The global aluminum fencing market is experiencing robust growth, driven by rising demand for low-maintenance, durable, and aesthetically pleasing perimeter solutions in residential and commercial sectors. According to Grand View Research, the global aluminum fencing market size was valued at USD 3.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.7% from 2023 to 2030. This expansion is fueled by increasing urbanization, growth in infrastructure spending, and a shift toward sustainable building materials—aluminum being 100% recyclable without loss of quality. A key trend shaping buyer preferences is the rising popularity of no-dig fence systems, which offer quick, tool-free installation without concrete footings, minimizing landscape disruption. As demand for these innovative solutions grows, several manufacturers have emerged as leaders in engineering high-performance, no-dig aluminum fencing systems. The following list highlights the top eight manufacturers excelling in product innovation, durability, and market reach—companies at the forefront of redefining perimeter security with smarter, more sustainable designs.

Top 8 No Dig Fence Aluminum Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Master Halco

Domain Est. 1996

Website: masterhalco.com

Key Highlights: Master Halco is your leading manufacturer and wholesale distributor of fencing & decking products across the US and Canada….

#2 Jerith

Domain Est. 1997

Website: jerith.com

Key Highlights: We manufacture aluminum fences for homes and businesses. Whether you need to meet pool codes, secure a property on the coast or keep your family and pets safe….

#3 Fence Depot

Domain Est. 2002

Website: fence-depot.com

Key Highlights: We sell aluminum fence, wrought iron fence, and more directly to homeowners and contractors who are looking for high quality fence, railing and gate products ……

#4 WamBam Fence

Domain Est. 2009

Website: wambamfence.com

Key Highlights: Free delivery over $3,000 30-day returnsNo Digging. No Concrete. No Mess. Patented leveling system provides adjustability for a straight and level fence. View Video Demonstration….

#5

Domain Est. 2014

Website: ameristarperimeter.com

Key Highlights: We provide Fence & Security Solutions to protect what matters most. From the quality of materials, American made manufacturing, and the largest support team ……

#6 SWI No Dig aluminum fence system products

Domain Est. 2015

Website: swifence.com

Key Highlights: Professional grade fence supplies and tools for professional fence installers and DIY homeowners. All the fence materials and tools you need to install ……

#7 iFence LLC

Domain Est. 2022

Website: ifencellc.com

Key Highlights: Our patented no dig aluminum fence system will make installing your fence easier and cleaner than ever – saving you time and making you more money!…

#8 Premium Aluminum Fence Supplies

Domain Est. 2020

Website: atozfencesupplies.com

Key Highlights: Our materials are manufactured to support our no mess, no dig installation & fit together easily. Durable. Our high-strength aluminum alloy fencing, ……

Expert Sourcing Insights for No Dig Fence Aluminum

H2: Market Trends for No Dig Fence Aluminum in 2026

The No Dig Fence Aluminum market is poised for significant transformation by 2026, driven by technological innovation, sustainability demands, and evolving consumer preferences in residential and commercial construction. As urbanization accelerates and land-use regulations tighten, the demand for quick, minimally invasive fencing solutions continues to rise—positioning aluminum no-dig systems as a leading alternative to traditional fencing methods.

1. Rising Demand for Eco-Friendly and Sustainable Solutions

By 2026, environmental regulations and consumer awareness are expected to heavily influence material choices in construction. Aluminum, being 100% recyclable and energy-efficient in production compared to steel or wood, aligns well with green building standards. No-dig installation further enhances sustainability by minimizing soil disruption, preserving landscaping, and reducing construction waste—key selling points for eco-conscious homeowners and developers.

2. Growth in Urban and High-Density Developments

Urban infill projects and high-density housing developments are increasingly adopting no-dig fencing due to space constraints and the need to avoid damaging underground utilities. Aluminum no-dig systems, which require no excavation or concrete footings, offer faster installation and lower labor costs. This makes them particularly attractive in metropolitan areas where time and space are at a premium.

3. Technological Advancements in Installation Systems

In 2026, expect to see enhanced modular designs and tool-assisted anchoring mechanisms that improve the stability and wind resistance of no-dig aluminum fences. Innovations such as adjustable ground spikes, tension-based anchoring, and smart alignment tools will make DIY installation more accessible, expanding the consumer base beyond professional contractors.

4. Expansion of Residential and Commercial Applications

While initially popular in residential pool enclosures and temporary boundaries, aluminum no-dig fences are gaining traction in commercial applications such as construction site perimeters, event security, and agricultural boundary markers. Their reusability and portability offer cost advantages over permanent structures, appealing to businesses seeking flexible, scalable solutions.

5. Competitive Pricing and Market Accessibility

As production scales and supply chains optimize, the cost of aluminum no-dig fencing is expected to decrease slightly by 2026, making it more competitive with traditional wood and vinyl options. Increased availability through e-commerce platforms and home improvement retailers will further drive market penetration, especially in North America and Europe.

6. Regulatory and Safety Compliance Drivers

Stricter safety codes, especially around pool fencing and child safety, are pushing municipalities to adopt durable, code-compliant barriers. Aluminum no-dig systems that meet ASTM and ICC-ES standards for strength and durability will benefit from regulatory tailwinds, particularly in regions with high homeowner association (HOA) influence.

Conclusion

By 2026, the No Dig Fence Aluminum market is expected to experience robust growth, fueled by sustainability trends, urban development needs, and technological improvements. As consumers and contractors prioritize speed, durability, and environmental impact, aluminum no-dig fencing is well-positioned to become a standard solution in modern perimeter security and boundary marking.

Common Pitfalls When Sourcing No Dig Fence Aluminum (Quality, IP)

Sourcing No Dig Fence Aluminum systems can offer speed and efficiency for temporary or semi-permanent fencing solutions. However, overlooking key quality and IP (Ingress Protection) factors can lead to significant issues. Here are common pitfalls to avoid:

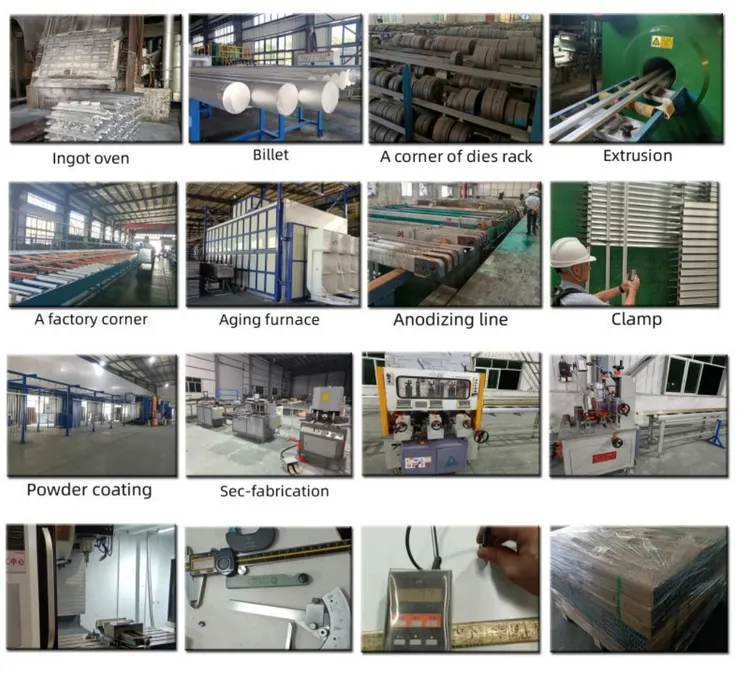

Overlooking Material Thickness and Alloy Grade

A frequent mistake is assuming all aluminum looks the same. Sourcing based solely on appearance without verifying the material specifications can result in weak, easily damaged fencing. Thin gauge aluminum or substandard alloys (e.g., non-marine-grade) degrade quickly under UV exposure, wind load, or physical impact. Always confirm the exact alloy (e.g., 6063-T5) and wall thickness—reputable suppliers provide mill test certificates.

Ignoring IP Rating for Integrated Electronics

Many No Dig Fence systems include integrated lighting, sensors, or power units requiring electrical components. A critical oversight is failing to check the IP (Ingress Protection) rating of these components. An insufficient IP rating (e.g., less than IP65) leaves electronics vulnerable to dust, moisture, and rain, leading to premature failure. Ensure all electronic housings meet at least IP65 for outdoor use, especially in harsh or coastal environments.

Assuming All “No Dig” Systems Are Equal

Not all No Dig Fence designs offer the same stability or durability. Some systems use flimsy ground anchors or shallow footplates that fail in high winds or uneven terrain. Poorly engineered joints or connectors can compromise the entire structure. Evaluate the anchoring mechanism, overall structural design, and third-party load testing data before procurement.

Skipping Real-World Durability Testing

Relying solely on manufacturer claims without requesting or conducting real-world testing is risky. Aluminum can suffer from galvanic corrosion when in contact with dissimilar metals or in saline environments. Verify if the product has undergone salt spray testing (e.g., ASTM B117) and UV resistance assessments to ensure long-term performance.

Neglecting Certifications and Compliance

Failing to confirm compliance with relevant standards (e.g., EN 1317 for safety barriers, IEC 60529 for IP ratings) can result in legal or safety issues. Ensure the supplier provides documentation proving compliance with industry and regional regulations—especially important for public projects or safety-critical applications.

Underestimating Long-Term Maintenance Needs

While aluminum is low-maintenance, poor-quality finishes or inadequate sealing can lead to staining, corrosion, or mechanical wear. Assume minimal maintenance only if the product has proven weather-resistant coatings (e.g., powder-coated or anodized) and robust seals on moving or electrical parts.

By addressing these pitfalls proactively, buyers can ensure they source high-quality, durable, and reliable No Dig Fence Aluminum systems with appropriate IP protection for their intended environment.

Logistics & Compliance Guide for No Dig Fence Aluminum

Product Overview

No Dig Fence Aluminum is a modern fencing solution designed for quick, tool-free installation without the need for digging or concrete footings. Ideal for both residential and commercial applications, it offers durability, low maintenance, and an aesthetically pleasing appearance. This guide outlines the logistics considerations and compliance requirements for handling, transporting, and installing No Dig Fence Aluminum systems.

Shipping & Handling

No Dig Fence Aluminum components are typically shipped in flat-pack configurations to maximize space efficiency and reduce shipping costs. Panels, posts, caps, and hardware are bundled securely on pallets, labeled clearly by section or project phase.

- Packaging: Weather-resistant wrapping protects against moisture and scratches during transit.

- Weight & Dimensions: Each panel averages 50–70 lbs (23–32 kg) and measures 6 ft (1.8 m) in height by 8 ft (2.4 m) in width. Posts are 3.5 in (89 mm) square and range from 6–7 ft (1.8–2.1 m) in length.

- Handling Instructions: Use mechanical lifting equipment (e.g., forklifts) when unloading; avoid dragging bundles across surfaces to prevent coating damage.

Storage Requirements

Proper on-site storage ensures material integrity prior to installation.

- Location: Store indoors or under a covered, dry area. If stored outdoors, elevate pallets off the ground and cover completely with waterproof tarps.

- Stacking: Limit stack height to 4 pallets to prevent deformation. Keep panels vertical whenever possible.

- Temperature: Avoid prolonged exposure to extreme heat (>100°F / 38°C) or freezing conditions (<32°F / 0°C).

Transportation Guidelines

Transport No Dig Fence Aluminum via enclosed trailers when possible to protect against weather, debris, and road vibration.

- Securing Loads: Use ratchet straps to anchor pallets to trailer floors. Prevent shifting during transit.

- Vehicle Compatibility: Standard flatbed or box trucks accommodate standard shipment volumes.

- International Shipments: Ensure compliance with ISPM 15 regulations for wooden pallets; consider heat-treated or plastic alternatives for global shipments.

Installation Compliance

No Dig Fence Aluminum systems must be installed according to manufacturer specifications and local building codes.

- Manufacturer Standards: Follow the official installation manual, including torque specifications for hardware and alignment tolerances.

- Local Regulations: Verify zoning laws, fence height restrictions (typically 6 ft in residential areas), and setback requirements with municipal authorities.

- Permitting: Obtain necessary building permits prior to installation. Submit engineered drawings if required.

Material Compliance & Certifications

No Dig Fence Aluminum meets recognized industry standards for structural integrity and environmental safety.

- Material Certification: Aluminum alloy (6063-T5) complies with ASTM B221 (Standard Specification for Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes).

- Coating Standards: Powder-coated finish meets AAMA 2604 for UV resistance, color retention, and corrosion protection.

- Sustainability: Components are 100% recyclable; manufactured using energy-efficient extrusion processes.

Environmental & Safety Compliance

Adhere to safety and environmental protocols during transport, storage, and installation.

- OSHA Guidelines: Use appropriate PPE (gloves, safety glasses) during handling and installation.

- Hazard Communication: Safety Data Sheets (SDS) available upon request for coating materials.

- Recycling: Coordinate with local recycling centers for end-of-life product disposal or reuse.

Documentation & Recordkeeping

Maintain accurate records to ensure traceability and compliance.

- Required Documents: Bill of lading, packing lists, product certifications, installation manuals, and warranty information.

- Project Logs: Record installation dates, inspector approvals, and permit numbers for audit purposes.

- Warranty Registration: Submit completed forms within 30 days of project completion to activate manufacturer warranty (typically 15–20 years).

Troubleshooting & Support

Contact the manufacturer or authorized distributor for compliance clarification or logistical issues.

- Support Channels: Phone, email, and online portal for logistics tracking and technical inquiries.

- Non-Conformance Reporting: Report damaged shipments or defective materials immediately with photos and batch numbers for resolution.

Conclusion for Sourcing No-Dig Fence Aluminium:

Sourcing aluminum for a no-dig fence system presents a strategic and sustainable solution for modern fencing needs. Aluminum offers a unique combination of durability, lightweight properties, and corrosion resistance, making it ideal for no-dig installation methods that minimize ground disruption. Its low maintenance requirements and long lifespan contribute to reduced lifecycle costs, while its recyclability supports environmental sustainability goals.

The no-dig approach, paired with aluminum’s versatility, allows for quick installation, reduced labor expenses, and minimal impact on landscaping—particularly beneficial in sensitive or urban environments. When sourcing aluminum, selecting high-quality, certified materials from reputable suppliers ensures structural integrity and compliance with industry standards.

In conclusion, aluminum is an optimal material for no-dig fencing, offering a cost-effective, eco-friendly, and aesthetically pleasing solution. With careful sourcing and quality assurance, it supports efficient project execution and long-term performance, making it a smart investment for residential, commercial, and infrastructure applications.