The global demand for precision machining solutions has surged in recent years, propelled by advancements in automotive, aerospace, and general manufacturing sectors. According to a 2023 report by Mordor Intelligence, the global grinding machines market was valued at approximately USD 5.8 billion in 2022 and is projected to grow at a CAGR of over 6.2% from 2023 to 2028. This growth is driven by increasing need for high-accuracy components, rising automation in production environments, and the adoption of advanced CNC technologies. Od (outside diameter) grinding machines, in particular, play a critical role in achieving micron-level tolerances in shafts, bearings, and other cylindrical parts. As industries prioritize efficiency and precision, leading manufacturers have responded with innovations in machine rigidity, automation integration, and process stability. Based on market presence, technological capability, global reach, and customer reviews, the following list highlights the top 10 OD grinding machine manufacturers shaping the future of precision manufacturing.

Top 10 Od Grinding Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 OD grinding

Domain Est. 1997

Website: kellenberger.com

Key Highlights: Kellenberger cylindrical grinding machines are synonymous worldwide with precision, flexibility, and the highest quality in industrial production….

#2 Cylindrical Grinding Machines

Domain Est. 1997

Website: nidec.com

Key Highlights: Machine Tools. Cylindrical Grinding Machines. Cylindrical Grinding Machine. Search by keyword. Search. Contact us. Nidec Machine Tool Corporation …Missing: od manufacturer…

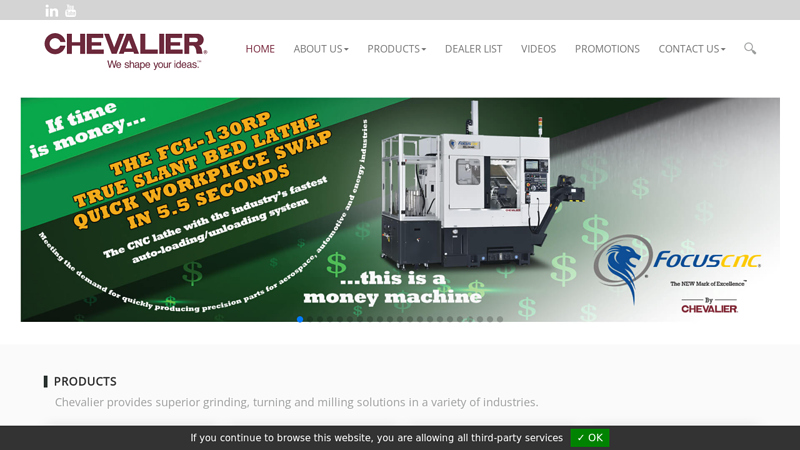

#3 Chevalier provides superior grinding, turning and milling solutions …

Domain Est. 1998

Website: chevalierusa.com

Key Highlights: Established more than 30 years ago, Chevalier Machinery USA is a leading manufacturer of grinding, turning and milling machining centers….

#4 High production Grinding Machines by…

Domain Est. 2022

Website: jtektmachinery.com

Key Highlights: JTEKT offers centerless, ID/OD, surface, shaft, vertical, and universal grinding machines for industrial applications….

#5 Okuma CNC Grinders

Domain Est. 1996

Website: okuma.com

Key Highlights: Okuma has a full line of both ID and OD grinders, with both plain and angled heads, suitable for everything from high production to small job shops….

#6 Grindal Company

Domain Est. 1998

Website: grindal.com

Key Highlights: Our Precision OD Grinding Department can grind parts from 0.032”to 18” on diameter by up to 60 inches long. CNC and manual….

#7 UNITED GRINDING North America

Domain Est. 1999

Website: grinding.com

Key Highlights: UNITED GRINDING is your solutions partner, with products and services designed to assist you throughout the life cycle of your CNC grinding machine….

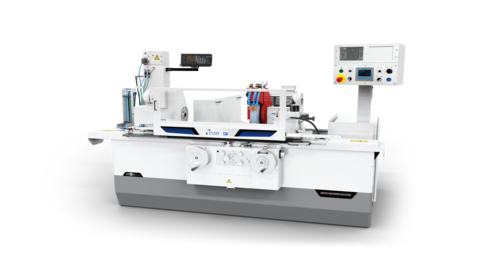

#8 Supertec Machinery

Domain Est. 2000

Website: supertecusa.com

Key Highlights: As one of Taiwan’s premier machine tool builders, Supertec specializes in Cylindrical, Centerless, Surface, ID/OD, Vertical grinding machines….

#9 JAGULAR

Domain Est. 2006

Website: en.jaguraweb.com

Key Highlights: We manufacture and provide a wide range of high quality grinding machines for various grinding applications….

#10 ID/OD grinding machines for small components

Domain Est. 2007

Website: fivesgroup.com

Key Highlights: ID/OD precision grinding machines for small components. Advanced capabilities in a compact footprint. Exceptional stiffness and high thermal stability….

Expert Sourcing Insights for Od Grinding Machine

2026 Market Trends for OD Grinding Machines

The global market for Outside Diameter (OD) grinding machines is poised for significant transformation by 2026, driven by technological advancements, evolving manufacturing demands, and industry-specific requirements. As industries such as automotive, aerospace, medical devices, and precision engineering continue to prioritize accuracy and efficiency, OD grinding machines are becoming increasingly critical in high-precision component production. This analysis explores the key market trends expected to shape the OD grinding machine sector in 2026.

Rising Demand for Precision and Automation

One of the most prominent trends in the 2026 OD grinding machine market is the escalating demand for ultra-precision and automation. Manufacturers are increasingly adopting CNC (Computer Numerical Control) OD grinding machines to achieve micron-level tolerances and consistent surface finishes. The integration of automation, including robotic loading/unloading systems and in-process measurement technologies, enhances productivity and reduces human error. As labor costs rise and skilled labor becomes scarce, automated grinding solutions are becoming essential, particularly in high-volume production environments.

Growth in Electric Vehicle and Aerospace Sectors

The rapid expansion of the electric vehicle (EV) and aerospace industries is a major driver for OD grinding machine adoption. EVs require high-precision components such as motor shafts, transmission gears, and bearing races, all of which benefit from OD grinding processes. Similarly, aerospace components—like turbine shafts and landing gear parts—demand exceptional dimensional accuracy and surface integrity, making OD grinding indispensable. By 2026, increased investments in EV manufacturing and next-generation aircraft development are expected to significantly boost demand for advanced grinding equipment.

Advancements in Machine Intelligence and IoT Integration

By 2026, smart manufacturing trends will have deeply influenced the OD grinding machine market. The integration of IoT (Internet of Things), AI-driven predictive maintenance, and real-time process monitoring will enable manufacturers to optimize machine performance, reduce downtime, and improve part quality. “Smart” grinding machines equipped with data analytics capabilities can adapt grinding parameters dynamically, ensuring consistent output under varying conditions. This digital transformation will position intelligent OD grinders as key assets in Industry 4.0 production ecosystems.

Regional Market Dynamics

Asia-Pacific, particularly China, Japan, and India, is expected to lead global demand for OD grinding machines in 2026. Rapid industrialization, government initiatives to boost domestic manufacturing (e.g., “Make in India” and “Made in China 2025”), and expanding automotive and electronics sectors are fueling investments in precision machinery. Meanwhile, North America and Europe will maintain strong markets due to their focus on high-end aerospace, medical, and defense applications. However, these regions will also emphasize sustainability and energy-efficient machine designs.

Sustainability and Energy Efficiency

Environmental regulations and sustainability goals are pushing machine tool manufacturers to develop energy-efficient OD grinding machines. By 2026, eco-friendly models featuring regenerative drives, optimized coolant systems, and reduced power consumption will gain market traction. Additionally, closed-loop coolant filtration and minimal quantity lubrication (MQL) systems are being adopted to minimize waste and environmental impact, aligning with green manufacturing standards.

Competitive Landscape and Innovation

The competitive landscape will be shaped by continuous innovation from key players such as Makino, Okamoto, Kellenberger, and Studer. These companies are focusing on developing compact, multi-functional grinding platforms that combine OD, ID, and surface grinding capabilities. Additionally, modular designs and user-friendly interfaces will enhance machine flexibility and ease of operation, appealing to both large manufacturers and small-to-medium enterprises (SMEs).

In conclusion, the 2026 OD grinding machine market will be defined by a convergence of precision engineering, digitalization, and sustainability. As industries demand higher performance and tighter tolerances, OD grinding technology will evolve to meet these challenges, ensuring its critical role in advanced manufacturing for years to come.

Common Pitfalls When Sourcing OD Grinding Machines (Quality and IP Concerns)

Sourcing an Outside Diameter (OD) grinding machine involves significant investment and long-term operational impact. Buyers often face challenges related to machine quality, performance, and intellectual property (IP) risks—especially when sourcing from international or less-regulated suppliers. Below are key pitfalls to be aware of.

Poor Build Quality and Inconsistent Performance

One of the most common issues when sourcing OD grinding machines is receiving equipment with substandard components or inconsistent manufacturing standards. Low-cost suppliers may use inferior materials, outdated technology, or lack rigorous quality control, leading to:

- Reduced precision and surface finish quality

- Frequent mechanical failures or downtime

- Higher maintenance costs and shorter machine lifespan

To mitigate this, verify the manufacturer’s certifications (e.g., ISO 9001), request third-party inspection reports, and whenever possible, conduct on-site factory audits.

Lack of Technical Support and Spare Parts Availability

Many suppliers, particularly smaller or offshore manufacturers, fail to provide adequate after-sales support. This includes limited access to technical assistance, training, or genuine spare parts. As a result, machine uptime suffers, and minor issues can lead to prolonged production halts.

Ensure the supplier offers a clear service agreement, has local or regional support channels, and provides a comprehensive spare parts catalog.

Inadequate Documentation and Machine Specifications

Incomplete or inaccurate technical documentation is a red flag. Misleading specifications—such as exaggerated grinding accuracy, spindle power, or automation capabilities—can result in mismatched expectations and performance shortfalls.

Always validate specifications with real-world test data or customer references, and include performance guarantees in the purchase contract.

Intellectual Property (IP) Infringement Risks

Sourcing from certain regions may expose buyers to IP-related legal and reputational risks. Some manufacturers reverse-engineer or copy patented designs from established brands (e.g., from Germany, Japan, or the U.S.), selling “clone” machines at lower prices. Purchasing such machines can:

- Expose your company to legal liability, especially in markets with strong IP enforcement

- Damage your brand reputation if linked to counterfeit or copied technology

- Result in poor performance due to unlicensed, poorly adapted designs

To avoid IP issues:

– Conduct due diligence on the manufacturer’s design origins

– Request proof of original engineering and patents

– Avoid suppliers offering well-known branded machines at unusually low prices

Insufficient Compliance with Safety and Environmental Standards

OD grinding machines must comply with regional safety and environmental regulations (e.g., CE, UL, or ANSI standards). Non-compliant machines may lack proper safety interlocks, dust extraction systems, or noise controls—posing risks to operators and potential legal consequences.

Always require compliance documentation and verify certification marks before purchase.

Conclusion

Sourcing an OD grinding machine requires careful evaluation beyond just price. Prioritize suppliers with proven quality, transparent engineering practices, and strong IP integrity. Conducting thorough due diligence protects your investment, ensures operational reliability, and minimizes legal and technical risks.

Logistics & Compliance Guide for OD Grinding Machine

Overview

This guide outlines the key logistics and compliance considerations for the transportation, import/export, installation, and operation of an OD (Outside Diameter) Grinding Machine. Adherence to these guidelines ensures regulatory compliance, safety, and efficient deployment.

Packaging and Handling Requirements

- Use robust, custom-fitted wooden crates with internal bracing to protect sensitive components (e.g., spindle, grinding wheel, control panel).

- Secure all moving parts with transit bolts or locking brackets to prevent shift during transport.

- Label packages with “Fragile,” “This Side Up,” and “Do Not Stack” indicators.

- Include moisture desiccants and anti-corrosion VCI (Vapor Corrosion Inhibitor) paper for long-distance or maritime shipments.

Transportation Logistics

- Coordinate with freight forwarders experienced in handling heavy machinery.

- Confirm equipment dimensions and weight (typically 1,000–5,000 kg) for proper vehicle and crane selection.

- Plan route in advance to avoid low bridges, weight-restricted roads, or narrow access points.

- Use flatbed trucks or containerized shipping based on destination and accessibility.

- Provide lift points and rigging instructions for safe unloading.

Import/Export Compliance

- Verify Harmonized System (HS) Code (e.g., 8460.20 for grinding machines) for accurate customs classification.

- Prepare commercial invoice, packing list, bill of lading/air waybill, and certificate of origin.

- Comply with export control regulations (e.g., EAR in the U.S.); confirm if machine contains controlled technology.

- Obtain necessary import permits, especially in regulated markets (e.g., China, India, Brazil).

- Ensure adherence to Incoterms® (e.g., FOB, CIF, DDP) as agreed with buyer/seller.

Regulatory and Safety Standards

- Confirm machine meets CE marking (EU), UL/CSA (North America), or other regional safety certifications.

- Ensure compliance with ISO 16090:2015 (safety of grinding machines) and local occupational safety regulations.

- Include safety documentation: risk assessment, emergency stop procedures, and guarding specifications.

- Provide multilingual operation and safety manuals where required.

Installation and Site Preparation

- Verify facility power supply (voltage, phase, frequency) matches machine requirements.

- Ensure adequate floor loading capacity (consult manufacturer specs).

- Provide vibration-isolated foundation if specified.

- Maintain clearance for operation, maintenance, and emergency access (per OSHA/ISO standards).

- Confirm availability of required utilities: coolant supply, compressed air, dust extraction.

Environmental and Waste Compliance

- Implement coolant management system to prevent spills and contamination.

- Collect and dispose of grinding sludge and used filters as hazardous or industrial waste per local regulations (e.g., EPA, REACH).

- Equip machine with dust extraction to meet permissible exposure limits (PELs) for metal particulates.

- Recycle packaging materials in accordance with local waste laws.

Documentation and Recordkeeping

- Retain shipping documents, customs filings, and compliance certificates for minimum of 5 years.

- Maintain log of machine maintenance, safety inspections, and operator training.

- Provide end-user with conformity declaration, warranty, and service contact details.

Training and Operator Certification

- Conduct on-site training covering safe operation, emergency procedures, and maintenance.

- Ensure operators are certified per internal or industry standards (e.g., NIMS in the U.S.).

- Supply lockout/tagout (LOTO) procedures and personal protective equipment (PPE) guidelines.

After-Sales and Service Compliance

- Register machine with manufacturer for warranty and software/firmware updates.

- Schedule periodic maintenance per OEM recommendations to maintain compliance and performance.

- Report any safety incidents or malfunctions to relevant authorities if required by law.

By following this guide, stakeholders can ensure the safe, legal, and efficient handling of OD grinding machines throughout their lifecycle.

Conclusion for Sourcing OD Grinding Machine:

After a thorough evaluation of technical requirements, supplier capabilities, cost considerations, and long-term operational needs, sourcing an OD (Outside Diameter) grinding machine is a strategic investment that significantly enhances production precision, efficiency, and product quality. The selected machine should align with current manufacturing demands while offering scalability for future needs. Factors such as machine accuracy, automation compatibility, ease of maintenance, spindle quality, and after-sales support play a critical role in ensuring optimal performance and return on investment.

Sourcing from reputable suppliers with proven industry experience, strong service networks, and compliance with international quality standards further mitigates risks and supports sustainable operations. Additionally, considering total cost of ownership—beyond the initial purchase price—enables informed decision-making that benefits the organization in the long term.

In conclusion, a well-sourced OD grinding machine not only improves dimensional accuracy and surface finish of components but also strengthens competitiveness by reducing cycle times, minimizing waste, and supporting high-volume precision manufacturing. Careful vendor selection, combined with technical validation and comprehensive lifecycle planning, ensures the machine becomes a valuable asset in achieving operational excellence.