The global chainsaw market is experiencing steady growth, driven by rising demand in forestry, agriculture, and residential landscaping. According to Grand View Research, the global chainsaw market size was valued at USD 6.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. As one of Stihl’s most popular consumer-grade models, the O38 (also known as MS 170 in some regions) continues to see strong aftermarket and manufacturing interest, particularly from third-party and licensed producers focused on performance, durability, and cost-efficiency. With increasing adoption in emerging economies and ongoing infrastructure development, the ecosystem of manufacturers producing compatible or equivalent O38 Stihl chainsaws has expanded significantly. Based on market dynamics and product availability, here are the top 5 O38 Stihl manufacturers leading innovation and output in this segment.

Top 5 O38 Stihl Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 STIHL International Website

Domain Est. 1996

Website: stihl.com

Key Highlights: STIHL Group ➤ Explore your world-leading Manufacturer of Battery-Driven & Motorized Power Garden Tools including Chainsaws, Brush Cutters & many more!…

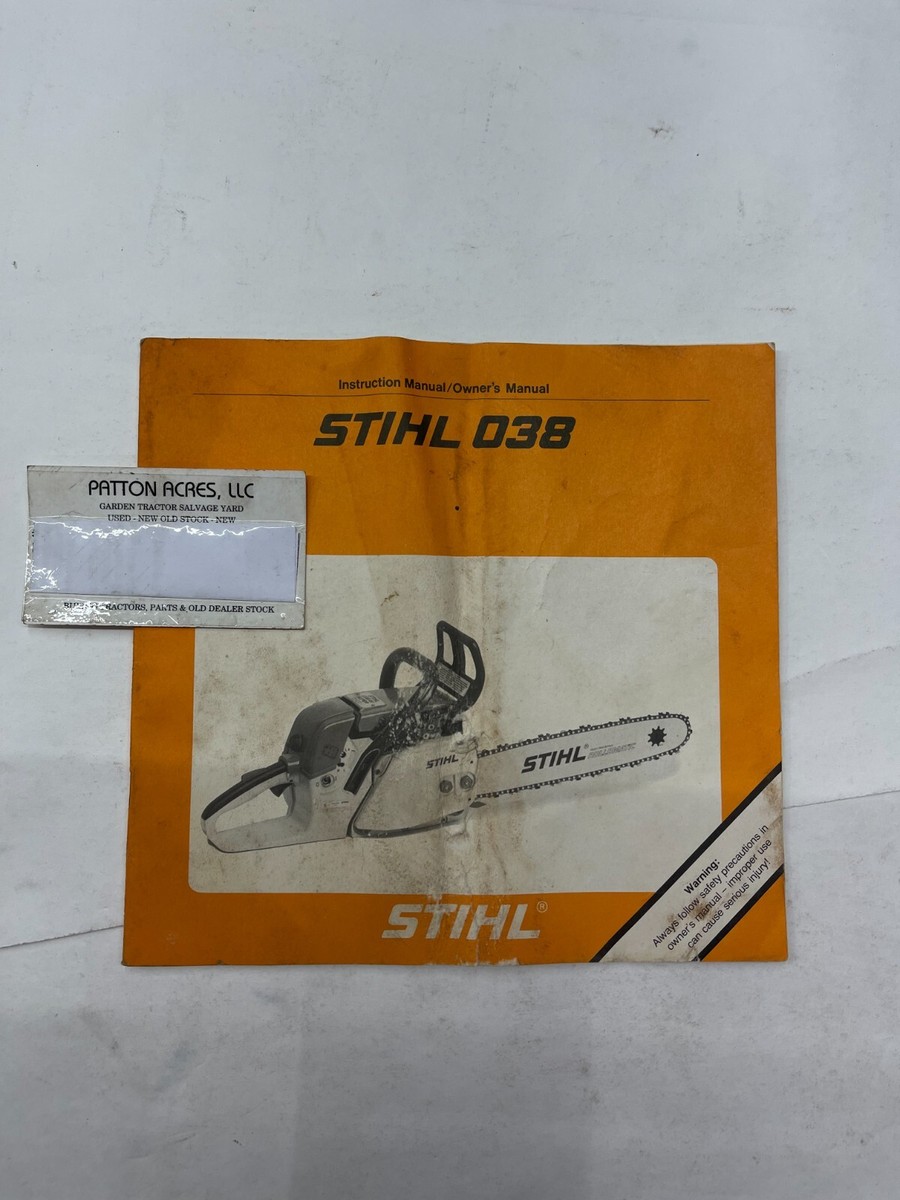

#2 STIHL owners manuals

Domain Est. 1996

Website: stihlusa.com

Key Highlights: The version of the Instruction Manual that you are about to download has been specifically prepared for STIHL products sold in the United States. Portions of ……

#3 C-A-L Ranch

Domain Est. 1998

Website: calranch.com

Key Highlights: C-A-L Ranch has 34 country retail store locations across the West. Shop dozens of product categories & top brands to support your farm, ranch, and home ……

#4 STIHL sales operations in Europe at a glance

Domain Est. 2000

Website: corporate.stihl.pl

Key Highlights: STIHL sales companies are on hand to offer advice and assistance in Europe as well. Click here to find out where and how to find STIHL in Europe….

#5 Chain Catcher For Stihl MS380 038 Chainsaw 1125 650 7700

Domain Est. 2011

Website: privacy.we-conect.com

Key Highlights: Rating 4.3 (990) Buy Stihl 038av in Chainsaw Parts & Accessories and get the best deals at the lowest prices on UK! Great Savings & Free Delivery / Collection on many items ……

Expert Sourcing Insights for O38 Stihl

H2 2026 Market Trends Analysis for O38 STIHL

As of H2 2026, the market for STIHL’s O38 chain oil is shaped by evolving regulatory landscapes, advancements in sustainable forestry practices, and shifting consumer preferences toward environmentally responsible products. The O38 formulation—known for its biodegradable properties and compatibility with high-performance STIHL chainsaws—continues to play a strategic role in the company’s ecosystem of outdoor power equipment.

-

Regulatory and Environmental Pressures

Environmental regulations in North America and the European Union have intensified in 2026, with stricter mandates on biodegradability and aquatic toxicity for lubricants used in forestry and landscaping. The O38 oil, already compliant with OECD 301 standards for biodegradability, benefits from these trends as a preferred option among professional arborists and land management agencies. In particular, California’s updated Air Resources Board (CARB) guidelines and the EU’s revised Ecolabel criteria have reinforced demand for eco-certified chain oils, giving O38 a competitive edge. -

Growth in Professional and Residential Landscaping Sectors

The professional landscaping and tree care industries experienced moderate growth in 2026, driven by increased urban green space development and storm-related tree maintenance needs. STIHL’s strong brand loyalty among certified arborists and forestry contractors has translated into sustained demand for O38. Additionally, a rise in residential chainsaw ownership—fueled by extreme weather events and DIY trends—has expanded the consumer base for original-equipment lubricants like O38, which are marketed through STIHL’s dealer network and e-commerce platforms. -

Supply Chain and Raw Material Dynamics

In H2 2026, STIHL has optimized its supply chain for O38, leveraging regionally sourced renewable base stocks to reduce carbon footprint and mitigate volatility in petrochemical prices. The company’s investment in bio-based additive technologies has improved O38’s performance in extreme conditions (e.g., cold weather and high-load cutting), enhancing customer retention. However, intermittent supply constraints in vegetable oil derivatives due to climate-related crop variability in key sourcing regions have prompted STIHL to diversify suppliers and explore synthetic ester alternatives. -

Competitive Landscape and Market Positioning

Competitors such as Oregon (Blount International) and Husqvarna have introduced biodegradable chain oils at competitive price points. However, STIHL’s integrated system approach—where O38 is promoted as part of a complete chainsaw maintenance solution—has preserved its premium positioning. In 2026, STIHL reinforced this with bundled marketing campaigns (e.g., “Total Performance System”) that pair O38 with new MS 261 C-M and MS 462 models, emphasizing efficiency and reduced wear. -

Technological Integration and Consumer Education

STIHL’s digital outreach in H2 2026, including AR-assisted maintenance tutorials and IoT-enabled chainsaws that monitor oil usage, has increased awareness of proper lubrication practices. These tools highlight the importance of using genuine STIHL oils like O38 to maintain warranty coverage and performance, further solidifying brand lock-in.

Conclusion

In H2 2026, O38 STIHL maintains a strong market position driven by regulatory tailwinds, brand trust, and strategic product integration. While price competition and raw material challenges persist, STIHL’s focus on sustainability, performance, and customer education ensures O38 remains a key component in the outdoor power equipment lubricants segment. Future growth will depend on continued innovation in bio-based formulations and expansion into emerging markets with rising demand for professional-grade forestry tools.

Common Pitfalls When Sourcing O38 Stihl Parts (Quality and Intellectual Property)

When sourcing O38 Stihl parts—commonly associated with Stihl chainsaw components such as piston rings or other engine parts—buyers often encounter significant challenges related to quality control and intellectual property (IP) risks. Recognizing these pitfalls is crucial for ensuring reliable performance and legal compliance.

Poor Quality Control from Third-Party Suppliers

One of the most common issues is receiving substandard parts from non-certified manufacturers. The O38 specification often refers to precise tolerances and material quality required for optimal engine performance. Many third-party suppliers offer “compatible” or “generic” versions that may look identical but fail under real-world conditions due to inferior materials, poor machining, or lack of proper testing. This can result in engine damage, reduced tool lifespan, and increased maintenance costs.

Risk of Counterfeit or IP-Infringing Products

Stihl is a registered trademark, and many of its parts, including those with part numbers like O38, are protected under intellectual property laws. Sourcing from unauthorized vendors increases the risk of purchasing counterfeit parts that infringe on Stihl’s IP. These products not only violate trademark and patent rights but may also mislead customers into believing they are buying genuine Stihl components. Using or distributing such parts can expose businesses to legal liability, customs seizures, and reputational damage.

Lack of Traceability and Certification

Genuine Stihl parts come with quality certifications and traceable manufacturing records. When sourcing O38 parts from unofficial channels, buyers often lack access to documentation proving authenticity, compliance with safety standards (e.g., CE, EPA), or origin. This absence of traceability makes it difficult to ensure reliability and can be a compliance issue in regulated markets.

Inconsistent Sizing and Fit

Even if a part appears visually accurate, minor deviations in dimensions or tolerances—common in imitation parts—can lead to improper fit, increased wear, or engine failure. The O38 designation typically refers to specific engineering specs that may not be replicated precisely by copycat manufacturers. This inconsistency undermines tool performance and safety.

Voided Warranties and Service Denials

Using non-genuine O38 parts, especially those that are counterfeit or of dubious origin, may void the warranty on Stihl equipment. Authorized service centers often refuse repairs or maintenance on tools containing non-OEM parts, citing potential risks to safety and performance. This can result in higher long-term costs and downtime.

Conclusion

To avoid these pitfalls, always source O38 Stihl parts from authorized distributors or certified suppliers. Verify authenticity through part numbers, packaging, and documentation. Prioritizing genuine components ensures quality, compliance, and protection against IP-related legal risks.

H2: Logistics & Compliance Guide for O38 STIHL

This guide outlines the essential logistics and compliance requirements for handling, storing, transporting, and managing O38, a high-concentration oxygen mixture (80% oxygen, 20% helium) used with STIHL professional power equipment, primarily for specialized applications like medical rescue tools or underwater cutting. Adherence to these guidelines is critical for safety, regulatory compliance, and operational efficiency.

H2: Regulatory Compliance Framework

-

Classification & Hazard Identification:

- OSHA (US): Classified as a Compressed Gas (Oxidizer) under 29 CFR 1910.101, 1910.104. O38 is a severe fire hazard due to high oxygen concentration. Helium is an asphyxiant.

- DOT (US): Regulated under 49 CFR as a Non-Flammable Compressed Gas (Helium component) and an Oxidizing Gas (Oxygen component). Primary Hazard Class: 2.2 (Non-Flammable, Non-Toxic Gas) with subsidiary hazard Class 5.1 (Oxidizer). UN Number: UN 1072 (Oxygen, compressed) or potentially UN 1076 (Helium, compressed) depending on mixture designation; consult SDS. Proper Shipping Name: “OXYGEN, COMPRESSED” or “COMBINATION GASES, OXIDIZING, N.O.S. (Helium, Oxygen)”.

- GHS/SDS: Must have a current Safety Data Sheet (SDS) meeting GHS standards (e.g., OSHA HazCom 2012). Key hazard statements: H270 (May cause or intensify fire; oxidizer), H280 (Contains gas under pressure; may explode if heated).

- NFPA: Complies with NFPA 55 (Compressed and Liquefied Gases Code) and NFPA 99 (Health Care Facilities Code) if used in medical contexts. Oxygen concentration >23.5% creates an oxygen-enriched atmosphere (OEA), significantly increasing fire risk.

- Local/State Regulations: Comply with all applicable state fire codes (e.g., California Fire Code) and local authority having jurisdiction (AHJ) requirements, which may be stricter.

-

Labeling & Documentation:

- Cylinders: Must be clearly labeled “O38”, “80% O2 / 20% He”, “OXYGEN / HELIUM”, and display DOT/TC (Canada) specification markings, service pressure, and serial number. Hazard warning labels (Oxidizer, Gas under Pressure) are mandatory.

- Shipping Papers: Bill of Lading (BOL) must accurately reflect UN Number, Proper Shipping Name, Hazard Class, Packing Group (II for oxidizing gases), and emergency contact information. Shipper’s Declaration for Dangerous Goods required for air transport (IATA).

- SDS: Must be readily accessible to all personnel handling or transporting O38.

H2: Storage Requirements

-

Location:

- Store in a well-ventilated, dry, cool area, protected from weather and direct sunlight. Temperature should not exceed manufacturer’s specifications (typically < 125°F / 52°C).

- Designated storage area must be clearly marked “OXYGEN – NO SMOKING – NO OIL OR GREASE”.

- Secure from damage (forklifts, vehicles) and unauthorized access. Use chains or cages if necessary.

- Store upright and secured against tipping.

-

Segregation:

- Mandatory Separation: Store at least 20 feet (6 meters) away from flammable gases/liquids (acetylene, propane, gasoline, solvents, oils, greases). If within 20 feet, use a non-combustible barrier at least 5 feet (1.5m) high with a fire-resistance rating of at least 1/2 hour.

- Separation from Combustibles: Keep away from combustible materials (wood, paper, fabrics, rags, coal) and ignition sources (welding, cutting, electrical equipment, open flames, smoking).

- Separation from Incompatible Materials: Isolate from chlorine, fluorine, and other reactive oxidizers.

-

Ventilation: Ensure adequate natural or mechanical ventilation to prevent accumulation of oxygen or helium, which could create an OEA or asphyxiation hazard.

H2: Handling & Use Procedures

-

Personal Protective Equipment (PPE):

- Mandatory: Clean, oil/grease-free leather or cotton gloves, safety glasses with side shields or face shield (especially when opening valves), and safety shoes/boots.

- Recommended: Flame-resistant (FR) clothing due to severe fire hazard in OEA. Hearing protection if high flow rates are used.

-

Cylinder Handling:

- Movement: Always use a suitable cylinder cart or hand truck. Secure cylinders during transport. Never roll, drag, or drop cylinders.

- Valve Protection: Keep cylinder valve caps securely in place when not in use or during transport.

- Opening Valves: Open valves slowly to prevent adiabatic heating. Stand aside when opening the first valve on a cylinder. Never use excessive force.

- Contamination Prevention: STRESS: Keep oxygen cylinders, valves, regulators, and equipment ABSOLUTELY FREE of oil, grease, and hydrocarbon-based contaminants. Use only oxygen-clean tools and components. Even a small amount can ignite violently under high pressure.

-

Use with STIHL Equipment:

- Compatibility: Ensure the STIHL tool (e.g., rescue saw) and its specific regulator/accessory kit are explicitly rated and approved for use with O38 (80/20) by STIHL.

- Regulators: Use only regulators designed and cleaned for oxygen service and compatible with O38 pressure. Inspect for damage before use.

- Connections: Ensure connections are tight but not over-torqued. Check for leaks using an oxygen-compatible leak detection solution (NEVER use soap/glycerin-based solutions on oxygen). Tighten connections ONLY if leak is detected; do not overtighten.

- Decompression: Follow STIHL procedures for safely purging and decompressing the system before disassembly.

H2: Transportation Guidelines

-

Vehicle Requirements:

- Secure cylinders upright in a well-ventilated area (e.g., open truck bed, ventilated cargo area). Never transport in enclosed passenger compartments or unventilated vans.

- Protect cylinders from direct sunlight, heat sources (exhaust), and physical damage.

- Ensure cylinders are restrained to prevent movement during transit (chained, strapped, or in racks).

- Post appropriate DOT hazard warning placards (Class 2.2 and Class 5.1) on the vehicle if required by quantity and regulations (refer to 49 CFR 172.504).

-

Driver/Personnel:

- Drivers and handlers must be trained in hazardous materials transportation (DOT HAZMAT training per 49 CFR 172.704) and specific O38 hazards.

- Carry required documentation: BOL, SDS, Emergency Response Guidebook (ERG), and shipper’s declaration (if applicable).

-

Loading/Unloading:

- Follow same handling procedures as storage (PPE, no oil/grease, protect valve caps, use carts).

- Perform in well-ventilated, designated areas away from ignition sources.

H2: Emergency Response & Incident Management

-

Fire:

- Extreme Hazard: Materials ignite easily and burn violently in an OEA. Fire can be explosive.

- Action: Evacuate immediately. Call emergency services (911). If safe to do so, remotely stop oxygen flow from a safe distance. Use water spray to cool exposed cylinders and protect exposures. DO NOT extinguish a gas fire unless flow can be safely stopped first (risk of re-ignition). Let gas burn off in a controlled manner if isolation is impossible. Keep cylinders cool with water.

-

Leak:

- Oxygen Leak: Creates OEA – extreme fire hazard. Eliminate all ignition sources immediately. Evacuate non-essential personnel. Ventilate area. If safe, stop flow at cylinder valve. Repair only by qualified personnel using oxygen-clean parts.

- Helium Leak: Asphyxiation hazard in confined spaces. Ventilate area. Evacuate if oxygen levels drop. Prevent accumulation in pits or low-lying areas.

-

Cylinder Damage/Overheating:

- Action: Evacuate area. Call emergency services. Cool exposed cylinders with water from maximum distance. Do not approach damaged or overheated cylinders.

-

First Aid:

- Inhalation (Helium/Asphyxiation): Move to fresh air. Administer oxygen if available and trained. Seek medical attention.

- Contact with Cryogenic Liquid (if applicable – unlikely for O38 gas): Flush with lukewarm water. Do not rub. Seek immediate medical attention. (Note: O38 is typically supplied as gas, not liquid).

- Fire/Explosion Burns: Treat as thermal burns. Seek immediate medical attention. Never apply oil, grease, or ointments to burns in an oxygen-enriched environment.

-

Reporting: Report all incidents (leaks, fires, injuries) immediately to supervisor and relevant authorities as required by regulation (e.g., OSHA, DOT).

H2: Training & Recordkeeping

-

Mandatory Training:

- All personnel handling, storing, transporting, or using O38 must receive comprehensive training covering:

- Specific hazards of O38 (Oxidizer, Asphyxiant, High Pressure).

- Proper handling, storage, and use procedures.

- PPE requirements and use.

- Contamination prevention (oil/grease).

- Emergency response procedures.

- Applicable regulations (OSHA, DOT, NFPA).

- SDS review.

- DOT HAZMAT training required for transporters.

- Training must be documented and refreshed periodically (e.g., annually).

- All personnel handling, storing, transporting, or using O38 must receive comprehensive training covering:

-

Recordkeeping:

- Maintain records of:

- Employee training (dates, content, attendees).

- Cylinder inspections (visual, hydrostatic test dates).

- Maintenance on regulators and equipment.

- Incident reports.

- SDS copies.

- Shipping documentation (as required).

- Retain records according to regulatory requirements (e.g., OSHA, DOT).

- Maintain records of:

Disclaimer: This guide provides general best practices. ALWAYS consult the most current STIHL O38-specific operating manuals, Safety Data Sheets (SDS), and all applicable local, state, and federal regulations (OSHA, DOT, NFPA, EPA, etc.) for definitive requirements. Regulations and product specifications may change. Safety is paramount when dealing with high-pressure oxidizing gas mixtures.

Conclusion for Sourcing O38 STIHL Chainsaw Parts or Equipment:

In conclusion, sourcing the O38 STIHL chainsaw—whether for parts, maintenance, or procurement—requires engagement with authorized STIHL dealers or verified distributors to ensure authenticity, reliability, and warranty support. As STIHL does not sell directly through third-party marketplaces or unofficial channels, partnering with an authorized dealer guarantees access to genuine components, proper technical guidance, and compliance with safety standards. Additionally, due to the possibility of confusion with model numbers—such as possible typographical errors (e.g., intended model being MS 381 or another variant)—accurate identification of the correct model is crucial. By sourcing through official channels, users benefit from quality assurance, professional support, and extended equipment lifespan, making it the most effective and secure approach for acquiring and maintaining STIHL O38 or equivalent products.