The global OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) landscape is experiencing robust expansion, driven by increasing demand for cost-effective, scalable, and efficient manufacturing solutions across industries such as electronics, automotive, healthcare, and industrial equipment. According to a 2023 report by Mordor Intelligence, the global ODM market was valued at approximately USD 394.7 billion in 2022 and is projected to grow at a CAGR of over 8.3% from 2023 to 2028. This growth is fueled by rising outsourcing trends, faster product development cycles, and the need for specialized manufacturing capabilities in emerging technology sectors.

Similarly, Grand View Research highlights the intensifying competitive dynamics in manufacturing, noting that OEM partnerships are becoming pivotal for companies aiming to reduce time-to-market and R&D costs. With Asia-Pacific dominating production capacity—particularly China, Taiwan, and South Korea—leading OEMs and ODMs are investing heavily in automation, vertical integration, and design innovation to maintain margins and service global clients.

Against this backdrop, we identify the top 8 OEM and ODM manufacturers that are setting benchmarks in quality, scalability, and technological expertise—companies that are not just responding to market trends but actively shaping the future of global manufacturing.

Top 8 Oem And Odm Definition Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 OEM vs ODM – Understanding the Difference

Domain Est. 1995

Website: aver.com

Key Highlights: ODM is a business model that produces the design and the final product. Therefore, they operate as both the designers and manufacturers….

#2 What is an OEM, ODM, and JDM?

Domain Est. 1995

Website: amax.com

Key Highlights: What is an OEM, ODM, and JDM? · Original Equipment Manufacturer (OEM) · Original Design Manufacturer (ODM) · Joint Development Manufacturer (JDM)….

#3 OEM / ODM Service and Customization 101 (Part 1 of 3)

Domain Est. 2000

Website: phocos.com

Key Highlights: OEM – An original equipment manufacturer · Traditionally is defined as a company whose goods are used as components in the products of another ……

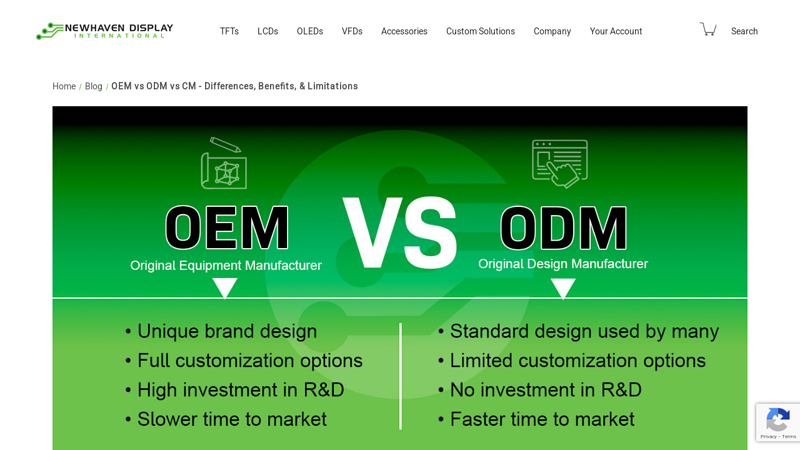

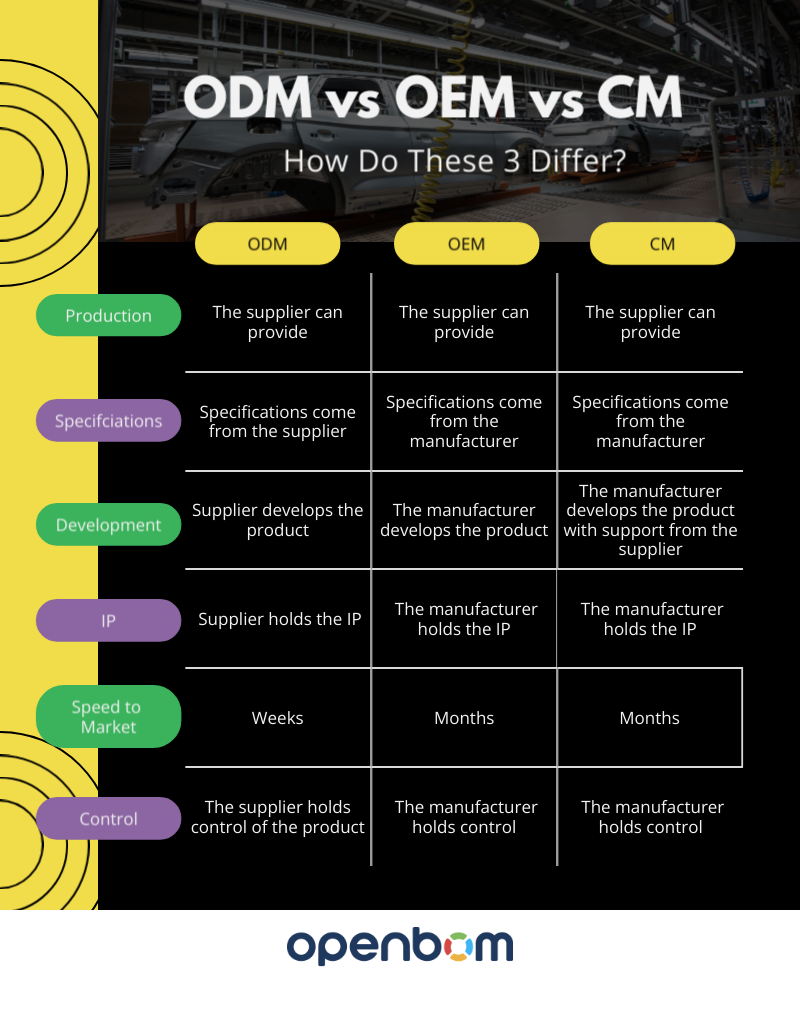

#4 OEM vs ODM vs CM

Domain Est. 2001

Website: newhavendisplay.com

Key Highlights: When outsourcing manufacturing, two terms come across: OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer)….

#5 Understanding the Differences Between OEM, ODM, EMS, and CEM

Domain Est. 2012

Website: smckyems.com

Key Highlights: OEM (Original Equipment Manufacturer) This term, also called “contract manufacturing” is used to describe a company which designs and produces electronic items….

#6 What is ODM? //ODM vs OEM And Original Design Manufacturing …

Domain Est. 2014

Website: cosmosourcing.com

Key Highlights: Definition: In the ODM model, the manufacturer designs and produces a product that is then branded and sold by another company. ODM ……

#7 Original Equipment Manufacturer (OEM)

Domain Est. 1999

Website: investopedia.com

Key Highlights: An original equipment manufacturer (OEM) is a company whose goods are used as components in the products of another company….

#8 OEM vs ODM

Domain Est. 2021

Website: oteplace.com

Key Highlights: OEMs take customers’ designs and build products • ODMs offer pre-designed products | A company can choose between tailored solutions or ready-made options….

Expert Sourcing Insights for Oem And Odm Definition

2026 Market Trends for OEM and ODM: Evolving Definitions and Industry Shifts

As global manufacturing and supply chains continue to evolve, the definitions and applications of Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) are undergoing significant transformation. By 2026, several key trends are reshaping how these models are understood and leveraged across industries such as electronics, automotive, healthcare, and consumer goods.

1. Blurring Lines Between OEM and ODM Roles

By 2026, the traditional distinction between OEM and ODM is becoming increasingly blurred. Many manufacturers are adopting hybrid models, where ODMs offer customizable designs that allow clients to brand and slightly modify products—functioning almost as co-developers. This flexibility supports faster time-to-market and reduced R&D costs, making ODMs more attractive even to large OEMs seeking agility.

2. Rise of Smart Manufacturing and Digital Integration

The integration of Industry 4.0 technologies—such as IoT, AI-driven design tools, and digital twins—is empowering ODMs to offer end-to-end digital product development. OEMs are increasingly partnering with tech-savvy ODMs that can deliver not only hardware but also embedded software and cloud integration, redefining the ODM role from a production partner to a full solution provider.

3. Regionalization and Supply Chain Resilience

Geopolitical tensions and supply chain disruptions have pushed companies to regionalize manufacturing. In 2026, OEMs are favoring ODMs located in nearshore or friend-shored regions (e.g., Mexico for North America, Eastern Europe for Western Europe). This shift emphasizes reliability and responsiveness over low-cost labor alone, altering how OEMs select ODM partners.

4. Sustainability and Compliance as Competitive Advantages

Environmental regulations and consumer demand for sustainable products are driving OEMs to work with ODMs that offer eco-design capabilities and circular economy practices. By 2026, ODMs that provide carbon footprint tracking, recyclable materials, and energy-efficient designs are gaining market share, effectively redefining the value proposition of the ODM model.

5. Increased IP Collaboration and Co-Innovation

The ODM model is moving beyond private labeling toward co-innovation. Leading OEMs are entering joint IP agreements with ODMs, especially in high-tech sectors like wearables and AI devices. This trend is redefining ODMs as strategic innovation partners rather than mere contract manufacturers.

6. Expansion into Emerging Markets

In regions like Southeast Asia, Africa, and Latin America, local ODMs are rising to meet demand for affordable, region-specific products. OEMs are increasingly outsourcing to these regional ODMs to customize offerings for local tastes and regulations—further expanding the global footprint and relevance of the ODM model.

Conclusion

By 2026, the definitions of OEM and ODM are no longer static. OEMs are becoming more design-integrated, while ODMs are evolving into innovation and technology partners. The future lies in flexible, collaborative, and sustainable manufacturing ecosystems where the value is derived not just from production, but from design intelligence, speed, and resilience.

Common Pitfalls in Sourcing OEM and ODM: Quality and Intellectual Property Risks

When sourcing products through Original Equipment Manufacturer (OEM) or Original Design Manufacturer (ODM) models, businesses often face significant challenges related to quality control and intellectual property (IP) protection. Understanding and mitigating these pitfalls is essential for long-term success and brand integrity.

Quality Control Challenges in OEM Sourcing

One of the most common issues in OEM arrangements is inconsistent product quality. Since OEMs manufacture products based on your specifications, the final output is only as good as the oversight you provide. Without rigorous quality assurance processes—such as pre-production samples, in-process inspections, and final random testing—defective or substandard goods may reach the market. Additionally, suppliers may substitute lower-cost materials to increase profit margins unless contracts explicitly prohibit such practices and include strict compliance checks.

Quality Risks in ODM Partnerships

ODM models present unique quality concerns because the manufacturer controls both design and production. While this can speed up time-to-market, it may result in generic or compromised designs that don’t fully align with your brand’s standards. Since multiple clients might purchase similar ODM products, differentiation becomes difficult, and quality may vary across batches if the supplier prioritizes volume over consistency. Without clear quality benchmarks and regular audits, businesses risk customer dissatisfaction and reputational damage.

Intellectual Property Theft in OEM Relationships

OEM arrangements involve sharing detailed technical specifications, designs, and branding elements—exposing your IP to potential misuse. A major pitfall occurs when the manufacturer replicates your product for competitors or sells it under another brand. Even with non-disclosure agreements (NDAs), enforcing IP rights across international borders can be complex and costly. Weak legal frameworks in some manufacturing regions further increase the risk of unauthorized production or counterfeiting.

IP Vulnerabilities in ODM Collaborations

In ODM sourcing, the manufacturer typically owns the design and tooling, which creates a dependency and limits your control over the product. If not clearly negotiated, you may not have exclusive rights to the design, allowing the ODM to sell the same or similar product to your competitors. Additionally, modifications made to an existing ODM design may not transfer full IP ownership to your company, leading to legal disputes or loss of competitive advantage.

Mitigation Strategies

To avoid these pitfalls, businesses should conduct thorough due diligence on suppliers, use legally binding contracts that specify quality standards and IP ownership, and consider third-party inspections. Registering trademarks, patents, and designs in relevant jurisdictions, along with working with legal experts familiar with international trade law, can further safeguard your interests. Regular communication and on-site audits also help maintain alignment and accountability throughout the sourcing process.

OEM and ODM: Logistics and Compliance Guide

Understanding the differences between Original Equipment Manufacturing (OEM) and Original Design Manufacturing (ODM) is crucial for businesses involved in product development, manufacturing, and global supply chains. Each model presents unique logistics and compliance challenges that must be carefully managed to ensure efficiency, legal adherence, and brand integrity. This guide outlines key considerations for logistics and compliance in both OEM and ODM arrangements.

What is OEM?

OEM, or Original Equipment Manufacturing, refers to a manufacturing model where a company (the OEM) produces parts or products based on the designs, specifications, and intellectual property (IP) provided by another company (the client). The client typically integrates these products into their own systems or sells them under their brand.

Logistics Considerations for OEM

- Design Control and Communication: Since the client controls the design, clear and continuous communication is essential. Logistics teams must ensure that design specifications are accurately relayed to the manufacturing facility to avoid production errors.

- Component Sourcing: OEMs often rely on the client to supply certain proprietary components or materials. Coordinating just-in-time (JIT) delivery of these materials is critical to avoid production delays.

- Quality Assurance Integration: OEM products must meet the client’s exact quality standards. Logistics must support rigorous inspection processes, including in-process and final quality checks, often requiring specialized handling or packaging.

- Traceability and Documentation: Full traceability—from raw materials to finished goods—is necessary for compliance and recalls. Detailed records of batch numbers, manufacturing dates, and shipping documentation must be maintained.

Compliance Considerations for OEM

- Intellectual Property Protection: The client retains IP rights. Legal agreements must clearly define ownership, confidentiality, and data protection. Compliance with international IP laws (e.g., TRIPS Agreement) is mandatory.

- Regulatory Certification: The client is typically responsible for product certifications (e.g., CE, FCC, FDA). However, the OEM must comply with manufacturing regulations (e.g., ISO 13485 for medical devices) and support certification by providing necessary documentation.

- Export Controls and Trade Compliance: OEMs must adhere to export control regulations (e.g., EAR, ITAR) when shipping components or finished goods internationally, especially if technology or materials are subject to restrictions.

- Product Liability and Responsibility: While the client brands and sells the product, both parties may share liability. Contracts should clearly define responsibilities in case of defects, recalls, or non-compliance.

What is ODM?

ODM, or Original Design Manufacturing, involves a manufacturer that both designs and produces a product which is then rebranded and sold by another company. The ODM retains ownership of the design and may sell similar products to multiple clients.

Logistics Considerations for ODM

- Standardized Production and Scalability: ODMs often use standardized platforms, enabling faster time-to-market. Logistics benefits from predictable production cycles and scalable inventory management.

- Inventory and Lead Time Management: Since ODMs may serve multiple clients, managing shared inventory and production schedules requires coordination to avoid delays or allocation conflicts.

- Customization and Branding: While the core design is shared, clients may request branding or minor modifications (e.g., logos, packaging). Logistics must support version control and customized packaging workflows.

- Global Distribution Networks: ODMs often operate in low-cost manufacturing regions (e.g., China, Vietnam). Efficient international shipping, customs clearance, and warehousing strategies are essential.

Compliance Considerations for ODM

- Design Ownership and Licensing: The ODM owns the design. Clients typically license the right to sell the product. Licensing agreements must define usage rights, geographical restrictions, and exclusivity.

- Regulatory Compliance Responsibility: The ODM may obtain initial product certifications, but the client (as the brand owner) is usually responsible for ensuring final compliance in target markets. Both parties must collaborate on technical documentation and testing.

- Labeling and Country-of-Origin Rules: Products must be correctly labeled with origin, safety warnings, and compliance marks. Rules of origin under trade agreements (e.g., USMCA, RCEP) affect tariff classifications and must be verified.

- Product Safety and Recalls: In case of safety issues, the brand owner (client) typically leads recall efforts. However, the ODM must cooperate by providing production data and may share liability if design flaws are involved.

Best Practices for Logistics and Compliance in OEM/ODM Partnerships

- Establish Clear Contracts: Define roles, responsibilities, IP ownership, compliance obligations, and dispute resolution mechanisms.

- Implement Robust Supplier Audits: Regularly audit OEMs/ODMs for quality, compliance, and ethical practices (e.g., ISO, SA8000).

- Use Integrated Supply Chain Systems: Leverage ERP and PLM software to enhance visibility, traceability, and coordination across design, production, and logistics.

- Stay Updated on Global Regulations: Monitor changes in trade policies, environmental laws (e.g., REACH, RoHS), and product safety standards in all target markets.

- Conduct Risk Assessments: Evaluate geopolitical, logistical, and compliance risks, especially when sourcing from high-risk regions.

By understanding the distinct logistics and compliance landscapes of OEM and ODM models, businesses can build resilient supply chains, reduce legal risks, and ensure successful product launches worldwide.

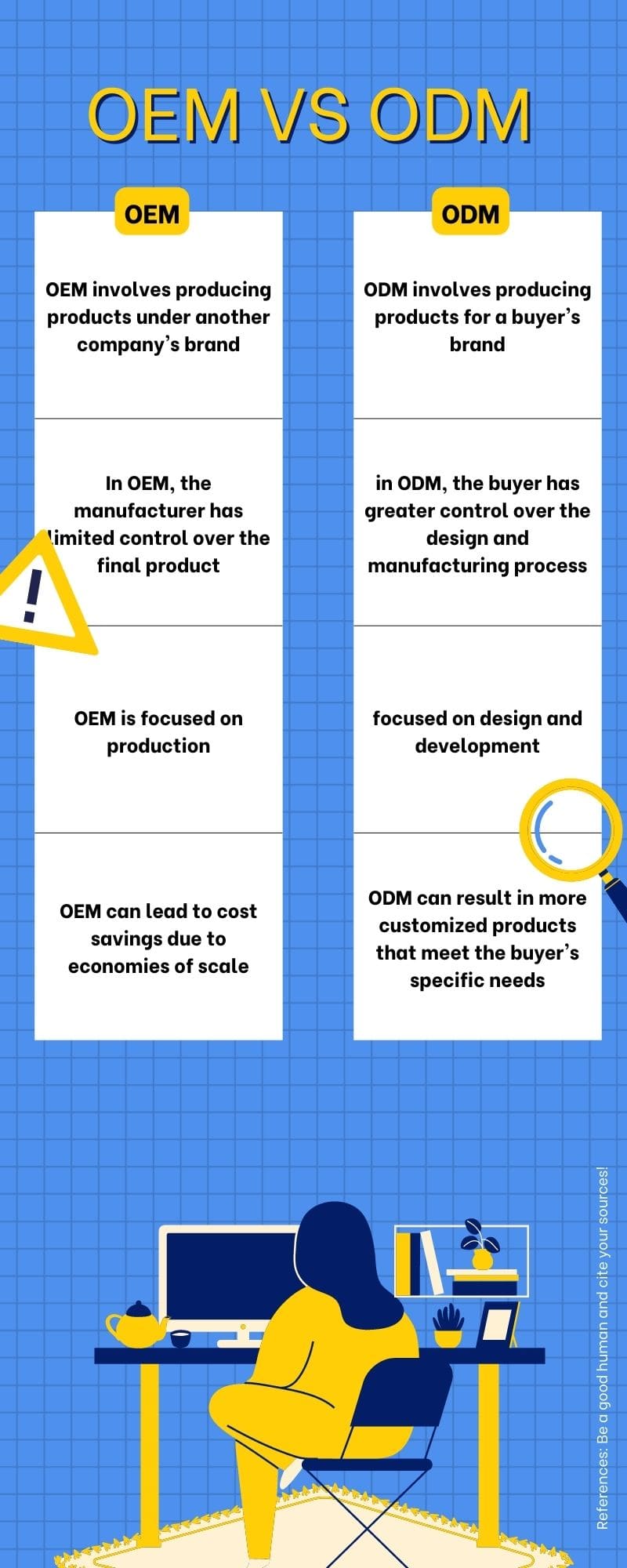

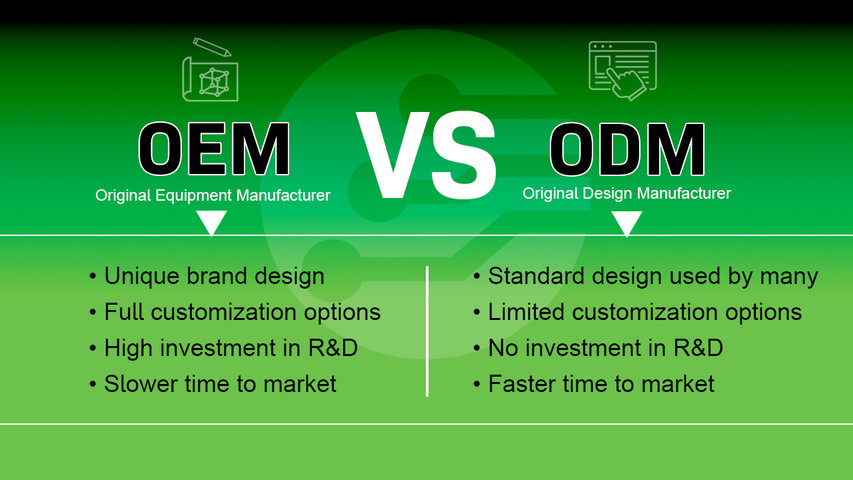

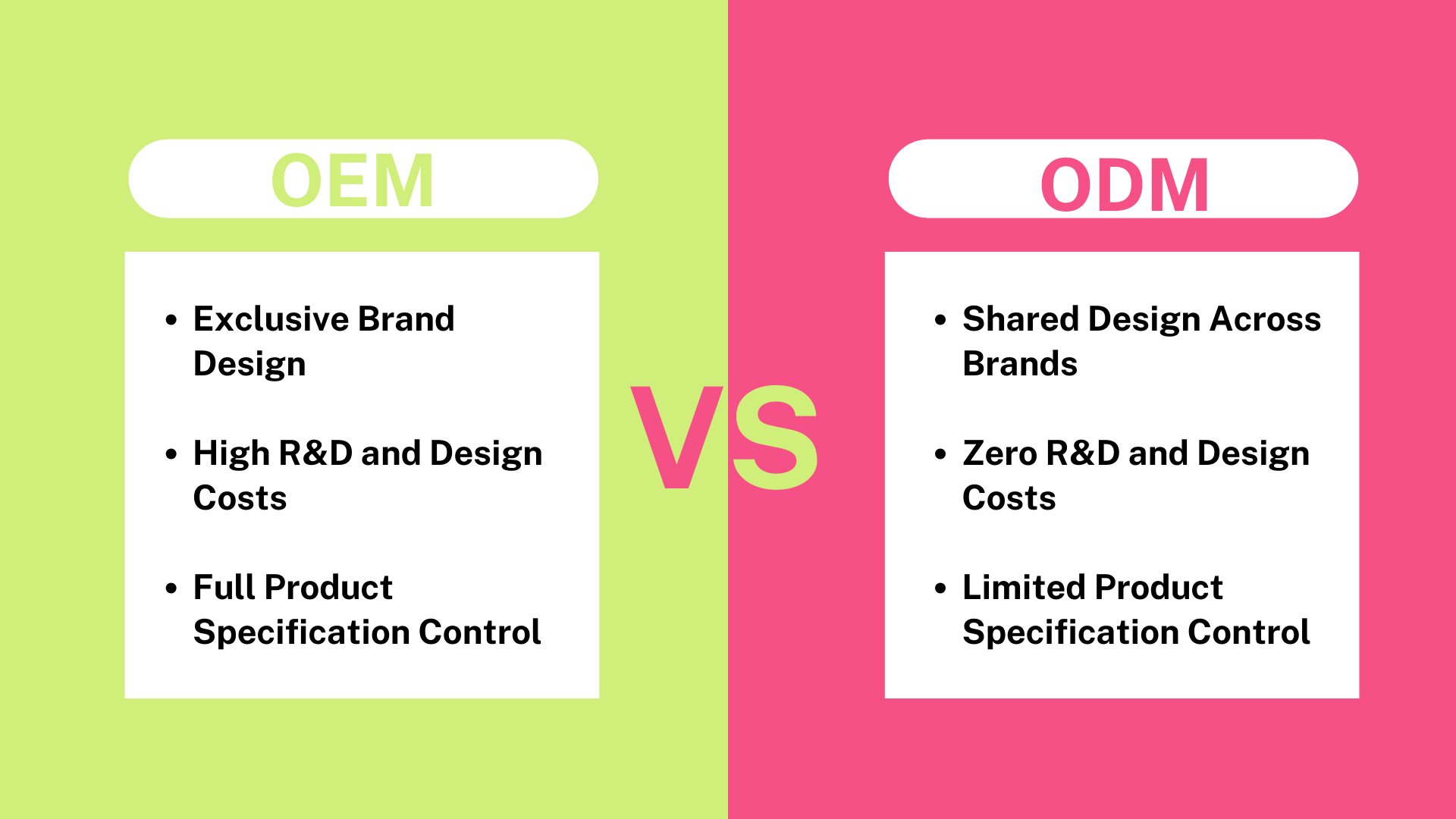

In conclusion, understanding the distinction between OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) is crucial for businesses seeking efficient and cost-effective sourcing strategies. OEM involves a manufacturer producing products based on the buyer’s design and specifications, allowing the buyer to maintain control over innovation and branding. In contrast, ODM provides ready-made products designed by the manufacturer, enabling faster time-to-market and lower development costs for the buyer. The choice between OEM and ODM depends on a company’s priorities—such as brand uniqueness, budget, product development capabilities, and speed to market. By carefully evaluating these factors, businesses can make informed sourcing decisions that align with their strategic goals, ensuring quality, scalability, and competitiveness in the global marketplace.