The global non-contact tachometer market is experiencing steady growth, driven by increasing demand for precision measurement tools across industrial automation, automotive, and manufacturing sectors. According to Mordor Intelligence, the global tachometer market is projected to grow at a CAGR of over 4.5% from 2023 to 2028, with non-contact variants gaining traction due to their ease of use, enhanced accuracy, and minimal maintenance requirements. The rising adoption of preventive maintenance programs and condition monitoring systems in industrial environments further accelerates the shift toward non-contact solutions. As industries prioritize efficiency and equipment longevity, manufacturers of non-contact tachometers are scaling innovation in laser and optical sensing technologies. Based on market reach, product reliability, and technological advancement, the following six companies have emerged as leading players in the non-contact tachometer space.

Top 6 Non Contact Tachometer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Non

Domain Est. 1999

Website: az-instrument.com.tw

Key Highlights: The Portable 8000 AZ Tachometer was being designed and manufactured by AZ Instrument, a well experienced manufacturer for Environmental Measuring Instrument….

#2 Quality & Durable Handheld Tachometers by Monarch Instrument

Domain Est. 1996

Website: monarchinstrument.com

Key Highlights: Free delivery over $250Handheld tachometers accurately measure rotational speed of gears, fans, motors and machinery. Monarch Instrument very accurate, noncontact tachometers….

#3 Laser Photo Tachometer

Domain Est. 1996

Website: triplett.com

Key Highlights: 30-day returnsTriplett provides non-contact and contact tachometers that assure fast and accurate RPM measurements of rotating objects and count (REV) measurements and ……

#4 Non

Domain Est. 1997

Website: generaltools.com

Key Highlights: The #LT2234C tachometer uses a laser and reflective tape to measure rotational speeds. It’s ideal for testing and troubleshooting motors, engines, gearboxes, ……

#5 Tachometers

Domain Est. 2003

Website: reedinstruments.com

Key Highlights: Dual function tachometer features the ability to measure RPM with non-contact built-in laser and contact (m/min) measurements quickly and accurately. Buy Now….

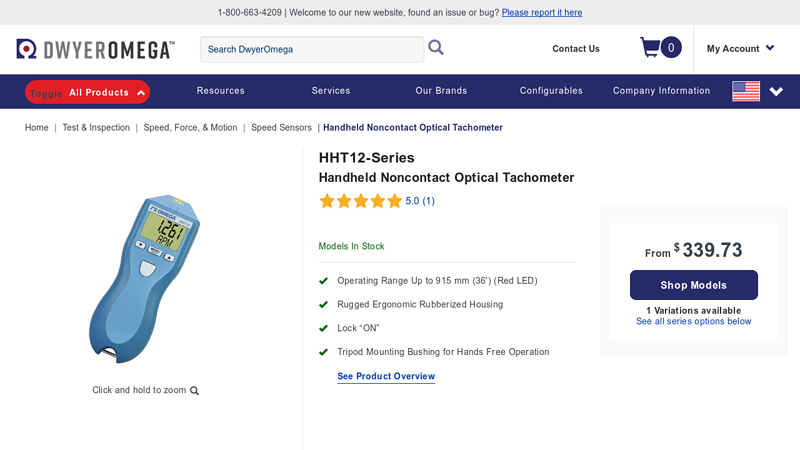

#6 Handheld Noncontact Optical Tachometer

Domain Est. 2022

Website: dwyeromega.com

Key Highlights: In stock Rating 5.0 (1) The HHT12 is an economical, digital, handheld optical tachometer that allows you to safely view both a target and the display. Click to learn more….

Expert Sourcing Insights for Non Contact Tachometer

Market Trends for Non-Contact Tachometers in 2026

As we approach 2026, the non-contact tachometer market is poised for significant evolution driven by technological advancements, expanding industrial automation, and heightened demands for precision and safety across diverse sectors. Key trends shaping this market include integration with digital ecosystems, miniaturization and enhanced connectivity, and growing adoption in emerging applications.

Integration with Industry 4.0 and IoT Platforms

By 2026, non-contact tachometers are increasingly becoming integral components of smart manufacturing and Industrial Internet of Things (IIoT) systems. These devices are evolving beyond standalone measurement tools to become connected sensors capable of real-time data transmission. Seamless integration with cloud-based platforms and predictive maintenance systems allows for continuous motor and machinery health monitoring. This trend supports proactive maintenance strategies, reduces downtime, and enhances operational efficiency—particularly in industries such as automotive, aerospace, and advanced manufacturing where uptime is critical.

Advancements in Sensor Technology and Connectivity

Technological improvements in laser and optical sensing have led to higher accuracy, faster response times, and greater measurement ranges in non-contact tachometers. Concurrently, the incorporation of Bluetooth, Wi-Fi, and mobile app compatibility is becoming standard, enabling technicians to record, analyze, and share RPM data directly from smartphones or tablets. In 2026, expect wider adoption of devices with augmented reality (AR) interfaces and AI-assisted diagnostics, allowing for intuitive operation and instant analysis of rotational speed anomalies.

Expansion into New and Niche Applications

While traditional uses in maintenance and quality control remain strong, the application scope of non-contact tachometers is broadening. Renewable energy sectors—particularly wind and solar—utilize these instruments for turbine and motor monitoring. Additionally, healthcare equipment maintenance, robotics, and drone propulsion systems are emerging as high-growth application areas. The demand for portable, precision instruments in field service and remote diagnostics is also accelerating, especially in developing markets undergoing industrial modernization.

Emphasis on Safety and Regulatory Compliance

With increasing workplace safety regulations, non-contact tachometers offer a critical advantage by enabling speed measurements without physical contact, reducing risks in high-voltage or high-temperature environments. In 2026, manufacturers are focusing on compliance with international safety standards (e.g., ISO, IEC) and designing devices with enhanced durability and environmental resistance, ensuring reliable performance in harsh industrial conditions.

Regional Market Growth and Competitive Landscape

Asia-Pacific is projected to lead market growth by 2026, fueled by rapid industrialization in countries like India and Vietnam, along with government initiatives promoting smart infrastructure and automation. North America and Europe maintain strong markets due to advanced manufacturing and stringent maintenance protocols. Competition is intensifying, with key players innovating in sensor fusion, data analytics integration, and cost-effective designs to capture wider market share.

In summary, the 2026 non-contact tachometer market will be defined by smarter, more connected, and versatile devices embedded within digital industrial ecosystems. Driven by automation, safety needs, and technological innovation, these instruments will play a pivotal role in ensuring efficiency and reliability across a broadening spectrum of industries.

Common Pitfalls When Sourcing a Non-Contact Tachometer (Quality and IP Protection)

When selecting a non-contact tachometer, overlooking key quality and Ingress Protection (IP) factors can lead to inaccurate readings, device failure, or safety risks. Avoid these common pitfalls:

1. Overlooking Build Quality and Sensor Accuracy

Low-cost tachometers may use inferior optical sensors or lack proper calibration, resulting in inconsistent or inaccurate RPM measurements. Avoid models without clear specifications on accuracy (e.g., ±0.05% + 1 digit) or those lacking certification from recognized standards bodies.

2. Choosing Insufficient IP Rating for the Environment

Failing to match the tachometer’s IP rating to its operating environment is a frequent error. For example, using an IP54-rated device in wet or dusty industrial settings can lead to internal damage. Always verify that the IP rating (e.g., IP65 for dust-tight and water-jet resistance) meets or exceeds the environmental demands.

3. Ignoring Lens and Optics Protection

The optical lens is critical for performance. Units without scratch-resistant or sealed lenses are prone to damage and contamination, degrading measurement reliability. Ensure the device has proper lens protection, especially in rugged environments.

4. Assuming All Lasers Are Equal

Low-quality lasers may have poor beam focus or inconsistent output, reducing effective measurement range and precision. Opt for tachometers with Class 2 lasers that comply with safety standards and offer stable, visible beams for accurate targeting.

5. Neglecting Calibration and Traceability

Devices without factory calibration certificates or traceability to international standards (e.g., NIST) may not be suitable for quality control or regulatory compliance. Always request documentation to verify calibration validity and service intervals.

6. Underestimating Environmental Durability

Beyond IP ratings, consider overall ruggedness—resistance to drops, vibration, and temperature extremes. A high IP rating doesn’t guarantee durability if the housing or internal components are poorly constructed.

7. Disregarding User Interface and Data Logging Features

Poor display readability or lack of data storage can undermine usability. Ensure the tachometer has a clear display, intuitive controls, and, if needed, data logging or Bluetooth connectivity for reliable record-keeping.

By carefully evaluating quality components and appropriate IP protection, you can avoid premature failures and ensure accurate, long-term performance in your specific application.

Logistics & Compliance Guide for Non-Contact Tachometer

Product Classification and Regulatory Overview

Non-contact tachometers, which measure rotational speed using laser or optical sensors without physical contact, are generally classified as electronic measurement instruments. They typically fall under industrial or scientific equipment categories. These devices are not usually subject to stringent health or safety regulations like medical devices, but they must comply with electromagnetic compatibility (EMC), safety, and environmental standards depending on the target market.

International Shipping and Customs Documentation

When shipping non-contact tachometers internationally, ensure the following documentation is prepared:

- Commercial Invoice: Includes product description (e.g., “Digital Non-Contact Tachometer”), quantity, unit price, total value, and Harmonized System (HS) code.

- Packing List: Details packaging type, weight, dimensions, and item breakdown.

- Bill of Lading or Air Waybill: Required for freight tracking and customs clearance.

- Certificate of Origin: May be required for preferential tariff treatment under trade agreements.

Harmonized System (HS) Code and Import Duties

The recommended HS code for non-contact tachometers is typically 9026.10 (“Instruments and apparatus for measuring or checking the flow, level, pressure or other variables of liquids or gases”), though classification may vary by country. Import duties and taxes depend on the destination country’s tariff schedule. Always verify the correct HS code with local customs authorities or a customs broker.

Electromagnetic Compatibility (EMC) and Safety Compliance

Non-contact tachometers must comply with EMC and electrical safety regulations in the destination market:

- European Union (EU): Must meet CE marking requirements under the EMC Directive (2014/30/EU) and Low Voltage Directive (2014/35/EU). Testing for emissions and immunity is required.

- United States (US): Must comply with FCC Part 15 regulations for unintentional radiators. No formal certification is required, but suppliers must ensure compliance.

- Canada: Requires compliance with ICES-003 (Interference-Causing Equipment Standards) and may needISED certification.

- Other Regions: Check local requirements such as KC (Korea), PSE (Japan), or EAC (Eurasian Customs Union).

Laser Safety and Regulatory Considerations

Many non-contact tachometers use Class 1 or Class 2 lasers, which are considered low-risk. However, compliance with laser safety standards is essential:

- IEC 60825-1: International standard for laser product safety. Class 1 lasers are safe under normal operation; Class 2 requires user warnings.

- FDA/CDRH (USA): Requires laser products to be reported and labeled according to 21 CFR 1040.10. Most non-contact tachometers qualify for exemption if they meet Class 1 criteria.

- Labeling: Include appropriate laser warning labels and classification (e.g., “Laser Radiation – Do Not Stare Into Beam”).

Environmental and RoHS Compliance

Ensure compliance with environmental directives:

- EU RoHS Directive (2011/65/EU): Restricts the use of hazardous substances (e.g., lead, cadmium, mercury) in electrical equipment.

- WEEE Directive (2012/19/EU): Requires producers to register and provide take-back options for electronic waste in the EU.

- REACH (EU): Requires disclosure of Substances of Very High Concern (SVHC) if present above threshold levels.

Manufacturers must provide a Declaration of Conformity (DoC) and maintain technical documentation to prove compliance.

Packaging and Labeling Requirements

Proper packaging ensures device protection and regulatory compliance:

- Use anti-static and shock-resistant materials for safe transport.

- Include multilingual user manuals and safety instructions if selling in multiple regions.

- Display required certifications (e.g., CE, FCC, RoHS) on product or packaging.

- Ensure labels include manufacturer information, model number, serial number, voltage rating, and laser classification.

Import Restrictions and Prohibited Destinations

While non-contact tachometers are generally unrestricted, verify that:

- The destination country does not classify the device as a dual-use or controlled item (unlikely but possible if used in sensitive industries).

- Laser-based models comply with local optical radiation regulations.

- Sanctioned countries (e.g., under U.S. OFAC or EU sanctions) are excluded from shipments without proper authorization.

Storage and Handling Guidelines

- Store in a dry, temperature-controlled environment (typically 0°C to 40°C).

- Avoid direct sunlight and high humidity to preserve electronic components and battery life.

- Handle with care to prevent damage to the optical/laser sensor window.

After-Sales Support and Warranty Compliance

- Provide warranty documentation aligned with local consumer protection laws (e.g., 2-year warranty in the EU).

- Establish a service or repair network, or offer return-to-base options.

- Maintain compliance records (e.g., test reports, DoC) for at least 10 years post-manufacture in the EU.

Summary and Best Practices

To ensure smooth logistics and compliance:

- Confirm product classification and HS code before shipping.

- Obtain necessary certifications (CE, FCC, etc.) prior to market entry.

- Include required labels and documentation with each unit.

- Partner with experienced freight forwarders familiar with electronic instruments.

- Regularly review regulatory updates in target markets to maintain compliance.

Conclusion for Sourcing a Non-Contact Tachometer:

Sourcing a non-contact tachometer is a strategic decision that enhances measurement accuracy, operational efficiency, and user safety in various industrial, automotive, and maintenance applications. By eliminating the need for physical contact with rotating components, these devices reduce wear and tear, minimize downtime, and allow for quick, real-time speed measurements under diverse conditions.

When selecting a non-contact tachometer, key factors such as measurement range, accuracy, resolution, distance-to-spot ratio, response time, and environmental durability must be carefully evaluated to match specific application requirements. Additionally, features like laser targeting, data logging, and digital interfaces add value and support integration into modern monitoring systems.

After thorough market assessment, reliable suppliers offering high-quality, calibrated instruments with technical support and warranty services should be prioritized. Whether for routine maintenance, quality control, or R&D purposes, investing in a well-sourced non-contact tachometer ensures long-term reliability, cost-effectiveness, and improved process control. Ultimately, the right sourcing decision supports enhanced productivity and safety across technical operations.