The global loudspeaker market is experiencing robust growth, driven by rising demand for high-performance audio systems across consumer electronics, automotive, and professional audio applications. According to Grand View Research, the global loudspeaker market size was valued at USD 10.5 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030. A key factor fueling this expansion is the increasing adoption of neodymium magnets in speaker manufacturing, owing to their superior strength-to-size ratio, which enables compact, lightweight designs without compromising sound quality. Neodymium speakers are now standard in premium headphones, portable Bluetooth speakers, soundbars, and high-fidelity audio systems. As innovation accelerates and OEMs seek reliable suppliers with advanced material engineering capabilities, a select group of manufacturers has emerged as leaders in neodymium speaker production—combining scale, R&D investment, and global supply chain reach to meet evolving market demands.

Top 8 Neodymium Speakers Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 B&C Speakers

Domain Est. 1999 | Founded: 1946

Website: bcspeakers.com

Key Highlights: Since 1946, B&C Speakers has been one of the largest and most prestigious professional loudspeaker transducer manufacturers in the world….

#2 Neodymium ( A Brand Of Numark Audio)

Domain Est. 2022

Website: neodymiumaudio.com

Key Highlights: Neodymium ( A Brand Of Numark Audio) ; Dj Speakers 15 Inch · Rs 4,500 / Piece. Speaker Type: ; 12 Inch 600 Watt neodymium · Rs 6,500 / Piece. Connectivity Type: ……

#3 Company Overview

Domain Est. 1995

Website: sonance.com

Key Highlights: Rock Speakers and Woofers. James. Outdoor Tower Speakers. OT66Q · OT84 · OT88Q … Neodymium mid drivers, and Beryllium Quad Tweeter Array. Specifications ……

#4 Transducers

Domain Est. 1996

Website: rcf.it

Key Highlights: NEODYMIUM COMPRESSION DRIVERS Lightweight and powerful, RCFs neodymium drivers are a reference in performance and reliability….

#5 Neodymium Series

Domain Est. 1998

Website: eminence.com

Key Highlights: From heavy-duty subwoofers, midranges, and transducers in truncated frames for line arrays, there is an Eminence Neodymium Professional model for your ……

#6 Vintage Neo

Domain Est. 2007

Website: jensentone.com

Key Highlights: As one of the first companies building great-sounding neodymium guitar speakers, Jensen’s decades of experience shine in the Vintage Neo series. Intensive ……

#7 Products

Domain Est. 2011

Website: lavocespeakers.com

Key Highlights: R&D team’s 30 years of expertise and endless passion for sound · Ferrite Low Freq. transducers · Neodymium Low Freq. transducers · Ferrite compression drivers….

#8 SPEAKERS

Domain Est. 2014

Website: smmagnetics.com

Key Highlights: Today, high quality and great sounding speakers are using neodymium magnets. This allows the entire speaker assembly (magnets, voice coil, steel and speaker ……

Expert Sourcing Insights for Neodymium Speakers

2026 Market Trends for Neodymium Speakers

The neodymium speaker market is poised for significant evolution by 2026, driven by technological advancements, shifting consumer preferences, and expanding applications. These powerful, lightweight rare-earth magnet-based speakers are becoming increasingly central to modern audio solutions across consumer electronics, automotive, and professional audio sectors.

1. Continued Dominance in Miniaturized and High-Performance Audio Devices

By 2026, neodymium speakers will remain the preferred choice for compact, high-efficiency audio systems. Their superior strength-to-size ratio makes them indispensable in the growing ecosystem of wearable tech, including premium true wireless earbuds (TWS), AR/VR headsets, and smart glasses. As consumer demand for richer sound in smaller form factors intensifies, manufacturers will increasingly leverage neodymium’s capabilities to deliver audiophile-grade performance in ultra-compact designs.

2. Accelerated Adoption in Electric and Smart Vehicles

The automotive sector will be a major growth driver. With the global shift toward electric vehicles (EVs) and intelligent infotainment systems, automakers are prioritizing lightweight components to extend battery range and enhance acoustic experiences. Neodymium speakers offer the ideal balance of power, clarity, and reduced weight, making them standard in premium and mid-tier automotive audio systems. By 2026, integration with active noise cancellation (ANC) and immersive 3D audio platforms will further boost demand.

3. Rising Demand in Professional and Immersive Audio Applications

Professional audio equipment—such as studio monitors, live sound systems, and portable PA units—will increasingly adopt neodymium drivers to reduce load weight and improve portability without sacrificing sound quality. Concurrently, the rise of spatial audio in home theaters, gaming setups, and virtual production will drive demand for compact, high-fidelity neodymium-based speaker arrays capable of precise sound localization.

4. Supply Chain and Sustainability Pressures

A key challenge shaping the 2026 landscape will be the volatility of rare earth element (REE) supply chains, particularly neodymium and praseodymium. Geopolitical factors and environmental concerns surrounding REE mining may prompt manufacturers to invest in recycling technologies and explore alternative materials. Companies that secure sustainable sourcing or develop hybrid magnet solutions are likely to gain a competitive edge.

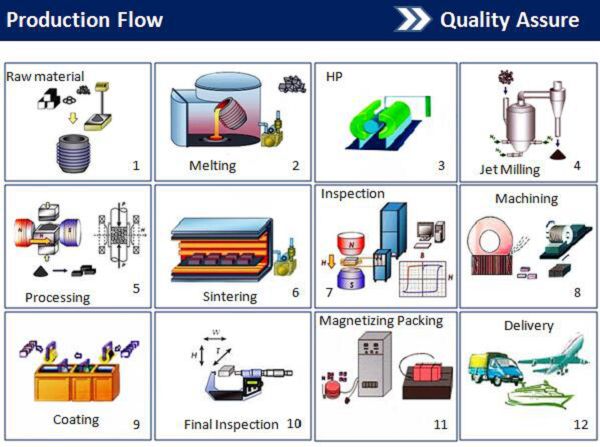

5. Innovation in Materials and Manufacturing

Ongoing R&D will focus on enhancing neodymium magnet performance while reducing dependency on critical raw materials. Advances in magnet coating technologies will improve thermal stability and corrosion resistance, broadening application scope. Additionally, automation and precision manufacturing techniques will lower production costs, enabling wider adoption in mid-range consumer products.

In conclusion, the 2026 neodymium speaker market will be characterized by robust growth in high-tech and mobile applications, tempered by supply chain considerations. Innovation and sustainability will be key differentiators as the industry balances performance demands with environmental and economic realities.

Common Pitfalls When Sourcing Neodymium Speakers (Quality, IP)

Sourcing neodymium speakers—especially for applications requiring high performance, durability, or environmental protection—can present several challenges. Buyers often face issues related to quality inconsistencies, misleading specifications, and intellectual property (IP) risks. Being aware of these pitfalls helps ensure reliable supply and product integrity.

Quality Inconsistencies and Performance Variability

Neodymium speakers are prized for their high magnetic strength and compact size, but low-cost manufacturers may cut corners, resulting in subpar performance. Common quality issues include inconsistent magnet grading (e.g., using lower-grade N35 instead of N52), poor voice coil alignment, and inferior diaphragm materials. These flaws can lead to reduced sensitivity, distorted audio output, and premature failure. Additionally, thermal management is often overlooked; inadequate heat dissipation can cause voice coil burnout during prolonged use. Buyers should demand detailed technical specifications, conduct sample testing, and consider third-party lab verification to validate performance claims.

Misrepresentation of IP (Ingress Protection) Ratings

Many suppliers claim their neodymium speakers are “waterproof” or “dustproof” with high IP ratings (e.g., IP67), but these claims are frequently exaggerated or unverified. Some manufacturers apply basic coatings or gaskets without proper sealing design, leading to moisture ingress and corrosion. True IP-rated speakers require rigorous engineering, including sealed enclosures, conformal-coated circuitry, and specialized membranes. Without independent certification (e.g., IEC 60529 testing), IP claims may be marketing tactics rather than functional guarantees. Always request test reports or certification documents and consider real-world environmental testing before mass procurement.

Risk of Counterfeit or Unlicensed Components

The high value of neodymium magnets and patented speaker designs makes this market vulnerable to counterfeit parts and IP infringement. Some suppliers use recycled or substandard magnets misrepresented as genuine, affecting magnetic flux and longevity. Others may replicate patented speaker architectures without authorization, exposing buyers to legal and reputational risks. To mitigate this, work with reputable suppliers, verify material certifications (e.g., RoHS, REACH), and include IP compliance clauses in contracts. Conducting factory audits and using trusted sourcing channels can further reduce exposure to counterfeit components.

Lack of Long-Term Supply Chain Reliability

Neodymium is a rare-earth element subject to geopolitical and supply chain volatility. Suppliers in certain regions may face export restrictions or raw material shortages, leading to delivery delays or sudden price hikes. Relying on a single source without contingency planning increases project risk. Diversifying suppliers, securing long-term agreements, and monitoring rare-earth market trends are essential strategies to maintain supply continuity and cost stability.

Logistics & Compliance Guide for Neodymium Speakers

Neodymium speakers, while offering superior sound quality and compact design, present unique challenges in logistics and regulatory compliance due to their composition—specifically the presence of rare earth magnets containing neodymium. This guide outlines key considerations for the safe, legal, and efficient transport and handling of these products globally.

Classification and Regulatory Overview

Neodymium speakers contain permanent magnets made from neodymium-iron-boron (NdFeB), which are classified as strong magnetic materials. Their transport is regulated under international dangerous goods regulations due to the potential to interfere with navigation and communication systems. Key regulatory frameworks include:

- IMDG Code (International Maritime Dangerous Goods): Governs sea transport; magnets with a magnetic field strength exceeding 0.159 A/m at 2.1 meters may be subject to Class 9 (Miscellaneous Dangerous Goods) requirements.

- IATA Dangerous Goods Regulations (DGR): Applies to air transport; magnetic materials must be tested and declared if they meet criteria under Class 9 (UN2807, Magnetized Material).

- 49 CFR (U.S. Department of Transportation): Regulates domestic U.S. transport; similar criteria apply for magnetized materials.

Note: Even if speakers are embedded in devices (e.g., audio systems), the magnetic field must be assessed to determine if classification is required.

Packaging and Labeling Requirements

Proper packaging is essential to minimize magnetic field emissions and ensure safe handling:

- Shielding: Use ferromagnetic shielding (e.g., steel plates or enclosures) to contain magnetic flux and reduce external field strength.

- Secure Containment: Pack speakers to prevent movement during transit. Use anti-static and moisture-resistant materials where applicable.

- Marking and Labeling:

- If classified as dangerous goods: Apply UN number (UN2807), Proper Shipping Name (“Magnetized Material”), Class 9 hazard label, and shipper/consignee information.

- Include a completed Shipper’s Declaration for Dangerous Goods for air and sea shipments when required.

- Non-hazardous shipments should still indicate “Fragile” and “This Way Up” for handling.

Testing and Documentation

- Magnetic Field Testing: Conduct a gauss meter test at 2.1 meters from the package to determine if field strength exceeds 0.159 A/m (0.002 Gauss). If below, the shipment may be exempt from dangerous goods regulations.

- Test Certificate: Maintain records of magnetic field testing for audit and customs purposes.

- Safety Data Sheet (SDS): While neodymium speakers are generally not classified as hazardous under GHS for chemical risks, an SDS may still be required in some jurisdictions or for customs clearance. Include information on materials used, including rare earth elements.

Import/Export Compliance

- Customs Classification: Use the correct HS (Harmonized System) code. Neodymium speakers typically fall under 8518.21 or 8518.29 (loudspeakers, whether or not mounted in enclosures). Confirm with local customs authorities as classifications may vary.

- Rare Earth Element Regulations: Some countries monitor or restrict the export/import of products containing rare earth elements (e.g., China, EU). Stay informed about trade policies related to critical raw materials.

- Product Standards and Certifications:

- Ensure compliance with regional standards (e.g., CE marking for EU, FCC for U.S., KC for South Korea).

- Include RoHS (Restriction of Hazardous Substances) and REACH compliance documentation, as applicable.

Handling and Storage Precautions

- Magnetic Interference: Keep speakers away from pacemakers, credit cards, hard drives, and sensitive electronic equipment.

- Mechanical Risks: Neodymium magnets are brittle and can shatter on impact; handle with care.

- Storage Environment: Store in a dry, temperature-controlled environment to prevent corrosion (neodymium magnets are prone to oxidation unless coated).

- Worker Safety: Use non-magnetic tools and wear protective gear when handling large quantities to avoid pinching injuries.

Environmental and Disposal Considerations

- Recycling: Neodymium is a valuable and scarce resource. Implement end-of-life recycling programs in compliance with WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions.

- Hazardous Waste: While intact speakers are not typically hazardous waste, damaged or separated magnets may require special disposal due to metal content. Follow local environmental regulations.

Best Practices Summary

- Conduct magnetic field testing before shipping.

- Package with shielding if necessary to meet regulatory thresholds.

- Maintain accurate documentation, including test reports and shipping declarations.

- Train logistics personnel on handling strong magnetic materials.

- Regularly review international regulations for updates on magnet transport and rare earth material restrictions.

By adhering to this guide, businesses can ensure compliant, safe, and efficient global distribution of neodymium speakers while minimizing risks and delays.

Conclusion for Sourcing Neodymium Speakers:

Sourcing neodymium speakers offers significant advantages due to their superior strength-to-size ratio, lightweight nature, and excellent audio performance, making them ideal for compact, high-efficiency audio devices such as portable speakers, headphones, and professional audio equipment. However, careful consideration must be given to the supply chain due to the reliance on rare earth elements, particularly neodymium, which is primarily sourced from a limited number of geopolitical regions—raising concerns about supply stability, price volatility, and environmental impact.

To ensure a responsible and sustainable sourcing strategy, manufacturers should diversify suppliers, consider ethical sourcing certifications (such as those from the Responsible Minerals Initiative), and explore partnerships with recyclers to support circular economy practices. Additionally, investing in research for alternative materials or speaker designs may mitigate future supply risks.

In summary, while neodymium speakers deliver unmatched acoustic performance in a compact form, a strategic, ethical, and long-term approach to sourcing is essential to balance performance, cost, sustainability, and supply chain resilience.