The global transmission systems market is experiencing steady growth, driven by increasing demand for heavy-duty and performance-focused vehicles, particularly in off-road and commercial applications. According to Grand View Research, the global automotive transmission market was valued at USD 175.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. A key segment within this market is manual transmissions designed for rugged, four-wheel-drive (4WD) applications—such as the NV4500, a robust five-speed manual gearbox widely used in trucks and off-road vehicles due to its durability and torque-handling capacity. As demand for reliable drivetrain components rises among OEMs and aftermarket suppliers, a select group of manufacturers has emerged as leaders in producing high-performance NV4500 4WD transmission systems. Based on production quality, market presence, technical innovation, and customer reviews, the following eight manufacturers represent the top players shaping the NV4500 transmission landscape today.

Top 8 Nv4500 4Wd Transmission Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

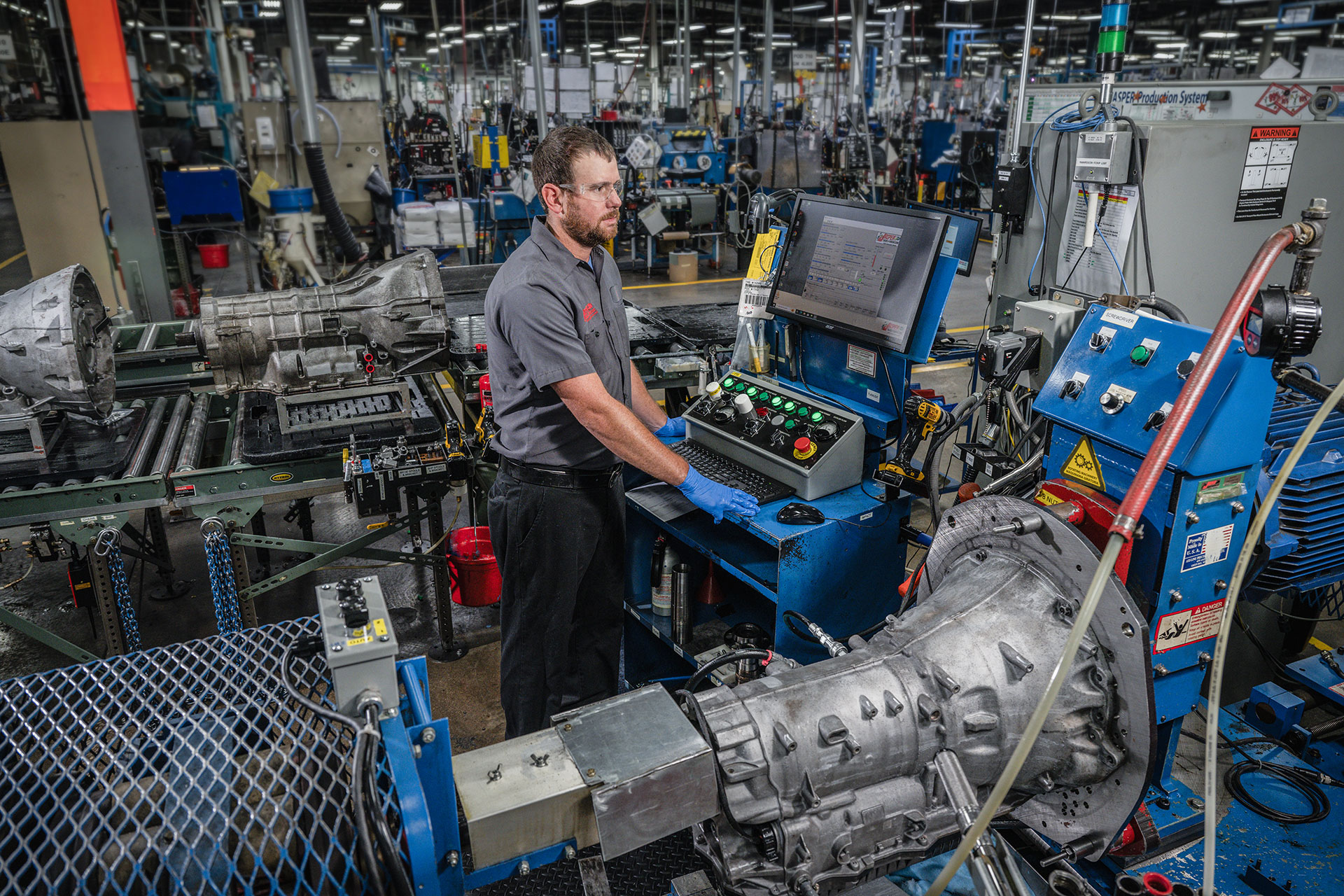

#1 JASPER® Engines & Transmissions

Domain Est. 1996

Website: jasperengines.com

Key Highlights: JASPER’s remanufactured automatic and standard transmissions are designed for your peace of mind. You don’t have to worry about your bill growing….

#2 1. NV4500 Specifications

Domain Est. 1996

Website: advanceadapters.com

Key Highlights: The NV4500 is a constant mesh helical geared, heavy-duty five-speed manual transmission. All forward gears are fully synchronized….

#3 NV4500 5-Speed Manual Transmission

Domain Est. 2001

Website: midwesttrans.com

Key Highlights: The NV4500 is a five speed, RWD or 4WD transmission. The NV4500 is a New Venture engineering design, this transmission is an end loaded cast iron case with ……

#4 Rebuilt NV4500 5 Speeds comes with Free Shipping & Core Return

Domain Est. 2001

Website: high-impact.net

Key Highlights: The NV4500 transmission is generally considered to be the most robust and reliable 5 speed transmission ever supplied in pickup trucks (up to 1 Ton)….

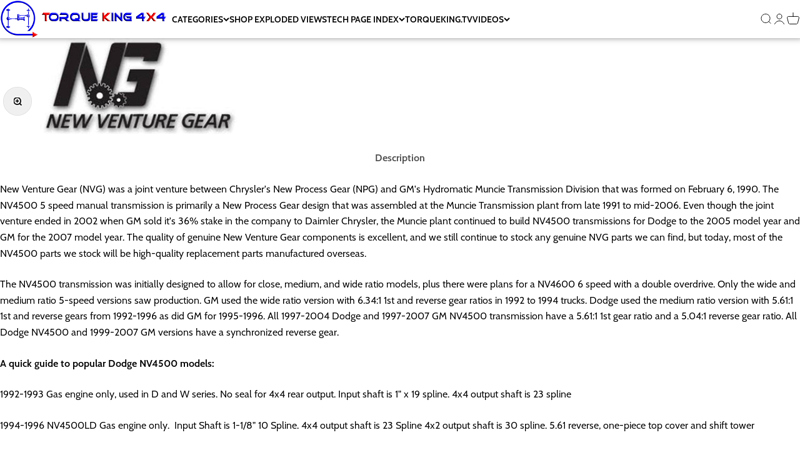

#5 New Venture NV4500 History

Domain Est. 2005

Website: torqueking.com

Key Highlights: The NV4500 5 speed manual transmission is primarily a New Process Gear design that was assembled at the Muncie Transmission plant from late 1991 to mid-2006….

#6 NV4500 Manual Transmission for 5 SPD, 4WD

Domain Est. 2014

Website: randysworldwide.com

Key Highlights: In stock $372.33 delivery 120-day returns…

#7 Remanufactured NV4500 Transmission

Domain Est. 2015

Website: streetsmarttransmission.com

Key Highlights: We provide an out-the-door price, with shipping, for a replacement remanufactured NV4500 transmission direct to the repair shop….

#8 NV4500 Manual Transmission for GM 99

Domain Est. 2017

Website: rigidaxle.com

Key Highlights: In stock Free deliveryNV4500 Manual Transmission for GM 99-04 Pickup, 4wd. $7,235.00 $5,565.38. Pay over time with Affirm. See if you qualify at checkout. Part Number: RMT4500C-9….

Expert Sourcing Insights for Nv4500 4Wd Transmission

2026 Market Trends for NV4500 4WD Transmission

As the automotive industry continues to evolve toward electrification and advanced drivetrain technologies, the market for legacy manual transmissions like the NV4500 4WD is undergoing significant transformation. Originally developed by New Venture Gear and widely used in light-duty trucks from General Motors, Dodge, and Ford during the 1990s and early 2000s, the NV4500 remains a staple in the aftermarket and off-road communities. This analysis explores the key market trends expected to shape the demand, availability, and usage of the NV4500 4WD transmission by 2026.

Declining OEM Use and Production

By 2026, original equipment manufacturer (OEM) production and integration of the NV4500 transmission will have ceased for over two decades. Automakers have shifted toward automated manual, dual-clutch, and advanced automatic transmissions, particularly in 4WD and off-road platforms. The transition reflects consumer demand for improved fuel efficiency, smoother driving experiences, and integration with driver-assistance technologies—none of which align with the NV4500’s mechanical design. As such, the NV4500 will exist almost exclusively in the secondary and restoration markets.

Growth in the Aftermarket and Custom Vehicle Sector

Despite its discontinuation, the NV4500 is expected to maintain strong demand in the aftermarket and custom fabrication sectors. Enthusiasts restoring older trucks—particularly GM’s C/K series, Dodge Rams, and Ford F-Series from the mid-1990s to early 2000s—continue to seek out durable, repairable transmissions. The NV4500’s ruggedness, torque capacity (up to 450 lb-ft), and straightforward design make it a preferred choice for off-road builds and diesel engine swaps. By 2026, this niche market is likely to grow as vintage truck values rise and customization becomes more popular.

Increased Demand for Rebuilt and Upgraded Units

With the original NV4500 units aging, the market for rebuilt, remanufactured, and performance-upgraded transmissions is expanding. Specialized shops now offer overhauled NV4500 units with improved synchronizers, stronger input shafts, and overdrive upgrades to enhance drivability. By 2026, demand for these enhanced versions is projected to rise, driven by a combination of aging vehicle fleets and the popularity of retro-modding. Companies offering warranty-backed remanufactured NV4500s are likely to see increased market share.

Parts Scarcity and Rising Prices

As the NV4500’s production base diminishes, sourcing original parts will become increasingly difficult. By 2026, key components such as shift forks, mainshafts, and tail housings may face supply constraints, leading to price inflation. This scarcity is expected to incentivize third-party manufacturing of reproduction parts, especially from companies catering to the restoration and off-road communities. However, quality control and compatibility with original specifications will remain concerns.

Integration with Alternative Powertrains

A notable trend by 2026 will be the adaptation of the NV4500 for use in hybrid or alternative fuel conversions. While not designed for modern EV integration, some DIY builders are retrofitting the NV4500 into electric truck conversions where manual control and mechanical engagement are desired. Though this remains a fringe application, it reflects the transmission’s enduring mechanical appeal and versatility in non-standard drivetrain configurations.

Conclusion

While the NV4500 4WD transmission no longer plays a role in modern OEM vehicle production, its legacy ensures continued relevance in specialty markets. By 2026, its value will be driven by collector interest, aftermarket support, and its reputation for durability in off-road and high-torque applications. However, increasing parts scarcity and rising costs may challenge long-term accessibility. Overall, the NV4500 is expected to remain a sought-after component for enthusiasts, but its market will remain niche and increasingly reliant on remanufacturing and restoration ecosystems.

Common Pitfalls When Sourcing an NV4500 4WD Transmission

Sourcing a reliable NV4500 4WD transmission for your truck build or repair can be tricky. While this robust manual transmission is highly regarded for its durability and aftermarket support, several pitfalls can catch buyers off guard—especially regarding quality and identifying the correct input shaft (IP). Understanding these issues can save time, money, and frustration.

Inconsistent Rebuild Quality

One of the most common issues when sourcing an NV4500 is encountering rebuilds of questionable quality. Many units sold online or through junkyards are advertised as “rebuilt” or “tested,” but may use worn or mismatched internal components. Poorly rebuilt transmissions often suffer from premature gear wear, synchro failure, or bearing noise due to improper tolerances or substandard parts. Always verify the reputation of the rebuilder and, if possible, request documentation of the rebuild process and parts used.

Misrepresentation of Mileage and Condition

Used NV4500 transmissions are frequently sold with inaccurate or unknown mileage. Some sellers claim low mileage or “excellent condition” without providing proof. A transmission pulled from a high-mileage or hard-used truck may have internal wear that isn’t immediately apparent. Inspect for external signs of leaks, damaged mounting ears, or a worn shift tower. Whenever possible, request service records or purchase from a trusted source with a return policy.

Incorrect Input Shaft Length (IP)

The NV4500 4WD transmission came with different input shaft lengths depending on the application (e.g., GM vs. Dodge/Ram). The two most common input shaft types are:

- GM 4WD NV4500: Typically uses a 1-1/8″ 10-spline input shaft with a shorter length.

- Dodge 4WD NV4500: Uses a 1-1/4″ 23-spline input shaft, longer than the GM version.

Purchasing the wrong input shaft configuration results in drivetrain incompatibility—your clutch disc won’t fit, or the input shaft won’t properly engage with the engine’s pilot bearing. Always confirm the input shaft spline count, diameter, and length before buying, especially when swapping between GM and Dodge platforms.

Missing or Damaged Parts

Used or surplus NV4500 units are often sold incomplete. Critical components like the shift tower, shift rails, speed sensor, or tailhousing may be missing or damaged. Some sellers remove valuable parts before listing. Confirm what’s included in the sale and inspect for stripped mounting holes or cracked housings—common issues in older units from trucks used for heavy towing.

Lack of Transfer Case Compatibility Verification

The NV4500 4WD transmission must interface correctly with the transfer case (e.g., NP241, NP231). Differences in output shaft spline count (e.g., 23-spline vs. 27-spline) and mounting patterns can create compatibility issues. Ensure the transmission you source matches your intended transfer case, or budget for necessary adapters and modifications.

Counterfeit or Non-OEM Parts in Rebuilds

Some low-cost rebuilds use aftermarket gears, bearings, or synchros that don’t meet OEM specifications. While some aftermarket parts are reliable, others can lead to noise, reduced lifespan, or failure under load. Ask if the rebuild uses OEM-spec or high-quality aftermarket components, especially if you plan on towing or off-road use.

Conclusion

To avoid these pitfalls, buy from reputable suppliers, verify input shaft specs, and insist on transparency about condition and rebuild quality. Taking the time to confirm compatibility and inspect the unit thoroughly will ensure your NV4500 4WD transmission performs reliably for years.

Logistics & Compliance Guide for NV4500 4WD Transmission

Overview

The NV4500 4WD transmission is a heavy-duty manual gearbox commonly used in light to medium-duty trucks, such as those manufactured by GM, Dodge, and Ford. Proper logistics handling and compliance with regulatory standards are essential for safe transport, storage, and installation. This guide outlines key considerations for logistics operations and regulatory compliance when managing the NV4500 4WD transmission.

Packaging & Handling Requirements

Ensure the NV4500 transmission is properly packaged to prevent damage during transit. Use a sturdy wooden crate or reinforced cardboard container with internal foam or padding to secure the unit. Always lift using appropriate equipment—such as a transmission jack or overhead hoist—grasping the case at designated lifting points. Avoid lifting by input/output shafts or linkage components to prevent internal damage.

- Palletization: Secure the transmission to a standard 48″x40″ pallet using strapping or shrink wrap.

- Orientation: Store and transport in an upright position to prevent fluid leakage and seal compromise.

- Labeling: Clearly label with “Fragile,” “This Side Up,” and part number (e.g., 1234567890-XX). Include handling instructions and weight (approximately 140–150 lbs).

Transportation & Shipping

Use freight carriers experienced in handling automotive components. For domestic U.S. shipments, comply with DOT (Department of Transportation) regulations for freight classification (typically NMFC 150, Class 85). International shipments must conform to IMDG (International Maritime Dangerous Goods) Code if lubricants are present, though dry units are generally non-hazardous.

- Mode of Transport: Suitable for truck, rail, or air freight. For air transport, verify weight and dimensional restrictions.

- Documentation: Include a commercial invoice, packing list, and bill of lading. For exports, provide an ECCN (Export Control Classification Number); the NV4500 typically falls under EAR99 (no license required for most destinations).

- Environmental Protection: Ensure seals are intact and breather plug is capped to prevent moisture or contaminant ingress.

Storage Conditions

Store the NV4500 transmission in a dry, climate-controlled environment with temperatures between 32°F (0°C) and 104°F (40°C). Relative humidity should not exceed 70% to prevent condensation and corrosion. Keep units off the floor on pallets or racks and away from direct sunlight or chemical exposure.

- Shelf Life: No strict expiration, but inspect seals and gaskets after prolonged storage (>12 months).

- Inventory Management: Use FIFO (First In, First Out) rotation to maintain part integrity.

Regulatory Compliance

Adherence to federal, state, and international regulations is mandatory for legal distribution and use.

- EPA & CARB Compliance: While the NV4500 itself is not emission-controlled, ensure it is installed in vehicles meeting EPA and California Air Resources Board (CARB) standards where applicable.

- DOT Safety Standards: Installations must comply with FMVSS (Federal Motor Vehicle Safety Standards), particularly regarding driveline shielding and vehicle integrity.

- REACH & RoHS (EU): Confirm material compliance if exporting to the European Union. The NV4500, as a mechanical component, typically meets RoHS exemption criteria (category 11) but verify with manufacturer documentation.

- Customs Declarations: Accurately classify under HTS Code 8708.40.60 (transmissions for motor vehicles) for U.S. import/export.

Installation & Aftermarket Compliance

When used in replacement or custom applications (e.g., vehicle swaps), ensure compliance with local motor vehicle regulations.

- Emissions Legality: Modifications involving engine-transmission pairing may require certification, particularly in states like California.

- Safety Inspections: Modified vehicles may need to pass state safety and emissions inspections.

- Documentation: Maintain records of transmission origin, installation date, and compliance certifications for audit purposes.

Disposal & Environmental Responsibility

At end-of-life, the NV4500 should be recycled responsibly.

- Drain Fluids: Remove all transmission fluid (typically 4–5 quarts of gear oil) in accordance with local environmental regulations. Used oil must be recycled or disposed of via licensed facilities.

- Metal Recycling: The cast aluminum and iron components are recyclable. Partner with certified metal recyclers compliant with EPA and OSHA standards.

- Hazardous Waste: Gaskets or seals containing regulated substances (e.g., PCBs in older units) must be handled as hazardous waste if present.

Conclusion

Proper logistics handling and strict compliance with regulatory standards ensure the safe and legal lifecycle management of the NV4500 4WD transmission. Adhering to packaging, transport, storage, and disposal guidelines minimizes risk, supports environmental responsibility, and maintains regulatory conformity across domestic and international operations.

In conclusion, sourcing an NV4500 4WD transmission requires careful consideration of compatibility, condition, and application requirements. Whether purchasing new, used, or rebuilt, it is essential to verify the transmission’s model year, input shaft size, bellhousing pattern, and tailshaft configuration to ensure proper fitment with your specific vehicle and drivetrain setup. Reputable suppliers, thorough inspections, and a clear understanding of your performance or towing needs will help ensure a reliable and long-lasting installation. Additionally, factoring in potential upgrades—such as a custom shifter, stronger output shaft, or enhanced clutch system—can improve durability and performance. With the NV4500’s proven reputation for strength and dependability in heavy-duty applications, a well-sourced unit can provide excellent service for high-torque diesel and performance gasoline engines in both on- and off-road environments.