The global kitchen appliance market, including specialized food preparation tools like onion ring slicers, is experiencing steady growth driven by rising demand from both commercial and residential sectors. According to Grand View Research, the global kitchen appliances market was valued at USD 194.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. A key contributor to this growth is the increasing focus on food efficiency and consistency in the foodservice industry, where time-saving tools like onion ring slicers play a critical role. Additionally, Mordor Intelligence projects that the commercial kitchen equipment market will grow at a CAGR of over 5.8% during the forecast period 2023–2028, fueled by expanding quick-service restaurants and convenience-oriented food preparation methods. As demand for efficient, high-volume food processing tools rises, manufacturers of onion ring slicers are innovating rapidly to meet performance, durability, and hygiene standards across diverse kitchen environments. Here are the top six onion ring slicer manufacturers leading this evolution with data-backed product quality and market reach.

Top 6 Onion Ring Slicer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Vollrath 503N Redco Onion King® 1/2″ Cut Slicer

Domain Est. 1996

Website: wasserstrom.com

Key Highlights: In stock $31.91 deliveryManufacturer: Vollrath. Consistently get perfect slices with this Redco Onion King 1/2 Inch Cut Slicer. You can slice a number of firm foods such as lemons …

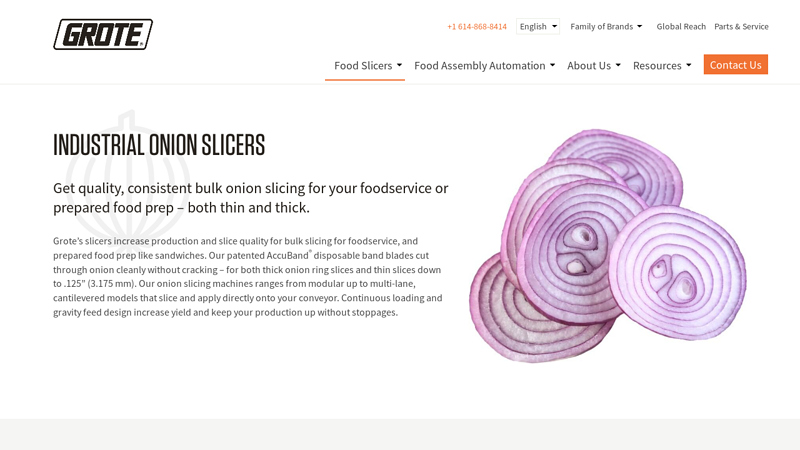

#2 Industrial Onion Slicers

Domain Est. 1997

Website: grotecompany.com

Key Highlights: Our onion slicing machines ranges from modular up to multi-lane, cantilevered models that slice and apply directly onto your conveyor. Continuous loading and ……

#3 CMI ONION SLICER, Y5658

Domain Est. 1997

Website: alard-equipment.com

Key Highlights: FEATURES: Manufacturer literature states this onion slicing machine is capable of cutting over 500 pounds per hour. y5658c_crop_email….

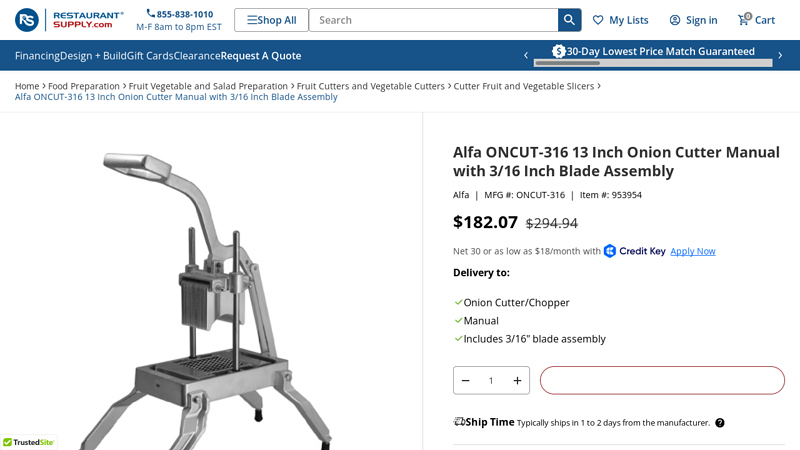

#4 Alfa ONCUT

Domain Est. 1998

Website: restaurantsupply.com

Key Highlights: In stock Free delivery over $2,500The Alfa ONCUT-316 Onion Cutter/Chopper is a commercial-grade manual foodservice equipment designed for precise vegetable and onion slicing applic…

#5 Onion King

Domain Est. 2017

Website: vollrathfoodservice.com

Key Highlights: The Vollrath® Onion King creates beautifully consistent onion slices with impressive efficiency. The strong blades easily cut through onions or other firm….

#6 Stainless Steel Onion Rings Slicer Machine Root Vegetable Cutting

Domain Est. 2020

Website: juiceprocessline.com

Key Highlights: Rating 5.0 (1) The onion rings slicer machine is professional for slicing root and stem fruits and vegetables according to the processing needs of snack foods….

Expert Sourcing Insights for Onion Ring Slicer

2026 Market Trends for Onion Ring Slicers

The global market for kitchen tools, including specialized devices like onion ring slicers, is poised for notable shifts by 2026, driven by evolving consumer behaviors, technological advancements, and broader culinary trends. Here’s an analysis of key trends shaping the onion ring slicer landscape in 2026:

Rising Demand for Convenience and Time-Saving Kitchen Tools

As urbanization increases and dual-income households become more common, consumers are prioritizing efficiency in meal preparation. Onion ring slicers—especially multi-functional models—offer a quick, consistent way to prepare ingredients without the mess or uneven cuts of manual slicing. By 2026, demand for user-friendly, dishwasher-safe, and compact onion ring slicers is expected to grow, particularly in fast-paced markets like North America, Western Europe, and parts of Asia-Pacific.

Growth of Home Cooking and Gourmet Food Trends

The post-pandemic surge in home cooking has evolved into a sustained interest in culinary experimentation. Consumers are increasingly preparing restaurant-style meals at home, including appetizers like onion rings. This trend supports the demand for specialized tools that enable consistent, professional results. Onion ring slicers with adjustable thickness settings or integrated safety features are likely to gain traction among home chefs seeking precision and safety.

Expansion of E-Commerce and Direct-to-Consumer Sales

By 2026, online retail will remain a dominant channel for kitchenware sales. Platforms like Amazon, Shopify, and social commerce apps are enabling niche products like onion ring slicers to reach global audiences. Brands that leverage influencer marketing, video demonstrations, and customer reviews will have a competitive edge. Subscription-based kitchen tool boxes and bundling slicers with related gadgets (e.g., fry baskets, seasoning kits) may also emerge as popular strategies.

Emphasis on Sustainable and Durable Materials

Environmental consciousness is influencing purchasing decisions. Consumers are favoring kitchen tools made from recyclable materials such as stainless steel or BPA-free plastics over disposable alternatives. By 2026, manufacturers offering eco-friendly packaging, modular designs for easy repair, or take-back programs are expected to stand out in a crowded market. This trend aligns with broader sustainability goals in the consumer goods sector.

Innovation in Multi-Functional and Smart Kitchen Gadgets

While basic onion ring slicers remain popular, there is growing interest in multifunctional devices—such as slicers that also julienne, dice, or spiralize vegetables. By 2026, integration with smart kitchen ecosystems may begin to appear, including slicers with embedded sensors or companion apps that suggest recipes based on ingredients. Although full “smart” slicers may still be niche, design innovation focusing on ergonomics, space-saving features, and easy storage will be critical.

Regional Market Diversification

While North America and Europe remain strong markets due to high disposable incomes and established home cooking cultures, emerging markets in Southeast Asia, India, and Latin America are showing increased interest in Western-style kitchen tools. Localization—such as smaller-sized models for compact kitchens or designs suited to local vegetable types—will be key to gaining market share in these regions by 2026.

Competitive Pressure and Brand Differentiation

As more brands enter the kitchen gadget space, differentiation through design, branding, and functionality will be essential. Brands that emphasize durability, aesthetic appeal (e.g., modern colors, minimalist design), and clear value propositions (e.g., time saved, reduced food waste) will be better positioned to capture consumer attention in 2026.

In conclusion, the onion ring slicer market in 2026 will be shaped by convenience, sustainability, digital engagement, and culinary enthusiasm. Success will depend on manufacturers’ ability to innovate while meeting the practical and ethical expectations of modern consumers.

Common Pitfalls When Sourcing an Onion Ring Slicer (Quality and Intellectual Property)

Sourcing an onion ring slicer—especially from international suppliers—can present several challenges related to both product quality and intellectual property (IP) protection. Being aware of these pitfalls helps mitigate risks and ensures a reliable, legally sound supply chain.

Poor Build Quality and Material Standards

One of the most frequent issues is receiving onion ring slicers made from substandard materials. Suppliers may use inferior-grade stainless steel or plastic components that corrode, warp, or break under regular kitchen use. Thin blades may dull quickly or fail to produce uniform rings, leading to inconsistent output and food waste. Always verify material specifications and request samples to assess durability and performance firsthand.

Inconsistent Cutting Performance

Low-quality slicers often suffer from misaligned blades or imprecise mechanisms, resulting in uneven or crushed onion rings. This inconsistency affects presentation and cooking performance, especially in commercial kitchens where uniformity is essential. Ensure the design includes precision engineering and consider third-party testing reports or on-site factory audits to evaluate machine consistency.

Lack of Safety Features

Many budget slicers omit critical safety mechanisms such as blade guards, non-slip bases, or finger guards. This increases the risk of workplace injuries and may lead to non-compliance with health and safety regulations in your target market. Confirm that the design adheres to relevant safety standards (e.g., CE, UL) before finalizing procurement.

Intellectual Property Infringement Risks

Sourcing from manufacturers in regions with lax IP enforcement increases the risk of inadvertently purchasing a counterfeit or copied design. Some suppliers replicate patented slicer mechanisms or branding without authorization, exposing your business to legal liability, product seizures, or reputational damage. Conduct thorough due diligence: verify patents, request IP ownership documentation, and avoid suppliers offering well-known branded products at suspiciously low prices.

Inadequate After-Sales Support and Spare Parts

Many overseas suppliers offer limited technical support or fail to provide replacement parts. When a blade breaks or a component fails, long lead times for spare parts can halt operations. Confirm the supplier’s service policies, availability of spare parts, and whether local support or warranties are offered in your region.

Misrepresentation of Compliance and Certifications

Some suppliers falsely claim certifications such as food-grade safety (FDA, LFGB) or electrical compliance (if motorized). Always request valid, up-to-date certification documents and consider using a third-party inspection service to verify claims before bulk ordering.

Hidden Costs from Poor Design

A poorly designed slicer may seem cost-effective initially but lead to higher long-term expenses due to frequent breakdowns, excessive maintenance, or low efficiency. Invest time in evaluating the total cost of ownership, including durability, ease of cleaning, and labor efficiency, not just the upfront price.

By proactively addressing these quality and IP-related pitfalls, businesses can source onion ring slicers that are safe, reliable, and legally compliant—protecting both operations and brand integrity.

Logistics & Compliance Guide for Onion Ring Slicer

This guide outlines the essential logistics and compliance considerations for the import, distribution, and use of an Onion Ring Slicer in regulated markets such as the United States, European Union, and other key regions. Adherence to these standards ensures product safety, legal distribution, and operational efficiency.

Product Classification & HS Code

Determine the correct Harmonized System (HS) code for customs clearance and duty assessment. The Onion Ring Slicer typically falls under kitchenware or food preparation equipment. A common HS code is 8205.59.95 (Other hand tools not elsewhere specified, of base metal), but this may vary by country and design (manual vs. electric). Confirm with local customs authorities or a trade compliance expert.

Regulatory Compliance

Food Contact Materials (FCM)

The slicer components that contact food (e.g., blades, cutting surface) must comply with food safety regulations:

– USA: Compliant with FDA 21 CFR standards for food contact substances (e.g., stainless steel grade 304 or 430).

– EU: Must meet Regulation (EU) No 10/2011 for plastic materials and Regulation (EC) No 1935/2004 for all food contact materials.

– Other Regions: Verify compliance with local FCM standards (e.g., LFGB in Germany, MFDS in South Korea).

Electrical Safety (if applicable)

Electric models must meet electrical safety standards:

– USA: UL 1817 (Household Electric Food Preparation Appliances) or ETL listing.

– EU: CE marking per Low Voltage Directive (2014/35/EU) and EMC Directive (2014/30/EU).

– Other Markets: Include certifications such as UKCA (UK), PSE (Japan), or SAA (Australia).

General Product Safety

Ensure the product meets general product safety directives:

– EU: General Product Safety Directive (2001/95/EC).

– USA: Consumer Product Safety Commission (CPSC) guidelines.

– Include safety warnings, user instructions, and risk mitigation (e.g., finger guards, blade protection).

Packaging & Labeling Requirements

Mandatory Labels

- Product name and model number

- Manufacturer/importer name and address

- Country of origin

- Electrical rating (if electric: voltage, wattage, frequency)

- Safety warnings and usage instructions

- Compliance marks (e.g., CE, UKCA, FCC, RoHS)

Language Requirements

User manuals and safety labels must be in the official language(s) of the destination country (e.g., English, French, German in EU; English in USA).

Import & Customs Documentation

Prepare the following for smooth customs clearance:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Test Reports (e.g., FDA, CE, RoHS)

– Import License (if required by destination country)

– Product Compliance Declaration (e.g., DoC for CE)

Transportation & Handling

Shipping Method

- Choose air freight for speed or sea freight for cost efficiency based on volume and timeline.

- Use insured, trackable shipping with reliable carriers (e.g., DHL, FedEx, Maersk).

Packaging Standards

- Use durable, moisture-resistant packaging.

- Include protective materials to prevent damage during transit.

- Clearly label packages with handling instructions: “Fragile,” “This Side Up.”

Environmental & Chemical Compliance

RoHS (EU & Similar Regulations)

Ensure electrical models comply with Restriction of Hazardous Substances Directive (RoHS 2 – 2011/65/EU), limiting lead, mercury, cadmium, and other substances.

REACH (EU)

Comply with Regulation (EC) No 1907/2006 for chemical substances, including SVHC (Substances of Very High Concern) declarations.

WEEE (if electric)

Electric models may fall under Waste Electrical and Electronic Equipment Directive (2012/19/EU). Include the “crossed-out wheeled bin” symbol and register with national WEEE programs.

After-Sales & Market Surveillance

- Maintain a technical file for at least 10 years (EU requirement).

- Monitor for product recalls or safety alerts.

- Provide customer support and handle warranty claims in accordance with local consumer laws.

Conclusion

Proper logistics planning and strict compliance with regulatory standards are critical for successfully launching and maintaining an Onion Ring Slicer in global markets. Always consult with legal, customs, and compliance experts to ensure ongoing adherence to evolving regulations.

In conclusion, sourcing an onion ring slicer is a practical and efficient investment for food service operations aiming to enhance productivity, ensure consistent product quality, and reduce labor costs. By evaluating key factors such as capacity, durability, ease of cleaning, safety features, and compatibility with kitchen workflows, businesses can select a slicer that meets their specific needs. Additionally, comparing suppliers, considering budget constraints, and reviewing customer feedback will help in making an informed procurement decision. Ultimately, the right onion ring slicer not only streamlines food preparation but also contributes to improved kitchen efficiency and customer satisfaction, making it a valuable addition to any commercial kitchen or food production facility.