The global cold brew coffee market has experienced robust growth over the past decade, driven by shifting consumer preferences toward premium, smooth-tasting coffee beverages. According to Grand View Research, the global cold brew coffee market size was valued at USD 1.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 13.2% from 2023 to 2030. This surge in demand has catalyzed innovation in commercial brewing equipment, particularly for nitro cold brew systems that deliver creamy texture and enhanced flavor through nitrogen infusion. As cafes, restaurants, and quick-service chains seek to capitalize on this trend, the need for reliable, high-performance nitro cold brew machines has intensified. This growing demand has positioned several manufacturers as industry leaders, offering scalable, efficient, and consistent commercial solutions. Based on production capabilities, market presence, customer reviews, and technological innovation, the following nine manufacturers have emerged as top providers of commercial nitro cold brew machines, serving businesses from specialty coffee shops to large-scale foodservice operations.

Top 9 Nitro Cold Brew Machine Commercial Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Commercial Cold Brew Coffee Maker Manufacturers

Domain Est. 2000

Website: puricom.com

Key Highlights: Nitro coffee provides a silky, smooth taste and is a healthier alternative to energy and soda drinks. welcome to contact Puricom for more hydrogen water ……

#2 Cold Brew & Nitro Countertop System

Domain Est. 2019

Website: nestlecoffeepartnerssl.com

Key Highlights: Nestlé Coffee Partners Solutions Lab Logo Cold Brew & Nitro Countertop System Get an overview of the WPS Cold Brew and Nitro Countertop System.Missing: commercial manufacturer…

#3 Wilbur Curtis

Domain Est. 1997 | Founded: 1941

Website: wilburcurtis.com

Key Highlights: Perfecting the art of brewing since 1941, Curtis manufactures a full line of commercial coffee brewing equipment, iced tea brewing systems, cappuccino ……

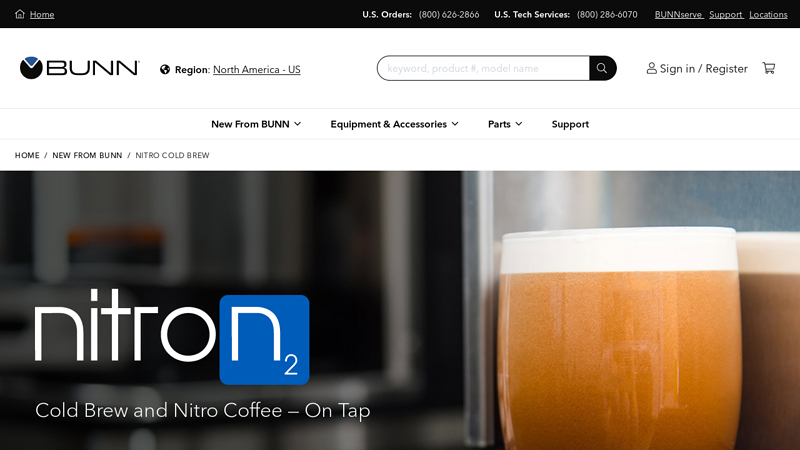

#4 Nitro Cold Brew

Domain Est. 1998

Website: commercial.bunn.com

Key Highlights: Keg-free design makes Nitron the ideal platform for delivering authentic Cold Brew taste without the need for a complex or lengthy brewing process….

#5 Cold Brew & Nitro Coffee Dispensers

Domain Est. 1998

Website: summitappliance.com

Key Highlights: We offer both flat iced coffee tap kits and nitro-infused tap kits with stout-style draft towers, available with single and dual tap options….

#6 NitroPress®

Domain Est. 2006

Website: nitropress.com

Key Highlights: It’s your gateway to barista-quality nitro drinks at home. With NitroPress, you get perfectly smooth, creamy coffee and beverages with just a push of a button….

#7 Discover Hardtank Equipment

Domain Est. 2015

Website: hardtank.com

Key Highlights: Hardtank is a revolutionary cold brew machine designed for professionals who want to deliver premium cold coffee at scale, without compromise. Using patented ……

#8 NITRO COLD BREW MAKER – NITRO COFFEE

Domain Est. 2016

Website: drinkbrood.com

Key Highlights: BROOD commercial nitro cold brew machines chill drinks down to a crisp 2 °C, infusing every cup with atmospheric nitrogen to bring you the creamiest, sweetest ……

#9 #1 Nitro Cold Brew Coffee Maker

Domain Est. 2020

Expert Sourcing Insights for Nitro Cold Brew Machine Commercial

H2: Market Trends for Commercial Nitro Cold Brew Machines in 2026

The commercial nitro cold brew machine market is poised for significant evolution by 2026, driven by shifting consumer preferences, technological innovation, and expansion in foodservice channels. As specialty coffee continues to gain traction globally, the demand for high-quality, ready-to-serve nitro cold brew solutions is reshaping the commercial equipment landscape. Below are the key market trends expected to define the industry in 2026:

1. Rising Demand for On-Tap Nitro Coffee in Cafés and Restaurants

By 2026, an increasing number of specialty coffee shops, quick-service restaurants (QSRs), and craft beverage establishments are projected to adopt nitro cold brew on tap as a premium menu offering. The smooth, creamy texture and naturally sweet profile of nitro cold brew—achieved through nitrogen infusion—align with consumer preferences for premium, low-acidity coffee experiences. This trend is fueling demand for compact, user-friendly commercial nitro cold brew dispensers capable of integrating seamlessly into diverse service environments.

2. Technological Advancements in Machine Efficiency and Automation

Manufacturers are investing in smart technology and automation to enhance the functionality of commercial nitro cold brew systems. By 2026, expect wider adoption of IoT-enabled machines with remote monitoring, predictive maintenance alerts, and customizable infusion settings. These innovations improve operational efficiency, reduce waste, and ensure consistency across high-volume service periods, making them especially appealing to chain operators and multi-unit retailers.

3. Sustainability and Energy Efficiency as Key Differentiators

As environmental concerns grow, sustainability is becoming a critical factor in purchasing decisions. Commercial nitro cold brew machine manufacturers are responding with energy-efficient models, recyclable components, and reduced nitrogen waste systems. Equipment that supports sustainable sourcing—such as compatibility with compostable kegs or low-carbon nitrogen generation—will gain competitive advantage in eco-conscious markets, particularly in North America and Western Europe.

4. Expansion into Non-Traditional Venues

Beyond traditional coffee shops, nitro cold brew is making inroads into non-traditional venues such as hotels, gyms, office complexes, and convenience stores. These locations are adopting commercial nitro systems to meet growing consumer demand for premium grab-and-go beverages. By 2026, modular and space-saving machine designs tailored for compact or high-traffic environments will be a key growth driver.

5. Growth of Private Label and Custom-Infused Nitro Beverages

Operators are increasingly offering house-blend or flavored nitro cold brews (e.g., vanilla, caramel, oat milk-infused) to differentiate their brands. This trend is encouraging the development of commercial machines with customizable infusion capabilities and multi-line dispensing systems. Equipment that supports easy switching between formulations will be in high demand among roasters and beverage brands launching private-label nitro products.

6. Regional Market Diversification

While North America remains the largest market for commercial nitro cold brew machines, regions such as Asia-Pacific and Latin America are expected to see accelerated growth by 2026. Urbanization, rising disposable incomes, and the proliferation of specialty coffee culture in countries like South Korea, Australia, Brazil, and Mexico are creating new opportunities for equipment suppliers. Localized machine designs that accommodate varying voltage standards, climate conditions, and menu preferences will be essential for global expansion.

7. Strategic Partnerships and Vertical Integration

Coffee roasters, beverage distributors, and equipment manufacturers are forming strategic partnerships to offer turnkey nitro cold brew solutions. By 2026, integrated packages—including machines, nitrogen systems, kegged coffee, and training—will become standard, lowering the barrier to entry for small and mid-sized operators. This bundling trend will streamline adoption and enhance customer retention in a competitive market.

In summary, the 2026 commercial nitro cold brew machine market will be defined by innovation, sustainability, and expanding accessibility. As consumer demand for premium coffee experiences grows, businesses that leverage advanced, efficient, and adaptable nitro dispensing technology will lead the next wave of market transformation.

Common Pitfalls When Sourcing a Commercial Nitro Cold Brew Machine (Quality & IP)

Sourcing a commercial nitro cold brew machine requires careful evaluation beyond just price and aesthetics. Overlooking critical quality and intellectual property (IP) aspects can lead to operational disruptions, legal risks, and reputational damage. Here are key pitfalls to avoid:

Overlooking Build Quality and Material Standards

Many suppliers offer machines with thin-gauge stainless steel or non-food-grade materials to cut costs. This compromises durability, increases corrosion risk, and may violate health codes. Always verify the machine uses 304 or 316 food-grade stainless steel, especially for components in direct contact with coffee or nitrogen. Poorly welded seams or substandard fittings can lead to leaks and contamination, impacting both safety and performance.

Ignoring Nitrogen Integration and Pressure Safety

Nitro cold brew relies on precise nitrogen infusion under pressure. Low-quality machines may lack proper pressure regulation, fail to integrate with food-grade nitrogen systems, or omit essential safety features like pressure relief valves. This not only affects beverage consistency (e.g., flat or overly foamy output) but also poses serious safety hazards. Ensure the machine complies with local pressure equipment regulations and includes certified components.

Assuming All “Nitro” Systems Are Equal

Some machines marketed as “nitro” are simply modified kegerators without proper diffusion technology. True nitro systems use specialized faucets (e.g., restrictor plates or sintered disks) to create the signature creamy texture. Sourcing a machine without verified diffusion performance leads to disappointing customer experiences. Request product demos or third-party performance data to validate output quality.

Underestimating Maintenance and Serviceability

Complex machines with proprietary parts or poor access design increase downtime and repair costs. Avoid models where critical components (pumps, regulators, taps) are difficult to access or require specialized tools. Lack of available service support in your region can cripple operations. Prioritize suppliers offering clear maintenance protocols, accessible spare parts, and local technical assistance.

Neglecting Intellectual Property (IP) and Brand Authenticity

Using a machine that replicates patented designs or infringes on IP rights—especially from well-known brands—can expose your business to legal action. Some low-cost manufacturers clone proprietary technologies (e.g., specific nitrogen infusion methods or tap designs) without licensing. Always verify the manufacturer’s legitimacy, request documentation of IP ownership or licensing, and avoid suppliers who cannot provide transparent information about their engineering and design rights.

Skipping Due Diligence on Supplier Credibility

Sourcing from unknown manufacturers, especially via online marketplaces, increases the risk of receiving non-compliant or counterfeit equipment. Check for certifications (e.g., CE, UL, NSF), customer references, and business registration. A lack of verifiable track record or reluctance to provide technical specifications should be a red flag.

Avoiding these pitfalls ensures you invest in a reliable, safe, and legally sound nitro cold brew system that supports long-term business success.

Logistics & Compliance Guide for Nitro Cold Brew Machine (Commercial)

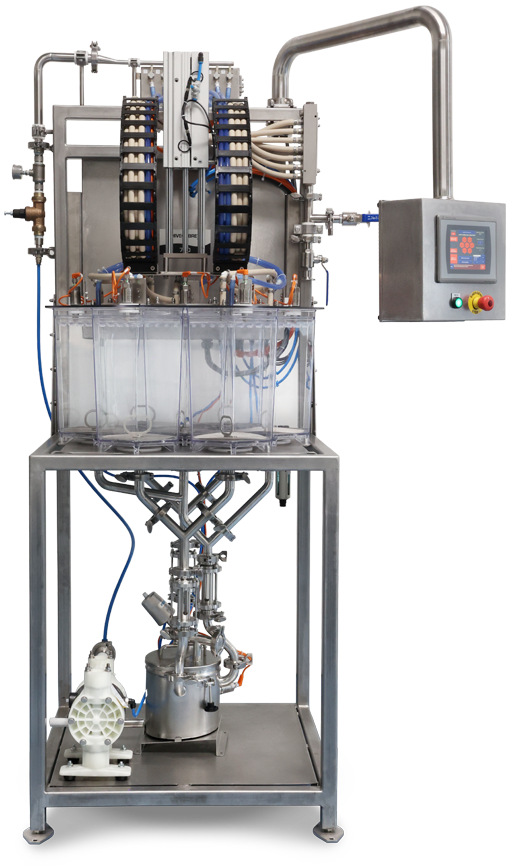

Product Overview and Intended Use

The Nitro Cold Brew Machine is a commercial beverage dispensing system designed for use in cafes, restaurants, and retail environments. It infuses cold brew coffee with nitrogen gas to create a smooth, creamy texture and cascading visual effect. This guide outlines the logistics and regulatory compliance requirements for safe installation, operation, and maintenance.

Shipping and Receiving Requirements

All units are shipped via freight carriers in secure, palletized packaging. Upon delivery:

– Inspect packaging for damage before signing the delivery receipt.

– Verify contents against the packing list, including machine, CO₂/N₂ regulator, shanks, faucet, and user manual.

– Store the machine indoors in a dry, temperature-controlled environment prior to installation.

– Notify the supplier immediately of any discrepancies or damages.

Installation and Setup Procedures

Installation must be performed by a qualified technician in accordance with local plumbing, electrical, and gas codes:

– Ensure a stable, level surface with adequate ventilation.

– Connect to a dedicated 110–120V GFCI-protected electrical outlet.

– Install nitrogen tank (food-grade N₂, 99.9%+ purity) with compatible pressure regulator (typically 35–45 PSI).

– Use only food-grade tubing and fittings rated for nitrogen service.

– Perform leak tests on all gas connections using a manufacturer-approved solution.

Regulatory Compliance Standards

The Nitro Cold Brew Machine complies with the following standards:

– Electrical Safety: UL 763 (Standard for Electric Food Preparation Equipment)

– Gas Safety: NFPA 55 (Compressed and Liquefied Gases Code) and CGA V-2 (Standard for Manifold Systems)

– Food Contact Materials: FDA 21 CFR §177 (Indirect Food Additives: Polymers)

– Energy Efficiency: ENERGY STAR® guidelines (if applicable)

Documentation, including CE marking (for EU) or ETL listing (for North America), must be retained on-site.

Operational Safety and Training

Operators must complete manufacturer-provided training covering:

– Safe handling and securing of nitrogen tanks (high-pressure hazards).

– Daily startup, dispensing, and shutdown procedures.

– Emergency shutdown in case of gas leaks or electrical faults.

– Prohibition of modifications to pressure systems or electrical components.

Display safety signage near the unit, including “High Pressure Gas” and “Do Not Operate Without Training.”

Maintenance and Sanitation Schedule

Maintain hygiene and performance through routine servicing:

– Daily: Clean faucet and drip tray with food-safe sanitizer.

– Weekly: Flush lines with hot water and approved cleaning solution.

– Monthly: Inspect gas hoses, regulator, and seals for wear or leaks.

– Quarterly: Professional inspection of internal components and pressure systems.

Keep a maintenance log accessible for health inspections.

Environmental and Disposal Considerations

- Nitrogen tanks are returnable or recyclable through certified gas suppliers.

- Dispose of electronic components (e.g., control boards) in accordance with local e-waste regulations (e.g., WEEE Directive in EU).

- Use biodegradable cleaning agents where possible to minimize environmental impact.

Documentation and Recordkeeping

Retain the following records for audit and compliance purposes:

– Equipment manual and warranty information

– Proof of technician certification for installation

– Gas tank inspection and hydrostatic test dates (typically every 5 years)

– Maintenance logs and sanitation records

– Health department permits (if required by jurisdiction)

Jurisdictional Variations and Permits

Local regulations may impose additional requirements:

– Health Department Approval: Required in most U.S. states for commercial beverage equipment.

– Gas Permits: Some municipalities require permits for storing compressed gases on-site.

– EU Compliance: CE marking, Declaration of Conformity, and adherence to PED (Pressure Equipment Directive 2014/68/EU) are mandatory.

Consult local authorities before installation to ensure full compliance.

Conclusion:

Investing in a commercial nitro cold brew machine is a strategic decision that can significantly enhance a café, restaurant, or specialty beverage business. These machines not only streamline the production of smooth, creamy nitro cold brew coffee but also elevate the overall customer experience with a visually appealing tap presentation and rich flavor profile. As consumer demand for premium coffee experiences continues to grow, offering nitro cold brew can differentiate your brand, increase average ticket size, and boost customer loyalty.

When sourcing a commercial nitro cold brew machine, it’s essential to consider factors such as production capacity, reliability, ease of maintenance, and compatibility with your existing draft system. Leading brands like Pepsi Nitro, BrewJä, and MicroMatic offer robust solutions tailored to high-volume environments.

Ultimately, the right nitro cold brew machine will support operational efficiency, deliver consistent quality, and provide a strong return on investment. By carefully evaluating your business needs and choosing a trusted supplier, you can successfully integrate nitro cold brew into your menu and capitalize on one of the most exciting trends in the specialty coffee industry.