The industrial valve market in the United States continues to expand, driven by increased demand from oil & gas, chemical processing, and water treatment sectors. According to Mordor Intelligence, the U.S. control valves market is projected to grow at a CAGR of over 5.2% from 2023 to 2028, with regional hubs like Tulsa, Oklahoma playing a pivotal role due to their strategic proximity to key energy infrastructure. Tulsa has emerged as a concentrated center for manufacturers specializing in OCV (Oil, Chemical, and Vapor) control valves—critical components for ensuring operational safety, precision, and efficiency in high-pressure and corrosive environments. Backed by Grand View Research, the global control valves market was valued at USD 53.8 billion in 2022 and is expected to grow at a CAGR of 6.1% through 2030, underpinned by rising automation and regulatory compliance needs. Within this growing landscape, Tulsa-based manufacturers are gaining recognition for engineering expertise, ASME-certified production, and rapid deployment capabilities. Based on production volume, product certifications, and industry partnerships, here are the top three OCV control valves manufacturers in Tulsa, OK currently leading innovation and reliability in the space.

Top 3 Ocv Control Valves Tulsa Ok Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

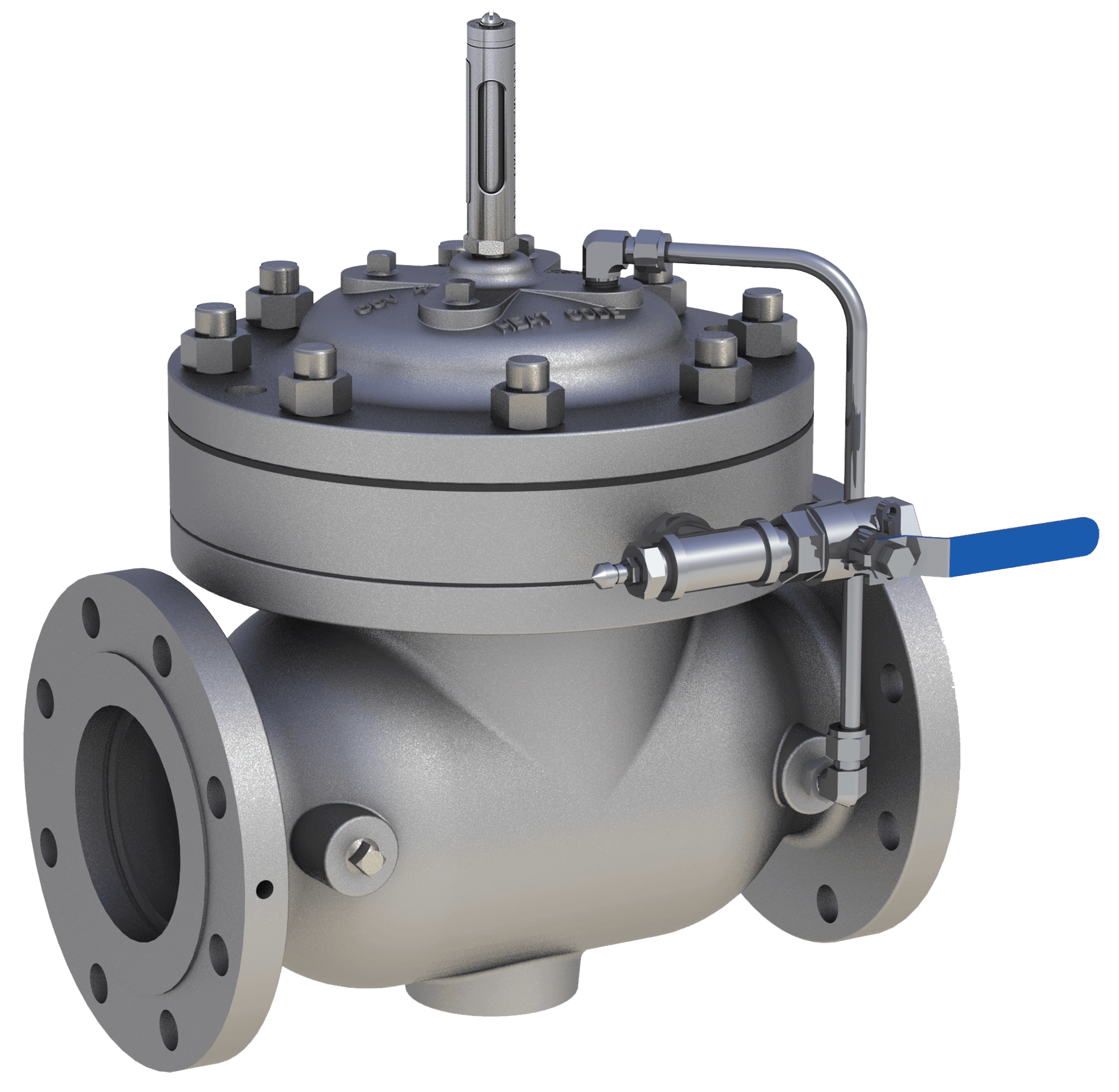

#1 OCV Control Valves

Domain Est. 1996

Website: controlvalves.com

Key Highlights: OCV, an Aquestia brand, is a global leader in the control valve industry. OCV valves can be found in some capacity in nearly every country in the world….

#2 OCV

Domain Est. 2001

Website: ahfindustries.com

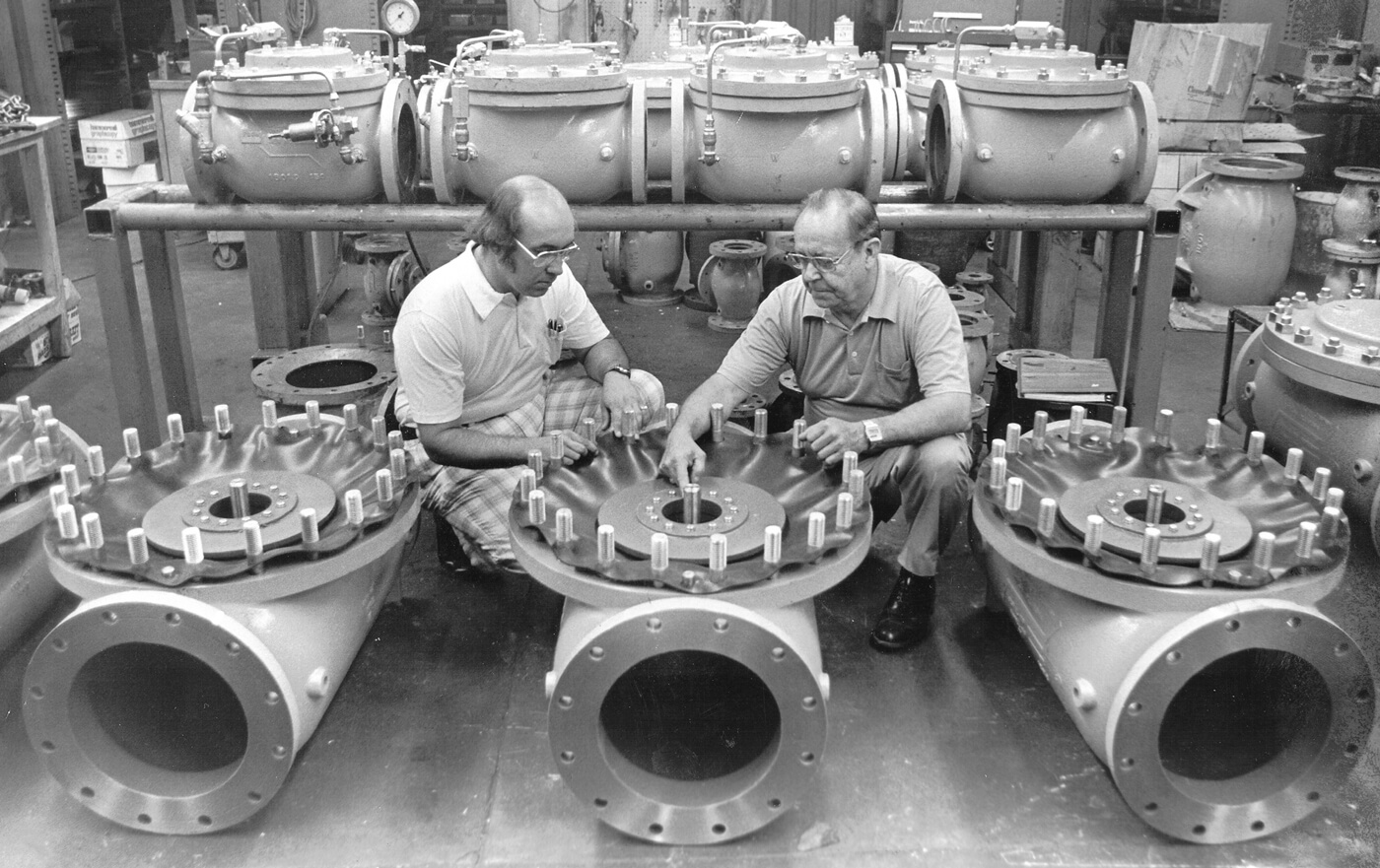

Key Highlights: OCV Control Valves is a privately-owned company, Located in Tulsa, Oklahoma. Founded more than 50 years ago, the company has over 50,000 square feet of ……

#3 Aquestia

Domain Est. 2021

Website: aquestia.com

Key Highlights: OCV S100 68F FM Approved. OCV S100 68F Series hydraulic control valves – now FM Approved. Read More · AQ LOGO. Products. By Product ……

Expert Sourcing Insights for Ocv Control Valves Tulsa Ok

H2: Projected 2026 Market Trends for OCV Control Valves in Tulsa, OK

The market for OCV (Ocv) control valves in Tulsa, Oklahoma, is poised for strategic growth and transformation by 2026, driven by regional industrial demand, energy sector dynamics, and technological advancements. As a key player in industrial valve manufacturing and distribution, OCV is well-positioned to benefit from several converging trends in the Tulsa market.

-

Expansion in Energy and Oil & Gas Sectors

Tulsa remains a historic hub for the oil and gas industry, and ongoing investments in midstream and downstream infrastructure are expected to bolster demand for high-performance control valves. With renewed focus on operational efficiency and emissions reduction, oil and gas operators are increasingly adopting smart valve technologies—many of which OCV offers—such as automated actuators and digital positioners. The anticipated rise in maintenance, repair, and operations (MRO) spending across aging pipeline systems will further support valve replacement cycles, favoring established suppliers like OCV. -

Growth in Water and Wastewater Infrastructure

The City of Tulsa and surrounding municipalities are prioritizing upgrades to aging water and wastewater systems. Federal funding from the Infrastructure Investment and Jobs Act (IIJA) is expected to flow into Oklahoma’s municipal projects through 2026, creating opportunities for control valve suppliers. OCV’s line of resilient-seated and high-capacity control valves is well-suited for municipal fluid management applications, positioning the company to capture public sector contracts. -

Demand for Smart and Digital Valve Solutions

Industry 4.0 integration is accelerating in Oklahoma’s industrial facilities. By 2026, process industries—including chemical processing, power generation, and food & beverage—will increasingly require IoT-enabled control valves for predictive maintenance and remote monitoring. OCV’s investment in digital diagnostics and compatibility with industrial automation platforms will be a competitive advantage in this evolving landscape. -

Workforce and Supply Chain Localization

Tulsa’s manufacturing renaissance, supported by initiatives like the Tulsa Remote program and local incentives for advanced manufacturing, is attracting skilled labor and reshoring efforts. OCV’s regional presence enables faster delivery, technical support, and customization—critical factors in a market that values supply chain resilience. Strategic partnerships with local engineering firms and contractors will enhance OCV’s market penetration. -

Sustainability and Regulatory Compliance

Environmental regulations are tightening across Oklahoma, particularly in air quality and water discharge standards. Control valves that offer tighter shutoff, reduced fugitive emissions, and energy efficiency will be in higher demand. OCV’s compliance with API, ASME, and ISO standards, along with its offering of low-emission (Low-E) valve solutions, aligns with these regulatory trends.

In summary, the 2026 outlook for OCV control valves in Tulsa is positive, supported by energy sector resilience, infrastructure modernization, digital transformation, and regional economic development. OCV’s ability to deliver reliable, technologically advanced, and compliant valve solutions will be key to capitalizing on these emerging opportunities.

Common Pitfalls When Sourcing On-Contact Voltage (OCV) Control Valves in Tulsa, OK (Quality & Intellectual Property)

Sourcing On-Contact Voltage (OCV) control valves—critical components in oil and gas, chemical processing, and industrial automation systems—requires careful consideration, especially in a hub like Tulsa, Oklahoma, known for its energy sector presence. While numerous suppliers operate in the region, organizations often encounter pitfalls related to product quality and intellectual property (IP) concerns. Being aware of these issues can help prevent costly delays, safety hazards, or legal complications.

Quality-Related Pitfalls

Inconsistent Manufacturing Standards

One of the most common quality issues when sourcing OCV control valves in Tulsa, OK, is inconsistent adherence to industry standards such as API 6D, ASME B16.34, or NACE MR0175. Some local or third-party suppliers may cut corners to reduce costs, leading to valves that fail under high-pressure or corrosive conditions. Always verify that the supplier follows certified manufacturing processes and provides full traceability documentation.

Lack of Testing and Certification

Not all suppliers conduct rigorous performance testing, such as leakage tests, pressure cycling, or thermal cycling. Without proper third-party certification (e.g., ISO 9001, API Q1), there’s increased risk of premature valve failure. Ensure valves come with a material test report (MTR) and are tested according to applicable standards.

Substandard Materials and Counterfeit Components

Tulsa’s proximity to major energy infrastructure makes it a target for suppliers using subpar or counterfeit materials to mimic high-performance alloys (e.g., stainless steel, Inconel). These materials may not withstand harsh downhole or refinery environments, resulting in corrosion, cracking, or system failure. Conduct material verification through independent lab testing when possible.

Poor Workmanship and Assembly

Even with high-quality components, poor assembly practices can compromise valve integrity. Misaligned seals, improper torque on bolts, or inadequate welding can lead to leaks or control inaccuracies. Visit supplier facilities or request audit reports to assess manufacturing capabilities.

Intellectual Property (IP) Risks

Unauthorized Replication or Reverse Engineering

Some local manufacturers may reverse-engineer proprietary OCV control valve designs from major OEMs (e.g., Emerson, Fisher, Schlumberger) without licensing. While these “compatible” valves may appear cost-effective, they often infringe on protected designs, exposing buyers to legal liability and warranty voidance.

Lack of IP Documentation and Licensing

Suppliers may fail to provide proof of legitimate IP ownership or licensing agreements. Always request documentation confirming that the valve design does not violate patents or trademarks. Purchasing from IP-infringing sources can result in cease-and-desist orders, recall costs, or reputational damage.

Ambiguous Warranty and Support

Valves sourced from suppliers with questionable IP standing often come with limited or voidable warranties. OEMs may refuse to support systems that integrate counterfeit or cloned components, increasing long-term maintenance costs and downtime.

Best Practices to Avoid Pitfalls

- Verify certifications: Ensure suppliers are ISO, API, or ANSI certified.

- Conduct supplier audits: Perform on-site evaluations or request third-party audit results.

- Require full documentation: Demand MTRs, test reports, and IP compliance statements.

- Partner with reputable distributors: Work with authorized representatives of known OEMs.

- Include IP clauses in contracts: Specify indemnification for IP infringement claims.

By proactively addressing quality and intellectual property concerns, companies sourcing OCV control valves in Tulsa, OK, can ensure reliability, compliance, and long-term operational safety.

Logistics & Compliance Guide for OCV Control Valves – Tulsa, OK

Shipping and Receiving Procedures

All incoming and outgoing shipments for OCV Control Valves in Tulsa, OK must adhere to company-established protocols and federal regulations. Shipments are received at the designated dock area located at 123 Industrial Parkway, Tulsa, OK 74104, between the hours of 7:00 AM and 4:00 PM, Monday through Friday. Advance shipment notifications (ASNs) must be submitted 24 hours prior to delivery via the OCV Logistics Portal. All packages must include proper labeling with purchase order number, part description, and hazardous material indicators (if applicable).

For outbound shipments, OCV-approved carriers must be used, including FedEx Freight, UPS Ground, and contracted regional LTL providers. International shipments require proper export documentation, including commercial invoices, packing lists, and any required certificates of origin. All shipments must be double-checked for accuracy against the order before dispatch.

Regulatory Compliance Requirements

OCV Control Valves Tulsa operates under strict compliance with federal, state, and local regulations. Key compliance areas include:

- OSHA Standards: All warehouse and shop personnel must complete annual safety training. Material Safety Data Sheets (MSDS) are maintained on-site for all chemicals and lubricants used in valve testing and maintenance.

- EPA Regulations: Proper handling and disposal of testing fluids and waste materials are governed by EPA rules under RCRA. Spill prevention control and countermeasure (SPCC) plans are in place and reviewed annually.

- DOT Compliance: Any shipment containing regulated materials (e.g., pressurized components, oils) must comply with Department of Transportation (DOT) 49 CFR guidelines. Employees involved in packaging hazardous materials must maintain current HAZMAT certifications.

- ITAR/EAR Compliance: For valves used in defense or dual-use applications, International Traffic in Arms Regulations (ITAR) and Export Administration Regulations (EAR) apply. Access to such products is restricted to authorized personnel only, and export licenses are verified prior to shipment.

Inventory Management and Tracking

Inventory at the Tulsa facility is managed through OCV’s centralized ERP system, SAP S/4HANA. All incoming goods are scanned upon receipt and assigned a unique stock-keeping unit (SKU) and location code. Cycle counts are conducted weekly, and full physical inventories occur quarterly. Serialized valves are tracked from manufacture to shipment to ensure traceability. RFID tags are used on high-value items to enhance tracking accuracy and reduce loss.

Customs and International Trade

For international deliveries originating from or transiting through the Tulsa facility, customs compliance is managed in coordination with OCV’s Global Trade team. Required documentation such as Shipper’s Export Declaration (SED), AES filings, and Certificate of Conformity (if required by destination country) must be completed accurately. All employees involved in export operations must complete annual training on U.S. Customs and Border Protection (CBP) regulations and Automated Export System (AES) reporting.

Quality Assurance and Documentation

All valves processed through the Tulsa facility must undergo final inspection per API 598 and API 6D standards. Inspection records, test reports, and material certifications are archived electronically for a minimum of 10 years. Non-conforming materials are quarantined and dispositioned per OCV’s Corrective Action Request (CAR) process. Third-party audits are conducted annually to ensure compliance with ISO 9001:2015 and API Q1 standards.

Emergency Response and Incident Reporting

In the event of a logistics-related incident (e.g., spill, damaged shipment, or compliance breach), personnel must follow the OCV Tulsa Emergency Response Plan. Immediate notification must be made to the Facility Manager and Environmental Health & Safety (EHS) Officer. Spill kits are located at all loading docks and testing bays. Incident reports must be filed within 24 hours using the OCV Safety Portal, and root cause analysis conducted for all reportable events.

In conclusion, sourcing OCv control valves in Tulsa, OK requires careful consideration of local suppliers, manufacturer representatives, and industrial distributors known for quality products and reliable service. Tulsa’s strategic location in the energy and pipeline corridor makes it a hub for industrial valve solutions, with several reputable vendors offering OCv (On/Off, Control, or specific brand) control valves suited for oil and gas, water treatment, and process industries.

Key factors in successful sourcing include verifying product specifications, ensuring compliance with industry standards (such as API, ASME, or ISA), evaluating technical support and after-sales service, and comparing lead times and pricing. Establishing relationships with trusted local suppliers—such as industrial distributors partnered with major valve manufacturers—can streamline procurement, reduce downtime, and ensure compatibility with existing systems.

Ultimately, sourcing OCv control valves in Tulsa, OK is both feasible and advantageous given the region’s industrial infrastructure. A proactive approach that emphasizes quality, reliability, and local expertise will ensure optimal valve performance and long-term operational efficiency.