The global shipping container market is experiencing robust growth, driven by rising international trade volumes, e-commerce expansion, and infrastructure development. According to a report by Mordor Intelligence, the shipping container market was valued at USD 6.72 billion in 2023 and is projected to reach USD 8.83 billion by 2029, growing at a CAGR of 4.7% during the forecast period. Open-top containers, in particular, have gained traction in industries requiring the transport of oversized or heavy cargo such as machinery, construction materials, and bulk goods, where crane loading and ventilation are critical. Increasing demand for adaptable and reusable shipping solutions has spurred innovation among manufacturers, positioning open-top containers as a vital niche within the container ecosystem. As supply chains grow more complex and regionally diverse, the need for durable, customizable, and certified open-top container solutions has never been greater—making the leading manufacturers in this space key enablers of global logistics efficiency.

Top 10 Open Top Shipping Container Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1

Domain Est. 1998

Website: singamas.com

Key Highlights: Singamas is a leading manufacturer of containers, operator of terminals and container depots and provider of logistics services….

#2 Interport

Domain Est. 1994

Website: iport.com

Key Highlights: Interport offers a wide selection of new and used ISO containers, also known as a cargo containers, perfect for all your needs….

#3 Open Top

Domain Est. 1994

Website: oocl.com

Key Highlights: Open top containers are particularly suitable for bulky cargo such as machinery. They are fitted with a PVC tarpaulin cover and attachable bows with cable ……

#4 Open Top Container

Domain Est. 1995

Website: zim.com

Key Highlights: General Use: Suitable for tall or large cargo that cannot be loaded through the container doors, such as machinery, sheet glass and building materials….

#5 Open Top Containers

Domain Est. 1996

Website: seabox.com

Key Highlights: SEA BOX offers a selection of Open Top ISO Cargo Containers. These are designed to simplify the process of loading and unloading cargo by allowing access from ……

#6 Florens

Domain Est. 1996

Website: florens.com

Key Highlights: We are one of the world’s leading container lessors. Over the past three decades, we have been committed to providing flexible and innovative solutions….

#7 Triton Containers

Domain Est. 2000

Website: tritoncontainer.com

Key Highlights: Our expansive fleet encompasses a full range of new and used intermodal equipment, including Dry Containers, Refrigerated Containers, Open Tops, Flatracks, Roll ……

#8 Bullbox: Shipping Containers

Domain Est. 2001

Website: bullbox.com

Key Highlights: BULLBOX is a global container manufacturing and trading company. Our services: We supply containers in the main ports and organize transportation to your ……

#9 Customizable & Scalable Modified Shipping Container Solutions

Domain Est. 2009

Website: falconstructures.com

Key Highlights: Falcon Structures is the leader in repurposing shipping containers that are fully customized or ordered at scale for a variety of organizations nationwide….

#10

Domain Est. 2012

Expert Sourcing Insights for Open Top Shipping Container

2026 Market Trends for Open Top Shipping Containers

The global open top shipping container market is poised for notable evolution by 2026, driven by shifting logistics demands, infrastructure developments, and sustainability initiatives across key industries. These specialized containers—featuring a removable or tarpaulin-covered top—offer flexibility in transporting oversized or heavy cargo such as machinery, construction materials, and bulk goods. As global trade adapts to new economic realities, technological advancements, and environmental regulations, several key trends are expected to shape the open top container sector by 2026.

Rising Demand from Construction and Heavy Industry Sectors

One of the primary drivers of growth in the open top container market is the expanding construction, mining, and heavy manufacturing industries—particularly in emerging economies across Asia-Pacific, Africa, and Latin America. As infrastructure projects increase, so does the need to transport large or irregularly shaped materials like steel beams, pipes, and industrial equipment. Open top containers provide a cost-effective and secure solution compared to flat-rack or specialized trailers, especially in intermodal transport systems. By 2026, continued investment in urbanization and energy projects is projected to sustain strong demand.

E-Commerce and Omnichannel Logistics Expansion

While standard dry containers dominate e-commerce logistics, the rise of bulky goods—such as furniture, home improvement items, and outdoor equipment—has increased interest in alternative container types. Open top containers are increasingly being used in last-mile and regional distribution networks where large items are loaded and unloaded frequently. Innovations in tarp systems and crane-assisted handling are making these containers more efficient for hybrid logistics models, contributing to their adoption in omnichannel supply chains.

Sustainability and Circular Economy Initiatives

Environmental regulations and corporate sustainability goals are pushing shipping companies and freight operators to optimize container reuse and reduce waste. Open top containers, often repurposed from retired standard containers, align well with circular economy practices. By 2026, we expect to see increased investment in retrofitting and modular design to extend container lifecycles. Additionally, eco-friendly tarp materials and recyclable components are likely to become standard features, driven by ESG (Environmental, Social, and Governance) compliance demands.

Technological Integration and Smart Container Adoption

Digitalization of the shipping industry is extending to open top containers through the integration of IoT sensors, GPS tracking, and remote monitoring systems. These technologies enable real-time monitoring of cargo conditions—especially important for sensitive or high-value goods transported in open top units. By 2026, smart open top containers with automated tarp control, load sensors, and anti-theft systems are expected to gain market share, particularly among premium logistics providers and multinational shippers.

Regional Market Developments

Asia-Pacific will remain the largest market for open top containers, fueled by China, India, and Southeast Asian countries’ industrial growth and port expansion projects. In contrast, North America and Europe are expected to focus on modernizing intermodal networks and adopting greener transport solutions, which may boost demand for lightweight, durable open top designs. Meanwhile, Africa and the Middle East present high growth potential due to ongoing infrastructure programs and increasing cross-border trade facilitated by regional agreements.

Challenges and Market Restraints

Despite positive outlooks, the market faces challenges including fluctuating steel prices, supply chain disruptions, and competition from alternative transport methods such as flat-rack containers and open-deck trailers. Regulatory inconsistencies in oversized cargo transportation across regions may also hinder seamless deployment. However, standardization efforts and industry collaborations are expected to mitigate some of these barriers by 2026.

In conclusion, the open top shipping container market by 2026 will be shaped by industrial growth, technological innovation, and sustainability imperatives. As global logistics networks become more dynamic and diverse, open top containers will play a critical role in enabling efficient and flexible freight solutions—especially for industries dealing with non-standardized cargo.

Common Pitfalls Sourcing Open Top Shipping Containers (Quality, IP)

Sourcing open top shipping containers can be cost-effective for various applications, from storage to construction. However, buyers often encounter significant challenges related to quality and intellectual property (IP) risks. Awareness of these pitfalls is crucial to avoid costly mistakes.

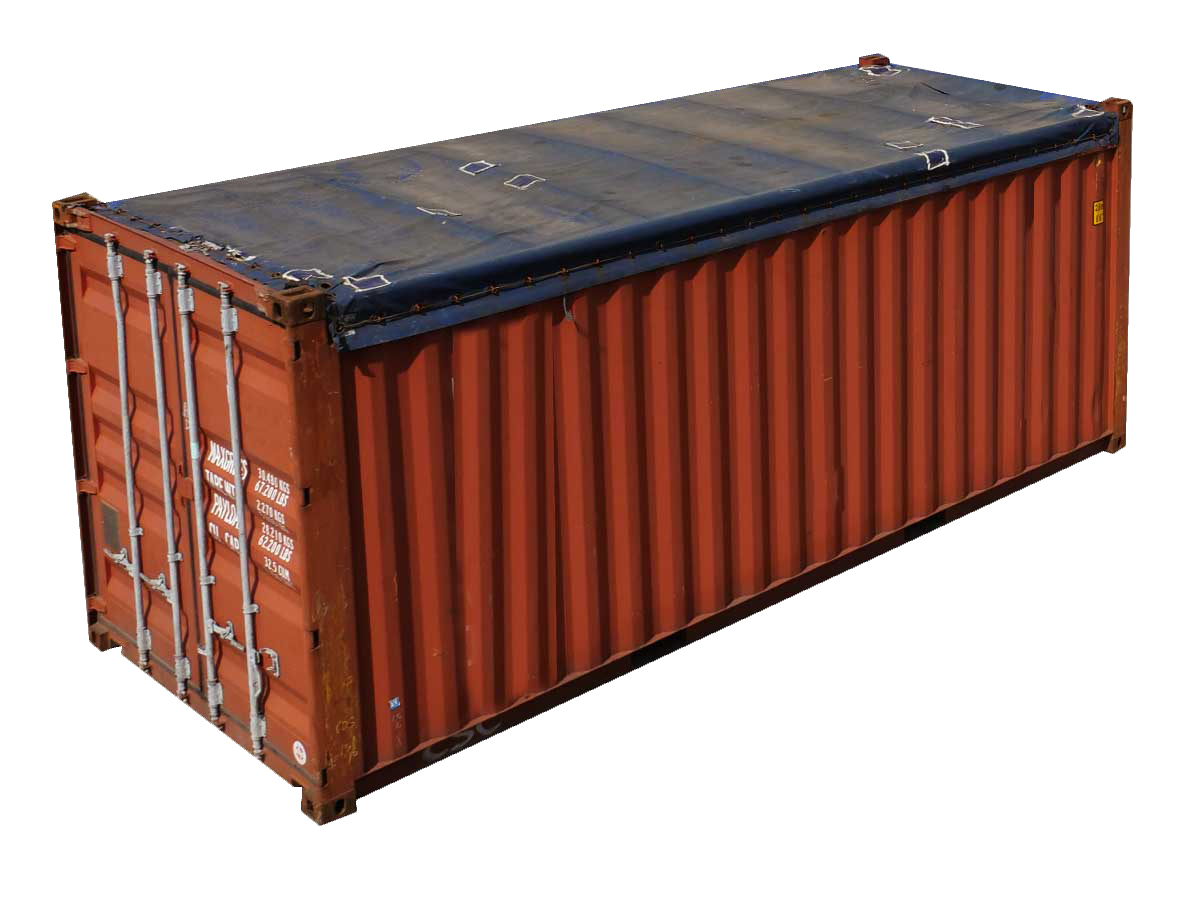

Poor Container Quality and Structural Integrity

One of the most frequent issues is receiving containers that appear serviceable but have hidden structural flaws. Open top containers are especially prone to damage due to their design—missing a rigid roof makes them more vulnerable to deformation during transit or stacking. Common quality concerns include corroded corner castings, bent or weakened side rails, compromised flooring (especially if wood floors are rotting or missing), and tears or holes in the tarpaulin or canvas cover. Buyers may assume they are getting a “one-trip” or like-new container, but end up with a unit that has been heavily used or poorly repaired.

Misrepresentation of Condition and Age

Suppliers may misrepresent the actual condition, age, or history of a container. Terms like “wind and watertight” (WWT) or “as-is” are often used ambiguously. Open top containers, in particular, may have been exposed to the elements for extended periods, accelerating wear. Without a physical inspection or reliable third-party certification, buyers risk investing in containers that require expensive repairs or fail to meet safety standards.

Inadequate or Counterfeit Documentation

Authentic shipping containers come with certification plates (such as CSC—Container Safety Convention) that verify they meet international safety standards. Sourcing from unreliable suppliers increases the risk of receiving containers with forged, missing, or expired certifications. This not only affects usability in regulated environments but may also lead to legal liabilities or rejection at ports and job sites.

Intellectual Property (IP) and Branding Risks

A less obvious but serious pitfall involves IP infringement. Open top containers previously used by major shipping lines (e.g., Maersk, MSC, COSCO) often retain original logos, branding, and proprietary paint schemes. Reselling or repurposing these containers without authorization may violate trademark laws. Even modifying the container may not eliminate IP exposure if branding elements remain visible. Buyers risk cease-and-desist orders, fines, or reputational damage if used in commercial projects.

Lack of Standardization and Custom Modifications

Open top containers vary in specifications, especially when sourced from secondary markets. Variations in dimensions, lifting points, and tarpaulin attachment systems can complicate integration into construction or logistics plans. Additionally, unauthorized modifications—such as cutting walls or reinforcing frames—can compromise structural integrity and void any remaining warranties or certifications.

Inadequate Due Diligence on Suppliers

Many buyers source containers through brokers or online marketplaces without verifying the supplier’s reputation. Unscrupulous sellers may provide containers that are stolen, embargoed, or subject to liens. Without proper due diligence, buyers may face legal disputes or lose their investment entirely.

Conclusion

To avoid these pitfalls, buyers should insist on detailed inspections, obtain certified documentation, verify the absence of IP-protected branding, and source from reputable, transparent suppliers. Investing time upfront in due diligence can prevent significant quality issues and legal complications down the line.

Logistics & Compliance Guide for Open Top Shipping Containers

Overview of Open Top Containers

Open top shipping containers are specialized intermodal freight containers designed with a removable or tarpaulin-covered top, enabling the loading of oversized, heavy, or bulky cargo from above using cranes or forklifts. Commonly used for machinery, construction materials, and project cargo, these containers typically come in 20-foot and 40-foot lengths and adhere to ISO standards for durability and stacking.

Key Features and Design

Open top containers feature a rigid steel frame with collapsible or removable corner posts and a flexible weatherproof tarpaulin or hard lid that covers the top opening. The absence of a fixed roof allows for easy overhead loading and the transport of items exceeding standard height restrictions inside regular containers. Reinforced walls and floors support heavy loads, while lashing rings provide secure internal tie-down points.

Appropriate Cargo Types

These containers are ideal for goods that are:

– Taller than standard container height (e.g., industrial machinery, boilers, transformers)

– Loaded via crane or hoist (e.g., timber, steel beams, pipes)

– Sensitive to top-loading requirements

They are not recommended for loose bulk materials or cargo requiring full weather protection unless properly covered and secured.

Loading and Securing Procedures

Proper loading is crucial for safety and compliance:

– Use cranes or lifting equipment to place cargo from the top.

– Distribute weight evenly across the container floor to avoid stress points.

– Secure cargo with straps, chains, or lashing to the container’s built-in lashing points.

– Ensure the tarpaulin or cover is tightly fastened to protect against rain and shifting during transit.

Weather Protection and Tarpaulin Use

While open top containers offer flexibility, they require reliable covers to prevent water ingress. High-quality, UV-resistant tarpaulins or rigid covers must be used and properly sealed. Regular inspection for tears or wear is essential, especially during long voyages or exposure to harsh weather.

Regulatory Compliance and Standards

Open top containers must comply with the following:

– IMO/IICL Standards: Regular inspection and maintenance per International Convention for Safe Containers (CSC).

– CSC Plate: Must be affixed and valid, certifying container safety for international transport.

– ISO 1496: Specifies technical requirements for freight containers.

– National Regulations: Comply with local transportation laws (e.g., FMCSA in the U.S., ADR in Europe) for road or rail movement.

Customs and Documentation

Ensure all standard shipping documentation is complete:

– Bill of Lading (B/L)

– Packing list with cargo description and dimensions

– Dangerous goods declaration (if applicable)

– Certificate of Origin (if required)

Clearly declare the use of an open top container, especially if cargo exceeds standard profiles, to avoid customs delays.

Hazardous Materials (Dangerous Goods)

Transporting hazardous materials in open top containers is highly restricted due to exposure risks. If permitted, the cargo must:

– Be fully covered and sealed to prevent leakage or environmental contact

– Comply with IMDG Code (for sea), ADR (for road), or other relevant regulations

– Be properly labeled, classified, and documented

Consult authorities before shipping hazardous cargo in open top units.

Stacking and Handling Considerations

Open top containers can be stacked when empty or with properly secured cargo, but stacking strength may be reduced if the top structure is compromised. Always follow terminal handling guidelines and avoid stacking loaded open tops under closed containers unless structurally supported.

Maintenance and Inspection

Routine checks should include:

– Integrity of corner castings and frame

– Condition of lashing points and flooring

– Tarpaulin or cover wear and tear

– Validity of CSC safety approval

Re-certify containers every 30 months or after major repairs.

Tips for Efficient Use

- Coordinate with ports and terminals to ensure crane availability.

- Pre-plan cargo dimensions and weight distribution.

- Use dunnage and edge protectors to prevent damage.

- Communicate container type clearly in shipping instructions to avoid misrouting.

Conclusion

Open top shipping containers offer a versatile solution for transporting oversized and heavy cargo when standard containers are unsuitable. Success depends on proper loading, secure covering, compliance with international standards, and accurate documentation. By following this guide, shippers can ensure safe, efficient, and compliant transportation operations.

Conclusion for Sourcing Open Top Shipping Containers

Sourcing open top shipping containers presents a practical and cost-effective solution for transporting oversized or heavy cargo that cannot be loaded through standard container doors. These specialized containers offer flexibility in loading and unloading via crane or forklift from the top, making them ideal for industries such as construction, manufacturing, and heavy machinery.

When sourcing open top containers, it is essential to consider factors such as container condition (new, used, or refurbished), compliance with international shipping standards (CSC certification), supplier reliability, and logistics support. Purchasing from reputable suppliers or leasing from established container providers ensures durability, safety, and regulatory compliance.

Additionally, evaluating long-term needs—whether for shipping, storage, or repurposing—can help determine whether buying or renting is more economical. With increasing availability and the growing trend of container reuse, open top containers remain a sustainable and versatile option in global logistics.

In conclusion, careful vendor selection, attention to specifications, and understanding of operational requirements are key to successfully sourcing open top shipping containers that meet both performance and budgetary goals.