The global non-slip epoxy coatings market is experiencing robust growth, driven by increasing demand for durable, safe, and low-maintenance flooring solutions in both residential and commercial applications. According to Grand View Research, the global epoxy resins market size was valued at USD 9.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is largely fueled by rising construction activities and heightened awareness of safety in wet environments such as bathrooms, kitchens, and healthcare facilities. Mordor Intelligence further projects a CAGR of approximately 6.5% for the epoxy coatings market through 2028, citing strong adoption in the building and infrastructure sector. With showers being one of the most high-risk areas for slips and falls, non-slip epoxy coatings have become a preferred solution for enhancing traction and longevity in shower floors. As demand surges, a select group of manufacturers have emerged as leaders in innovation, performance, and reliability—setting industry benchmarks for quality and safety. Here are the top 8 non-slip epoxy manufacturers leading this dynamic segment.

Top 8 Non Slip Epoxy For Shower Floor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 High Performance Flooring

Domain Est. 1998

Website: industrial.sherwin-williams.com

Key Highlights: Sherwin-Williams High Performance Flooring offers durable, seamless resinous systems for commercial and industrial applications. Get in touch with us today!…

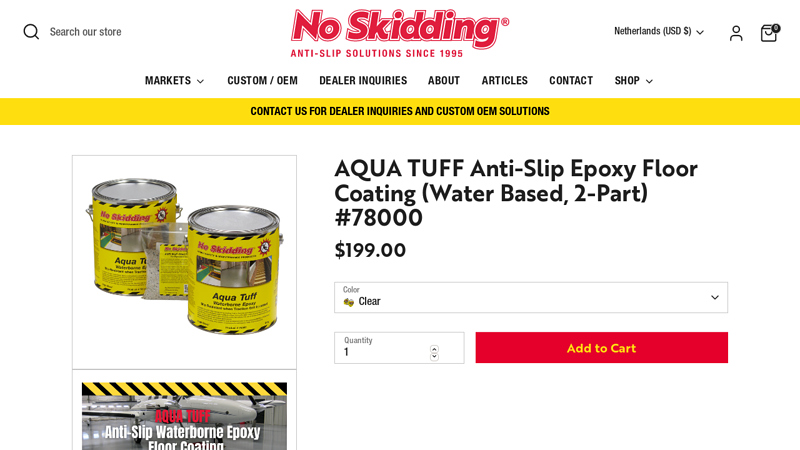

#2 AQUA TUFF Anti

Domain Est. 1997

#3 STOP

Domain Est. 1999

Website: garonproducts.com

Key Highlights: Stop-Slip™ HD is a 98% solids, heavy-duty non-slip epoxy coating engineered to enhance traction and safety in wet, slippery, or high-traffic environments….

#4 Do

Domain Est. 2002

Website: safetydirectamerica.com

Key Highlights: Free delivery over $119 21-day returnsWe offer anti-slip floor coatings that create non-skid surfaces for pool decks, garages, outdoor walkways, showers, tubs, & more. Safe & easy …

#5 Daich Real Stone Coatings

Domain Est. 2002

Website: daichcoatings.com

Key Highlights: Plus we also manufacture a full range of primers, waterproofers, sealers and epoxy floor systems. … Anti-Slip Floor Coatings. TracSafe’s high performance sealer ……

#6 Sure Step Non-Slip: Non-Slip Services

Domain Est. 2005

Website: surestepnonslip.com

Key Highlights: Our non-slip services and products have been formulated and proven effective for almost every floor and tub surface imaginable. Contact us now!…

#7 Anti

Domain Est. 2009

#8 Locker Room Flooring

Domain Est. 2014

Expert Sourcing Insights for Non Slip Epoxy For Shower Floor

2026 Market Trends for Non-Slip Epoxy for Shower Floor

The market for non-slip epoxy coatings specifically designed for shower floors is poised for notable growth and transformation by 2026, driven by evolving consumer preferences, advancements in material science, and increasing emphasis on home safety and durability. This analysis explores key trends expected to shape the industry over the coming years.

Rising Demand for Home Safety and Accessibility

A major driver of the non-slip epoxy market is the growing awareness of bathroom safety, particularly among aging populations and families with young children. By 2026, the demand for slip-resistant surfaces in wet areas like showers is projected to increase significantly. With bathroom falls being a leading cause of household injuries, homeowners and contractors are prioritizing anti-slip solutions. Non-slip epoxy coatings offer a high-traction surface that reduces accident risks, aligning with universal design principles and aging-in-place trends.

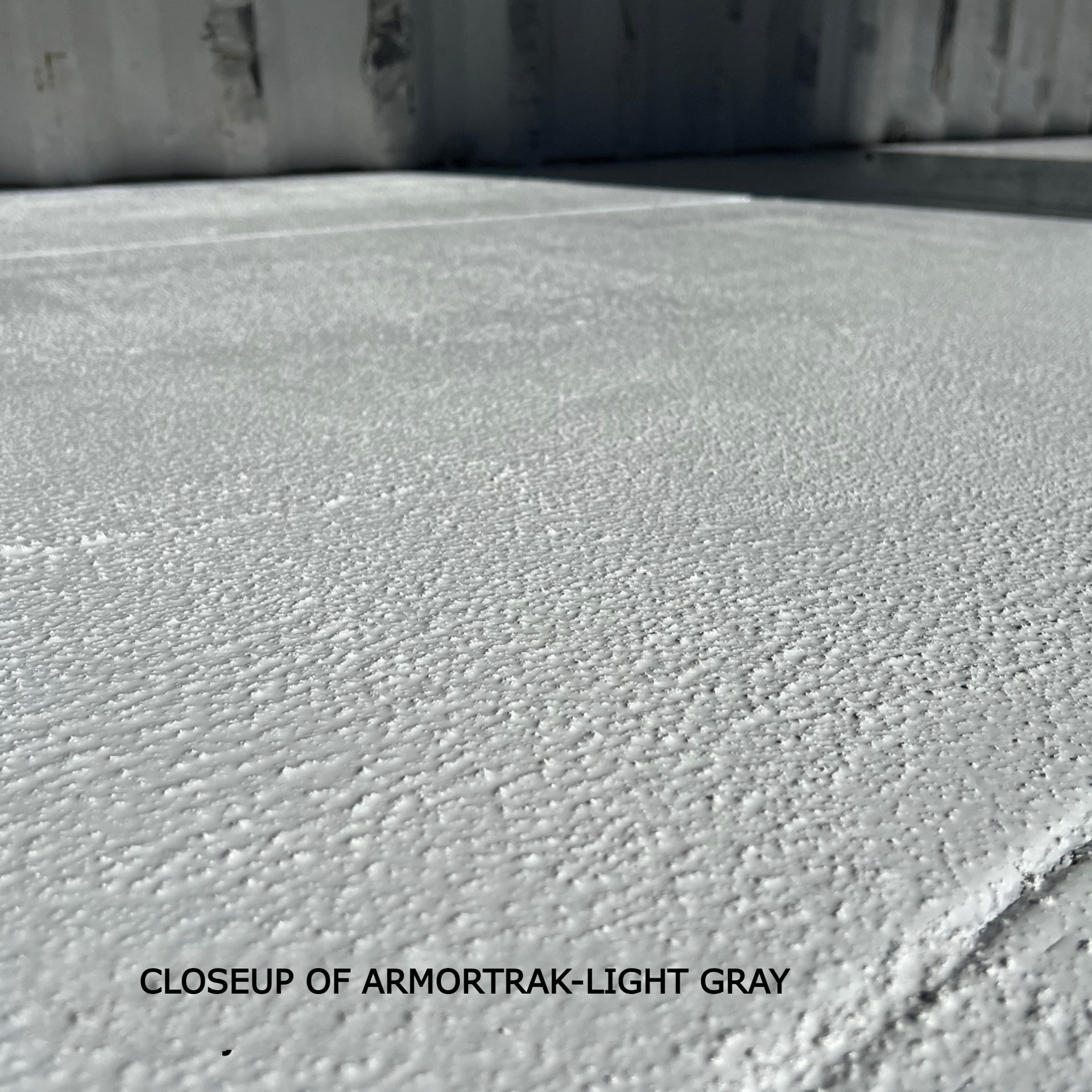

Advancements in Epoxy Formulations

Innovation in resin chemistry and aggregate integration is enhancing the performance of non-slip epoxy systems. By 2026, expect to see more eco-friendly, low-VOC (volatile organic compound) formulations that comply with tightening environmental regulations. Additionally, manufacturers are incorporating nano-textured additives and hybrid polymers to improve slip resistance without compromising aesthetics. These new-generation epoxies provide superior adhesion, faster curing times, and enhanced resistance to mold, mildew, and water penetration—critical features for shower environments.

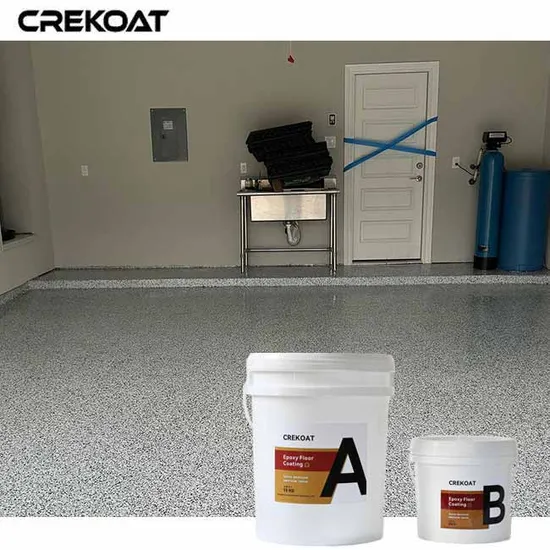

Growth in DIY and Prosumer Markets

The do-it-yourself (DIY) home improvement sector continues to expand, and non-slip epoxy kits for shower floors are becoming increasingly popular among prosumers—consumers with professional-level skills. By 2026, user-friendly epoxy kits with pre-measured components, detailed instructions, and anti-slip additives included are expected to dominate retail channels. Online tutorials, augmented reality (AR) guidance apps, and e-commerce platforms will further fuel adoption, enabling homeowners to achieve professional-looking, durable finishes without hiring contractors.

Integration with Bathroom Renovation and Smart Home Trends

Bathroom renovations are a top home improvement priority, and shower flooring is a focal point. As homeowners invest in modern, spa-like bathrooms, non-slip epoxy offers both functional and aesthetic benefits. By 2026, customizable color options, metallic finishes, and quartz-infused epoxies will appeal to design-conscious consumers. Furthermore, integration with smart bathroom ecosystems—such as moisture sensors and automated ventilation—will enhance the longevity of epoxy floors by minimizing humidity-related degradation.

Expansion in Commercial and Multifamily Applications

Beyond residential use, the commercial sector—including hotels, gyms, assisted living facilities, and public restrooms—is increasingly adopting non-slip epoxy flooring. These venues require durable, hygienic, and code-compliant surfaces. By 2026, stricter building codes and ADA (Americans with Disabilities Act) compliance requirements will drive institutional demand for certified non-slip flooring systems, positioning epoxy as a preferred solution over traditional tiles.

Regional Market Variations and Sustainability Focus

Geographically, North America and Western Europe are expected to lead the market due to high renovation activity and safety standards. Meanwhile, the Asia-Pacific region will experience rapid growth as urbanization and middle-class expansion boost home improvement spending. Sustainability will also play a pivotal role, with consumers and regulators favoring recyclable packaging, water-based epoxies, and products with third-party certifications (e.g., Greenguard, FloorScore).

Conclusion

By 2026, the non-slip epoxy market for shower floors will be characterized by innovation, safety prioritization, and broader market accessibility. As technology improves and consumer awareness grows, non-slip epoxy is set to become a standard solution in both residential and commercial wet-area flooring, offering a compelling blend of safety, durability, and design flexibility.

Common Pitfalls When Sourcing Non-Slip Epoxy for Shower Floor (Quality & IP)

When selecting a non-slip epoxy for a shower floor, several pitfalls can compromise both the performance and safety of the installation. Paying attention to quality and intellectual property (IP) aspects is crucial to avoid long-term issues such as premature failure, slip hazards, or legal risks.

Poor Adhesion and Chemical Resistance

Many low-quality epoxy products fail to properly bond to shower substrates (e.g., concrete, cement board) or degrade when exposed to constant moisture and cleaning chemicals. Look for epoxies specifically formulated for wet environments. Verify third-party testing data for adhesion strength and resistance to water, mildew, and common bathroom cleaners.

Inadequate or Unreliable Non-Slip Performance

Some epoxies claim “non-slip” properties but do not meet recognized safety standards like ASTM E303 or DIN 51130 for slip resistance (R-rating). Avoid products without documented coefficient of friction (COF) values. Ensure the non-slip additive is integrated into the system, not just a surface spray, to maintain effectiveness over time.

Use of Counterfeit or IP-Infringing Products

Sourcing from unauthorized distributors or unknown brands risks purchasing counterfeit epoxies that mimic reputable brands but lack the patented formulations and quality controls. These may infringe on intellectual property and fail to deliver the performance expected. Always buy from authorized suppliers and verify batch traceability and manufacturer certifications.

Lack of UV or Yellowing Resistance

In bathrooms with natural light, some epoxies degrade and yellow over time due to UV exposure. Opt for products with UV stabilizers if the shower receives sunlight, and confirm this feature with technical data sheets (TDS) and warranties.

Insufficient Cure Time or Application Complexity

Low-quality or improperly formulated epoxies may have unrealistic cure times or require perfect conditions (temperature, humidity) that are hard to achieve in a bathroom. This increases the risk of improper curing, leading to bubbling, delamination, or a tacky surface. Choose systems designed for DIY or professional use with clear instructions and tolerance to typical bathroom conditions.

Missing or Incomplete Compliance Documentation

Reputable epoxy products come with full technical support, safety data sheets (SDS), and compliance certifications (e.g., VOC content, FDA compliance for indirect food contact if applicable). Avoid products lacking proper documentation, as this may indicate poor quality control or regulatory non-compliance.

By avoiding these common pitfalls and prioritizing verified quality and legitimate intellectual property, you ensure a durable, safe, and compliant non-slip epoxy shower floor.

Logistics & Compliance Guide for Non-Slip Epoxy for Shower Floor

Product Overview

Non-slip epoxy for shower floors is a two-part resin system designed to provide a durable, water-resistant, and slip-resistant surface in wet environments. This guide outlines the logistics and compliance considerations essential for safe handling, transportation, storage, and regulatory adherence.

Regulatory Compliance

Ensure all non-slip epoxy products meet relevant national and international standards. Key compliance areas include:

VOC Emissions Regulations

Verify that the epoxy formulation complies with volatile organic compound (VOC) limits under:

– U.S. EPA Architectural Coatings Rule

– California Air Resources Board (CARB) regulations

– EU Directive 2004/42/EC (Paints Directive)

Products should be labeled with VOC content (g/L) and confirm compliance with regional requirements.

Safety Data Sheet (SDS) Requirements

Maintain up-to-date Safety Data Sheets (SDS) compliant with:

– Globally Harmonized System (GHS) standards

– OSHA Hazard Communication Standard (29 CFR 1910.1200)

– REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in the EU

The SDS must include hazard classifications, first-aid measures, handling and storage instructions, and personal protective equipment (PPE) recommendations.

Slip Resistance Standards

Confirm that the cured epoxy meets recognized slip resistance standards such as:

– ANSI A137.1 for dynamic coefficient of friction (DCOF)

– ASTM E303 for skid resistance measurement

– DIN 51130 (R9–R13 ratings) for inclined ramp testing

Documentation from independent testing labs may be required for commercial or public installations.

Packaging & Labeling

Adhere to proper packaging and hazard communication protocols:

Container Specifications

- Use chemically resistant, sealed containers (typically HDPE plastic or metal)

- Ensure containers are leak-proof and compatible with epoxy resin and hardener

- Package components in correct ratios with clear labeling of Part A (resin) and Part B (hardener)

Labeling Requirements

Labels must include:

– Product name and batch/lot number

– Net quantity

– Hazard pictograms (e.g., flammable, skin irritation)

– Signal words (e.g., “Danger” or “Warning”)

– Precautionary statements and first-aid measures

– Manufacturer contact information

– Applicable certifications (e.g., GREENGUARD, FloorScore)

Storage Conditions

Proper storage is critical to maintain product integrity and safety:

Temperature Control

- Store in a cool, dry place between 60°F and 80°F (15°C–27°C)

- Avoid freezing or exposure to temperatures above 90°F (32°C)

- Protect from direct sunlight and heat sources

Shelf Life Management

- Monitor expiration dates; typical shelf life is 12–24 months when unopened

- Rotate stock using FIFO (First In, First Out) method

- Do not use expired products, as performance and curing may be compromised

Segregation & Ventilation

- Store away from oxidizers, acids, and ignition sources

- Keep in well-ventilated areas to prevent vapor accumulation

- Use secondary containment for spill prevention

Transportation Guidelines

Follow regulations for shipping hazardous materials:

Domestic (U.S.) Transport

- Classify under DOT 49 CFR as ORM-D or “Consumer Commodity” if meeting criteria

- Use UN-tested packaging for air or ground transport if required

- Include proper shipping name, hazard class, and packaging group on documentation

International Shipping

- Comply with IMDG Code (sea), IATA DGR (air), or ADR (road in Europe)

- Declare as “Epoxy Resin Kit, 3, PG II” if flammable

- Provide transport index and emergency contact details

Carrier Coordination

- Inform carriers of chemical contents and hazard class

- Use temperature-controlled transport if ambient conditions exceed safe limits

- Secure packages to prevent tipping or leakage during transit

Handling & Application Safety

Ensure end-users and installers comply with safety protocols:

Personal Protective Equipment (PPE)

Mandatory PPE includes:

– Nitrile gloves

– Chemical-resistant apron

– Safety goggles or face shield

– NIOSH-approved respirator with organic vapor cartridges (especially in poorly ventilated areas)

Ventilation Requirements

- Provide mechanical ventilation during mixing and application

- Use exhaust fans to maintain air exchange in enclosed shower spaces

- Allow curing area to remain unoccupied during initial cure phase (typically 24–72 hours)

Waste Disposal

Dispose of unused product, containers, and cleanup materials in accordance with:

– Local, state, and federal regulations (e.g., EPA 40 CFR)

– Do not pour epoxy down drains or into soil

– Use approved hazardous waste disposal services when required

Certification & Documentation

Maintain records to support compliance and traceability:

Product Certifications

Keep documentation for:

– GREENGUARD Gold (for indoor air quality)

– FloorScore or CHPS certification

– ADA compliance (if applicable for public facilities)

Batch Traceability

- Retain batch-specific SDS and test reports

- Record lot numbers for every shipment and installation

- Enable quick recall or investigation if quality issues arise

Training & Installer Certification

For professional-grade products:

– Require installers to complete manufacturer-approved training

– Provide certification upon completion to ensure proper application techniques

– Distribute technical data sheets (TDS) and installation guides with each order

Emergency Response

Prepare for potential incidents:

Spill Response

- Contain spill with absorbent materials (e.g., vermiculite or sand)

- Do not use water; collect material and dispose as hazardous waste

- Ventilate the area and evacuate if vapors are strong

Medical Response

- In case of skin contact: Wash with soap and water; remove contaminated clothing

- For eye exposure: Flush with water for at least 15 minutes; seek medical attention

- If inhaled: Move to fresh air; provide oxygen if needed and contact poison control

This guide ensures that non-slip epoxy products for shower floors are handled, stored, transported, and applied in full compliance with safety and environmental regulations. Always consult the manufacturer’s specific instructions and local regulatory authorities for additional requirements.

In conclusion, sourcing a non-slip epoxy for a shower floor requires careful consideration of durability, safety, water resistance, and ease of application. A high-quality, slip-resistant epoxy coating provides a long-lasting, waterproof, and aesthetically pleasing finish that enhances shower safety by minimizing the risk of slips and falls. When selecting a product, prioritize epoxy systems specifically designed for wet environments, with added anti-slip aggregates or textured finishes. Proper surface preparation and adherence to manufacturer instructions are crucial for optimal adhesion and performance. By choosing a reputable brand and considering certifications such as VOC compliance and mold/mildew resistance, you can ensure a safe, durable, and low-maintenance shower floor solution. Ultimately, investing in the right non-slip epoxy not only improves functionality but also adds value to the overall bathroom renovation or maintenance project.