The global hydraulics market continues to gain momentum, driven by rising demand for efficient power transmission systems across construction, manufacturing, and agriculture sectors. According to Grand View Research, the global hydraulic equipment market size was valued at USD 29.3 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 4.1% from 2024 to 2030. This growth is fueled by increasing automation, technological advancements in fluid power systems, and the expansion of heavy machinery applications in emerging economies. Amid this expanding landscape, national hydraulics manufacturers play a pivotal role in delivering reliable, high-performance components that power industrial and mobile equipment. Here, we highlight the top 6 national hydraulics manufacturers that are shaping the industry through innovation, scalability, and domestic manufacturing excellence.

Top 6 National Hydraulics Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 National Hydraulics, Inc.

Domain Est. 2018

Website: nationalhydraulicsatl.com

Key Highlights: We do all phases of hydraulic repair. Whether it’s Concrete Pumping, Logging, Excavating, Road Building, Agricultural or Marine equipment….

#2 National Fluid Power Association

Domain Est. 1995

Website: nfpa.com

Key Highlights: Strengthening the Fluid Power Industry. A community for growing the entire hydraulic and pneumatic supply chain….

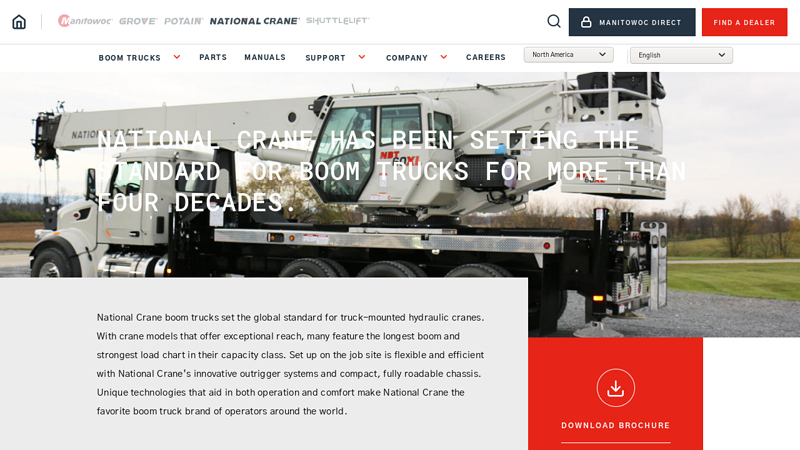

#3 NATIONAL CRANE

Domain Est. 1995

Website: manitowoc.com

Key Highlights: National Crane boom trucks set the global standard for truck-mounted hydraulic cranes. With crane models that offer exceptional reach….

#4 National Hydraulic Systems

Domain Est. 2012

Website: nationalhydraulicsystems.com

Key Highlights: National Hydraulic Systems has an expansive inventory of hydraulic hose, hose fittings, adapters and accessories! Check out our company today!…

#5 National Hydraulic Supply

Domain Est. 2013

Website: nationalhydraulicsupply.com

Key Highlights: National Hydraulic Supply is a full line supplier and stocking distributor for SPX Stone/Fenner hydraulic power units and components and Power Team high force ……

#6 National Hydraulics

Domain Est. 2019

Website: nathyd.com

Key Highlights: National Hydraulic. 724-547-9222. Location In Mt. Pleasant, PA … Transportation companies use our solutions to provide uninterrupted container shipping….

Expert Sourcing Insights for National Hydraulics

H2: Market Trends Shaping National Hydraulics in 2026

As we approach 2026, the industrial and manufacturing landscape is undergoing significant transformation, directly influencing the trajectory of companies like National Hydraulics. Several macroeconomic, technological, and regulatory trends are converging to redefine demand, competition, and innovation within the hydraulics sector. Below is an analysis of key market trends expected to shape National Hydraulics’ position and strategy in 2026.

1. Rising Demand in Infrastructure and Construction

Government-led infrastructure investments, particularly in North America and parts of Asia, are projected to surge through 2026. Initiatives such as the U.S. Bipartisan Infrastructure Law are driving long-term funding for transportation, water systems, and energy projects—sectors that heavily rely on hydraulic systems. National Hydraulics stands to benefit from increased demand for high-performance hydraulic components in construction equipment, cranes, and municipal machinery.

2. Electrification and Hybridization of Mobile Equipment

A major shift toward electrification in off-highway and mobile machinery (e.g., excavators, loaders, and agricultural vehicles) is influencing hydraulic system design. While full electric systems may reduce reliance on traditional hydraulics, hybrid systems that integrate electric motors with hydraulic power units (e-hydraulics) are gaining traction. National Hydraulics will need to innovate in energy-efficient, compact, and smart hydraulic solutions compatible with hybrid powertrains to remain competitive.

3. Digitalization and Smart Hydraulics

The integration of IoT, predictive maintenance, and real-time monitoring into hydraulic systems—often referred to as “smart hydraulics”—is accelerating. By 2026, customers will increasingly demand systems with embedded sensors, remote diagnostics, and data analytics capabilities. National Hydraulics can leverage this trend by developing connected hydraulic components and partnering with digital platform providers to offer value-added services such as performance optimization and predictive maintenance.

4. Sustainability and Regulatory Pressures

Environmental regulations are tightening around fluid efficiency, leakage prevention, and recyclability. The EU’s Green Deal and similar initiatives are pushing manufacturers toward eco-friendly hydraulic fluids and energy-efficient designs. National Hydraulics must prioritize R&D in low-emission systems, biodegradable fluid compatibility, and lightweight materials to meet compliance standards and appeal to environmentally conscious clients.

5. Supply Chain Resilience and Localization

Ongoing geopolitical tensions and past disruptions have prompted a shift toward supply chain localization. In 2026, customers will favor suppliers with regional manufacturing and distribution networks. For National Hydraulics, this presents an opportunity to strengthen domestic production capabilities and reduce reliance on global supply chains, improving delivery times and customer trust.

6. Expansion in Emerging Markets

Growth in industrialization across Southeast Asia, Africa, and Latin America will create new markets for hydraulic equipment. National Hydraulics can capitalize on this by establishing strategic partnerships, localized service centers, and cost-optimized product lines tailored to developing economies.

7. Talent and Automation in Manufacturing

The labor shortage in skilled manufacturing roles is driving investment in automation and robotics. National Hydraulics may need to adopt advanced manufacturing technologies—such as automated assembly lines and AI-driven quality control—to maintain production efficiency and scalability in 2026.

Conclusion

By 2026, National Hydraulics will operate in a market defined by technological convergence, sustainability, and global restructuring. To thrive, the company must embrace innovation in smart and hybrid hydraulic systems, enhance operational resilience, and align with global infrastructure and environmental trends. Strategic foresight and agility will be critical to maintaining a competitive edge in the evolving industrial ecosystem.

H2. Common Pitfalls When Sourcing National Hydraulics (Quality, IP)

Sourcing hydraulic components, especially from suppliers like National Hydraulics (or similar domestic manufacturers), can offer benefits such as reduced lead times and domestic support. However, several common pitfalls related to quality and intellectual property (IP) can compromise project outcomes if not carefully managed.

1. Inconsistent Quality Standards

One of the primary concerns when sourcing National Hydraulics is variability in manufacturing quality. Not all domestic suppliers adhere to consistent international standards (e.g., ISO 4406 for fluid cleanliness or ISO 10763 for hydraulic fittings). This can lead to premature system failures, leaks, or incompatibility with existing equipment. Buyers may assume “domestic” equates to “high quality,” but without third-party certifications or rigorous supplier audits, inconsistencies in materials, tolerances, and assembly processes can result in subpar performance.

2. Lack of Traceability and Documentation

Domestic suppliers may not always provide full traceability for components—such as material test reports, batch numbers, or calibration data. This lack of documentation can create challenges during quality audits, warranty claims, or failure analysis. In regulated industries (e.g., aerospace, energy), missing traceability can lead to non-compliance and increased liability.

3. Risk of Counterfeit or Non-Genuine Parts

Some suppliers may claim to offer “National Hydraulics” parts but actually distribute counterfeit, reconditioned, or off-spec components. This is especially problematic when sourcing through third-party distributors or online marketplaces. Using such parts increases the risk of system failure, voids OEM warranties, and may result in safety hazards.

4. Intellectual Property (IP) Infringement

A significant pitfall involves IP violations when sourcing domestic alternatives. Some National Hydraulics suppliers reverse-engineer proprietary designs from major OEMs (e.g., Parker, Bosch Rexroth) without licensing. While these components may appear identical and cost less, they can infringe on patents, trademarks, or design rights. Purchasers may unknowingly become complicit in IP infringement, exposing their organization to legal action, especially in international markets with strict IP enforcement.

5. Limited Innovation and Design Ownership

Many domestic hydraulic suppliers focus on replication rather than innovation. This can limit access to patented technologies, energy-efficient designs, or smart hydraulics (e.g., integrated sensors, IoT connectivity). Relying on such suppliers may result in outdated solutions and reduced competitive advantage.

6. Inadequate Legal Protections in Contracts

Procurement contracts with National Hydraulics suppliers often lack strong IP indemnification clauses or warranties for non-infringement. Without clear terms, buyers bear the risk if a component is later found to violate third-party IP rights.

Mitigation Strategies

To avoid these pitfalls:

– Conduct supplier qualification audits and request certifications (e.g., ISO 9001).

– Specify traceability and testing requirements in procurement agreements.

– Verify authenticity through authorized distribution channels.

– Include IP indemnity clauses in contracts.

– Perform due diligence on design origins, especially for “compatible” or “aftermarket” parts.

By proactively addressing quality and IP risks, organizations can leverage domestic sourcing advantages without compromising compliance, performance, or legal integrity.

Logistics & Compliance Guide for National Hydraulics

This guide outlines the essential logistics and compliance procedures for National Hydraulics to ensure efficient operations, regulatory adherence, and customer satisfaction. All team members involved in shipping, receiving, documentation, and supply chain management must follow these standards.

Shipping & Receiving Procedures

All incoming and outgoing shipments must be logged in the company’s inventory management system within one business hour of receipt or dispatch. Use standardized packing slips and bill of lading (BOL) forms for every shipment. Verify part numbers, quantities, and serial numbers against purchase orders or sales orders at the time of pickup or delivery. Any discrepancies must be reported immediately to the Logistics Supervisor.

Domestic Transportation Standards

Utilize approved freight carriers that comply with Department of Transportation (DOT) regulations. Ensure all hydraulic components are securely packaged to prevent damage during transit, using protective materials such as foam inserts, wooden crates, or waterproof wrapping as necessary. Hazardous materials, including hydraulic fluids meeting OSHA or DOT criteria, must be labeled, stored, and shipped in accordance with 49 CFR regulations.

International Trade Compliance

For cross-border shipments, ensure compliance with U.S. Customs and Border Protection (CBP) requirements and the International Traffic in Arms Regulations (ITAR), if applicable. Accurately complete commercial invoices, packing lists, and export declarations. Classify products using the appropriate Harmonized System (HS) codes and obtain Export Control Classification Numbers (ECCNs) where required. Maintain records of all export transactions for a minimum of five years.

Regulatory & Safety Compliance

All logistics operations must adhere to Occupational Safety and Health Administration (OSHA) standards, especially regarding material handling and warehouse safety. Forklift operators must be certified and equipment inspected monthly. Store flammable materials in designated, ventilated areas with appropriate signage. Conduct quarterly compliance audits to verify adherence to environmental (EPA), safety (OSHA), and transportation (FMCSA) regulations.

Documentation & Recordkeeping

Maintain a centralized digital archive for all logistics documentation, including bills of lading, customs forms, inspection reports, and carrier agreements. Ensure records are backed up and accessible to authorized personnel only. Data retention must comply with IRS, DOT, and customer-specific requirements—typically a minimum of three to seven years, depending on document type.

Carrier & Vendor Management

Only work with carriers and suppliers who meet National Hydraulics’ compliance and performance standards. Conduct annual evaluations of carrier performance based on on-time delivery, damage rates, and responsiveness. Require all vendors to provide up-to-date insurance certificates and compliance documentation before initiating business.

Emergency Response & Incident Reporting

In the event of shipment delays, damages, or regulatory violations, notify the Logistics Manager and Compliance Officer within two hours. Complete an Incident Report Form detailing the event, corrective actions, and preventive measures. For spills or hazardous material releases, follow the National Hydraulics Emergency Response Plan and report to relevant authorities as required by law.

Training & Employee Responsibilities

All logistics and warehouse staff must complete annual training on compliance topics, including hazardous materials handling, DOT regulations, and proper documentation. New hires must pass a certification assessment before performing independent shipping or receiving duties. Managers are responsible for ensuring team adherence to this guide and updating procedures as regulations evolve.

By following this guide, National Hydraulics ensures safe, compliant, and reliable logistics operations across all facets of its supply chain.

Conclusion on Sourcing National Hydraulics

In conclusion, sourcing hydraulic components from National Hydraulics presents a strategic advantage for businesses requiring reliable, high-performance fluid power solutions. National Hydraulics has established a strong reputation for quality manufacturing, technical expertise, and comprehensive product offerings, including cylinders, power units, hose assemblies, and custom engineering services. Their extensive distribution network and commitment to customer support enhance supply chain efficiency and reduce lead times.

Sourcing from National Hydraulics ensures compliance with industry standards, consistency in product performance, and access to innovative hydraulic solutions tailored to diverse industrial applications. Additionally, their focus on domestic manufacturing in the United States supports supply chain resilience, reduces dependency on international logistics, and aligns with preferences for American-made components.

Overall, partnering with National Hydraulics offers a balance of quality, reliability, and service that makes them a preferred supplier in the hydraulic industry. For organizations looking to optimize equipment uptime, reduce maintenance costs, and ensure long-term operational efficiency, sourcing from National Hydraulics is a sound and strategic decision.