The global OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) market is experiencing robust expansion, driven by rising demand for cost-effective, scalable production solutions across electronics, automotive, and healthcare sectors. According to a 2023 report by Mordor Intelligence, the global OEM market was valued at USD 2.8 trillion and is projected to grow at a CAGR of 9.4% from 2023 to 2028. Similarly, Grand View Research estimates that the ODM market—known for offering design and manufacturing services under client branding—will expand at a CAGR of 8.2% during the same period, fueled by accelerating product development cycles and increasing outsourcing trends among tech companies. With Asia-Pacific dominating production capacity due to established supply chains and competitive labor costs, the landscape is highly competitive, making the identification of top-tier manufacturers critical for businesses seeking quality, innovation, and scalability.

Top 5 Odm And Oem Meaning Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 OEM vs ODM vs CM

Domain Est. 2001

Website: newhavendisplay.com

Key Highlights: When outsourcing manufacturing, two terms come across: OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer)….

#2 What’s the Difference Between ODM and OEM?

Domain Est. 2013

Website: onlogic.com

Key Highlights: ODM, or Original Design Manufacturing, refers to a producer/reseller relationship in which the full specifications of a project are determined by the reseller….

#3 Identifying True Manufacturers in Tech

Domain Est. 1997

Website: cybernetman.com

Key Highlights: Original equipment manufacturers (OEM) are companies that manufacture and sell products or parts of a product that other companies then sell under their own ……

#4 Original Equipment Manufacturer (OEM)

Domain Est. 1999

Website: investopedia.com

Key Highlights: An original equipment manufacturer (OEM) is a company whose goods are used as components in the products of another company….

#5 The Difference Between OEM vs ODM

Domain Est. 2007

Website: inflowinventory.com

Key Highlights: ODMs (Original Design Manufacturers) handle both design and production, offering white label products that multiple brands can rebrand, which ……

Expert Sourcing Insights for Odm And Oem Meaning

2026 Market Trends for ODM and OEM Meaning

As global supply chains evolve and demand for customized, cost-effective manufacturing solutions increases, the roles of Original Design Manufacturers (ODM) and Original Equipment Manufacturers (OEM) are becoming more strategic and nuanced. By 2026, market dynamics across industries such as electronics, automotive, healthcare, and consumer goods are expected to reshape how businesses interpret and leverage ODM and OEM models.

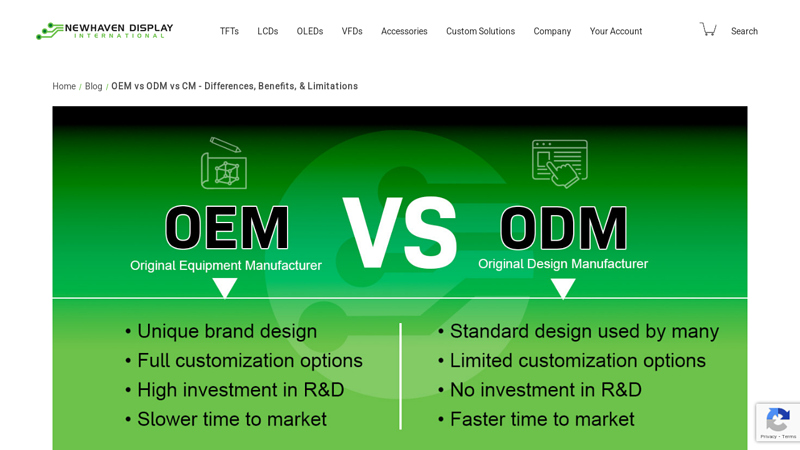

Understanding ODM and OEM: Core Definitions

Before analyzing 2026 trends, it’s essential to clarify the meanings of ODM and OEM:

-

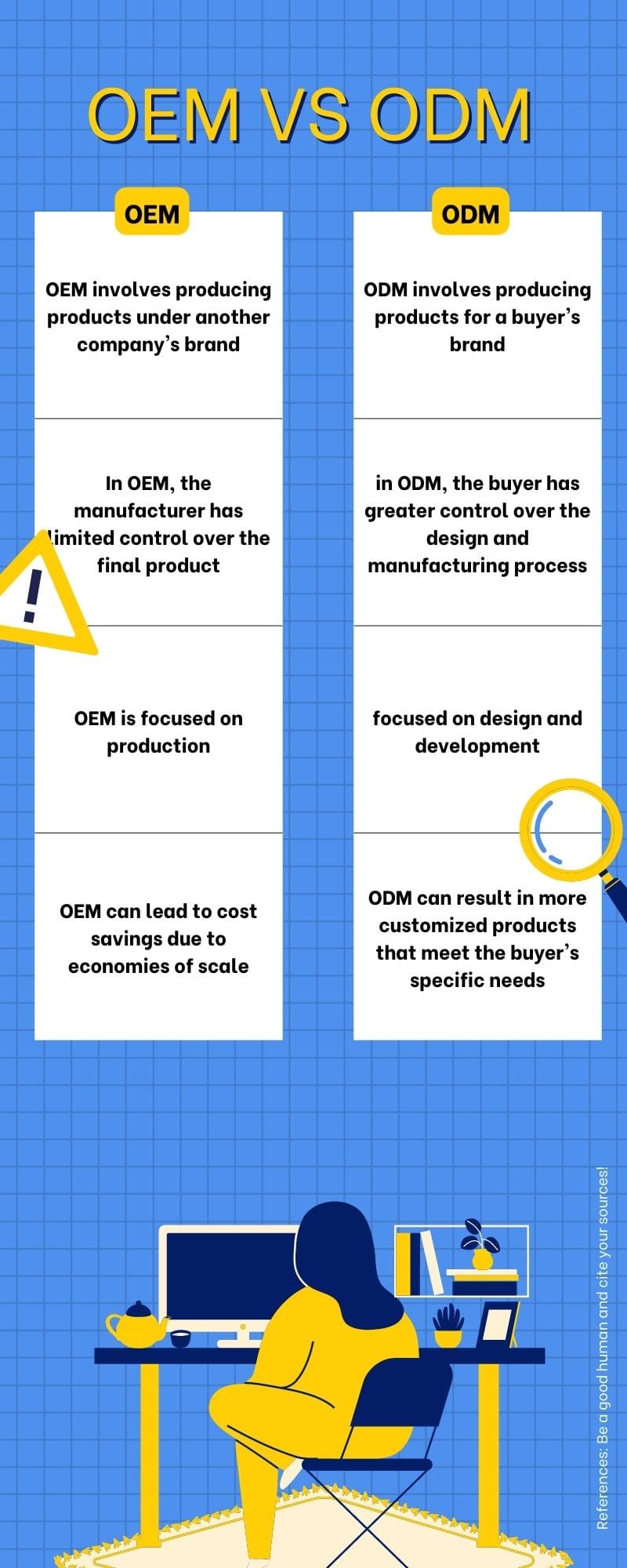

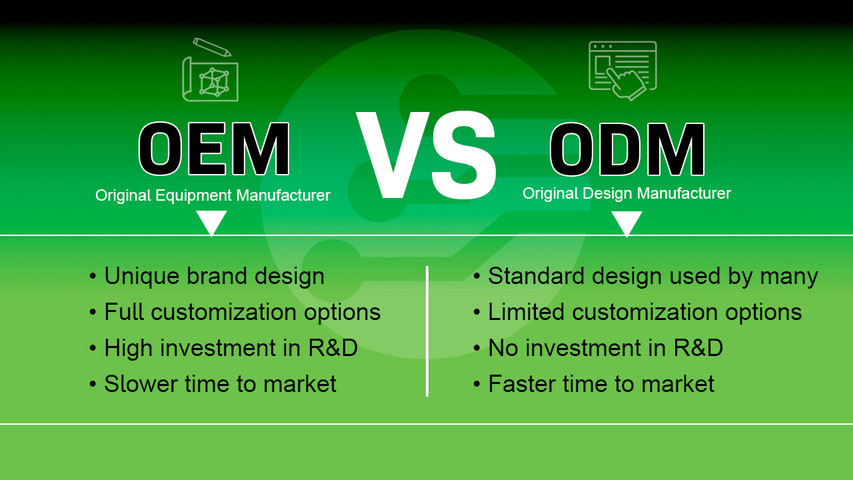

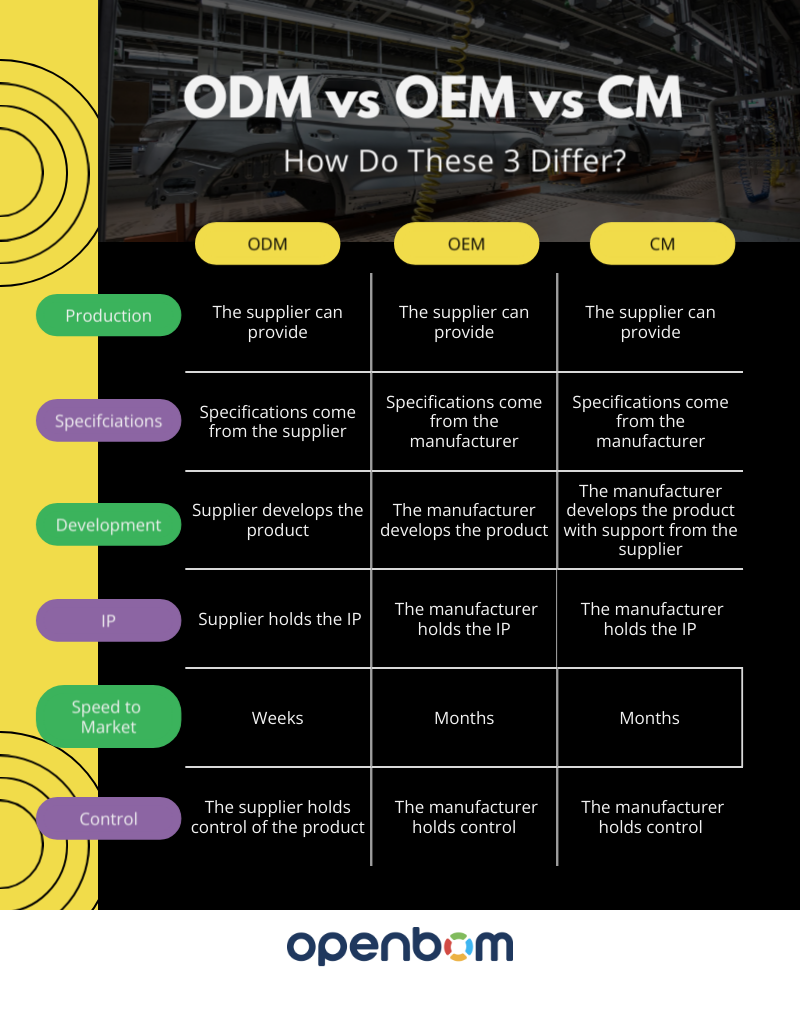

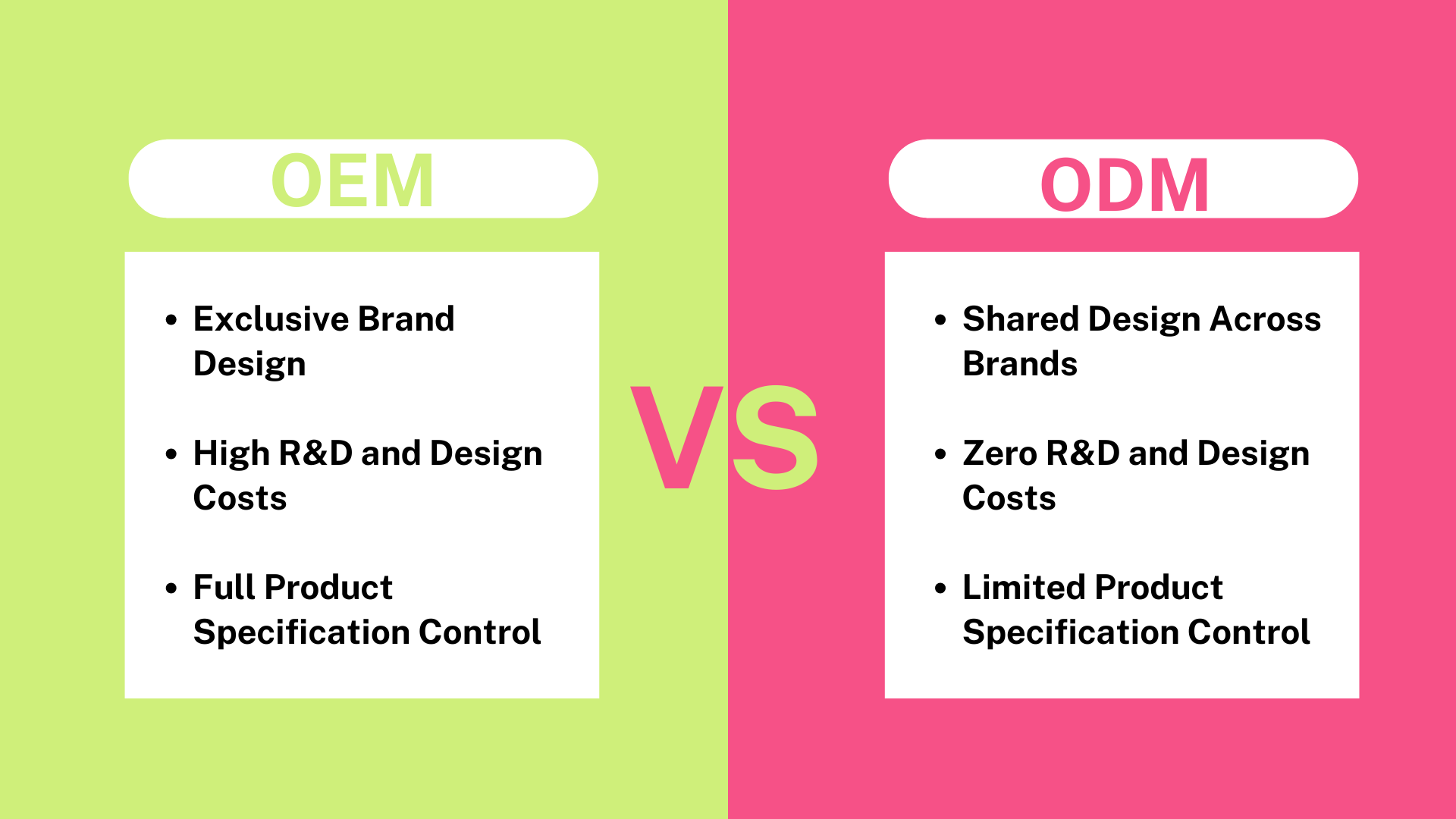

OEM (Original Equipment Manufacturer): A company that produces parts or equipment that are used in another company’s end product. The OEM typically manufactures based on the client’s exact design and specifications. The final product is branded and sold under the client’s name.

-

ODM (Original Design Manufacturer): A manufacturer that designs and produces a product that is later rebranded and sold by another company. In this model, the ODM owns the product design, and the client purchases a ready-made solution with minimal customization.

These models are foundational to global manufacturing, but their applications are rapidly shifting due to technological advancements and market demands.

Rising Demand for Hybrid ODM-OEM Models

By 2026, a key trend will be the emergence of hybrid ODM-OEM partnerships. Companies are increasingly seeking flexibility—leveraging ODMs for rapid product development while incorporating OEM-style customization for brand differentiation. This hybrid approach allows businesses to reduce time-to-market while maintaining control over key design elements and brand identity.

For example, in consumer electronics, a tech startup might use an ODM’s base smart device design but collaborate with an OEM partner to customize components like sensors or software interfaces. This trend reflects a broader shift toward modular manufacturing ecosystems.

Expansion of ODMs in High-Tech and Green Technology Sectors

The ODM model is gaining traction in high-growth industries such as electric vehicles (EVs), renewable energy systems, and AI-powered devices. By 2026, ODMs are expected to play a pivotal role in accelerating innovation cycles, particularly in Asia, where manufacturing hubs like China, Taiwan, and Vietnam offer integrated design and production capabilities.

Automotive OEMs are increasingly partnering with ODMs to co-develop EV platforms, reducing R&D costs and speeding up deployment. This trend is especially evident among new EV brands that lack in-house design capabilities but require fast go-to-market strategies.

OEMs Focus on Precision and High-Value Components

While ODMs scale in innovation-driven sectors, OEMs are shifting focus toward specialized, high-precision manufacturing. Industries such as aerospace, medical devices, and semiconductor equipment rely heavily on OEMs for components that require strict compliance, traceability, and quality control.

By 2026, OEMs are anticipated to invest heavily in automation, AI-driven quality assurance, and Industry 4.0 technologies to meet rising standards. These advancements will reinforce OEMs as critical partners in complex supply chains where customization and reliability are paramount.

Geographic Shifts and Supply Chain Resilience

Geopolitical factors and supply chain disruptions have prompted companies to diversify manufacturing bases. In 2026, we expect to see a geographic reconfiguration of both ODM and OEM operations.

- ODMs are expanding into Southeast Asia and India to reduce dependency on single markets and benefit from favorable trade agreements.

- OEMs are adopting “nearshoring” and “friend-shoring” strategies, particularly in North America and Europe, to ensure supply chain resilience and reduce lead times.

This shift is redefining the global footprint of manufacturing and influencing how companies choose between ODM and OEM partnerships based on proximity, risk, and scalability.

Digital Integration and Smart Manufacturing

By 2026, digital transformation will be deeply embedded in both ODM and OEM operations. Cloud-based collaboration platforms, digital twins, and IoT-enabled production lines will allow clients to monitor design, prototyping, and manufacturing processes in real time.

This transparency strengthens trust and enables faster iterations. For ODMs, digital tools facilitate mass customization; for OEMs, they enhance precision and compliance tracking. Businesses will increasingly evaluate ODMs and OEMs not just on cost and capacity, but on their digital maturity and integration capabilities.

Conclusion: Strategic Alignment Over Cost-Centric Decisions

The evolving meaning of ODM and OEM in 2026 reflects a move from transactional manufacturing relationships to strategic partnerships. Companies will prioritize agility, innovation speed, and supply chain resilience over cost savings alone.

Understanding the distinctions—and synergies—between ODM and OEM models will be crucial for businesses aiming to compete in fast-moving markets. As the lines between design and production blur, the future of manufacturing lies in intelligent collaboration across the ODM-OEM spectrum.

Common Pitfalls Sourcing ODM and OEM: Navigating Quality and Intellectual Property Risks

When sourcing products through Original Design Manufacturing (ODM) or Original Equipment Manufacturing (OEM) models, businesses can achieve faster time-to-market and lower development costs. However, these benefits come with significant risks—particularly in the areas of product quality and intellectual property (IP) protection. Understanding and mitigating these common pitfalls is crucial for long-term success.

Quality Control Challenges

One of the most frequent issues in ODM and OEM sourcing is maintaining consistent product quality. Since manufacturing is outsourced, direct oversight is limited, increasing the risk of substandard outputs.

- Inconsistent Production Standards: ODM/OEM partners may use different materials or processes across production runs, especially when scaling up, leading to variations in product performance or appearance.

- Lack of In-House Testing: Some manufacturers cut corners on quality assurance to reduce costs. Without rigorous third-party or on-site inspections, defects may go unnoticed until products reach customers.

- Hidden Subcontracting: The manufacturer might outsource part of the production to unauthorized subcontractors with lower quality standards, compromising the final product.

Mitigation Tip: Establish clear quality specifications in contracts, conduct regular audits, and require third-party inspections (e.g., via SGS or Intertek) before shipment.

Intellectual Property (IP) Exposure and Theft

IP protection is a major concern when working with ODMs and OEMs, especially in regions with weaker legal enforcement.

- Design and Technology Replication: In ODM arrangements, the manufacturer owns the design. They may sell the same or similar product to your competitors, eroding your market advantage.

- Lack of IP Clarity in Contracts: Poorly drafted agreements may fail to specify who owns new designs, molds, or modifications. This ambiguity can lead to disputes or loss of exclusive rights.

- Reverse Engineering Risk: Once a manufacturer has access to your specifications or prototypes (in OEM models), they could reverse engineer and replicate your product independently.

Mitigation Tip: Use robust legal agreements that clearly assign IP ownership to your company, require non-disclosure (NDA), and prohibit unauthorized use or resale of designs. Consider filing patents or design registrations in relevant markets.

Supply Chain and Communication Gaps

Misalignment in expectations due to language barriers, cultural differences, or poor communication can lead to delays, errors, and quality issues.

- Misunderstood Specifications: Small miscommunications about materials, dimensions, or features can result in incorrect products and costly rework.

- Limited Transparency: Some suppliers may withhold information about component sources or production timelines, making it difficult to manage risks or respond to disruptions.

Mitigation Tip: Assign a dedicated project manager, use detailed technical documentation, and maintain regular communication. Consider on-the-ground representation for larger projects.

Conclusion

While ODM and OEM models offer strategic advantages, businesses must proactively manage quality and IP risks. Thorough due diligence, clear contractual terms, and ongoing oversight are essential to protect your brand, products, and competitive edge in global markets.

Understanding OEM and ODM in Logistics and Compliance

When navigating global supply chains, understanding the distinctions between Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) is critical for effective logistics management and regulatory compliance. These models influence everything from product development and branding to shipping, customs clearance, and adherence to international standards.

What Is OEM? (Original Equipment Manufacturer)

An OEM refers to a company that produces components or products based on another company’s design and specifications. The purchasing company (often a brand owner) provides detailed blueprints, technical requirements, and quality standards. The OEM manufactures the product, which is then sold under the brand owner’s name.

Logistics Implications of OEM:

– Customization and Control: Since designs are brand-specific, OEM arrangements allow for high product customization and tighter control over quality.

– Longer Lead Times: The need for precise engineering, prototyping, and testing can extend production timelines.

– Intellectual Property (IP): The brand retains ownership of the design, which must be protected through legal agreements and secure documentation during transit and storage.

Compliance Considerations:

– Regulatory Alignment: The brand owner is responsible for ensuring the product meets destination market regulations (e.g., FCC, CE, RoHS).

– Labeling and Documentation: Accurate labeling (including country of origin, safety certifications, and user manuals) must reflect the brand, not the manufacturer.

– Supply Chain Transparency: OEM relationships require detailed traceability for audits, recalls, and customs scrutiny.

What Is ODM? (Original Design Manufacturer)

An ODM designs and manufactures a product that is later rebranded and sold by another company. The ODM owns the product design and often sells the same or similar products to multiple brands. The purchasing company selects from existing designs, customizes branding (e.g., logo, packaging), and brings the product to market.

Logistics Implications of ODM:

– Faster Time to Market: Pre-existing designs reduce development time, enabling quicker production and delivery.

– Inventory Management: ODMs may offer shared production lines, requiring coordination to avoid stock mix-ups.

– Scalability: Brands can scale orders quickly, but may face competition with other clients using the same ODM product.

Compliance Considerations:

– Design Ownership and Liability: The brand assumes responsibility for the product once rebranded, even if the design originates from the ODM. Due diligence on ODM certifications is essential.

– Regulatory Certification Transfer: Ensure the ODM has existing compliance certifications (e.g., ISO, UL) that are transferable or acceptable in target markets.

– Country of Origin Rules: Customs authorities may scrutinize rebranded ODM products; accurate declaration of origin and component sourcing is crucial.

Key Differences: OEM vs. ODM

| Factor | OEM | ODM |

|——-|—–|—–|

| Design Ownership | Brand owner | ODM |

| Customization Level | High | Limited (based on available designs) |

| Time to Market | Longer | Shorter |

| IP Rights | Held by brand | Held by manufacturer |

| Compliance Responsibility | Shared, with brand having final accountability | Brand assumes compliance after rebranding |

Logistics Best Practices for OEM and ODM Models

- Supplier Vetting: Conduct audits of OEMs/ODMs for manufacturing standards, environmental practices, and labor compliance (e.g., BSCI, SMETA).

- Contract Clarity: Define responsibilities for compliance, IP, defective goods, and recall procedures in manufacturing agreements.

- Incoterms Selection: Choose appropriate Incoterms (e.g., FOB, EXW, DDP) to clarify shipping, insurance, and customs responsibilities.

- Customs Classification: Ensure correct HS codes are used for both OEM and ODM products to avoid delays or fines.

- Documentation Control: Maintain accurate records of design specs, test reports, and compliance certificates throughout the supply chain.

Compliance Strategies for Global Markets

- Product Testing: Require third-party testing for safety, EMC, and environmental standards relevant to the destination market.

- Regulatory Updates: Monitor changes in regulations (e.g., EU’s CE Marking updates, U.S. CPSC rules) and adapt ODM/OEM agreements accordingly.

- Labeling Requirements: Work with legal teams to ensure labels meet local language, safety warnings, and recycling laws (e.g., WEEE in Europe).

- Import Compliance: Train logistics teams on proper declaration of value, origin, and product classification to prevent customs holds.

Conclusion

Choosing between OEM and ODM models impacts logistics efficiency and regulatory compliance. OEM provides greater control and differentiation but demands more oversight. ODM accelerates time to market but requires careful vetting and branding compliance. Regardless of the model, robust contracts, clear communication, and proactive compliance planning are essential for successful global distribution.

Conclusion on Sourcing ODM and OEM: Understanding the Meaning and Strategic Implications

In conclusion, understanding the meanings and distinctions between ODM (Original Design Manufacturer) and OEM (Original Equipment Manufacturer) is essential for businesses engaged in product development and sourcing. OEM refers to a manufacturer that produces components or products based on the buyer’s design and specifications, allowing the buyer to brand and sell the product as their own. This model offers greater control over design and quality but requires more involvement in R&D and tooling.

On the other hand, ODM involves sourcing ready-made or semi-customized products designed by the manufacturer. The buyer can rebrand these products with minimal design input, significantly reducing time-to-market, development costs, and complexity. This model is ideal for businesses seeking faster launches or with limited technical resources.

Choosing between ODM and OEM depends on a company’s goals, resources, brand strategy, and desired level of control. While OEM provides customization and differentiation, ODM offers speed and cost-efficiency. A well-informed sourcing strategy that leverages the strengths of either or both models can enhance competitiveness, scalability, and market responsiveness in today’s global supply chain landscape.