The global market for electrical connectors, including NEMA 5-20P plugs, is experiencing steady expansion driven by rising demand in commercial, industrial, and residential infrastructure. According to a report by Mordor Intelligence, the global electrical connectors market was valued at USD 76.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.3% from 2024 to 2029. This growth is fueled by increasing electrification, the proliferation of EV charging stations, and the modernization of power distribution systems—all of which rely on standardized, reliable components like the NEMA 5-20P plug. As demand for high-performance, code-compliant electrical connectors rises, especially in North America, sourcing from reputable manufacturers becomes critical. The following analysis highlights eight leading manufacturers renowned for innovation, quality assurance, and market presence in producing NEMA 5-20P plugs, catering to stringent safety standards and evolving application needs.

Top 8 Nema 5 20P Plug Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 NEMA Plugs and Receptacles

Domain Est. 1993

Website: volex.com

Key Highlights: Volex is a leading global manufacturer and supplier of NEMA electrical plugs and receptacles….

#2 Wire Grounding, 20A 125V, 5-20P and White

Domain Est. 1995

Website: hubbell.com

Key Highlights: 30-day returnsStraight Blade Devices, Male Plug, Insulgrip Heavy Duty, Industrial/Commercial Grade, Straight, 2-Pole 3- Wire Grounding, 20A 125V, 5-20P, Black and White, ……

#3 NEMA 5

Domain Est. 2002

Website: mtixtl.com

Key Highlights: Description Corrosion resistant Chemical and impact resistant Nylon housing Industrial Strength Specifications Amperage (amps) : 20 A Color/Finish : black ……

#4 NEMA 5

Domain Est. 2010

Website: jaketime.com.tw

Key Highlights: Designed for both everyday and industrial power applications, our straight-blade plugs deliver stable and reliable performance in compliance with strict ……

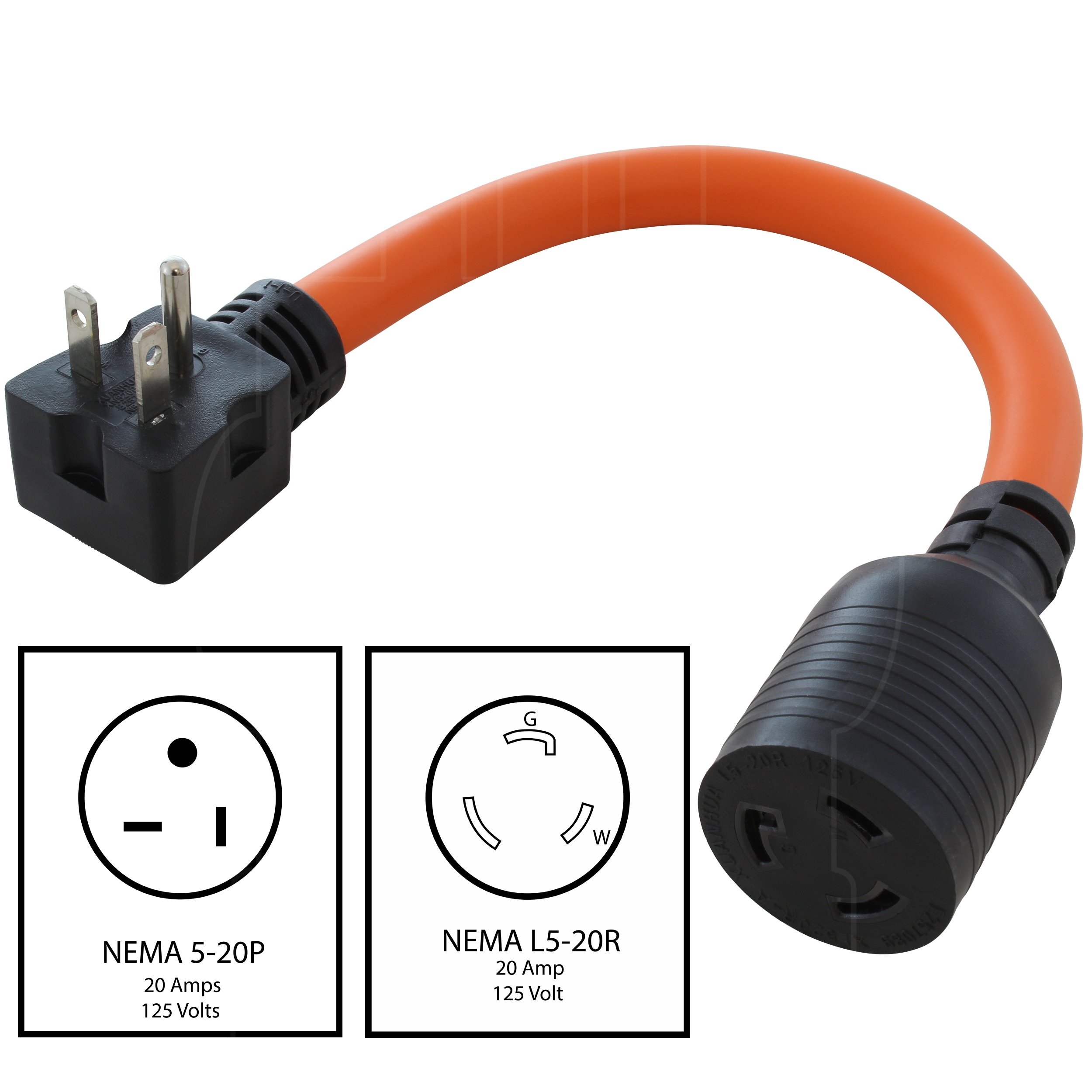

#5 520PA

Domain Est. 1995

Website: leviton.com

Key Highlights: 6–7 day delivery 30-day returnsYellow – 20 Amp, 125 Volt, NEMA 5-20P, 2-Pole, 3-Wire Grounding Plug, Straight Blade, Armored….

#6 Power Cords and Adapters

Domain Est. 1996

Website: tripplite.eaton.com

Key Highlights: Looking for an IT-grade power cord? We carry over 250 top quality power cords for computers, servers, PDUs and special applications like hospitals and ……

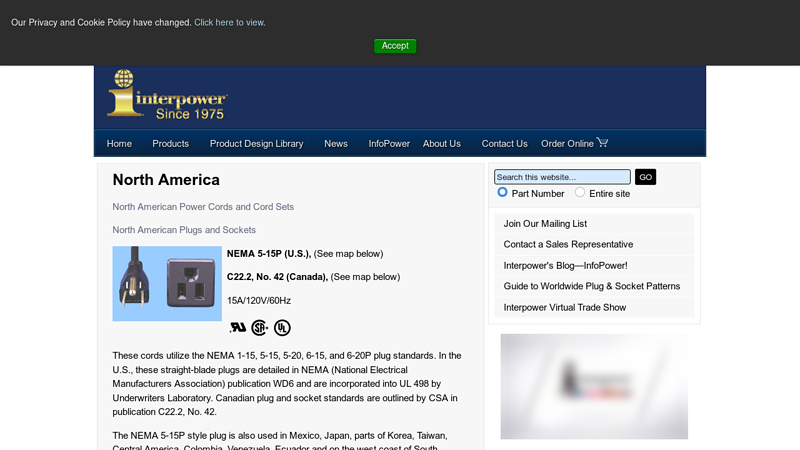

#7 North America

Domain Est. 1996

Website: interpower.com

Key Highlights: These cords utilize the NEMA 1-15, 5-15, 5-20, 6-15, and 6-20P plug standards. In the U.S., these straight-blade plugs are detailed in NEMA (National ……

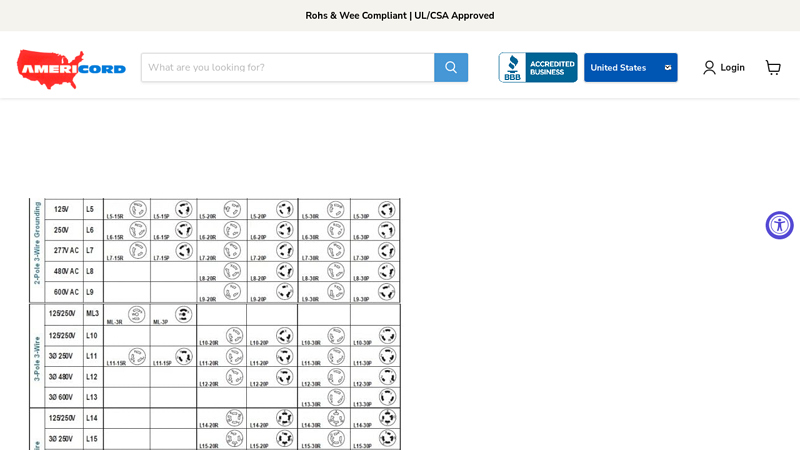

#8 NEMA Plug Charts

Domain Est. 1999

Website: americord.com

Key Highlights: These charts describe the layout of the connector plugs and sockets, voltage, and current limits, for their aim is to offer a uniform means of connecting ……

Expert Sourcing Insights for Nema 5 20P Plug

H2: Projected 2026 Market Trends for NEMA 5-20P Plug

The NEMA 5-20P plug, a 125V, 20-ampere grounding electrical connector widely used in North America, is expected to experience notable shifts in demand and application by 2026, driven by evolving energy standards, technological advancements, and infrastructure development. Key market trends shaping the NEMA 5-20P landscape include:

-

Increased Demand in Commercial and Industrial Sectors

As businesses adopt higher-power equipment such as commercial kitchen appliances, medical devices, and industrial tools, the need for 20-amp circuits rises. The NEMA 5-20P plug is favored for its ability to handle sustained loads safely, positioning it for growth in facilities upgrading electrical systems to meet modern energy requirements. -

Growth in Data Centers and EV Charging Infrastructure

The expansion of edge data centers and electric vehicle (EV) charging stations is a significant driver. While Level 2 EV chargers typically use NEMA 14-50 or hardwired connections, many commercial and light-duty charging solutions utilize 20-amp circuits. NEMA 5-20P outlets may be used in low-power or temporary installations, especially in fleet depots and multi-unit dwellings. -

Residential Electrification and Smart Home Integration

Home electrification initiatives, including the replacement of gas appliances with electric alternatives (e.g., induction cooktops, heat pumps), are increasing household electrical loads. The NEMA 5-20P plug supports high-demand residential devices, especially in kitchens and workshops. Additionally, smart power strips and energy-monitoring outlets compatible with NEMA 5-20P are gaining traction, enhancing energy efficiency and user control. -

Regulatory Influence and Safety Standards

The 2026 National Electrical Code (NEC) updates are expected to emphasize arc-fault and ground-fault protection, particularly in living and working spaces. This could lead to increased installation of NEMA 5-20P outlets with integrated protection mechanisms, bolstering demand for compliant, high-safety components. -

Sustainability and Material Innovation

Manufacturers are shifting toward recyclable materials and energy-efficient production processes. By 2026, expect to see NEMA 5-20P plugs made with bio-based plastics or recycled polymers, aligning with broader ESG (Environmental, Social, and Governance) goals in the construction and manufacturing sectors. -

Supply Chain Diversification and Localization

Ongoing global supply chain challenges are prompting North American manufacturers to localize production. This trend is likely to reduce lead times and import dependency, increasing the availability and customization options for NEMA 5-20P plugs tailored to specific regional needs.

In summary, the 2026 market for NEMA 5-20P plugs will be shaped by rising power demands across sectors, regulatory evolution, and integration with smart and sustainable technologies. Stakeholders should anticipate increased innovation in design and functionality, as well as stronger market penetration in both traditional and emerging applications.

Common Pitfalls When Sourcing NEMA 5-20P Plugs (Quality & IP)

Sourcing reliable NEMA 5-20P plugs requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to safety hazards, compliance failures, and legal risks.

Quality Pitfalls

Substandard Materials and Construction

Many low-cost suppliers use inferior materials such as brittle thermoplastics or undersized copper contacts. These can lead to overheating, arcing, or physical failure under normal load, increasing fire risk and reducing product lifespan. Always verify material specifications and look for UL, CSA, or ETL certification marks.

Inconsistent Dimensional Accuracy

Poor manufacturing tolerances can result in plugs that don’t fit securely into NEMA 5-20R receptacles. This leads to intermittent connections, voltage drops, and potential equipment damage. Request samples and conduct fit-testing with standard outlets before bulk procurement.

Lack of Safety Certifications

Counterfeit or uncertified plugs may appear identical to compliant ones but fail to meet UL 498 or other safety standards. Relying on documentation alone is risky—verify certification status directly through the listing database of the issuing agency (e.g., UL Product iQ).

Inadequate Strain Relief and Cord Grip

Weak or poorly designed strain relief mechanisms can cause internal wire disconnection when the cord is tugged. This creates a shock hazard and unreliable power delivery. Inspect internal construction or request test reports for pull and flex endurance.

Intellectual Property (IP) Pitfalls

Unauthorized Use of Trademarked Designs

Some suppliers replicate proprietary plug designs protected under trademark or design patents (e.g., features unique to brands like Hubbell or Leviton). Using such products—even unknowingly—can expose your company to infringement claims, shipment seizures, or legal liability.

Counterfeit Components and Packaging

Illegitimate vendors may sell counterfeit plugs with falsified certification marks or brand logos. These not only violate IP rights but also pose significant safety risks. Source only from authorized distributors or verified manufacturers with documented IP clearance.

Lack of Freedom-to-Operate Analysis

Before integrating a NEMA 5-20P plug into your product, ensure it doesn’t infringe on existing patents, especially in safety interlocks, locking mechanisms, or ergonomic features. Conducting a freedom-to-operate (FTO) search mitigates legal exposure in target markets.

OEM Rebranding Without Licensing

Some suppliers offer “white label” plugs that replicate patented designs. Using these under your brand without proper licensing agreements can result in cease-and-desist orders or costly litigation. Confirm that rebranded products are legally authorized for resale.

H2: Logistics & Compliance Guide for NEMA 5-20P Plug

The NEMA 5-20P plug is a standard North American electrical connector designed for 125V, 20A circuits. Understanding its logistics and compliance requirements is essential for manufacturers, distributors, importers, and users to ensure safety, regulatory adherence, and smooth supply chain operations.

Compliance Requirements

1. Electrical Safety Standards

– UL 498 (Standard for Attachment Plugs and Receptacles): Mandatory in the U.S. for plugs and receptacles. Certification by a Nationally Recognized Testing Laboratory (NRTL) such as UL, ETL, or CSA is required.

– CSA C22.2 No. 42: Canadian equivalent; required for sale in Canada. Often bundled with UL 498 certification via harmonized standards (e.g., cULus).

– NEMA Standards Publication No. 5: Defines dimensional and performance specifications for NEMA 5-20P plugs. Must meet physical configuration (one horizontal neutral blade, one vertical hot blade, and ground pin).

2. Marking and Labeling

– Must be permanently marked with:

– Manufacturer’s name or trademark

– Voltage (125V)

– Current rating (20A)

– NEMA configuration (5-20P)

– Certification marks (e.g., UL, CSA, ETL)

– Labels must be legible and indelible under normal use.

3. RoHS & REACH Compliance

– RoHS (EU): Restricts hazardous substances (e.g., lead, cadmium) in electrical equipment. Required for products sold in the EU or to EU-based customers.

– REACH (EU): Regulates chemical substances; requires disclosure of Substances of Very High Concern (SVHCs). Applies even if product is not sold directly in EU if components contain regulated substances.

4. Country-Specific Regulations

– United States: FCC Part 15 does not typically apply unless the plug includes electronic components (e.g., smart plugs).

– Canada: Must comply with the Canadian Electrical Code (CEC), Part II, and carry CSA or cUL certification.

– Mexico: NOM-001-SCFI (electrical safety) and NOM-019-SCFI (plug/receptacle standards) may apply for import and sale.

Logistics Considerations

1. Packaging & Handling

– Use anti-static and moisture-resistant packaging to prevent damage during transit.

– Clearly label packages with product type, voltage, amperage, and certification marks.

– Avoid compression or bending that could deform blades or housing.

2. Shipping & Import/Export

– Harmonized System (HS) Code: Typically 8536.69 (other electrical apparatus for switching or protecting electrical circuits). Confirm with local customs.

– Import Documentation: Include commercial invoice, packing list, and certificates of compliance (e.g., UL, RoHS, REACH).

– Battery Proximity: If shipped with battery-powered devices, comply with IATA/IMDG regulations for lithium batteries if applicable.

3. Storage

– Store in dry, temperature-controlled environments (typically 10°C–30°C).

– Keep away from direct sunlight and corrosive chemicals to prevent material degradation.

4. Supply Chain Traceability

– Maintain documentation of component sourcing, test reports, and certification validity.

– Implement a system for lot traceability to support recalls or compliance audits.

Best Practices

- Verify third-party test reports and certification status before procurement.

- Conduct periodic audits of suppliers to ensure ongoing compliance.

- Train logistics staff on handling requirements and regulatory labeling.

- Monitor updates to standards (e.g., UL, CSA, NEMA) and regulatory changes in target markets.

Adhering to this guide ensures safe, compliant, and efficient handling of NEMA 5-20P plugs throughout the supply chain.

In conclusion, sourcing a NEMA 5-20P plug requires careful consideration of electrical specifications, application requirements, and safety standards. The NEMA 5-20P plug, rated for 125V and 20A, is designed for use with equipment that demands higher current than standard 15A outlets can provide. When sourcing, it’s essential to verify compatibility with NEMA 5-20R receptacles, ensure compliance with regulatory standards such as UL or CSA, and choose high-quality materials for durability and safety.

Suppliers should be evaluated based on reliability, product certification, and availability—whether through electrical supply distributors, industrial hardware retailers, or reputable online marketplaces. Additionally, attention should be paid to wire gauge compatibility (e.g., 12 AWG minimum) and proper installation practices to prevent overheating and ensure long-term performance.

Ultimately, selecting the right NEMA 5-20P plug involves balancing technical requirements, safety, and sourcing credibility to support reliable power delivery in commercial, industrial, or high-demand residential environments.