, and links to endocrine disruption and chronic health issues continue to drive public opposition and regulatory crackdowns. These factors suppress market expansion and deter investment.

-

Technological Substitution: The agricultural sector has largely transitioned to organophosphate, carbamate, neonicotinoid, and bio-based pesticides, which offer improved environmental profiles and targeted action. Innovations in integrated pest management (IPM) and precision agriculture further reduce reliance on legacy chemical solutions.

-

Regulatory Enforcement and Monitoring: In 2026, regulatory agencies in North America, Europe, and increasingly in emerging economies enforce strict bans or highly controlled use. Compliance monitoring and residue testing in food and environmental samples remain robust, discouraging illegal use.

-

Illicit Use and Stockpile Management: A minor but concerning trend involves the illegal use of stockpiled organochlorine pesticides in some developing regions, often due to low cost and availability. International efforts focus on the safe disposal of obsolete pesticide stockpiles to mitigate risks.

In summary, the 2026 organochlorine pesticide market is highly constrained, serving only limited public health applications under strict oversight, with no prospects for commercial agricultural revival. The broader trajectory remains one of phase-out, replaced by safer, more sustainable pest control technologies.

Common Pitfalls in Sourcing Organochlorine Pesticides (Quality and Intellectual Property)

Sourcing organochlorine pesticides (OCPs) presents significant challenges due to their historical use, regulatory restrictions, and complex intellectual property landscape. Navigating these requires careful attention to both quality assurance and IP compliance.

Quality-Related Pitfalls

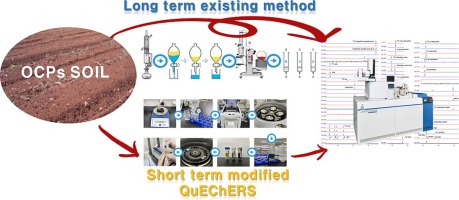

- Degradation and Impurity Profiles: OCPs are often old chemicals prone to degradation over time. Sourcing from unreliable suppliers risks obtaining materials with high levels of toxic degradation products (e.g., DDT degrading to DDE, DDD) or synthesis by-products, compromising research validity or analytical accuracy.

- Contamination: Cross-contamination during manufacturing, storage, or handling is a major concern. Impurities from other pesticides, solvents, or heavy metals can significantly affect assay results and lead to false positives or skewed data.

- Inaccurate Concentration/Assay: Suppliers may provide materials with stated concentrations that do not match actual content due to poor manufacturing controls or aging. This directly impacts dosing accuracy in research or calibration.

- Lack of Comprehensive Certification: Inadequate or missing Certificates of Analysis (CoA) lacking key parameters like purity (assay), impurity profile (HPLC/GC), water content, residue solvents, and heavy metals makes quality assessment impossible.

- Unverified Source and Synthesis Route: Opaque supply chains can obscure the original manufacturer and synthesis method, increasing the risk of sourcing materials with unknown or undesirable impurity profiles.

- Inadequate Storage and Handling: Poor storage conditions (e.g., exposure to light, heat, moisture) by the supplier can degrade the product before it reaches the buyer, even if initially pure.

Intellectual Property-Related Pitfalls

- Patent Infringement (Historical & Design-Arounds): While core patents for most OCPs have expired, sourcing intermediates, specific formulations, or novel analytical standards derived from OCPs might still be protected. Using these without licenses risks infringement claims, especially if sourced from entities holding newer patents on processes or uses.

- Trademark Infringement: Using the commercial brand name (e.g., “Lindane”) instead of the generic chemical name when sourcing or referencing, especially in publications or product labeling, can infringe on existing trademarks, even if the chemical itself is off-patent.

- Trade Secret Exposure: Reputable suppliers often protect specific purification processes or analytical methods as trade secrets. Attempting to reverse-engineer sourced materials or demanding overly detailed process information can create legal risks and damage supplier relationships.

- Unclear Licensing for Reference Standards: High-purity OCP reference standards used in analytical labs may be sold under specific licenses restricting their use (e.g., “for research only,” “not for therapeutic use”). Violating these terms, even unintentionally, can breach contractual agreements.

- Sourcing from Jurisdictions with Weak IP Enforcement: Procuring OCPs from regions known for IP violations increases the risk of receiving counterfeit, substandard, or legally questionable materials, potentially implicating the buyer in IP disputes.

- Misrepresentation of Origin/Status: Suppliers might misrepresent the legal status (e.g., falsely claiming a material is “patent-free” when associated processes are patented) or origin of the material, leading buyers into inadvertent IP violations.

Logistics & Compliance Guide for Organochlorine Pesticides

Organochlorine pesticides, such as DDT, chlordane, and lindane, are persistent organic pollutants (POPs) that have been largely banned or restricted globally due to their environmental persistence, bioaccumulation, and toxic effects on human health and ecosystems. Despite restrictions, certain organochlorine pesticides may still be used under strict regulatory oversight in specific circumstances (e.g., disease vector control). This guide outlines key logistics and compliance considerations for the handling, transport, storage, and disposal of organochlorine pesticides where permitted.

Regulatory Framework

Organochlorine pesticides are regulated under multiple international, regional, and national frameworks. Compliance begins with understanding applicable regulations.

Stockholm Convention on Persistent Organic Pollutants

The Stockholm Convention prohibits or restricts the production and use of most organochlorine pesticides. Parties to the Convention must:

- Eliminate or restrict production and use of listed substances.

- Safely manage stockpiles and wastes containing POPs.

- Report on measures taken and submit national implementation plans.

Rotterdam Convention (Prior Informed Consent – PIC)

This treaty promotes shared responsibility in the international trade of hazardous chemicals. Exporters must:

- Obtain prior informed consent from importing countries.

- Provide detailed information on risks and safe handling.

National Regulations

Countries maintain their own regulatory systems. Examples include:

- USA: Regulated by the Environmental Protection Agency (EPA) under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA).

- EU: Banned under Regulation (EU) 2019/1021 (POP Regulation).

- Other Countries: May allow restricted use for public health purposes (e.g., malaria control).

Operators must confirm legal status and permitted uses in origin, transit, and destination countries.

Classification and Labeling

Proper classification is essential for compliance with chemical safety and transport regulations.

Globally Harmonized System (GHS)

Organochlorine pesticides typically require labeling with the following GHS hazard statements:

- H300: Fatal if swallowed

- H310: Fatal in contact with skin

- H330: Fatal if inhaled

- H410: Very toxic to aquatic life with long-lasting effects

- H411: Toxic to aquatic life with long-lasting effects

Signal word: Danger

Hazard pictograms: Skull and crossbones, exclamation mark, environment

UN Number and Proper Shipping Name

Common classifications for transport:

- UN 2761: PESTICIDE, TOXIC, LIQUID, N.O.S. (e.g., DDT solution)

- UN 2762: PESTICIDE, TOXIC, SOLID, N.O.S.

Class: 6.1 (Toxic substances)

Packing Group: II or I, depending on toxicity

Packaging and Containment

Strict packaging standards are required to prevent leaks and exposure.

Requirements

- Use UN-certified containers with compatible materials (e.g., HDPE, glass).

- Inner packaging must prevent leakage; outer packaging must withstand stacking and handling.

- Seal containers with tamper-evident closures.

- Absorbent material required for liquid formulations in combination packaging.

Secondary Containment

- Palletize and secure loads to prevent movement.

- Use spill trays or overpacks for added protection.

- Label all packages clearly with hazard class, UN number, and orientation arrows.

Transport and Logistics

Transportation must comply with international and national regulations.

Road, Rail, and Inland Waterways (ADR/RID/ADN)

- Drivers must be trained in hazardous materials handling.

- Vehicles must display appropriate hazard placards (Class 6.1).

- Emergency response information (e.g., TREV, transport emergency card) must be onboard.

Air Transport (ICAO/IATA DGR)

- Subject to strict limitations; some organochlorines may be forbidden.

- Requires Shipper’s Declaration for Dangerous Goods.

- Maximum net quantity per package limited (e.g., 25 kg for solids in Packing Group I).

Sea Transport (IMDG Code)

- Packages must be stowed away from living quarters and foodstuffs.

- Segregation from incompatible materials (e.g., oxidizers, acids) required.

- Documentation: Dangerous Goods Manifest and Transport Document.

Storage Requirements

Secure and compliant storage minimizes risks of exposure and environmental release.

Facility Design

- Designated hazardous materials storage area with impermeable, chemically resistant flooring.

- Secondary containment (e.g., bunds) capable of holding 110% of largest container.

- Ventilation to prevent vapor accumulation.

- Fire suppression systems and spill control equipment on-site.

Operational Controls

- Access restricted to trained personnel.

- Inventory logs maintained with dates, quantities, and locations.

- First-in, first-out (FIFO) system to prevent degradation.

- Regular inspections for container integrity and leaks.

Worker Safety and Training

Personnel handling organochlorine pesticides must be protected and trained.

Personal Protective Equipment (PPE)

- Chemical-resistant gloves, aprons, and boots.

- Respiratory protection (e.g., NIOSH-approved respirator with organic vapor cartridge).

- Eye protection (goggles or face shield).

Training Requirements

- Hazard communication (GHS labels and SDS).

- Spill response and decontamination procedures.

- Emergency protocols (evacuation, first aid).

- Refresher training annually or when procedures change.

Emergency Response

Prepare for incidents involving spills, exposure, or fire.

Spill Response

- Evacuate non-essential personnel.

- Contain spill using absorbent materials (e.g., vermiculite, activated carbon).

- Collect contaminated material for disposal as hazardous waste.

- Decontaminate surfaces with appropriate agents (e.g., bleach solution for organics).

Exposure Response

- Inhalation: Move to fresh air; seek medical attention.

- Skin Contact: Remove contaminated clothing; wash with soap and water.

- Ingestion: Do NOT induce vomiting; seek immediate medical help.

Fire Response

- Use dry chemical, CO₂, or foam extinguishers.

- Avoid water jets (may spread contamination).

- Evacuate area and wear full protective gear including SCBA.

Waste Management and Disposal

Disposal must follow POPs waste guidelines under the Stockholm Convention.

Waste Characterization

- Confirm waste contains organochlorine pesticides above threshold levels (e.g., 50 mg/kg under Stockholm Convention).

Acceptable Disposal Methods

- High-temperature incineration (>1200°C with scrubbing).

- Chemical destruction (e.g., base-catalyzed decomposition).

- Secure landfill only if destruction is not feasible and in compliance with national regulations.

Documentation

- Waste manifest system to track from generation to final disposal.

- Certificates of destruction from licensed facilities required.

Recordkeeping and Audits

Maintain comprehensive records to demonstrate compliance.

Required Records

- Shipping documents (dangerous goods declarations).

- Training logs and certification.

- Inventory and usage logs.

- Inspection reports and maintenance records.

- Waste disposal manifests and certificates.

Audits

Conduct internal and external audits annually to verify compliance with all applicable regulations.

Conclusion

Handling organochlorine pesticides requires strict adherence to international treaties and national laws due to their high toxicity and environmental persistence. Proper classification, packaging, transport, storage, training, and disposal are critical to ensuring safety and compliance. Organizations involved in any aspect of the lifecycle of these substances must maintain rigorous controls and documentation to protect human health and the environment.

Conclusion on the Sourcing of Organochlorine Pesticides

The sourcing of organochlorine pesticides (OCPs) presents significant environmental, health, and regulatory challenges. While these chemicals were once widely used for their effectiveness in pest control, their persistence in the environment, bioaccumulation in the food chain, and associated toxicological risks to humans and wildlife have led to strict global regulations and bans under agreements such as the Stockholm Convention on Persistent Organic Pollutants (POPs).

Today, the sourcing of OCPs is highly restricted, with only limited exceptions permitted for specific public health uses (e.g., malaria control using DDT under WHO guidelines). Illicit trade, stockpile mismanagement, and historical contamination remain ongoing concerns, particularly in developing regions. Safe sourcing, if permitted, requires adherence to international protocols, rigorous documentation, secure handling, and environmentally sound disposal practices.

In conclusion, due to their long-term ecological and health impacts, the sourcing of organochlorine pesticides should be avoided whenever possible. Sustainable alternatives, such as integrated pest management (IPM) and safer agrochemicals, should be prioritized to protect both human health and the environment. Continued monitoring, international cooperation, and capacity building are essential to prevent the re-emergence or misuse of these hazardous substances.