The global aramid fiber market, driven by increasing demand for heat-resistant, high-strength materials in industries such as aerospace, defense, and personal protective equipment (PPE), is experiencing robust growth. According to Grand View Research, the global aramid fiber market was valued at USD 3.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.2% from 2023 to 2030. A key segment within this space is meta-aramid fibers, including Nomex 410—a paper-grade insulation material widely used in electrical and thermal applications due to its excellent dielectric strength and thermal stability. With rising investments in electric vehicles, renewable energy infrastructure, and industrial safety, demand for high-performance Nomex variants continues to climb. This growth trajectory underscores the strategic importance of reliable Nomex 410 manufacturers capable of meeting stringent quality and volume requirements. Based on production capacity, innovation, and global reach, the following six manufacturers stand out as leading suppliers in the current market landscape.

Top 6 Nomex 410 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Nomex Distribution and Fabrication

Domain Est. 2000

Website: espemfg.com

Key Highlights: ESPE Manufacturing Co., Inc., stocks a full range of Nomex 410, Nomex 993, and Nomex 994 product lines, covering every type of Nomex paper and pressboard and ……

#2 Nomex® 410 Insulation for Electrical & Industrial Applications

Domain Est. 2016

Website: addevmaterials.com

Key Highlights: Nomex® 410 is a high-density insulating material that has been a benchmark in the industry for over 50 years. Its excellent dielectric strength, ……

#3 Nomex® 410 & Nomex® 400 Series

Domain Est. 1987

Website: dupont.com

Key Highlights: Nomex® 410 is used in almost every known sheet insulation application. This high-density product has high inherent dielectric strength, mechanical toughness, ……

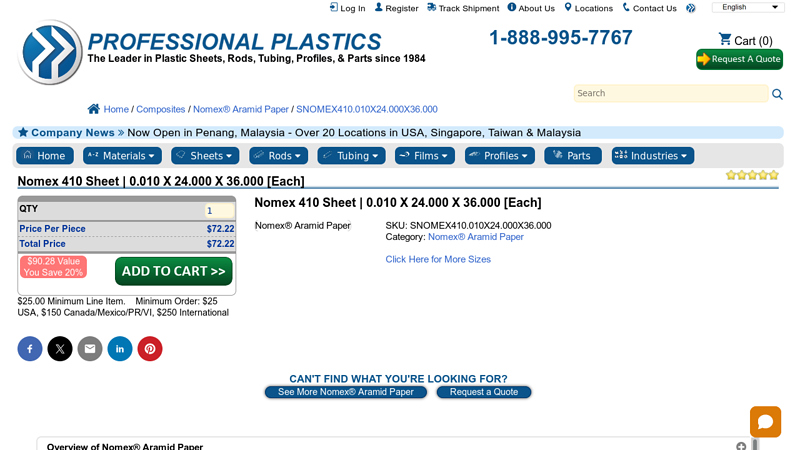

#4 Nomex 410 Sheet

Domain Est. 1997

Website: professionalplastics.com

Key Highlights: Nomex Type 410 is a calendered insulation paper which offers high inherent dielectric strength, mechanical toughness, flexibility and resilience….

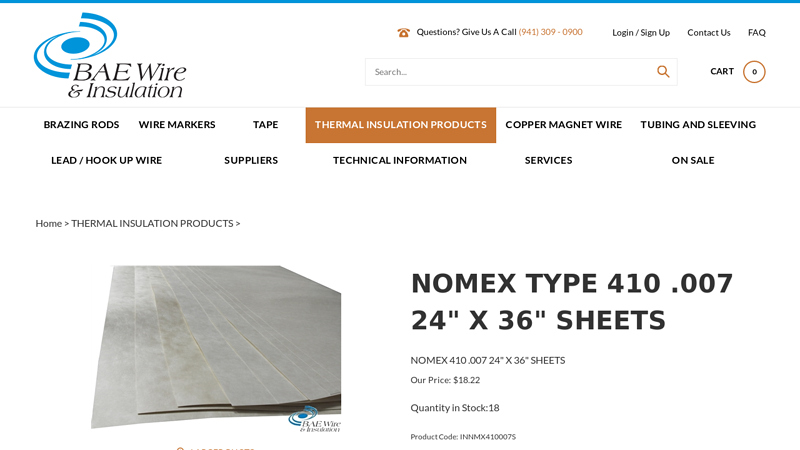

#5 NOMEX TYPE 410 .007 24″ X 36″ SHEETS

Domain Est. 2002

Website: baewire.com

Key Highlights: Our Price: $18.22 ; Thickness .007″ (7 mil) ; Product Type, NOMEX Type 410 ; Color, Natural ; Size, 24″ X 36″ Sheet ; Material, Aramid paper….

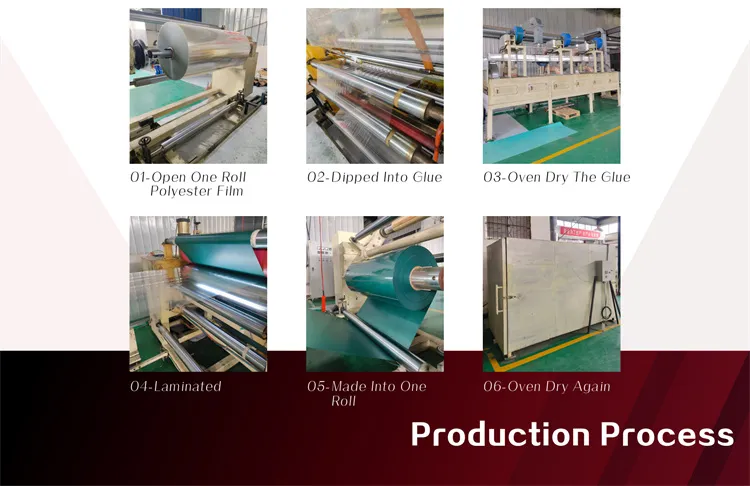

#6 Nomex 410 Dhesive Tape Adhesive Tape,Double Sided Tape,High …

Domain Est. 2016

Website: yousantape.com

Key Highlights: Nomex 410 is a unique aramid enhanced cellulose material, composed of high quality electrical grade cellulose pulp. Among the Dupont Nomex family, Nomex 410 ……

Expert Sourcing Insights for Nomex 410

H2: 2026 Market Trends for Nomex 410

The global market for Nomex 410, a high-performance meta-aramid paper developed by DuPont (now part of DuPont de Nemours, Inc.), is expected to witness steady growth and strategic evolution by 2026. As a key dielectric and insulation material in electrical and electronic applications, Nomex 410 is poised to benefit from broader industrial and technological trends, particularly in energy, transportation, and advanced manufacturing. Below is an analysis of the key market trends shaping the demand, supply, and innovation landscape for Nomex 410 through 2026.

1. Growing Demand in Renewable Energy and Electric Vehicles (EVs)

One of the most significant drivers for Nomex 410 by 2026 is the global shift toward sustainable energy and electrification. The material’s thermal stability (withstanding temperatures up to 220°C), excellent dielectric strength, and mechanical durability make it ideal for use in:

– Electric motors and generators in EVs and hybrid vehicles.

– Power transformers and inverters in solar and wind energy systems.

With increasing investments in EV infrastructure and grid modernization, demand for reliable insulation materials like Nomex 410 is projected to rise, particularly in Asia-Pacific and North America.

2. Expansion in High-Voltage and Smart Grid Technologies

As utilities upgrade aging infrastructure and deploy smart grid technologies, there is a growing need for high-reliability insulation in high-voltage equipment. Nomex 410 is increasingly used in dry-type transformers, switchgear, and distribution systems where fire resistance and long service life are critical. By 2026, the push for grid resilience and efficiency, especially in urban and industrial settings, will further boost adoption.

3. Regional Shifts and Manufacturing Growth in Asia-Pacific

Asia-Pacific—particularly China, India, and South Korea—is emerging as a key growth region for Nomex 410. Rapid industrialization, government support for electric mobility, and expansion of renewable energy projects are driving demand. Local manufacturing of electrical components is also increasing, reducing reliance on imports and fostering partnerships between DuPont and regional suppliers.

4. Supply Chain Resilience and Raw Material Challenges

The production of meta-aramid fibers (the base material for Nomex 410) involves complex chemical processes and limited global suppliers. By 2026, companies are expected to focus on:

– Vertical integration and long-term supply agreements to ensure continuity.

– Sustainability improvements, including reduced solvent use and energy-efficient production methods, in response to ESG (Environmental, Social, and Governance) pressures.

5. Competition and Substitution Pressures

While Nomex 410 remains a benchmark in high-temperature insulation, alternative materials such as:

– Polyimide films (e.g., Kapton)

– Cellulose-based insulation with nanocoatings

– New-generation aramid blends from emerging manufacturers in China

pose competitive threats. However, Nomex 410’s proven reliability, certifications, and established supply chains give it a strong position, especially in safety-critical applications.

6. Technological Innovation and Product Enhancements

DuPont and its partners are expected to introduce upgraded variants of Nomex 410 by 2026, featuring:

– Enhanced moisture resistance.

– Improved dielectric performance at higher frequencies (important for high-speed EV motors).

– Integration with smart sensors for condition monitoring in transformers.

These innovations will help maintain Nomex 410’s relevance in next-generation electrical systems.

7. Regulatory and Safety Standards Driving Adoption

Stringent fire safety regulations in transportation (e.g., rail, aviation, EVs) and building codes are favoring inherently flame-resistant materials. Nomex 410’s self-extinguishing properties and UL (Underwriters Laboratories) certification support compliance with global standards, reinforcing its market position.

Conclusion:

By 2026, the Nomex 410 market is projected to grow at a CAGR of approximately 4–6%, driven by electrification, energy transition, and industrial modernization. While challenges related to cost and competition persist, the material’s unmatched performance in high-temperature and high-reliability applications ensures its continued importance. Stakeholders should focus on strategic partnerships, regional market expansion, and sustainability to capitalize on emerging opportunities.

Common Pitfalls When Sourcing Nomex 410: Quality and Intellectual Property Concerns

Sourcing genuine Nomex 410, a high-performance meta-aramid paper developed and trademarked by DuPont, involves significant risks related to quality consistency and intellectual property (IP) infringement. Buyers must be vigilant to avoid common pitfalls that can compromise safety, performance, and legal compliance.

Quality Inconsistencies and Counterfeit Materials

One of the most prevalent issues when sourcing Nomex 410 is the risk of receiving substandard or counterfeit materials. Many suppliers offer products labeled as “Nomex 410 equivalent” or “aramid paper,” but these often fail to meet the stringent thermal, electrical, and mechanical specifications of genuine DuPont Nomex 410. Key quality pitfalls include:

- Inferior Raw Materials: Use of lower-grade aramid fibers or blends that degrade under high-temperature conditions, leading to reduced dielectric strength and shortened service life.

- Inconsistent Thickness and Density: Off-spec caliper and density affect electrical insulation performance and mechanical fit in applications like transformers and motors.

- Poor Thermal Stability: Counterfeit materials may exhibit excessive shrinkage or decomposition below the 220°C continuous operating temperature standard, posing fire and safety hazards.

- Lack of Certification: Absence of valid test reports, mill certificates, or traceability to DuPont undermines confidence in material authenticity.

Intellectual Property and Trademark Violations

Nomex is a registered trademark of DuPont, and unauthorized use of the name constitutes IP infringement. Common IP-related pitfalls include:

- Mislabeling and Branding: Suppliers falsely labeling non-DuPont products as “Nomex 410” violate trademark law and mislead buyers.

- Unauthorized Distribution Channels: Purchasing from third-party resellers without authorization from DuPont increases the risk of receiving counterfeit or diverted goods.

- Legal and Compliance Risks: Using infringing materials can expose end-users to legal liability, product recall risks, and voided warranties, especially in regulated industries like aerospace and energy.

To mitigate these risks, buyers should source directly from DuPont or authorized distributors, request full material traceability documentation, and conduct independent material verification testing when necessary.

H2: Logistics & Compliance Guide for Nomex 410

Nomex 410 is an aramid paper developed by DuPont, widely used in electrical insulation, aerospace, and high-temperature applications due to its excellent thermal, mechanical, and dielectric properties. Proper logistics and compliance management are essential to ensure safety, regulatory adherence, and product integrity throughout the supply chain.

1. Regulatory Classification & Compliance

-

Chemical Identity:

Nomex 410 is a meta-aramid (poly-m-phenylene isophthalamide) paper. It is not classified as a hazardous substance under major global regulations when in its solid, dry form. -

GHS/CLP Classification:

Typically not classified as hazardous under the Globally Harmonized System (GHS) or EU CLP Regulation when supplied as finished sheet or roll stock. However, dust generated during machining may require assessment: - May be harmful if inhaled (dust form).

-

No known carcinogenicity for the bulk material.

-

REACH (EU):

Nomex 410 is registered under REACH. Safety Data Sheet (SDS) Section 15 confirms compliance with EU regulations. No SVHCs (Substances of Very High Concern) are present above threshold limits. -

TSCA (USA):

Compliant with the U.S. Toxic Substances Control Act. Listed on the TSCA Inventory. -

RoHS & REACH SVHC:

Compliant with RoHS 2 (2011/65/EU) and does not contain restricted substances above permissible levels.

2. Transportation & Shipping

-

UN Number:

Not regulated as hazardous under ADR (road), IATA (air), or IMDG (sea) when shipped in solid form. No UN number required. -

Packaging:

- Supplied in moisture-resistant packaging (e.g., sealed polyethylene bags inside rigid cardboard or wooden crates).

-

Protect from moisture, as Nomex 410 is hygroscopic and may absorb water, affecting dielectric performance.

-

Labeling:

- Standard industrial labeling with product name, grade, batch number, and handling instructions.

-

No hazard labels required for bulk transport unless processed into dust or waste form.

-

Storage Conditions:

- Store in a cool, dry place with controlled humidity (<50% RH recommended).

- Keep away from direct sunlight and sources of heat.

- Shelf life: Typically 12–24 months when stored properly (refer to manufacturer’s technical data sheet).

3. Handling & Worker Safety

- Personal Protective Equipment (PPE):

- Gloves and safety glasses recommended during handling.

-

If cutting, grinding, or machining generates dust: use NIOSH-approved respirators (N95 or equivalent), local exhaust ventilation, and protective clothing.

-

Dust Control:

- Avoid generating airborne dust. Use wet-cutting methods or vacuum-assisted tools where possible.

-

Clean work areas with HEPA-filtered vacuums—do not dry sweep.

-

First Aid Measures (per SDS):

- Inhalation: Move to fresh air.

- Skin Contact: Wash with soap and water.

- Eye Contact: Rinse thoroughly with water for at least 15 minutes.

4. Environmental & Disposal Considerations

-

Environmental Impact:

Nomex 410 is stable and non-leaching in normal conditions. Does not present significant environmental hazard if contained. -

Disposal:

- Non-hazardous waste when uncontaminated. Can be disposed of in licensed landfills per local regulations.

-

Incineration: Should be conducted in facilities with appropriate air pollution controls due to potential release of nitrogen oxides (NOx) at high temperatures.

-

Recycling:

Not generally recyclable through conventional means. Consider energy recovery in permitted industrial incinerators.

5. Documentation & Traceability

-

Safety Data Sheet (SDS):

Always obtain and maintain the latest SDS from DuPont or the supplier (revise every 3–5 years or as updated). -

Certificates of Conformance (CoC):

Request CoC for each batch to confirm material meets specifications (e.g., ASTM D2494, UL 746). -

Import/Export Controls:

Generally not subject to ITAR or EAR restrictions. Confirm with supplier for country-specific export compliance.

6. Special Considerations for End-Use Industries

-

Aerospace:

May require additional traceability (e.g., lot tracking, Nadcap certification for processing). -

Electrical Equipment:

Ensure compliance with insulation system standards (e.g., IEC 60216, UL 1446).

Note: Always refer to the most current product-specific documentation from the manufacturer (e.g., DuPont Technical Data Sheet and SDS) for authoritative guidance. Regulations may vary by jurisdiction—consult local authorities when in doubt.

Conclusion for Sourcing Nomex 410

Sourcing Nomex 410 requires a strategic approach that balances quality, reliability, cost, and compliance with industry standards. As a high-performance aramid paper developed by DuPont, Nomex 410 is widely used in electrical insulation applications due to its excellent thermal, mechanical, and dielectric properties. Given its critical role in ensuring the safety and efficiency of electrical equipment, it is essential to source this material from authorized and reputable suppliers to guarantee authenticity and consistent performance.

Key considerations in the sourcing process include verifying material certifications (such as UL recognition and RoHS compliance), evaluating supplier reliability, and ensuring supply chain transparency. While alternative or aftermarket suppliers may offer cost advantages, the risk of receiving substandard or counterfeit material can lead to operational failures and safety hazards. Therefore, prioritizing partnerships with DuPont-authorized distributors or direct procurement from DuPont is recommended for mission-critical applications.

In conclusion, successful sourcing of Nomex 410 hinges on a thorough supplier assessment, adherence to quality standards, and long-term supply stability. Investing in genuine, certified material ensures optimal performance, regulatory compliance, and enhanced safety in demanding electrical environments.