The global notcher machine market is experiencing steady growth, driven by increasing demand for precision metal fabrication across industries such as automotive, construction, and manufacturing. According to Mordor Intelligence, the metal fabrication equipment market—which includes notcher machines—is projected to grow at a CAGR of over 4.5% from 2023 to 2028. Similarly, Grand View Research reports that the global metal processing machinery market was valued at USD 95.6 billion in 2022 and is expected to expand at a CAGR of 5.2% through 2030, fueled by automation trends and rising industrialization. As fabrication accuracy and efficiency become critical competitive advantages, notcher machines have evolved with advanced CNC controls, improved tooling systems, and enhanced integration capabilities. With market demand on the rise, identifying leading manufacturers who deliver innovation, durability, and performance is essential for businesses aiming to optimize their metalworking operations. Here are the top 9 notcher machine manufacturers shaping the industry today.

Top 9 Notcher Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

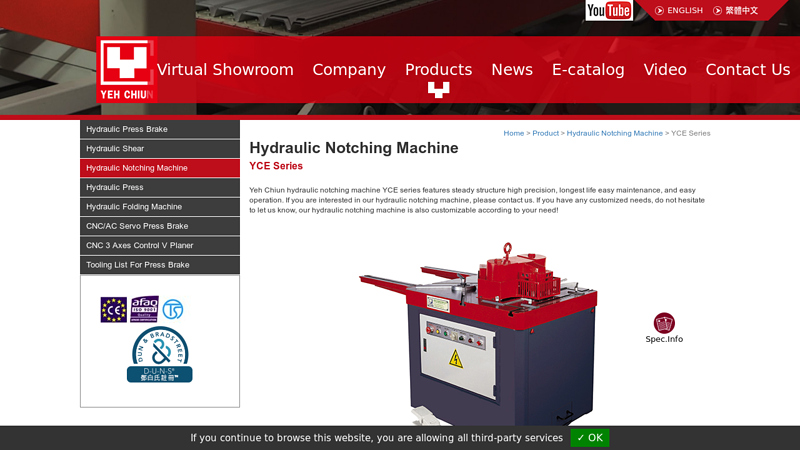

#1 Hydraulic Notching Machine

Domain Est. 2000

Website: yehchiun.com

Key Highlights: As a notching machinery manufacturer, we provide YCE series hydraulic notching machine with a steady structure high precision, longest life easy maintenance ……

#2 Pneumatic Corner Notcher

Domain Est. 2001

#3 Scotchman Industries

Domain Est. 1996

Website: scotchman.com

Key Highlights: Create the perfect notch in seconds with Scotchman’s lineup of tube and pipe notchers. We offer Manual, Electric, and Abrasive Grinder/Notcher models ……

#4 Angle Notcher

Domain Est. 1997

Website: edwardsironworkers.com

Key Highlights: Out of stockDesigned for the Edwards 65, 75, 100 Ton, Elite 110, and Elite 100/65 Ton Ironworkers, this Angle Notching machine takes a precise 92° notch out of mild steel….

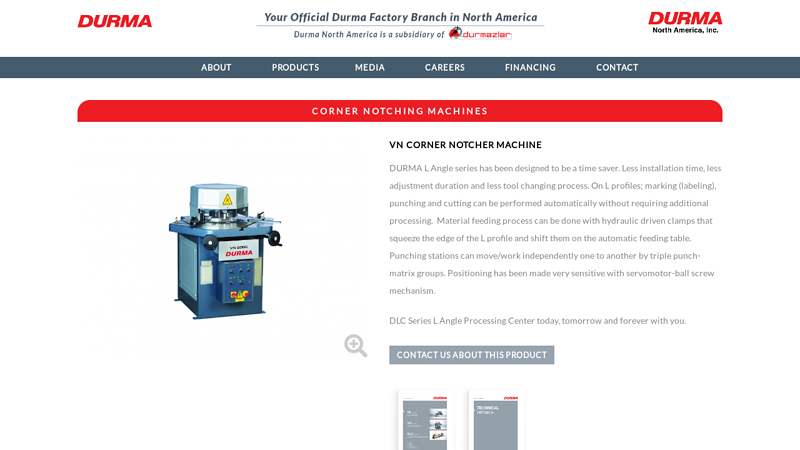

#5 Corner Notching Machines

Domain Est. 2010

Website: durmanorthamerica.com

Key Highlights: VN Corner Notcher Machine. DURMA L Angle series has been designed to be a time saver. Less installation time, less adjustment duration and less tool changing ……

#6 Boschert Metal Notching Machinery

Domain Est. 2010

Website: carlsonfab.com

Key Highlights: The world’s best notchers with variable angle. Patented TriGide ram guidance for exceptional blade life, better cuts and virtually maintenance free….

#7 Notchers

Domain Est. 2014

Website: gofastmfg.com

Key Highlights: Go Fast Notchers are built with the highest quality standards, continued innovation and focused on solutions for your operation….

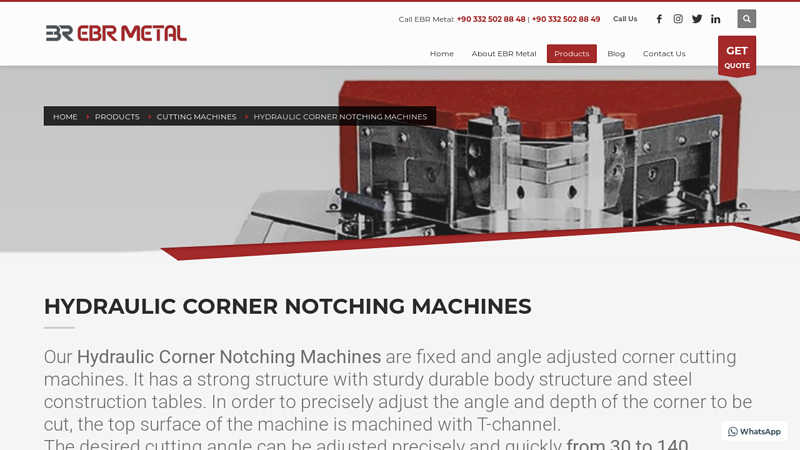

#8 Hydraulic Corner Notching Machines

Domain Est. 2016

Website: ebrmetal.com

Key Highlights: Our Hydraulic Corner Notching Machines are fixed and angle adjusted corner cutting machines. It has a strong structure with sturdy durable body structure….

#9 Tube notching equipment

Domain Est. 2019

Website: gekaus.com

Key Highlights: Tube notching equipment, designed to provide precision and efficiency in shaping tubes for various metalworking applications….

Expert Sourcing Insights for Notcher Machine

H2: Market Trends Shaping the Notcher Machine Industry in 2026

By 2026, the notcher machine market is poised for significant transformation, driven by evolving manufacturing demands, technological advancements, and broader industrial trends. Here’s an analysis of the key H2 market trends:

1. Heightened Demand for Precision and Automation

- Trend: Manufacturers across aerospace, automotive, and precision engineering sectors will increasingly require tighter tolerances and repeatable accuracy in sheet metal and tube notching.

- Impact on Notcher Machines: Machine manufacturers will prioritize integration of advanced CNC controls, servo-driven systems, and closed-loop feedback mechanisms. Fully automated notcher cells with robotic loading/unloading will become standard in high-volume production environments.

2. Integration with Smart Manufacturing and Industry 4.0

- Trend: The proliferation of IoT, data analytics, and interconnected factory systems will push machine tools toward smarter operations.

- Impact on Notcher Machines: Notcher machines will feature embedded sensors for real-time monitoring of tool wear, material alignment, and machine health. Cloud-connected platforms will enable remote diagnostics, predictive maintenance, and seamless integration with MES (Manufacturing Execution Systems) for optimized workflow.

3. Growth in Customization and Flexibility

- Trend: Market demand for customized and low-volume/high-mix production will continue to rise, especially in niche fabrication and prototyping.

- Impact on Notcher Machines: Modular notcher designs and quick-change tooling systems will gain prominence. Machines capable of handling diverse materials (steel, aluminum, composites) and thicknesses with minimal setup time will have a competitive edge.

4. Sustainability and Energy Efficiency Focus

- Trend: Regulatory pressures and corporate sustainability goals will drive demand for energy-efficient and eco-friendly manufacturing equipment.

- Impact on Notcher Machines: Manufacturers will develop notcher machines with lower power consumption, reduced noise emissions, and recyclable components. Emphasis will grow on minimizing material waste through optimized nesting and precision cutting.

5. Expansion in Renewable Energy and EV Infrastructure

- Trend: The global push for clean energy and electric vehicles will boost fabrication needs for solar racking, wind turbine components, and EV battery enclosures.

- Impact on Notcher Machines: These sectors require robust, high-speed notching for structural supports and chassis components. Notcher machines designed for heavy-duty, continuous operation with high durability will see increased adoption.

6. Adoption of Hybrid and Multi-Function Systems

- Trend: Fabricators are seeking space-saving, cost-effective solutions that combine multiple processes.

- Impact on Notcher Machines: We’ll see growth in hybrid machines that integrate notching with punching, bending, or laser cutting. These all-in-one systems improve throughput and reduce material handling.

7. Regional Market Shifts and Supply Chain Localization

- Trend: Geopolitical factors and supply chain resilience concerns are accelerating manufacturing localization, particularly in North America and Southeast Asia.

- Impact on Notcher Machines: Regional demand will grow outside traditional markets, prompting OEMs to expand local service networks and offer region-specific machine configurations.

Conclusion:

By 2026, the notcher machine market will be defined by intelligence, integration, and adaptability. Success will depend on manufacturers’ ability to deliver precision automation solutions that align with Industry 4.0, support sustainable practices, and meet the dynamic needs of advanced fabrication industries. Companies investing in digitalization, flexible design, and energy efficiency will lead the market.

Common Pitfalls Sourcing a Notcher Machine (Quality, IP)

Sourcing a notcher machine, especially from international or less-established suppliers, involves several risks related to both product quality and intellectual property (IP). Being aware of these pitfalls can help avoid costly mistakes and operational disruptions.

Poor Build Quality and Performance

One of the most frequent issues when sourcing notcher machines is receiving equipment with substandard construction. Low-cost suppliers may use inferior materials, imprecise machining, or inadequate welding, leading to premature wear, inconsistent notching accuracy, and frequent breakdowns. This results in increased downtime, higher maintenance costs, and compromised production quality.

Lack of Quality Control and Testing

Many manufacturers, particularly in emerging markets, may lack rigorous quality assurance processes. Machines might be shipped without thorough testing under real-world conditions, meaning performance issues or safety hazards only become apparent after installation. This can delay production and require expensive modifications or replacements.

Misrepresentation of Technical Specifications

Suppliers sometimes exaggerate machine capabilities—such as tonnage, stroke rate, maximum material thickness, or notch precision—to win contracts. Buyers may discover too late that the machine cannot handle the required workload or material types, leading to inefficiencies or unsafe operating conditions.

Inadequate or Missing Documentation

Poorly documented machines—missing operation manuals, maintenance guides, electrical schematics, or CE/UL certification—pose significant risks. Lack of documentation complicates installation, training, troubleshooting, and compliance with local safety regulations, potentially exposing the buyer to legal or operational liabilities.

Intellectual Property Infringement

A serious but often overlooked risk is purchasing a notcher machine that infringes on existing patents or design rights. Some manufacturers replicate branded designs without authorization, offering “look-alike” machines at lower prices. Buyers risk being implicated in IP violations, facing legal action, customs seizures, or forced equipment removal, especially in regions with strict IP enforcement.

Counterfeit or Branded Knock-offs

Suppliers may falsely claim association with reputable brands or use logos and model numbers that mimic well-known manufacturers. These counterfeit machines not only lack the reliability of genuine equipment but also void warranties and support, while exposing the buyer to reputational and legal risks.

Hidden Costs from Poor After-Sales Support

Even if the initial price is attractive, poor after-sales service—including limited spare parts availability, unresponsive technical support, or language barriers—can significantly increase total cost of ownership. Downtime due to unavailable components or lack of expertise to perform repairs impacts productivity and profitability.

Non-Compliance with Regional Safety and Environmental Standards

Notcher machines sourced internationally may not meet the safety, noise, or emissions standards of the buyer’s country (e.g., EU Machinery Directive, OSHA in the U.S.). Importing non-compliant equipment can lead to fines, operational shutdowns, or costly retrofits to achieve compliance.

Conclusion

To mitigate these risks, conduct thorough due diligence: verify supplier credentials, request machine testing or third-party inspections, review all technical and legal documentation, and consult IP databases if considering a branded design. Investing time upfront can prevent long-term quality and legal complications.

Logistics & Compliance Guide for Notcher Machine

This guide provides essential information for the safe, efficient, and compliant handling, transport, installation, and operation of the Notcher Machine. Adherence to these guidelines ensures regulatory compliance, minimizes risks, and supports optimal machine performance.

Shipping & Transportation

- Packaging: The Notcher Machine must be shipped in its original manufacturer-approved packaging, including protective foam, wooden crating, and moisture barriers (if applicable). Ensure all loose components are secured and labeled.

- Weight & Dimensions: Confirm the machine’s gross weight and external dimensions before transport. Use this data to select appropriate lifting equipment and transportation vehicles.

- Lifting Points: Only use designated lifting points indicated in the manual. Never lift by control panels, hoses, or structural components not rated for lifting.

- Transport Orientation: Maintain the machine in the upright position as specified by the manufacturer during all transport stages. Tipping may damage internal components or hydraulic systems.

- Documentation: Provide a complete bill of lading, packing list, and commercial invoice (for international shipments). Include machine model, serial number, and HS code (e.g., 8461.50 for mechanical presses).

Import/Export Compliance

- Regulatory Classification: Verify correct HS (Harmonized System) code classification. Common classifications for notcher machines fall under Chapter 84 (Nuclear Reactors, Boilers, Machinery).

- Export Controls: Check export regulations (e.g., EAR in the U.S.) to determine if the machine or its components require an export license, especially if incorporating advanced automation or dual-use technology.

- Certifications: Ensure the machine complies with destination country standards (e.g., CE for EU, UKCA for the UK, CCC for China). Maintain copies of all conformity certificates (e.g., CE Declaration of Conformity).

- Customs Clearance: Submit required documentation, including Certificate of Origin, Commercial Invoice, Packing List, and Bill of Lading/Air Waybill. Use a licensed customs broker if necessary.

Installation Requirements

- Site Preparation: Ensure the installation area is level, clean, and has adequate floor load capacity (refer to machine specifications). Allow recommended clearance around the machine for maintenance and ventilation.

- Power Supply: Match input voltage, phase, and frequency to local electrical standards. Provide dedicated circuitry with appropriate grounding and overcurrent protection.

- Utilities: Confirm availability of required utilities (e.g., compressed air, coolant, hydraulic fluid) at specified pressure and flow rates.

- Environmental Conditions: Install in an environment within the machine’s operating temperature (e.g., 10°C–40°C) and humidity range. Avoid exposure to dust, moisture, or corrosive atmospheres.

Safety & Operational Compliance

- Machine Guarding: Ensure all safety guards, interlocks, and emergency stops are fully installed and functional before operation. Never bypass safety systems.

- Operator Training: Only trained and authorized personnel should operate the machine. Provide training on proper use, emergency procedures, and lockout/tagout (LOTO).

- Risk Assessment: Perform a site-specific risk assessment in compliance with local OSH regulations (e.g., OSHA in the U.S., HSE in the UK). Document mitigation measures.

- Noise & Emissions: Monitor noise levels; provide hearing protection if above 85 dB(A). Ensure proper ventilation if fumes or particulates are generated during operation.

Maintenance & Documentation

- Scheduled Maintenance: Follow the manufacturer’s maintenance schedule for lubrication, inspection, and part replacement. Keep a log of all maintenance activities.

- Spare Parts: Use only OEM or certified replacement parts to maintain compliance and warranty validity.

- Record Keeping: Maintain records of inspections, repairs, safety checks, operator training, and regulatory certifications for audit purposes.

- Decommissioning: At end-of-life, dispose of the machine in accordance with local environmental regulations (e.g., WEEE directive in the EU). Recycle components where possible.

Regulatory References

- ISO 12100:2010 – Safety of machinery – General principles for design

- ISO 13849-1 – Safety-related parts of control systems

- Local electrical codes (e.g., NEC, IEC 60204-1)

- Applicable regional directives (e.g., EU Machinery Directive 2006/42/EC)

For questions or compliance verification, contact the manufacturer or a certified industrial compliance consultant.

Conclusion for Sourcing a Notcher Machine:

After thorough evaluation of available options, technical specifications, supplier reliability, pricing, and after-sales support, sourcing a notcher machine is a strategic investment that will significantly enhance fabrication efficiency and precision in metalworking operations. The selected machine meets all required specifications in terms of capacity, durability, and ease of integration into existing production workflows. Additionally, the chosen supplier offers competitive pricing, timely delivery, comprehensive training, and dependable service support, ensuring long-term operational reliability.

In conclusion, procuring the recommended notcher machine will improve productivity, reduce material waste, and support the production of high-quality components, ultimately contributing to increased operational efficiency and customer satisfaction. This acquisition aligns with our manufacturing goals and positions the company for future scalability and growth.