The global NEMA enclosure market is experiencing steady growth, driven by increasing demand for protective electrical enclosures across industrial, commercial, and utility sectors. According to Grand View Research, the global electrical enclosures market size was valued at USD 8.9 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. A significant portion of this demand comes from NEMA Type 1 enclosures, which are widely used for indoor environments requiring basic protection against dust, light, and non-corrosive liquids. As industries prioritize equipment safety and regulatory compliance, manufacturers specializing in NEMA Type 1 enclosures are scaling innovation in materials, design efficiency, and customization. Based on market presence, product range, and industry reputation, the following are the top five NEMA Type 1 enclosure manufacturers shaping the landscape today.

Top 5 Nema Type 1 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 NEMA Enclosures

Domain Est. 1999

Website: nemaenclosures.com

Key Highlights: Nema Enclosures manufactures industrial NEMA enclosures with powder-coated carbon steel, 304 stainless steel, 316 stainless steel, or 5052 aluminum….

#2 NEMA

Domain Est. 1994

Website: nema.org

Key Highlights: An ANSI-accredited Standards Developing Organization, NEMA gives members a competitive edge in today’s rapidly changing marketplace….

#3 Enclosures for Electrical Equipment, ANSI/NEMA 250

Domain Est. 1994

Website: blog.ansi.org

Key Highlights: ANSI/NEMA 250-2020: Enclosures For Electrical Equipment (1000 Volts Maximum) specifies standard NEMA ratings used to protect personnel….

#4 Understanding NEMA Ratings

Domain Est. 2000

Website: steeltubeinstitute.org

Key Highlights: NEMA ratings give a recommendation of where electrical panels and systems can be safely used and what environments may suit them….

#5 NEMA Standards

Domain Est. 2023 | Founded: 1926

Website: makeitelectric.org

Key Highlights: Since 1926, NEMA standards have played a critical role in the design, production, installation, and operation of technologies and products….

Expert Sourcing Insights for Nema Type 1

2026 Market Trends for NEMA Type 1 Enclosures

As the industrial automation and electrical infrastructure sectors evolve, NEMA Type 1 enclosures—designed primarily for indoor use to protect against dust, light, and indirect splashing—will experience several key market trends by 2026. These trends reflect broader shifts in manufacturing, sustainability demands, digitalization, and supply chain dynamics.

1. Increased Demand from Smart Manufacturing and IIoT Integration

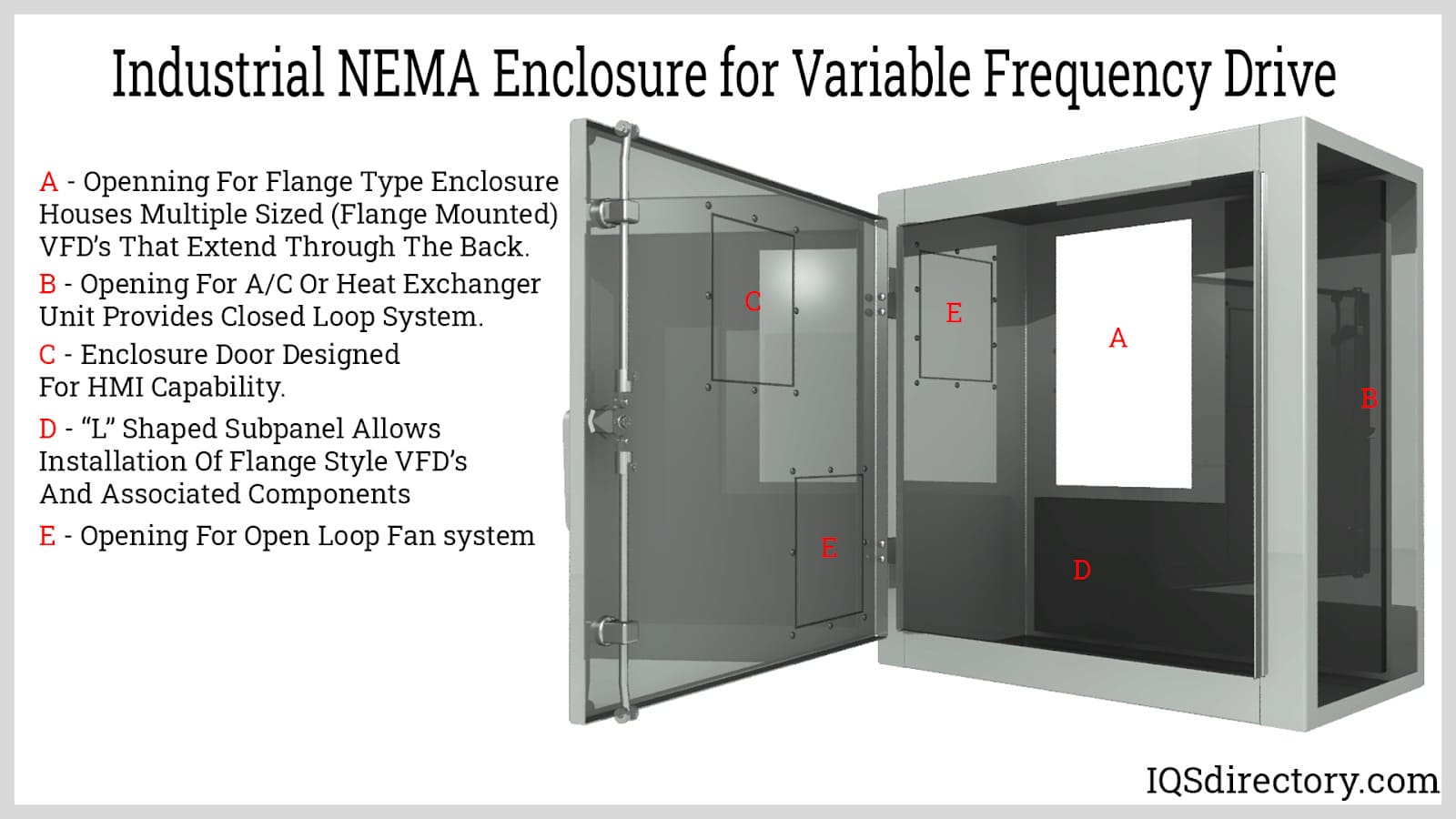

The continued expansion of Industry 4.0 and the Industrial Internet of Things (IIoT) is driving growth in electrical control systems. NEMA Type 1 enclosures remain essential for housing low-voltage control components like PLCs, relays, and HMIs in non-hazardous indoor environments. By 2026, rising investments in smart factories, predictive maintenance systems, and connected machinery will boost demand for standardized, cost-effective enclosures—positioning NEMA Type 1 as a foundational element in control panel design.

2. Emphasis on Energy Efficiency and Sustainability

Environmental regulations and corporate sustainability goals are influencing enclosure materials and design. Manufacturers are increasingly adopting recyclable steel and aluminum, reducing volatile organic compound (VOC) emissions during powder coating, and designing enclosures for longer lifespans. By 2026, eco-certifications and energy-efficient manufacturing processes will become competitive differentiators, with NEMA Type 1 enclosures expected to meet higher environmental standards.

3. Supply Chain Resilience and Regional Manufacturing Shifts

Ongoing global supply chain volatility is prompting a shift toward nearshoring and regional production, particularly in North America. This trend benefits domestic manufacturers of NEMA Type 1 enclosures, reducing lead times and logistics costs. By 2026, companies prioritizing supply chain agility are expected to favor local suppliers, accelerating innovation in modular and customizable enclosure solutions.

4. Growth in Customization and Pre-Assembled Solutions

End users in industries such as food & beverage, pharmaceuticals, and commercial HVAC are demanding faster deployment and reduced installation errors. This is fueling demand for pre-fabricated, pre-wired NEMA Type 1 enclosures with integrated components. By 2026, enclosure providers offering configurable platforms and digital design tools (e.g., 3D CAD integration) will gain market share, especially among system integrators.

5. Competitive Pressure from Alternative Standards and Materials

While NEMA Type 1 remains dominant in North America, global projects increasingly reference IEC standards (e.g., IP54). Additionally, lightweight composite and polycarbonate enclosures are gaining traction in specific applications. By 2026, traditional metal NEMA Type 1 manufacturers will face pressure to offer hybrid solutions or enhanced versions that bridge NEMA and IEC requirements to remain competitive internationally.

6. Digital Transformation in Sales and Support

Digital procurement platforms, augmented reality (AR) for installation support, and AI-driven configuration tools are transforming how enclosures are specified and purchased. By 2026, leading NEMA Type 1 suppliers will leverage digital ecosystems to streamline quoting, reduce engineering time, and enhance customer experience—integrating directly with building information modeling (BIM) and industrial automation software.

In summary, the 2026 market for NEMA Type 1 enclosures will be shaped by technological integration, sustainability imperatives, supply chain localization, and digital innovation. While the core function of indoor electrical protection remains unchanged, success will depend on adaptability, speed-to-market, and alignment with broader industrial trends.

Common Pitfalls When Sourcing NEMA Type 1 Enclosures (Quality and IP Considerations)

When sourcing NEMA Type 1 enclosures—designed primarily for indoor use to provide a degree of protection against dust, light, and indirect splashing—several quality and ingress protection (IP) related pitfalls can compromise performance and safety. Being aware of these issues helps ensure you select a reliable, fit-for-purpose enclosure.

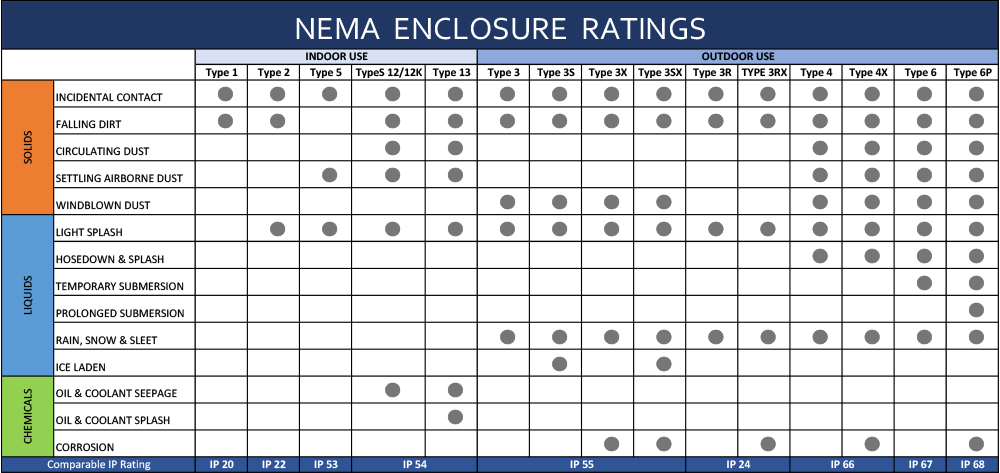

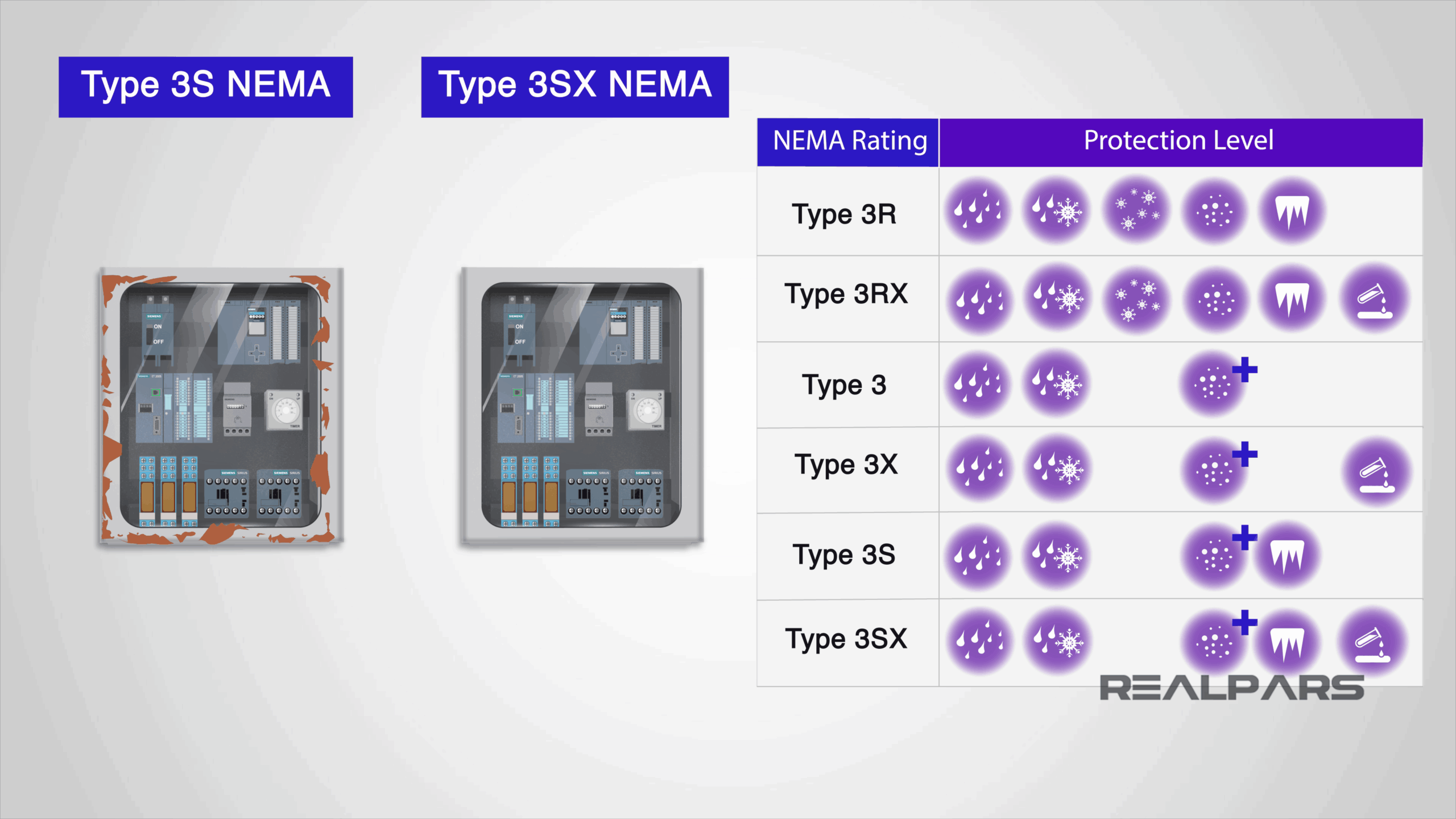

Misunderstanding NEMA vs. IP Ratings

A common mistake is assuming NEMA Type 1 directly correlates to a specific IP rating. While NEMA Type 1 offers protection similar to IP5X (dust protection) and partial protection against dripping water (similar to IPX1), there is no exact one-to-one conversion. Relying solely on IP ratings without verifying NEMA compliance can lead to selecting enclosures that don’t meet regional or industry standards, especially in North America.

Overlooking Build Quality and Material Integrity

Low-cost enclosures may use thin-gauge steel, poor welds, or substandard finishes that compromise durability. Inadequate powder coating or improper grounding provisions can lead to corrosion, electrical hazards, or failure during inspection. Always verify material thickness, finish quality, and conformance to UL 50 or NEMA 250 standards.

Inadequate Sealing and Gasket Performance

NEMA Type 1 enclosures are not inherently watertight, but they must still resist light dust and incidental contact with water. Poorly designed or missing door gaskets can allow dust ingress or moisture penetration, especially in environments with HVAC drafts or cleaning activities. Confirm that gaskets are present, properly compressed, and made from durable, non-degrading materials.

Improper Knockout and Conduit Entry Quality

Pre-punched knockouts or conduit entries that are poorly formed can damage cables during installation or compromise the enclosure’s integrity. Burrs, sharp edges, or misaligned entries not only pose safety risks but may also invalidate certifications. Inspect entries for smoothness and compatibility with your wiring methods.

Lack of Certification or Non-Compliant Markings

Some suppliers offer enclosures labeled as “NEMA Type 1” without third-party certification (e.g., UL Listing). Uncertified enclosures may not have undergone proper testing, leading to non-compliance during inspections. Always request certification documentation and look for genuine UL/cUL marks.

Ignoring Environmental and Application Fit

NEMA Type 1 is intended for general indoor use only. Using it in damp, dusty, or industrial environments where NEMA 3R, 4, or 4X would be appropriate leads to premature failure. Ensure the enclosure matches the actual environment—don’t downspec to save costs if conditions require a higher-rated enclosure.

By addressing these pitfalls during the sourcing process, you can ensure reliable performance, regulatory compliance, and long-term durability of your NEMA Type 1 enclosures.

Logistics & Compliance Guide for NEMA Type 1 Enclosures

NEMA Type 1 enclosures are widely used in industrial and commercial environments to protect electrical components from personnel contact and falling debris. Proper logistics handling and compliance with standards are critical for safety, performance, and regulatory adherence. This guide outlines key considerations for managing NEMA Type 1 enclosures throughout the supply chain and installation lifecycle.

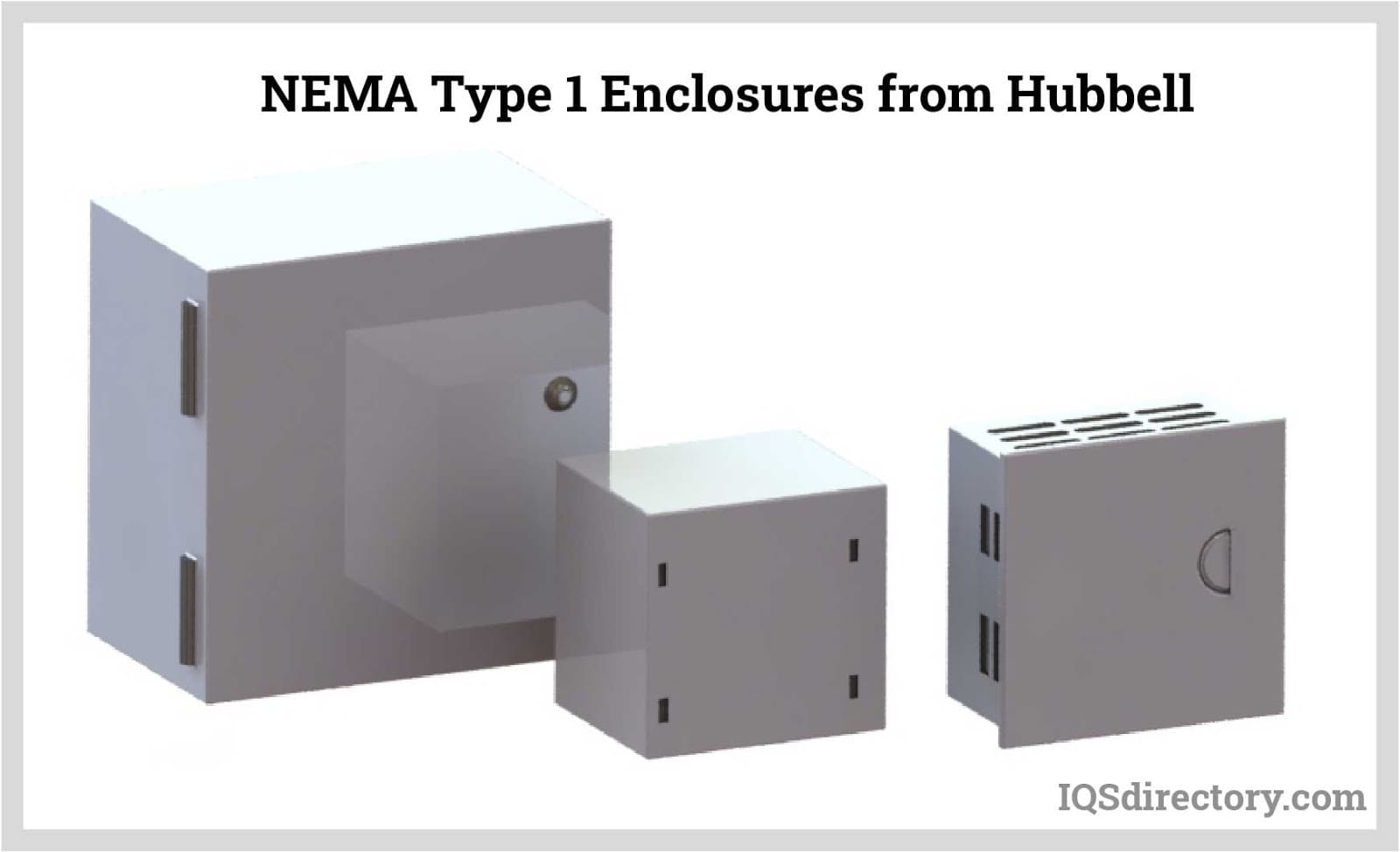

Understanding NEMA Type 1 Enclosures

NEMA Type 1 enclosures, as defined by the National Electrical Manufacturers Association (NEMA), provide a degree of protection primarily intended for indoor use. They are designed to:

- Protect personnel against accidental contact with hazardous parts

- Prevent the ingress of solid foreign objects (e.g., tools, wires, dust)

- Offer basic mechanical protection

These enclosures are commonly used for control panels, motor starters, disconnect switches, and similar equipment in non-hazardous, dry locations.

Regulatory and Standards Compliance

To ensure compliance, NEMA Type 1 enclosures must adhere to the following standards and regulations:

- NEMA 250: Primary standard defining enclosure types, including Type 1 specifications

- UL 50/UL 50E: Underwriters Laboratories standards for electrical enclosures; UL-listed Type 1 enclosures are often required for code compliance

- OSHA Regulations: Workplace safety standards requiring protection from live electrical parts

- NEC (National Electrical Code): Article 110.28 references NEMA enclosure types for suitability in various environments

Always verify that enclosures carry appropriate certification marks (e.g., UL, CSA) and are labeled as NEMA Type 1.

Procurement and Sourcing Considerations

When sourcing NEMA Type 1 enclosures:

- Confirm the enclosure is explicitly rated and labeled as NEMA Type 1

- Specify material (typically steel, stainless steel, or polycarbonate) based on environmental and corrosion requirements

- Ensure compatibility with internal components (e.g., breakers, terminals) and mounting configurations

- Source from reputable suppliers with traceable quality certifications

Shipping and Handling Logistics

Proper handling during transportation prevents damage and maintains enclosure integrity:

- Use palletized or crated packaging to prevent deformation

- Protect painted or powder-coated finishes from scratches and moisture

- Avoid stacking excessive weight on enclosure boxes

- Store in a dry, indoor environment before installation to prevent rust or warping

Handle enclosures with care during loading/unloading to avoid denting or misalignment of doors and gaskets.

Storage and Inventory Management

- Store in climate-controlled, indoor areas away from excessive humidity, temperature extremes, and corrosive vapors

- Keep enclosures in original packaging until ready for installation

- Rotate stock using FIFO (First In, First Out) to prevent long-term storage degradation

- Inspect enclosures periodically for signs of corrosion, warping, or damage

Installation and Field Compliance

During installation, ensure compliance with:

- Manufacturer’s instructions: Follow torque specifications, grounding procedures, and mounting guidelines

- Grounding: Provide a continuous grounding path per NEC Article 250

- Sealing: While NEMA Type 1 does not require protection against liquids, ensure conduit entries and knockouts are properly sealed to prevent dust or debris ingress

- Labeling: Affix appropriate warning labels and equipment identification per OSHA and NEC requirements

Inspection and Maintenance

Routine inspections help maintain compliance and safety:

- Check for door alignment, hinge integrity, and latch functionality

- Verify grounding continuity

- Inspect for internal dust accumulation or signs of overheating

- Ensure access remains unobstructed per NEC clearance requirements

Document inspections and maintenance activities for audit and compliance purposes.

Disposal and Environmental Considerations

At end-of-life:

- Recycle metal enclosures through certified scrap metal processors

- Follow local, state, and federal regulations for disposal of electrical components and hazardous materials (e.g., PCBs, if present)

- Comply with environmental regulations such as EPA and RoHS where applicable

Summary

Adhering to logistics best practices and compliance standards for NEMA Type 1 enclosures ensures safety, regulatory acceptance, and long-term reliability. From procurement to disposal, every stage should emphasize proper handling, certification verification, and adherence to NEMA, UL, NEC, and OSHA requirements.

Conclusion on Sourcing NEMA Type 1 Enclosures

Sourcing NEMA Type 1 enclosures requires a strategic approach focused on verifying compliance with industry standards, assessing quality and durability, and selecting reliable suppliers. These enclosures are designed primarily for indoor environments to provide protection against human contact and limited ingress of dust, making them ideal for general-purpose electrical applications in commercial and light industrial settings.

When sourcing NEMA Type 1 enclosures, it is essential to confirm genuine NEMA certification, ensure material suitability (such as steel, stainless steel, or polycarbonate), and evaluate environmental compatibility. Partnering with reputable manufacturers and suppliers who provide detailed specifications, certification documentation, and consistent product quality helps mitigate risks related to performance and safety.

Additionally, considerations such as customization options, cost-efficiency, lead times, and technical support play a crucial role in the procurement decision. By prioritizing standards compliance and supplier reliability, organizations can effectively source NEMA Type 1 enclosures that meet operational requirements, ensure worker safety, and support long-term system integrity.