The global market for NEMA 14-60 connectors—widely used in electric vehicle (EV) charging stations, recreational vehicles, and industrial applications—has seen robust growth driven by the accelerating adoption of EVs and expanding infrastructure investments. According to Grand View Research, the global electric vehicle charging equipment market was valued at USD 18.4 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 34.0% from 2023 to 2030. This surge directly fuels demand for high-amperage connectors like the NEMA 14-60, which delivers 50-amp, 250-volt power and is increasingly favored for Level 2 EV charging setups. Similarly, Mordor Intelligence projects the EV charging station market will grow at a CAGR of over 31% through 2028, further amplifying the need for reliable, high-performance electrical components. As demand climbs, a select group of manufacturers has emerged as leaders in producing durable, code-compliant NEMA 14-60 connectors, combining innovation, scale, and rigorous safety standards to support the clean energy transition.

Top 6 Nema 14-60 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 14

Domain Est. 1994

Website: grainger.com

Key Highlights: NEMA straight-blade plugs and receptacles are made to standards designated by the US National Electrical Manufacturers Association….

#2 9460

Domain Est. 1995

Website: leviton.com

Key Highlights: 6–7 day delivery 30-day returns9460. 60 Amp, 125/250 Volt, NEMA 14-60R, 3P, 4W, Flush Mtg Receptacle, Straight Blade, Industrial Grade, Grounding, , Side Wired, Steel Strap, – Blac…

#3 Straight Blade Devices, Receptacles, RTP, Industrial Grade, 3

Domain Est. 1995

Website: hubbell.com

Key Highlights: 30-day returnsNema Rating. 14-60R. Operational. Horsepower – Maximum. 3. Operating Temperature. Maximum continuous 75°C and minimum -40°C without Impact. Performance….

#4 Eaton Wiring 60 Amp Power Receptacle, NEMA 14

Domain Est. 2010

Website: homelectrical.com

Key Highlights: In stock $11.95 deliveryIs ideal for any high amperage industrial or commercial power application · Compatible with #4-#10 AWG wire · Best used with copper or aluminum wire….

#5 Hubbell HBL9460A AC Receptacle NEMA 14

Domain Est. 1996

Website: stayonline.com

Key Highlights: In stock Rating 5.0 1 Hubbell HBL9460A AC Receptacle NEMA 14-60 Female Black 60A/ 125/250V. Usually in stock in North Carolina. Normally ships in 3-4 business days from the ……

#6 Winco Power Cord Plug

Domain Est. 2005

Website: absolutegenerators.com

Key Highlights: In stock Rating 5.0 (1) Sep 21, 2016 · The Winco 300137 NEMA14-60P 60 amp straight blade plug can be used for running power into a transfer switch or other distribution box….

Expert Sourcing Insights for Nema 14-60

H2: 2026 Market Trends for NEMA 14-60 Connectors

The NEMA 14-60, a 50-amp, 250-volt, four-prong (hot-hot-neutral-ground) locking electrical connector, is poised for significant shifts in 2026, driven primarily by the accelerating adoption of electric vehicles (EVs) and evolving energy infrastructure. Here’s an analysis of the key market trends:

1. Dominant Driver: Residential and Commercial EV Charging Expansion

* Home Charging Surge: As EV adoption continues its upward trajectory, the demand for Level 2 home charging (requiring 208-240V) is exploding. The NEMA 14-50 is common, but the 14-60 offers higher current capacity (60A vs 50A). While 50A circuits are standard, 60A circuits are increasingly offered by EVSE (Electric Vehicle Supply Equipment) manufacturers (like Tesla’s Wall Connector, JuiceBox, ChargePoint Home Flex) as a future-proof option or for faster charging on compatible circuits. This drives demand for the 14-60 outlet itself and compatible plugs.

* Commercial & Fleet Charging: Light-duty commercial fleets, delivery vans, and service vehicles (e.g., electric pickups, SUVs, vans) often utilize dual or triple-port Level 2 chargers. The higher amperage of a 14-60 circuit allows for more power distribution flexibility in multi-vehicle setups or faster charging times compared to 14-50, making it attractive for commercial installations.

* OEM Bundling: Expect increased bundling of NEMA 14-60 plugs with high-power Level 2 EVSEs sold by automakers and third-party suppliers as standard or premium options.

2. Shift Towards Hardwired EVSEs (A Potential Limiting Factor)

* While plug-in convenience is valued, safety and code compliance (NEC 625) are pushing the market towards hardwired EVSE installations, especially for new construction and dedicated high-power circuits. This reduces the need for the physical NEMA 14-60 receptacle at the charging point, potentially capping demand growth for the outlet component.

* Trend: The circuit requirement (60A, 240V, 4-wire) remains crucial, but the endpoint is increasingly a hardwired connection instead of a plug/receptacle. Demand may shift more towards compatible plugs for portable chargers or temporary setups.

3. Competition from Higher-Power and DC Fast Charging

* High-Power AC (e.g., 80A+): For larger vehicles (e.g., electric trucks like F-150 Lightning, Rivian R1T, Cybertruck) or rapid home charging, circuits exceeding 60A (requiring different connectors like NEMA 6-50 for 240V/50A, or custom high-amp solutions) are becoming necessary. This limits the 14-60’s role as the primary high-power home solution for next-gen EVs.

* DC Fast Charging (DCFC) Proliferation: Expansion of public DCFC networks reduces the absolute necessity for the fastest possible home charging. Consumers may accept slightly slower Level 2 charging (adequate for overnight), potentially reducing the urgency to install the highest amperage AC circuits like 60A.

4. Niche Applications and Industrial Use

* Beyond EVs: The 14-60 will maintain steady demand in its traditional niches:

* RV Parks: While NEMA TT-30 (30A) and 14-50 are more common, 14-60 outlets are available at some premium sites for larger RVs with high power demands.

* Industrial/Workshop Equipment: Powering large air compressors, welders, kilns, or other heavy-duty 240V equipment requiring up to 60A.

* Data Centers/Backup Power: Occasionally used in specific power distribution scenarios.

* Trend: This demand is stable but not a major growth driver compared to the EV sector.

5. Supply Chain, Cost, and Code Considerations

* Cost: 60A circuits and 14-60 components (wire, breaker, receptacle) are more expensive than 50A (14-50) circuits. This cost premium may deter some consumers unless the faster charging benefit is clearly justified.

* Electrical Code: NEC requirements for AFCI (Arc-Fault) protection on branch circuits can add complexity and cost to 60A circuits, influencing design choices (sometimes favoring subpanels or specific EVSE features).

* Availability: Receptacles and plugs remain readily available from major electrical suppliers (Leviton, Hubbell, Bryant, GE) and EVSE manufacturers, but hardwired solutions dominate premium offerings.

Conclusion for 2026:

The NEMA 14-60 market in 2026 will be primarily shaped by the EV charging ecosystem, but with headwinds from the hardwiring trend. While the underlying need for 60A, 240V circuits for faster Level 2 charging will grow, the physical plug and receptacle market may see moderate growth or plateau. Demand will be strongest for:

1. Plugs for use with portable EVSE cords or specific high-power EVSEs offering plug-in options.

2. Receptacles in commercial/fleet settings, new construction where plug-in flexibility is desired, and niche industrial/RV applications.

3. Components for DIY or specialized installations.

The trajectory points towards the NEMA 14-60 remaining a relevant, but increasingly specialized, component within the broader high-power AC charging infrastructure, overshadowed in new installations by hardwired solutions and challenged by the rise of even higher-power AC and ubiquitous DC fast charging.

Common Pitfalls When Sourcing NEMA 14-60 Connectors (Quality & IP Considerations)

Sourcing NEMA 14-60 connectors—commonly used for EV charging, heavy-duty appliances, and industrial equipment—requires attention to both build quality and Ingress Protection (IP) ratings to ensure safety, durability, and compliance. Overlooking these factors can lead to equipment failure, safety hazards, or non-compliance with regulations. Below are key pitfalls to avoid:

Choosing Low-Quality Materials or Construction

One of the most frequent issues is selecting connectors made from substandard materials. Cheap NEMA 14-60 plugs and inlets may use inferior thermoplastics that degrade under UV exposure, temperature fluctuations, or physical stress. Poorly manufactured contacts can overheat due to high resistance, leading to arcing or fire hazards. Always verify that the connector is made from UL-listed materials and meets NEMA and NEC standards.

Ignoring Ingress Protection (IP) Ratings

Many standard NEMA 14-60 connectors are not inherently weatherproof. While the NEMA configuration defines the pin layout and grounding, it doesn’t automatically guarantee environmental protection. For outdoor or harsh environments, an IP rating is critical. A common mistake is assuming “NEMA 14-60” implies weather resistance. In reality, look for additional ratings like IP65 (dust-tight and protected against water jets) or IP67 (submersion protection) and confirm the entire assembly (including cord grip and housing) maintains this rating.

Overlooking Proper Strain Relief and Cord Grip

Inadequate strain relief is a leading cause of wire pull-out and internal damage. Low-cost connectors often skimp on robust cable clamping mechanisms, increasing the risk of exposed conductors and electrical faults. Ensure the connector includes a secure, adjustable cord grip compatible with your cable diameter and type (e.g., SOOW, SJOOW).

Failing to Verify Certification and Compliance

Not all NEMA 14-60 connectors are created equal in terms of certification. Beware of counterfeit or non-listed products that mimic genuine UL/CSA/ETL marks. Always request certification documentation and verify listings through official databases. Using uncertified components can void equipment warranties and violate electrical codes.

Mismatching Connector and Inlet Ratings

Even if the plug and inlet share the NEMA 14-60 designation, differences in current carrying capacity, temperature rating, or duty cycle can lead to overheating. For example, a connector rated for intermittent use may fail under continuous high-load EV charging. Ensure both plug and inlet are rated for the same voltage (120/240V), current (60A continuous), and duty cycle.

Neglecting Installation Environment

Sourcing a connector without considering the installation environment—such as exposure to moisture, chemicals, dust, or physical impact—can lead to premature failure. For outdoor EV charging stations, use connectors specifically designed for exterior use with gaskets, sealed housings, and corrosion-resistant metal components (e.g., brass or stainless steel contacts).

Relying on Incompatible or Proprietary Designs

Some suppliers offer “NEMA 14-60” labeled connectors that deviate slightly in pin dimensions or housing design, causing poor fit or arcing. Stick to reputable manufacturers (e.g., Hubbell, Leviton, Eaton) and avoid proprietary or rebranded units without third-party validation.

By addressing these common pitfalls, you can ensure the NEMA 14-60 connectors you source are safe, reliable, and fit for purpose—especially in demanding applications like electric vehicle supply equipment (EVSE).

Logistics & Compliance Guide for NEMA 14-60

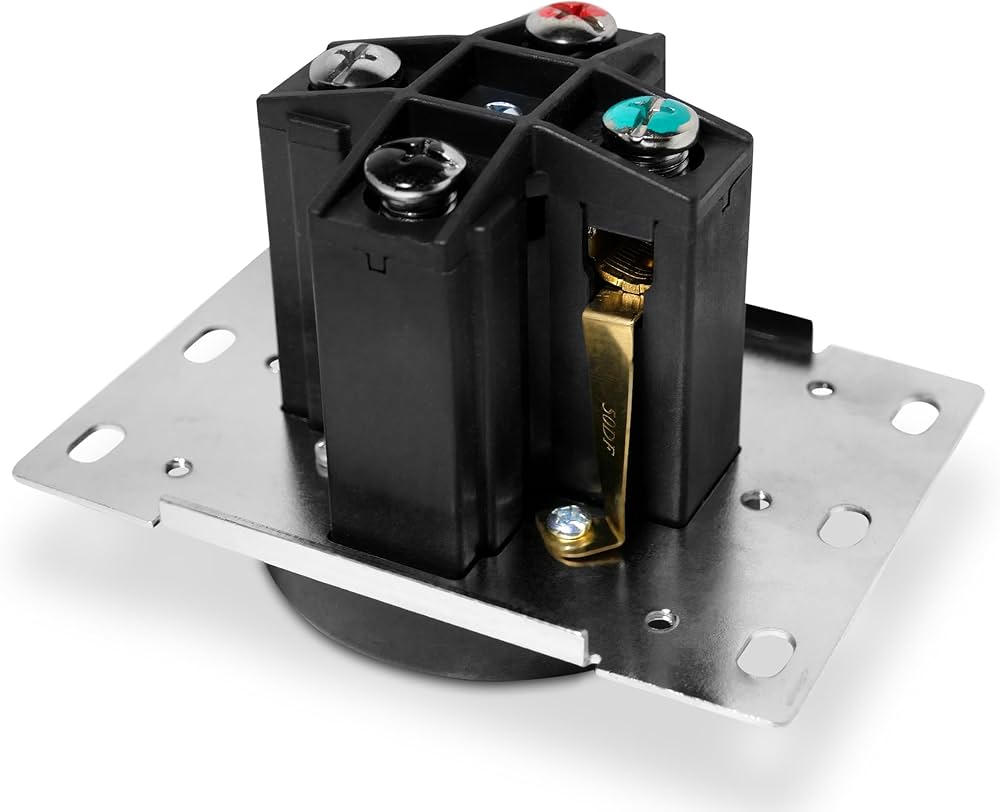

Overview of NEMA 14-60 Configuration

The NEMA 14-60 is a locking electrical connector rated for 60 amps at 120/240 volts, commonly used in commercial and industrial applications such as electric vehicle (EV) charging stations, recreational vehicles (RVs), and heavy-duty equipment. It features four prongs: two hot wires (X and Y), one neutral (W), and one ground (G), enabling split-phase power delivery. Proper logistics and compliance ensure safe, code-compliant installations.

Electrical Specifications and Compatibility

NEMA 14-60 connectors are designed for 250V maximum, with a current rating of 60A. They are not interchangeable with other NEMA configurations due to unique blade arrangements. Confirm device compatibility—especially EV chargers or RV pedestals—supports NEMA 14-60 input. Using adapters or mismatched components can violate safety codes and create fire hazards.

National Electrical Code (NEC) Requirements

Installation must comply with the National Electrical Code (NFPA 70), particularly Article 625 for EV charging and Article 551 for recreational vehicles. Key NEC requirements include circuit protection with a 60A double-pole breaker, use of appropriately sized conductors (typically 6 AWG copper for 60A circuits), and proper grounding. The 2023 NEC also emphasizes Arc-Fault Circuit Interrupter (AFCI) protection in certain applications.

Equipment and Cable Logistics

Procure UL-listed NEMA 14-60 plugs, inlets, and cables rated for 60A and suitable environmental conditions (e.g., sunlight, moisture resistance for outdoor use). Logistics planning should account for cable length, bend radius, and termination methods. Pre-assembled cords should be strain-relieved and secured to prevent disconnection under load.

Installation Best Practices

Installations must be performed by licensed electricians. Mount outlets at accessible, weather-protected locations if outdoors. Use conduit where required to protect wiring from physical damage. Torque all connections to manufacturer specifications—loose terminals are a leading cause of overheating. Label circuits clearly at the panel and outlet.

Inspection and Certification

After installation, a local Authority Having Jurisdiction (AHJ) inspection may be required for code compliance, especially for EV charging infrastructure. Provide documentation including equipment specifications, wiring diagrams, and certification of compliance (e.g., UL, ETL). Retain records for audits or resale purposes.

Maintenance and Safety Compliance

Regularly inspect connectors for signs of arcing, overheating, or physical damage. Remove and replace damaged components immediately. Ensure GFCI functionality if integrated. Train users on proper plug insertion and removal techniques to prevent contact wear. Follow OSHA and NEC guidelines for workplace safety in commercial settings.

Regional and Jurisdictional Considerations

While NEC provides a national baseline, local amendments may apply. For example, California’s Title 24 includes additional energy efficiency and safety mandates. Verify requirements with municipal building departments before installation. International shipments or installations may require additional certifications (e.g., CSA in Canada).

Environmental and Weatherproofing Standards

Outdoor NEMA 14-60 installations must use enclosures rated at least NEMA 3R (rain-tight) or NEMA 4X (watertight and corrosion-resistant) depending on exposure. Use dielectric grease on contacts to inhibit corrosion. Ensure drip loops in cabling to prevent water ingress.

Documentation and Recordkeeping

Maintain a compliance file including: equipment data sheets, installation permits, inspection reports, as-built wiring diagrams, and maintenance logs. This documentation supports insurance claims, facility audits, and future modifications.

In conclusion, sourcing a NEMA 14-60 receptacle or plug requires careful consideration of application, compliance, and availability. Widely used in electric vehicle (EV) charging, recreational vehicles, and certain industrial equipment, the NEMA 14-60 provides a 60-amp, 125/250-volt configuration ideal for high-power needs. While standard in North America, availability may vary by region and supplier.

When sourcing, prioritize UL-listed or ETL-certified products from reputable manufacturers to ensure safety and code compliance. Evaluate installation requirements—such as appropriate wiring (typically 6 AWG copper), proper grounding, and compatibility with circuit breakers—to prevent hazards. Due to increased EV adoption, NEMA 14-60 components are increasingly available through electrical supply houses, online retailers, and EV infrastructure companies.

Ultimately, successful sourcing involves balancing product quality, code compliance, and application-specific needs. Consulting a licensed electrician is recommended to ensure safe and correct installation. With the right approach, the NEMA 14-60 is a reliable and accessible solution for high-capacity power delivery.