The global demand for high-performance raw materials in coatings, adhesives, and polymer applications continues to rise, driven by rapid industrialization and technological advancements in emerging markets. According to Mordor Intelligence, the global synthetic rubber market—closely linked to specialty powders like N110—is projected to grow at a CAGR of over 5.8% from 2023 to 2028, underpinned by increasing demand from the automotive and construction sectors. N110 carbon black powder, known for its excellent reinforcement and UV stabilization properties, plays a critical role in enhancing product durability and performance. As manufacturers seek consistent quality, scalability, and technical support, the competitive landscape among N110 powder producers has intensified. Based on production capacity, geographic reach, product consistency, and technological innovation, the following are the top three N110 powder manufacturers shaping the industry’s future.

Top 3 N110 Powder Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

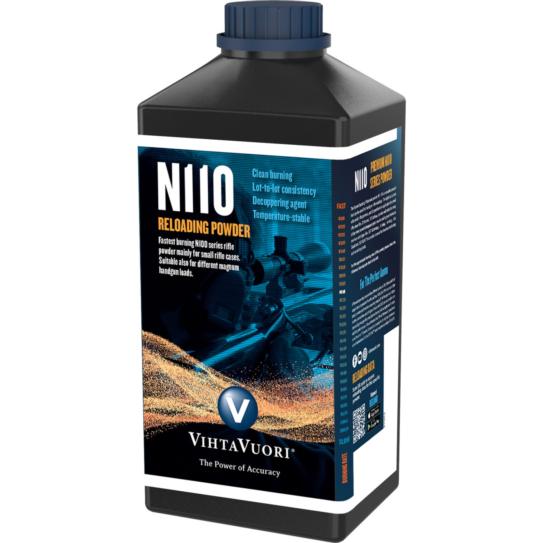

#1 Vihtavuori N110 Smokeless Powder (1 lb)

Domain Est. 1998

Website: ballisticproducts.com

Key Highlights: Vihtavuori N110 smokeless powder is a versatile choice for magnum handgun, rifle, and select shotshell loads. Known for its clean burn and reliable ……

#2 Current powder prices

Domain Est. 1998

Website: forum.castbulletassoc.org

Key Highlights: N110 happens to be my favourite cast bullet powder, I shoot it a lot, and have done so for a few years now. It requires no filler, and works ……

#3 Archives: Powders

Domain Est. 2003

Website: vihtavuori.com

Key Highlights: The N110 rifle powder The N110 powder, formerly known as 4N19 and N3SS, is a tubular powder type with grain dimensions of 1,1 mm length and 0,8 mm diameter….

Expert Sourcing Insights for N110 Powder

H2: Analysis of 2026 Market Trends for N110 Powder

1. Overview of N110 Powder

N110 Powder, commonly known as N110 carbon black, is a high-surface-area, high-reinforcing carbon black grade primarily used in the rubber industry—especially in tire treads and sidewalls. Its fine particle size and superior reinforcing properties enhance abrasion resistance, tensile strength, and durability in rubber compounds. As key end-use industries evolve, the market dynamics for N110 are expected to shift significantly by 2026.

2. Demand Drivers in 2026

– Automotive and Tire Industry Growth: The global push toward electric vehicles (EVs) is shaping tire manufacturing requirements. EVs demand tires with higher load-bearing capacity, improved rolling resistance, and extended tread life—all properties enhanced by N110. By 2026, increasing EV production, especially in China, Europe, and North America, will drive demand for high-performance carbon blacks like N110.

– Expansion in Emerging Markets: Rising vehicle ownership and infrastructure development in Southeast Asia, India, and Latin America will support tire production growth, indirectly boosting N110 consumption.

– Sustainability Pressures and Innovation: While carbon black faces scrutiny due to its fossil fuel-based production and carbon footprint, manufacturers are investing in sustainable alternatives. However, N110 remains preferred in high-performance applications where synthetic replacements (e.g., silica) still fall short in certain mechanical properties.

3. Supply Chain and Production Trends

– Feedstock Volatility: N110 is produced via the furnace black process using heavy aromatic oils. Fluctuations in crude oil prices and regulations on aromatic content will continue to affect production costs and supply stability through 2026.

– Regional Production Shifts: China remains the largest producer of carbon black, including N110, but environmental regulations are pushing manufacturers toward cleaner technologies. In contrast, investment in new capacity is expected in the Middle East due to lower energy costs and government support.

– Integration and Consolidation: Leading carbon black producers (e.g., Orion, Birla Carbon, Cabot Corporation) are increasingly vertically integrating and adopting circular economy models—such as recovering heat energy from production or using bio-based feedstocks—to improve margins and meet ESG goals.

4. Competitive Landscape and Substitution Risks

– Competition from Silica and Hybrid Systems: In tire treads, highly dispersible silica is often blended with carbon black (including N110) to reduce rolling resistance and improve fuel efficiency. By 2026, hybrid filler systems may partially displace pure carbon black in some segments, though N110 will remain critical for reinforcement.

– Niche Dominance: N110’s high reinforcement makes it difficult to replace in performance tires, off-the-road (OTR) tires, and industrial rubber goods. Its market share in these segments is expected to remain stable or grow.

5. Price and Trade Dynamics

– Pricing Pressure and Volatility: Energy costs, logistics, and environmental compliance will keep upward pressure on N110 prices. However, competition and bulk purchasing by large tire OEMs may moderate increases.

– Trade Flows: Geopolitical tensions and trade policies—such as anti-dumping duties in the U.S. and EU on Chinese carbon black—will influence regional availability. Diversification of supply sources will be a key strategy for tire manufacturers.

6. Regulatory and Environmental Outlook

– Carbon Emissions Regulations: As global decarbonization targets tighten, carbon black producers will face stricter emissions standards. Investment in carbon capture, utilization, and storage (CCUS) technologies may become essential by 2026.

– Recycling and Circular Economy: Advances in pyrolysis-derived carbon black (rCB) from scrap tires could create competition. However, rCB typically has lower and inconsistent performance compared to virgin N110, limiting immediate displacement.

7. Forecast for 2026

– Market Growth: The global N110 powder market is projected to grow at a CAGR of 3.5–4.2% from 2023 to 2026, reaching an estimated value of USD 1.8–2.1 billion by 2026.

– Regional Outlook:

– Asia-Pacific: Dominates consumption, driven by China and India.

– Europe: Steady demand with emphasis on sustainable production.

– North America: Moderate growth, supported by EV adoption and onshoring of tire production.

– Rest of World: Emerging opportunities in Africa and Latin America.

8. Strategic Implications

– Producers should focus on product differentiation, energy efficiency, and sustainability certifications to maintain competitiveness.

– Long-term supply agreements with tire manufacturers will be key to securing market share.

– R&D into hybrid fillers and improved dispersion technologies will help extend N110’s relevance amid evolving material demands.

Conclusion

By 2026, the N110 powder market will be shaped by the convergence of automotive innovation, sustainability mandates, and regional industrial policies. While facing substitution pressures in certain applications, N110 will retain a critical role in high-performance rubber goods, supported by ongoing demand from the global tire industry. Strategic adaptation to environmental and technological trends will determine leadership in this mature yet evolving market segment.

Common Pitfalls When Sourcing N110 Powder: Quality and Intellectual Property Risks

Sourcing N110 carbon black powder, a critical reinforcing agent in rubber and tire manufacturing, involves navigating significant challenges related to both material quality consistency and intellectual property (IP) protection. Failure to address these pitfalls can lead to product failures, supply chain disruptions, and legal liabilities.

Quality-Related Pitfalls

- Inconsistent Physical Properties: N110 is defined by stringent specifications (e.g., ASTM D1765 N110, GB/T 3778-2011). Key pitfalls include variability in:

- Nitrogen Surface Area (NSA) / Iodine Adsorption Number (IAN): Deviations impact reinforcement and dispersion in rubber compounds, affecting tire performance (e.g., rolling resistance, wear).

- DBP Oil Absorption Number: Affects compound viscosity and filler-rubber interaction; inconsistency leads to processing difficulties.

- Tint Strength: Critical for achieving consistent blackness in final products; variations cause cosmetic defects.

- Ash, Moisture, and Volatile Content: High levels can degrade compound stability, cause porosity in molded parts, or interfere with curing.

- Contamination: Impurities like metal particles (from mill wear), sand, or foreign materials can act as stress concentrators in rubber, drastically reducing product lifespan and safety.

- Agglomeration and Dispersion Issues: Poorly processed N110 forms hard agglomerates that resist dispersion during rubber mixing. This leads to weak spots, reduced reinforcement, and compromised product integrity.

- Lack of Traceability and Certification: Inadequate supplier documentation (e.g., Certificates of Analysis, Material Safety Data Sheets) makes it difficult to verify quality, troubleshoot production issues, or meet regulatory requirements.

- Inadequate Quality Control at Source: Suppliers without robust in-process and final product testing (using standardized methods) are more likely to ship non-conforming material.

Intellectual Property (IP) Pitfalls

- Trade Secret Misappropriation: The specific manufacturing process for high-performance N110 (e.g., furnace conditions, quenching techniques, surface treatment) is often a closely guarded trade secret. Engaging with suppliers lacking strong IP protection protocols risks exposure or accidental disclosure of your own formulation IP.

- Unclear IP Ownership in Custom Grades: If you require a modified N110 (e.g., surface-treated for specific applications), agreements must explicitly state who owns the IP for the modification process and the resulting specifications. Ambiguity can lead to disputes and loss of proprietary advantage.

- Supplier Reliance on Infringing Technology: Sourcing from a supplier unknowingly using patented manufacturing processes (e.g., specific reactor designs, pollution control tech) can expose your company to indirect infringement claims, especially if your product incorporates the infringing material.

- Weak or Absent Confidentiality Agreements (NDAs): Failing to establish comprehensive NDAs before technical discussions allows suppliers to potentially use shared information (e.g., your target compound performance) for competitive advantage or with other customers.

- “Gray Market” or Unlicensed Production: Sourcing from unauthorized distributors or producers in regions with lax IP enforcement increases the risk of counterfeit or substandard material, potentially violating the original patent holder’s rights and compromising quality.

Mitigation: Thorough due diligence on suppliers, stringent quality agreements with clear specifications and testing protocols, robust NDAs, clear IP clauses in contracts, and sourcing from reputable, licensed manufacturers are essential to avoid these significant pitfalls.

H2: Logistics & Compliance Guide for N110 Powder

H2: Overview of N110 Powder

N110 Powder, also known as N110 Carbon Black, is a high-structure, high-surface-area carbon black primarily used in rubber reinforcement applications, especially in tire treads for improved wear resistance and tensile strength. Due to its fine particulate nature and industrial application, its logistics and compliance requirements must strictly adhere to health, safety, and environmental regulations.

H2: Regulatory Classification and Identification

– Chemical Name: Carbon Black (N110)

– CAS Number: 1333-86-4

– UN Number: UN 1361

– Class: 4.2 (Substances liable to spontaneous combustion)

– Packing Group: III (Low danger)

– GHS Classification:

– Not classified as hazardous under GHS for physical or health hazards in bulk form under normal conditions.

– However, may be classified as a nuisance dust; inhalation of fine particles may pose respiratory risks.

– Some regulatory bodies may consider certain carbon blacks as Group 2B (possibly carcinogenic to humans) by IARC due to impurities.

H2: Packaging Requirements

– N110 Powder must be packed in moisture-resistant, durable multi-wall paper bags with polyethylene liners or in flexible intermediate bulk containers (FIBCs / super sacks) rated for powder materials.

– Containers must be sealed to prevent dust emission during transit.

– FIBCs should be Type C or Type D if static discharge is a concern in flammable environments.

– Packaging must comply with IMDG, IATA, and ADR regulations for road, sea, and air transport.

H2: Storage Guidelines

– Store in a cool, dry, well-ventilated area away from sources of ignition.

– Keep containers closed when not in use to minimize dust generation.

– Avoid accumulation of dust in storage areas to prevent potential fire or explosion risks (dust explosion hazard under certain conditions).

– Use grounded equipment to prevent static buildup.

– Segregate from strong oxidizing agents.

H2: Transportation Requirements

– Road (ADR): Classified under UN 1361, Class 4.2, PG III. Vehicles must carry appropriate hazard signage.

– Air (IATA): Permitted as non-dangerous goods if tested and proven not to be spontaneously combustible; otherwise, requires Class 4.2 labeling and documentation.

– Sea (IMDG): Listed under UN 1361, Class 4.2, PG III. Must be stowed to avoid contamination and moisture.

– Proper shipping name: “Carbon black”

– Safety data sheet (SDS) must accompany shipments.

H2: Handling and Worker Safety

– Use local exhaust ventilation or dust control systems in handling areas.

– Operators should wear:

– NIOSH-approved respirators (N95 or equivalent) when dust levels exceed permissible exposure limits.

– Safety goggles, gloves, and protective clothing to prevent skin and eye contact.

– Avoid creating or inhaling dust clouds.

– Prohibit eating, drinking, or smoking in handling areas.

– Conduct regular air monitoring for particulate levels.

H2: Environmental and Disposal Compliance

– N110 Powder is not acutely toxic to aquatic life but can cause physical contamination.

– Prevent release into sewers, waterways, or soil.

– Waste disposal must comply with local, national, and international regulations (e.g., RCRA in the U.S., Waste Framework Directive in the EU).

– Spills should be collected using approved industrial vacuums (not dry sweeping) to avoid dust dispersion.

– Incineration in approved facilities is acceptable for waste disposal.

H2: Documentation and Compliance

– Maintain up-to-date Safety Data Sheet (SDS) compliant with GHS and local regulations (e.g., OSHA HazCom, REACH, CLP).

– Shipments must include:

– Proper shipping name, UN number, hazard class.

– Transport emergency card (TREM card) if required.

– Declaration of transport compliance for air/sea shipments.

– For EU: Ensure REACH registration is complete; communicate safe use via SDS and exposure scenarios.

– For U.S.: Comply with OSHA 29 CFR 1910.1200 (Hazard Communication Standard).

H2: Emergency Procedures

– Inhalation: Move to fresh air; seek medical attention if breathing is difficult.

– Skin Contact: Wash with soap and water; remove contaminated clothing.

– Eye Contact: Rinse thoroughly with water for at least 15 minutes; consult a physician if irritation persists.

– Fire: Use dry chemical, CO₂, or water spray. Carbon black fires are rare but may burn if dispersed in air as a dust cloud.

– Spill Response: Contain spill, avoid raising dust, collect in sealed container, and dispose as industrial waste.

H2: Training and Recordkeeping

– Train personnel on:

– Safe handling procedures

– Emergency response

– Use of PPE

– Regulatory compliance

– Maintain records of training, exposure monitoring, and incident reports for audit and compliance purposes.

H2: Conclusion

N110 Powder requires careful logistics planning and strict compliance with safety and environmental regulations due to its physical form and potential health hazards from dust exposure. Adhering to proper packaging, storage, transportation, and handling protocols ensures operational safety and regulatory compliance across the supply chain.

Conclusion for Sourcing N110 Powder:

Sourcing N110 carbon black powder requires a strategic approach that balances quality, cost, reliability, and compliance. As a high-surface-area furnace black, N110 is critical in applications demanding superior reinforcement and wear resistance, particularly in tire treads and high-performance rubber products. Successful sourcing involves identifying reputable suppliers with consistent product specifications, robust quality control, and the capacity to meet volume demands. Evaluating factors such as purity, particle size distribution, and bulk density is essential to ensure compatibility with manufacturing processes. Additionally, establishing long-term partnerships, considering logistical efficiencies, and staying compliant with environmental and safety regulations will contribute to a resilient and cost-effective supply chain. Ultimately, a well-structured sourcing strategy for N110 powder enhances product performance and supports sustainable operations in the rubber and polymer industries.