The global nail gun market is experiencing steady growth, driven by rising demand in residential and commercial construction, as well as increased focus on efficient, labor-saving tools in finish carpentry. According to Grand View Research, the global power tools market—of which nailers are a critical segment—was valued at USD 33.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Mordor Intelligence projects similar momentum, citing advancements in cordless technology and growing DIY activity as key contributors to market expansion. With baseboard installation being one of the most precision-dependent applications in interior finishing, the demand for specialized nailers that offer accuracy, reduced surface damage, and compatibility with delicate trims has surged. This increasing demand has spurred innovation among manufacturers, leading to the emergence of high-performance nailers tailored specifically for baseboard and molding work. The following list highlights the top seven manufacturers excelling in this niche, evaluated based on product performance, technological innovation, market presence, and user feedback.

Top 7 Nailer For Baseboards Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 SENCO

Domain Est. 1993

Website: senco.com

Key Highlights: METAL CONNECTOR NAILERS. Redesigned with more power than competing nailers and our previous-generation tools. Explore the JN series metal connector nailers….

#2 Finish Nailers

Domain Est. 1996

Website: paslode.com

Key Highlights: Browse our collection of finish nailers, built for precision, consistency and productivity. Filter 9 Items Finish Nailers…

#3 Nailers & Compressors

Domain Est. 1997

Website: maxusacorp.com

Key Highlights: MAX nail guns are durable yet lightweight tools engineered with highly innovative and patented features. MAX offers a 30 day no hassle policy….

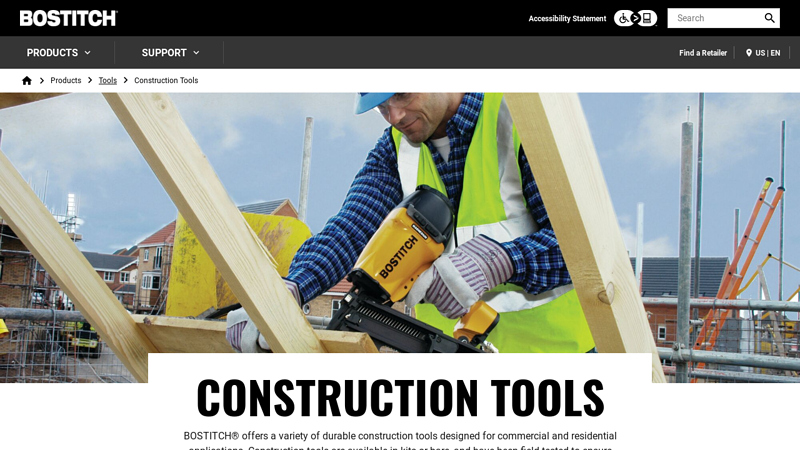

#4 Construction Tools

Domain Est. 1999

Website: bostitch.com

Key Highlights: Our line of innovative Smart Point® nailers allow you to more easily reach tight spaces, improve nailing accuracy, and reduce work surface damage….

#5 M18 FUEL 18 Gauge Brad Nailer

Domain Est. 2000

Website: milwaukeetool.com

Key Highlights: MILWAUKEE® M18 FUEL™ 18 Gauge Brad Nailer makes clean, consistent nail holes, is compact in size with zero ramp-up time. The cordless brad nailer operates ……

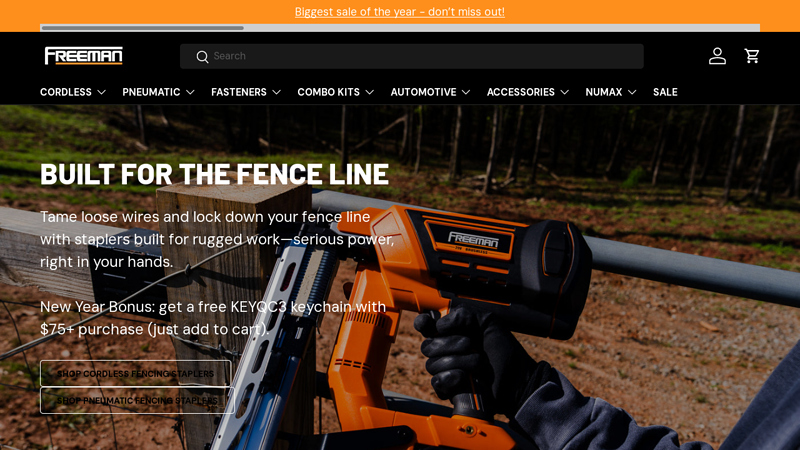

#6 Freeman Tools

Domain Est. 2008

Website: freemantools.com

Key Highlights: Tired of your trim or molding splitting every time you drive a nail? A brad nailer gives you the control and finesse you need to work with delicate materials….

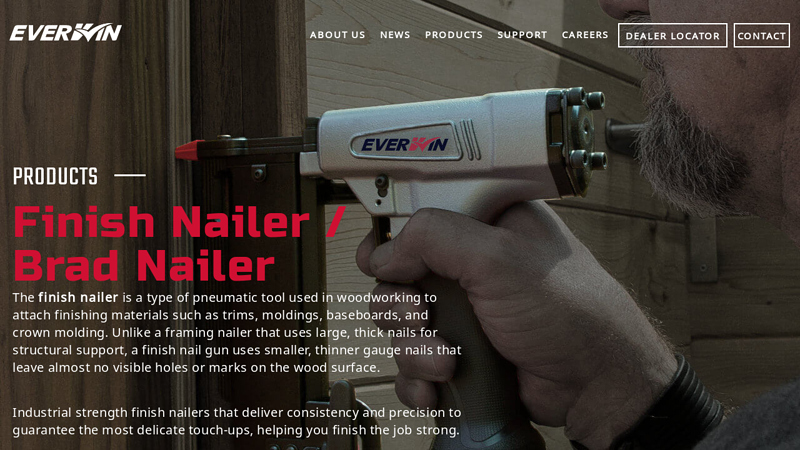

#7 Finish Nailer

Domain Est. 2012

Website: everwinpneumatic.com

Key Highlights: The finish nailer is a type of pneumatic tool used in woodworking to attach finishing materials such as trims, moldings, baseboards, and crown molding….

Expert Sourcing Insights for Nailer For Baseboards

H2: 2026 Market Trends for Nailers for Baseboards

The market for nailers used in baseboard installation is poised for notable evolution by 2026, driven by advancements in tool technology, increased demand in residential construction and renovation, and a growing emphasis on efficiency and precision in DIY and professional contracting. Below are key trends shaping the nailer for baseboards segment in 2026:

1. Rise of Cordless and Battery-Powered Nailers

A major trend in 2026 is the accelerated shift from pneumatic to cordless nailers. Manufacturers are investing heavily in lithium-ion battery technology, enabling cordless brad and finish nailers to deliver performance comparable to air-powered models. This transition is particularly beneficial for baseboard installations, where mobility and ease of use in tight spaces are crucial. Cordless models reduce setup time, eliminate the need for compressors and hoses, and enhance portability—making them increasingly popular among both professionals and homeowners.

2. Demand for Precision and Reduced Surface Damage

As homeowners opt for higher-end trim materials such as solid wood and pre-finished baseboards, there is a growing demand for nailers that minimize surface marring. In 2026, manufacturers are focusing on refining nail depth control, contact triggers, and ergonomic designs to ensure clean, accurate fastening. Innovations such as adjustable depth drivers and low-rebound mechanisms help prevent blow-through or dimpling on delicate baseboard surfaces.

3. Growth in the DIY and Home Improvement Sector

The DIY market continues to expand, fueled by online tutorials, home renovation shows, and e-commerce accessibility. In 2026, more consumers are investing in professional-grade tools like finish nailers for baseboard projects. Entry-level models with user-friendly features—such as jam-clear indicators, lightweight builds, and simplified maintenance—are gaining traction, lowering the barrier to entry for novice users.

4. Sustainability and Tool Longevity

Environmental considerations are influencing tool manufacturing. By 2026, brands are incorporating recycled materials in tool housings, offering longer battery life to reduce waste, and designing modular nailers that allow for part replacement instead of full-unit disposal. Additionally, energy efficiency in cordless systems is becoming a selling point, aligning with broader sustainability goals in the construction industry.

5. Smart Features and Connectivity

Though still emerging, smart technology is beginning to enter the nailer market. By 2026, high-end models may feature Bluetooth connectivity, usage tracking, and diagnostic alerts via mobile apps. These features help professionals monitor tool performance, schedule maintenance, and optimize job-site efficiency—particularly useful for contractors managing multiple baseboard installation projects.

6. Regional Market Expansion

North America remains a dominant market due to strong residential construction activity, but growth is also evident in Europe and parts of Asia-Pacific, where urban renovation and modernization projects are on the rise. In these regions, compact, versatile nailers tailored for smaller living spaces and intricate molding designs are seeing increased adoption.

7. Competitive Pricing and Brand Differentiation

As the market becomes more saturated, competition is intensifying. In 2026, brands are differentiating through warranty terms, customer support, bundled accessories (e.g., magnetic nail trays, carrying cases), and compatibility with multiple fastener types. Price points are stabilizing, with mid-range models offering professional features at accessible costs.

In summary, the 2026 market for nailers for baseboards is characterized by technological innovation, user-centric design, and expanding consumer access. Cordless adoption, precision engineering, and sustainability are key drivers shaping product development and purchasing decisions across both professional and DIY segments.

Common Pitfalls When Sourcing a Nailer for Baseboards (Quality and IP Considerations)

When sourcing a nailer for baseboards, it’s essential to avoid common mistakes that can compromise both the quality of your work and the longevity of the tool. Ignoring key aspects such as build quality and Ingress Protection (IP) ratings can lead to inefficiencies, safety hazards, and premature tool failure. Below are the most frequent pitfalls to watch out for.

Poor Build Quality Leading to Durability Issues

One of the most common pitfalls is selecting a nailer based solely on price without evaluating its construction. Low-cost models often use plastic components, inferior metals, and subpar internal mechanisms. These tools may fail under regular use, especially during extended baseboard installations. Look for nailers with durable aluminum or magnesium housings, precision-machined drivers, and reputable brand certifications to ensure reliability.

Overlooking the Importance of IP Rating

Ingress Protection (IP) ratings indicate a tool’s resistance to dust and moisture—critical factors if you’re working in environments with sawdust, humidity, or outdoor exposure. Many users overlook the IP rating, assuming all nailers are equally protected. However, without an adequate IP rating (e.g., IP54 or higher), internal components can degrade from dust buildup or moisture, leading to malfunctions and electrical hazards in corded or battery-powered models.

Inadequate Precision for Delicate Baseboard Work

Baseboard installation requires accuracy and control. Some nailers marketed for general use lack the finesse needed for trim work. Using a framing nailer instead of a dedicated brad or finish nailer can cause splitting, misfires, or visible damage to baseboards. Always choose a nailer specifically designed for finish work, with adjustable depth control and a slim nose for tight spaces.

Misjudging Power Source and Portability Needs

Corded, pneumatic, and cordless nailers each come with trade-offs. Relying on a pneumatic nailer without access to a compatible air compressor reduces efficiency. Similarly, opting for a low-battery cordless model can result in inconsistent performance. Assess your worksite conditions and choose a power source that balances portability, runtime, and consistent driving force.

Skipping Safety and Ergonomic Features

A high-quality nailer should include safety mechanisms like sequential triggers and jam-clearance features. Ignoring ergonomics—such as grip comfort, weight distribution, and noise levels—can lead to user fatigue and increased risk of injury during long installations. Always test the tool or read detailed user feedback before purchasing.

Failing to Verify Warranty and Support

Lastly, skimping on customer support and warranty coverage is a hidden risk. If a nailer fails mid-project, having access to prompt service and replacement parts is crucial. Avoid brands with limited or unclear warranty terms, especially when sourcing from third-party suppliers or overseas markets.

By avoiding these common pitfalls, you can select a high-quality, appropriately rated nailer that ensures clean, efficient, and durable baseboard installations.

Logistics & Compliance Guide for Nailer For Baseboards

Product Classification and HS Code

Identify the correct Harmonized System (HS) code for nailers used in baseboard installation. Typically, these fall under category 8467 (Tools for driving or nailing, pneumatically, hydraulically or by other means), with a more specific code depending on power source (e.g., 8467.89 for non-electric, 8467.21 for pneumatic). Accurate classification ensures proper customs clearance and duty assessment.

Import/Export Regulations

Comply with customs and trade regulations in both origin and destination countries. Ensure all export documentation, including commercial invoices, packing lists, and certificates of origin, are complete and accurate. Verify any import restrictions, licensing requirements, or product-specific regulations (e.g., EPA, DOT) that may apply.

Packaging and Labeling Requirements

Package nailers securely to prevent damage during transit. Use standardized, durable packaging with protective materials. Labels must include product identification, model number, safety warnings, voltage/power specifications, manufacturer details, and compliance marks (e.g., CE, ETL, CSA). Bilingual labeling may be required for certain markets.

Safety and Certification Compliance

Ensure the nailer meets safety standards in target markets. Required certifications may include:

– CE Marking (EU): Complies with Machinery Directive and relevant EN standards.

– UL/ETL Certification (USA/Canada): Meets safety standards for power tools.

– CSA Certification (Canada): Required for electrical and mechanical safety.

– UKCA Marking (UK): Post-Brexit compliance requirement.

Maintain technical documentation and test reports to support certification claims.

Battery and Power Regulations (if applicable)

For cordless models, comply with regulations for lithium-ion batteries, including UN38.3 testing certification for air transport and proper labeling (e.g., Class 9 hazardous material). Include battery safety data sheets (SDS) and ensure packaging meets IATA/IMDG standards.

Environmental and RoHS Compliance

Confirm the product complies with environmental directives such as the EU’s RoHS (Restriction of Hazardous Substances), which limits lead, mercury, cadmium, and other substances. Ensure compliance with WEEE (Waste Electrical and Electronic Equipment) labeling and recycling obligations where applicable.

Shipping and Transportation Logistics

Choose appropriate freight modes (air, ocean, ground) based on volume, urgency, and cost. For air freight, follow dangerous goods regulations if batteries are included. Use insured shipments and track consignments. Coordinate with customs brokers to facilitate timely clearance.

Warranty and After-Sales Compliance

Provide clear warranty documentation compliant with local consumer protection laws (e.g., EU Consumer Rights Directive, U.S. Magnuson-Moss Warranty Act). Include multilingual user manuals with installation, operation, and maintenance instructions.

Recordkeeping and Audit Preparedness

Maintain detailed records of compliance certifications, test reports, import/export filings, and quality audits for a minimum of 5–10 years depending on jurisdiction. Be prepared for regulatory inspections or customer audits.

Updates and Regulatory Monitoring

Stay informed about changes in international trade rules, safety standards, and environmental legislation. Subscribe to regulatory updates from agencies such as U.S. CBP, EU Commission, Health Canada, and Standards Council of Canada to ensure ongoing compliance.

In conclusion, sourcing a nailer for baseboard installation requires careful consideration of several key factors to ensure efficiency, precision, and durability. A brad nailer or a finish nailer is typically the best choice, depending on the thickness and material of the baseboards. Brad nailers (18-gauge) are ideal for lightweight trim and delicate work, offering smaller holes and reduced risk of splitting, while finish nailers (15- or 16-gauge) provide stronger holding power for larger or denser baseboards.

Ease of use, weight, jam-clearing mechanism, and compatibility with nail types (angled vs. straight) are important practical considerations. Cordless and pneumatic options each have their advantages—pneumatic nailers offer consistent power and are often more affordable, while cordless models provide greater portability and convenience for remote or mobile jobs.

Ultimately, the right nailer will balance performance, reliability, and value based on your specific project needs and frequency of use. By evaluating reputable brands, reading user reviews, and possibly testing tools firsthand, you can make an informed decision that enhances both the quality and speed of your baseboard installations.