The global lubricating grease market is experiencing steady expansion, driven by rising industrial automation, automotive production, and demand for high-performance maintenance solutions. According to Grand View Research, the global grease market was valued at USD 2.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 4.1% from 2023 to 2030. A significant segment within this market is NLGI 0-grade grease—known for its semi-fluid consistency, excellent pumpability, and effectiveness in centralized lubrication systems and low-temperature applications. Industries such as manufacturing, mining, wind energy, and heavy equipment rely on NLGI 0 grease for optimal equipment performance and longevity. With increasing emphasis on operational efficiency and equipment reliability, demand for high-quality NLGI 0 grease continues to grow. Based on market presence, product innovation, and global reach, the following eight manufacturers have emerged as leaders in the production and distribution of NLGI 0 greases.

Top 8 Nlgi 0 Grease Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 NLGI 0

Domain Est. 2003

Website: lubetechnologies.com

Key Highlights: Wirelife® Almasol® Coating Grease (453). Product Category: Lubricants. Lubricant Type: Industrial Grease. NLGI Grade: NLGI 0. Proprietary ……

#2 Super Lube Multi-Purpose Synthetic Grease (NLGI 00)

Domain Est. 1996

Website: super-lube.com

Key Highlights: This product is NSF H1 registered and is safe for incidental food contact. Ideal for food processing equipment, it meets strict safety standards for lubricants ……

#3 No. 1240 NLGI #0, Lithium 12 Hydroxy grease

Domain Est. 1996

Website: lubriplate.com

Key Highlights: No. 1240. NLGI #0, Lithium 12 Hydroxy grease. For heavy loads where you require a grease that can be pumped through an automatic system….

#4 About Us

Domain Est. 2000

Website: nlgi.org

Key Highlights: NLGI is a not-for-profit trade association, primarily composed of companies who manufacture and market all types of lubricating grease….

#5 NLGI 0 Grease for Sale

Domain Est. 2004

Website: petroleumservicecompany.com

Key Highlights: $99 delivery · 30-day returnsNLGI 0 grade grease is a very soft grease about the consistency of brown mustard. Grease consistency is a major contributor….

#6 02740

Domain Est. 2016

Website: schaeffersoilshop.com

Key Highlights: In stock Rating 5.0 (1) Moly EP Synthetic Plus Grease NLGI #0 is an aluminum complex, para-synthetic, low tack grease with excellent low temperature pumpability characteristics….

#7 NLGI 0 grease by ADDINOL

Website: addinol.de

Key Highlights: Lubricating greases of NLGI class 0 are suitable for a variety of applications, eg as liquid greases or adhesive lubricants….

#8 Mobilux EP 1

Website: mobil.eg

Key Highlights: These lithium hydroxystearate greases are formulated to provide extra protection against wear, rusting and water washout. They are available in NLGI grades ……

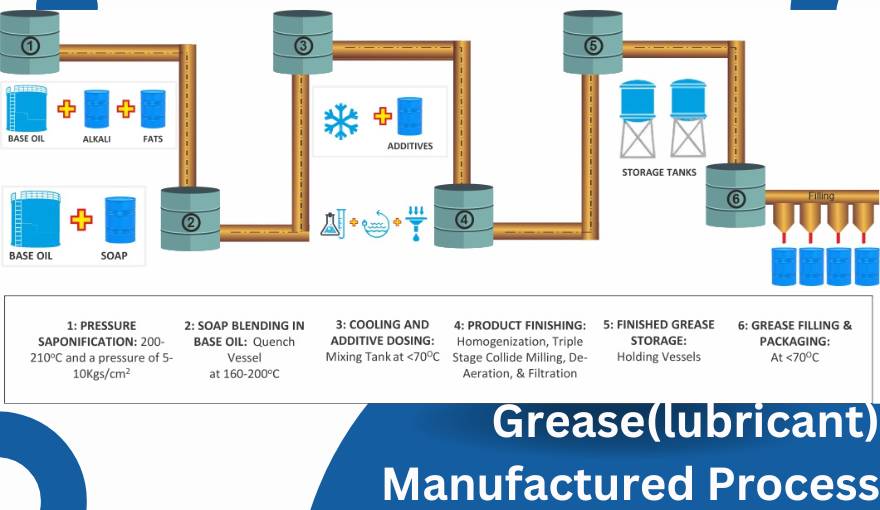

Expert Sourcing Insights for Nlgi 0 Grease

H2: Projected Market Trends for NLGI 0 Grease in 2026

The global market for NLGI 0 grease is poised for steady growth by 2026, driven by increasing industrial automation, rising demand from heavy machinery sectors, and advancements in lubricant formulations. As industries continue to prioritize equipment reliability and longevity, the use of consistent, high-performance greases like NLGI 0 — known for its semi-fluid consistency and excellent lubrication under moderate to severe conditions — is expected to expand.

Key trends shaping the NLGI 0 grease market in 2026 include:

-

Growing Demand in Industrial and Manufacturing Sectors: With the resurgence of manufacturing activities, particularly in emerging economies in Asia-Pacific and Latin America, the need for reliable lubrication in gearboxes, open gears, and centralized lubrication systems is rising. NLGI 0 grease, ideal for such applications due to its pumpability and resistance to leakage, is witnessing increased adoption.

-

Expansion in Wind Energy Applications: The wind power industry is a major growth driver. NLGI 0 greases are frequently used in wind turbine pitch and yaw systems, where effective lubrication under variable loads and temperatures is critical. As global renewable energy targets accelerate wind farm installations, demand for specialized greases, including synthetic-based NLGI 0 variants, is projected to grow significantly by 2026.

-

Shift Toward High-Performance and Synthetic Formulations: Market preferences are shifting from conventional mineral-based greases to synthetic and bio-based alternatives offering superior thermal stability, oxidation resistance, and longer service life. By 2026, manufacturers are expected to launch more eco-friendly, high-efficiency NLGI 0 greases tailored for extreme operating conditions, aligning with sustainability goals.

-

Automotive and Off-Highway Equipment Growth: The off-highway vehicle sector — including construction, mining, and agricultural machinery — continues to adopt NLGI 0 grease for centralized lubrication systems. As automation and electrification progress in these vehicles, lubricant requirements are evolving, favoring greases with enhanced load-carrying capacity and compatibility with seals and materials.

-

Regional Market Dynamics: North America and Europe will maintain strong market shares due to stringent regulations on equipment maintenance and energy efficiency. However, the Asia-Pacific region is expected to record the highest CAGR, fueled by infrastructure development, industrialization, and growing investments in renewable energy.

-

Impact of Supply Chain and Raw Material Costs: Fluctuations in base oil and lithium prices (a key thickener in many NLGI 0 greases) may influence pricing and formulation strategies. By 2026, companies are likely to invest in alternative thickeners (e.g., calcium sulfonate, polyurea) and recycling initiatives to mitigate supply chain risks.

In conclusion, the NLGI 0 grease market in 2026 will be characterized by innovation, sustainability, and sector-specific customization. Stakeholders who align with these trends — particularly in renewable energy, industrial automation, and eco-conscious manufacturing — are likely to capture significant market share.

Common Pitfalls When Sourcing NLGI 0 Grease (Quality & IP)

Sourcing NLGI 0 grease requires careful attention to both technical specifications and intellectual property (IP) considerations. Overlooking these aspects can lead to performance issues, equipment damage, legal risks, and supply chain disruptions. Below are the most common pitfalls to avoid.

Poor Performance Due to Inadequate Quality Control

One of the biggest risks when sourcing NLGI 0 grease is receiving a product that fails to meet required performance standards. Low-quality greases may use inferior base oils or thickeners, leading to poor thermal stability, oxidation resistance, or water washout resistance. This can result in premature equipment failure, especially in demanding environments like mining, construction, or high-temperature industrial applications.

Misrepresentation of NLGI Grade and Consistency

Some suppliers may inaccurately label grease consistency. NLGI 0 grease has a specific penetration range (355–385 1/10 mm). Grease outside this range may not pump effectively through centralized lubrication systems or may leak from housings. Always verify independent lab test results and request ASTM D217 penetration data to confirm the correct grade.

Inconsistent Additive Packages

The performance of NLGI 0 grease heavily depends on its additive package—including anti-wear, extreme pressure (EP), rust inhibitors, and oxidation stabilizers. Off-spec or inconsistent additives can compromise protection under load or in corrosive environments. Ensure the supplier provides detailed technical data sheets (TDS) and performance certifications (e.g., NLGI GC-LB, ISO 12922).

Lack of Traceability and Batch Testing

Reputable suppliers provide batch-specific quality reports and material traceability. Without this, it’s difficult to troubleshoot performance issues or conduct root cause analysis. Always require Certificates of Analysis (CoA) for each shipment to confirm consistency and compliance.

Use of Counterfeit or Repackaged Grease

In some markets, counterfeit or repackaged grease is a serious concern. These products may be diluted, expired, or contaminated. They often lack proper labeling, batch numbers, or manufacturer information. Sourcing through authorized distributors and verifying packaging authenticity helps mitigate this risk.

Intellectual Property (IP) Infringement Risks

Using or sourcing grease formulations that mimic patented technologies (e.g., specialized thickeners, additive systems, or synthetic base stocks) without proper licensing can expose your organization to IP litigation. This is especially relevant when sourcing “equivalent” or “compatible” greases from third-party manufacturers.

Unverified “Equivalent” Claims

Suppliers may claim their NLGI 0 grease is “equivalent” to a branded product (e.g., Shell, Mobil, Chevron). However, true equivalency requires rigorous testing and formulation expertise. Without independent validation, such claims can mislead and result in substandard performance. Always insist on compatibility and performance testing data.

Inadequate Regulatory and Environmental Compliance

Depending on the application, NLGI 0 grease may need to meet environmental standards (e.g., biodegradability, low toxicity for marine or forestry use) or food-grade certifications (e.g., NSF H1). Sourcing non-compliant grease can lead to regulatory penalties or environmental harm.

Supply Chain Instability and Supplier Reliability

Relying on suppliers without proven track records or robust quality management systems (e.g., ISO 9001) increases the risk of inconsistent supply and quality drift. Conduct supplier audits and assess their manufacturing capabilities before committing long-term.

Failure to Test for Compatibility

When switching grease brands or types, compatibility with existing lubricants is critical. Incompatible greases can cause softening, hardening, or separation, leading to lubrication failure. Always conduct compatibility testing before full-scale implementation.

By addressing these common pitfalls—focusing on verified quality, accurate specifications, and IP compliance—organizations can ensure reliable performance and reduce operational and legal risks when sourcing NLGI 0 grease.

Logistics & Compliance Guide for NLGI 0 Grease

Overview of NLGI 0 Grease

NLGI 0 grease is a soft consistency lubricant classified under the National Lubricating Grease Institute (NLGI) grading system. It falls under consistency grade 0, making it semi-fluid and suitable for centralized lubrication systems, low-temperature applications, and equipment requiring high pumpability. Proper logistics handling and regulatory compliance are essential due to its chemical composition and potential environmental impact.

Storage & Handling Requirements

Temperature Control

– Store in a cool, dry, and well-ventilated area.

– Ideal storage temperature: 10°C to 30°C (50°F to 86°F).

– Avoid exposure to extreme heat or freezing conditions to prevent oil separation or thickening.

Container Integrity

– Keep grease in original, sealed containers to prevent contamination.

– Use clean, dedicated tools when dispensing to avoid cross-contamination.

– Label all containers clearly with product name, grade (NLGI 0), and date of receipt.

Shelf Life

– Typical shelf life: 3 to 5 years when stored properly.

– Monitor for signs of degradation (e.g., phase separation, odor changes).

Transportation Guidelines

Packaging Standards

– Transport in UN-certified containers if required by region.

– Common packaging: 16 kg (35 lb) pails, 170 kg (400 lb) drums, or bulk totes.

– Ensure containers are tightly sealed and secured to prevent leakage.

Hazard Classification

– NLGI 0 greases are generally classified as non-hazardous under transport regulations (e.g., ADR, IMDG, IATA), but may vary by formulation.

– Confirm with Safety Data Sheet (SDS) for specific product classification.

– Some greases containing additives (e.g., heavy metals, EP additives) may require hazardous material labeling.

Documentation

– Provide SDS with each shipment.

– Include proper shipping name, UN number (if applicable), and transport classification.

Regulatory Compliance

GHS/CLP Classification

– Review SDS for Global Harmonized System (GHS) or EU CLP classification.

– Most NLGI 0 greases are labeled as:

– H304: May be fatal if swallowed and enters airways.

– H315: Causes skin irritation.

– H336: May cause drowsiness or dizziness (if volatile solvents present).

– H411: Toxic to aquatic life with long-lasting effects.

Environmental Regulations

– Comply with local environmental laws (e.g., EPA in the U.S., REACH and CLP in the EU).

– Avoid discharge into soil, waterways, or sewers.

– Used grease is often classified as hazardous waste; dispose of through licensed waste handlers.

Worker Safety (OSHA / EU Directives)

– Implement controls per OSHA Hazard Communication Standard (29 CFR 1910.1200) or EU Directive 1999/45/EC.

– Provide PPE: gloves, safety goggles, and protective clothing.

– Ensure adequate ventilation in handling areas.

Disposal & Waste Management

Used or Contaminated Grease

– Collect waste grease in labeled, leak-proof containers.

– Dispose of in accordance with local, state, and federal regulations.

– Recycle through certified re-refining facilities where possible.

Spill Response

– Contain spills immediately using absorbent materials (e.g., clay, oil-absorbent pads).

– Avoid washing into drains; collect contaminated materials as hazardous waste.

– Report large spills per local environmental agency requirements.

Documentation & Recordkeeping

- Maintain up-to-date Safety Data Sheets (SDS) for all grease products.

- Keep records of shipments, storage conditions, employee training, and disposal manifests.

- Conduct periodic audits to ensure compliance with transportation and environmental regulations.

Summary

NLGI 0 grease requires careful attention to storage, transportation, and regulatory compliance due to its physical properties and potential health/environmental risks. Always consult the product-specific SDS and adhere to regional regulations to ensure safe and compliant handling across the supply chain.

Conclusion for Sourcing NLGI 0 Grease

In conclusion, sourcing NLGI 0 grease requires a thorough evaluation of application requirements, equipment specifications, and operating conditions such as temperature, load, and speed. This semi-fluid grease is particularly suitable for centralized lubrication systems, low-temperature environments, and applications requiring excellent pumpability and drip resistance.

When selecting a supplier, key considerations include product quality and compliance with industry standards (e.g., ISO, OEM specifications), consistency in supply, technical support, and cost-effectiveness. Engaging with reputable manufacturers or distributors with proven track records ensures reliability and performance.

Additionally, prioritizing greases with desirable properties—such as good shear stability, water resistance, and oxidation protection—enhances equipment longevity and reduces maintenance costs. Environmental and sustainability factors, including biodegradability and packaging, may also influence sourcing decisions depending on operational priorities.

Ultimately, a strategic sourcing approach that balances performance, availability, and total cost of ownership will ensure optimal lubrication performance and operational efficiency when using NLGI 0 grease.