The global oxygen (O2) sensor socket wrench market is experiencing steady growth, driven by rising automotive production and the increasing need for emission control compliance. According to Mordor Intelligence, the automotive oxygen sensor market—which directly influences the demand for specialized tools like O2 sensor socket wrenches—is projected to grow at a CAGR of over 6.5% from 2023 to 2028. This growth is further supported by stricter environmental regulations and the expansion of vehicle maintenance and repair services worldwide. As demand for precision tools rises, manufacturers specializing in O2 sensor socket wrenches are scaling innovation in design, material durability, and compatibility with diverse sensor types. In this evolving landscape, identifying the top eight manufacturers provides critical insight into product quality, technological advancement, and market leadership.

Top 8 O2 Sensor Socket Wrench Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Oxygen Sensor Socket For MINIs

Domain Est. 1996

Website: roverparts.com

Key Highlights: In stock Rating 5.0 (20) This 22mm socket wrench is exactly what you need for removal and replacement of oxygen sensors. Tools for Your Land Rover from CTA Manufacturing…

#2 Emission Sensor Tools

Domain Est. 1997

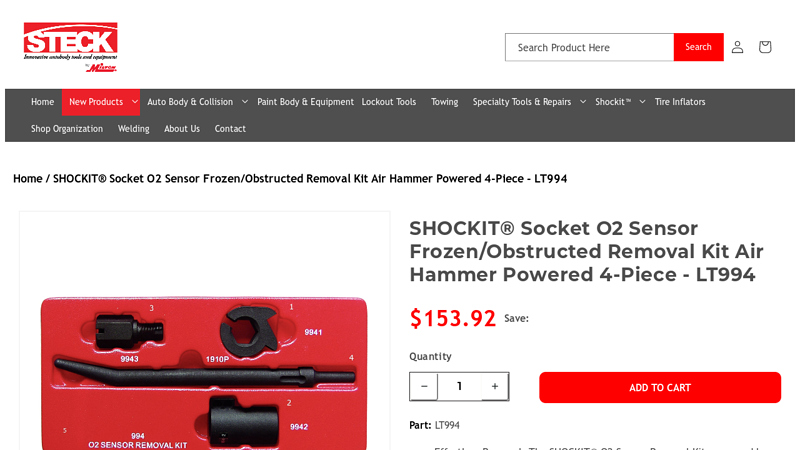

#3 Shockit™ Socket O2 Sensor Removal Kit

Domain Est. 1998

Website: steckmfg.com

Key Highlights: Free delivery 15-day returnsEffortless Removal: The SHOCKIT® O2 Sensor Removal Kit, powered by an air hammer, effortlessly removes O2 sensors, even in challenging automotive scenar…

#4 Oxygen Sensor Sockets

Domain Est. 2001

Website: tekton.com

Key Highlights: Free delivery over $25 · 30-day returnsSize: 7/8 inch, 22 mm. Use to remove and install oxygen sensors while preventing damage to any wires. Also available in an offset socket sty…

#5 LT994 Shockit Socket O2 Sensor Removal Kit

Domain Est. 2004

Website: miltonindustries.com

Key Highlights: Access, loosen, and easily remove frozen and obstructed 22mm O2 sensors and diesel NOx sensors. Works when ratchets, wrenches and regular sockets don’t fit….

#6 OTC-Bosch Automotive 7807

Domain Est. 2008

Website: autotoolworld.com

Key Highlights: In stock 1–2 day deliveryOTC-Bosch Automotive 7807 | Heated Oxygen Sensor Socket. We put a slot in the side of this wrench to accommodate connectors on heated oxygen sensors, ……

#7 11 PC Oxygen Sensor Socket Set

Domain Est. 2009

#8 O2 Sensor Socket Best Supplier in China

Domain Est. 2014

Website: viktec.com

Key Highlights: We can design and manufacture O2 sensor socket based on your details, sample, or drawings. VIKTEC engineers are willing to cooperate with you. Send Inquiry ……

Expert Sourcing Insights for O2 Sensor Socket Wrench

H2: 2026 Market Trends for O2 Sensor Socket Wrench

The global market for O2 sensor socket wrenches is expected to experience steady growth and transformation by 2026, driven by evolving automotive technologies, increased emissions regulations, and the expansion of the aftermarket tools sector. Key market trends shaping the industry include:

-

Stringent Emissions Regulations Driving Demand

Governments worldwide, particularly in North America, Europe, and Asia-Pacific, are enforcing stricter vehicle emission standards to combat air pollution. This has led to a higher frequency of O2 (oxygen) sensor maintenance and replacement, increasing the need for specialized tools like O2 sensor socket wrenches. As vehicles undergo more frequent emissions testing and diagnostics, the demand for precision tools to service O2 sensors will rise. -

Growth in Automotive Aftermarket and DIY Culture

The rise of the automotive aftermarket and a growing do-it-yourself (DIY) mechanic community are significant drivers. Enthusiasts and independent repair shops are investing in high-quality, cost-effective tools to perform sensor replacements without relying on dealerships. O2 sensor socket wrenches, known for their specialized design (e.g., swivel heads, notched interiors, and compatibility with torque wrenches), are becoming staple tools in home garages and small repair facilities. -

Electric Vehicle (EV) Impact and Market Adaptation

While the global shift toward electric vehicles (which do not use internal combustion engines or O2 sensors) may reduce long-term demand in certain segments, hybrid vehicles still require O2 sensors. Additionally, the large base of existing internal combustion engine (ICE) vehicles ensures continued demand through 2026 and beyond. Tool manufacturers are likely to focus on hybrid compatibility and multi-functional designs to extend product relevance. -

Innovation in Tool Design and Materials

By 2026, expect to see advanced materials such as chrome-molybdenum steel and ergonomic composite handles offering improved durability and user comfort. Integration with smart tools (e.g., digital torque feedback or Bluetooth connectivity) may begin to emerge, catering to tech-savvy mechanics and service centers aiming for precision repairs. -

E-Commerce Expansion and Distribution Channels

Online retail platforms such as Amazon, eBay, and specialized automotive tool websites are becoming primary sales channels. This shift allows manufacturers to reach a broader audience and offer competitive pricing, detailed product information, and customer reviews—factors that influence purchasing decisions in the tool market. -

Regional Market Dynamics

North America and Europe remain key markets due to high vehicle ownership and strict emissions testing (e.g., U.S. EPA standards and Euro 6/7). Meanwhile, the Asia-Pacific region, particularly China and India, is witnessing rapid growth in automotive tool demand due to expanding vehicle fleets and increasing service infrastructure. -

Consolidation and Brand Competition

The market is seeing increased competition among established brands (e.g., OEMTOOLS, GearWrench, OTC) and emerging private-label toolmakers. Differentiation through quality, warranty offerings, and kit bundling (e.g., O2 socket wrenches included in sensor replacement kits) will be critical for market share.

In summary, the O2 sensor socket wrench market in 2026 will be shaped by regulatory pressures, aftermarket growth, and innovation. While electrification poses a long-term challenge, the extensive ICE vehicle base and hybrid adoption will sustain demand, positioning the O2 sensor socket wrench as an essential tool in automotive diagnostics and repair.

Common Pitfalls When Sourcing O2 Sensor Socket Wrenches (Quality & IP)

When sourcing O2 sensor socket wrenches, overlooking quality and intellectual property (IP) considerations can lead to significant operational, legal, and reputational risks. Below are key pitfalls to avoid:

Poor Material Quality and Durability

Many low-cost O2 sensor socket wrenches are made from substandard chrome vanadium steel or inadequate heat treatment, resulting in sockets that crack, deform, or strip under torque. This compromises tool longevity and poses safety risks during vehicle maintenance. Always verify material specifications and prioritize suppliers with proven quality control processes and certifications (e.g., ISO 9001).

Inaccurate Socket Dimensions

Incorrect internal hex sizes or wall thicknesses can lead to improper fit on O2 sensors—causing slippage, rounded sensor edges, or damage to the exhaust system. Sourcing from unverified manufacturers increases the risk of dimensional inaccuracies. Ensure suppliers provide detailed tolerance specifications and conduct sample testing before bulk procurement.

Lack of IP Compliance

Sourcing from manufacturers that replicate patented socket designs—such as those with proprietary swivel mechanisms, integrated extensions, or unique venting systems—exposes buyers to intellectual property infringement claims. Always confirm that the supplier holds proper licensing or produces original, non-infringing designs. Request documentation to verify freedom to operate in your target markets.

Inadequate Surface Finish and Corrosion Resistance

Poor plating or insufficient anti-corrosion treatment leads to rust and reduced tool lifespan, especially in humid or saline environments. Inferior finishes also increase friction, making socket removal difficult. Specify minimum plating thickness (e.g., 10–15 µm chrome) and salt spray test requirements (e.g., ASTM B117) in procurement agreements.

Misrepresentation of Compatibility

Some suppliers falsely claim universal compatibility with all O2 sensor types (e.g., 22mm, 7/8″, narrow vs. wideband). This can result in tool failure or vehicle damage. Validate compatibility claims through technical datasheets and real-world testing across multiple vehicle makes and models.

Unverified Supplier Credentials

Engaging with suppliers lacking traceable manufacturing histories or third-party audits increases the risk of receiving counterfeit or non-compliant products. Conduct due diligence, including site visits or third-party inspections, to verify production capabilities and adherence to IP and quality standards.

Avoiding these pitfalls requires due diligence, clear technical specifications, and proactive IP risk assessment during the sourcing process.

H2: Logistics & Compliance Guide for O2 Sensor Socket Wrench

This guide outlines the key logistics and compliance considerations for the distribution, import/export, and use of O2 Sensor Socket Wrenches across international markets. Adherence ensures smooth operations and regulatory alignment.

H2: Logistics Considerations

- Packaging & Labeling

- Use durable, tamper-evident packaging to prevent damage during transit.

- Clearly label each unit with product name, model number, size (e.g., 7/8″, 22mm), SKU, and barcode.

- Include multilingual labeling if distributing across regions (e.g., English, Spanish, French).

-

Ensure packaging is recyclable and complies with regional environmental standards (e.g., EU Packaging Waste Directive).

-

Storage & Handling

- Store in dry, temperature-controlled environments to prevent corrosion of steel components.

- Stack packages securely and avoid overloading pallets (max load per pallet must be specified).

-

Follow FIFO (First-In, First-Out) inventory rotation to prevent obsolescence.

-

Transportation

- Ship via ground freight for domestic distribution; use air or sea freight for international.

- Declare accurate weight, dimensions, and HS code (see below) for customs clearance.

- Use carriers compliant with ISO 9001 or equivalent quality standards.

-

Ensure proper insurance coverage during transit.

-

Inventory Management

- Maintain real-time inventory tracking using barcode or RFID systems.

- Monitor lead times for raw materials (e.g., chrome vanadium steel) and finished goods.

- Establish safety stock levels based on historical demand and seasonal trends.

H2: Compliance Requirements

- Regulatory Certifications

- CE Marking (EU): Required for tools sold in the European Economic Area. Compliance with Machinery Directive 2006/42/EC and relevant EN standards (e.g., EN ISO 17457 for hand tools) is mandatory.

- UKCA Marking (UK): Required for tools placed on the market in Great Britain (England, Wales, Scotland). Follow UK regulations post-Brexit.

- ANSI/ASME Standards (USA): While not federally mandated, conformance to ASME B107.100 (Hand Tool Standards) is strongly recommended for market acceptance.

-

RoHS Compliance (EU/UK/China): Ensure restricted substances (e.g., lead, cadmium) are below threshold limits in metal components and coatings.

-

Product Safety & Labeling

- Include user instructions in local languages with safety warnings (e.g., “Use eye protection,” “Do not exceed torque rating”).

- Mark wrench with size, material type (e.g., Cr-V), and manufacturer ID.

-

Comply with CPSIA (Consumer Product Safety Improvement Act) if sold in the U.S. consumer market.

-

Customs & Trade Compliance

- HS Code: 8207.50 (Tools for working in the hand, of which the cutting or working parts are interchangeable; socket wrenches and handles therefor).

- Provide accurate commercial invoices, packing lists, and certificates of origin.

- Comply with import regulations in target markets (e.g., FDA not applicable; CBP requirements in U.S.).

-

Monitor export controls—generally not subject to ITAR or EAR, but verify based on materials and destination.

-

Environmental & Sustainability

- Comply with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in the EU.

- Follow WEEE (Waste Electrical and Electronic Equipment) guidelines if the wrench includes electronic components (rare).

-

Provide end-of-life disposal guidance: Recycle as scrap metal through authorized facilities.

-

Documentation & Recordkeeping

- Maintain technical files for CE/UKCA compliance (including risk assessments, test reports).

- Keep records of supplier certifications (e.g., material mill test reports).

- Retain shipping and customs documentation for minimum of 5 years (varies by country).

Note: Always consult local regulatory authorities or legal counsel for jurisdiction-specific requirements, especially when entering new markets. Regularly review updates to standards and trade agreements affecting tool imports/exports.

In conclusion, sourcing an O2 sensor socket wrench requires careful consideration of compatibility, quality, and application needs. This specialized tool is essential for safely removing and installing oxygen sensors without damaging the sensor or surrounding components. When selecting a socket wrench, prioritize features such as a secure fit, durable construction (typically chrome vanadium steel), protective slots for sensor wires, and compatibility with common drive sizes (8mm, 12-point, or universal designs).

Sourcing options include automotive specialty retailers, online marketplaces (such as Amazon, eBay, or automotive tool suppliers), and local auto parts stores. Reading customer reviews, comparing prices, and verifying tool specifications can help ensure you obtain a reliable and long-lasting product. Additionally, investing in a reputable brand often pays off in terms of performance and durability.

Ultimately, having the right O2 sensor socket wrench simplifies maintenance tasks, reduces the risk of costly sensor damage, and improves overall efficiency—making it a worthwhile addition to any mechanic’s toolkit.