The global multimode fiber optic cable market is experiencing robust expansion, driven by escalating demand for high-speed data transmission across data centers, enterprise networks, and telecommunication infrastructures. According to Grand View Research, the global fiber optic cable market size was valued at USD 6.53 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 8.3% from 2024 to 2030—with multimode cables playing a pivotal role in short-reach, high-bandwidth applications. Similarly, Mordor Intelligence projects a CAGR of over 7.5% for the fiber optic cable market during the forecast period of 2024–2029, citing rising investments in 5G deployment, cloud computing, and smart city initiatives as key growth accelerators. As bandwidth requirements surge, multimode fiber (MMF) solutions—especially OM3, OM4, and emerging OM5 standards—have become essential for supporting data rates up to 100 Gbps and beyond within confined environments. This increasing demand has intensified competition among manufacturers to deliver high-performance, cost-effective, and future-ready cabling solutions. In this landscape, a select group of global manufacturers have emerged as leaders through innovation, scalability, and extensive product certification. Below, we highlight the top 10 multimode fiber optic cable manufacturers shaping the present and future of high-speed connectivity.

Top 10 Multimode Fiber Optic Cable Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Optical Cable Corporation

Domain Est. 1996

Website: occfiber.com

Key Highlights: OCC is dedicated to being a diverse manufacturer of high-performance connectivity products and solutions in the world….

#2 Broadcast Fiber Optic Cable Solutions and Accessories

Domain Est. 1997

Website: camplex.com

Key Highlights: A leading US manufacturer and provider of fiber optic cable solutions and accessories for the Broadcast, Pro-Audio, and Pro-AV markets….

#3 Fibertronics, Inc.

Domain Est. 2000

Website: fibertronics.com

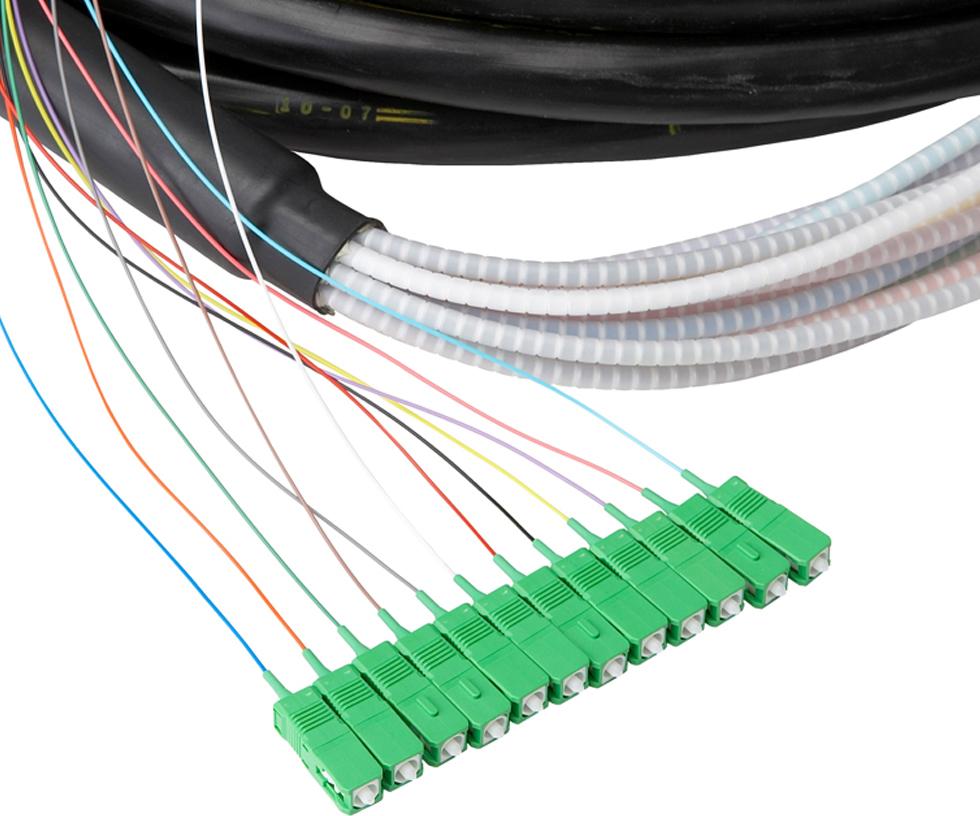

Key Highlights: 2–12 day deliveryFibertronics, Inc. is an SBA certified woman-owned small business providing USA manufactured customized fiber optic and low voltage cable assemblies, ……

#4 Fiber Optic Cables

Domain Est. 1991

Website: corning.com

Key Highlights: Corning has fiber optic cables for outdoor, indoor/outdoor, and indoor environments in a variety of types and applications….

#5 Fiber Optic Cables

Domain Est. 1994

Website: commscope.com

Key Highlights: CommScope designs and manufactures a comprehensive line of fiber optic cables—from outside plant to indoor/outdoor and fire-rated indoor fiber ……

#6 Multimode Fiber

Domain Est. 1994

Website: newport.com

Key Highlights: Free delivery 30-day returnsWe offer graded index, step index, and power delivery multimode fibers to meet most bulk light transport requirements….

#7 Fiber Optic Cable Assemblies

Domain Est. 1997

Website: unicor.gov

Key Highlights: UNICOR can build a broad range of high-reliability, multi-strand fiber optic cable assemblies in single- and multi-mode using military-qualified components….

#8 Multimode Optical Fiber and Cables

Domain Est. 2002

Website: ofsoptics.com

Key Highlights: Our premium multimode optical fibers and cables are designed to provide reliable, low-power and high-bandwidth connections for a variety of short-reach ……

#9 Optical Fiber Solutions

Domain Est. 2005

Website: na.prysmian.com

Key Highlights: Prysmian produces optical fiber solutions for high-speed, reliable digital connectivity and next-gen communication infrastructure. Learn more!…

#10 Fiber Optic Cable Solutions

Domain Est. 2008

Website: aflglobal.com

Key Highlights: We have a wide variety of fiber cable types to choose from, including single-mode, multimode, armored, and non-armored cable. We also offer a variety of ……

Expert Sourcing Insights for Multimode Fiber Optic Cable

H2: Projected Market Trends for Multimode Fiber Optic Cable in 2026

By 2026, the multimode fiber optic cable market is expected to undergo significant transformation driven by rising demand for high-speed data transmission, advancements in data center infrastructure, and the proliferation of bandwidth-intensive applications. Key trends shaping the market include:

1. Continued Growth in Data Center Deployments

The expansion of hyperscale and enterprise data centers remains a primary driver for multimode fiber (MMF) adoption. As cloud computing, artificial intelligence (AI), and machine learning (ML) workloads increase, data centers are upgrading to support higher bandwidths. OM5 and OM4 multimode fibers are particularly favored for short-reach, high-speed interconnects within data centers due to their cost-effectiveness and compatibility with parallel optics like 40G, 100G, and emerging 400G Ethernet standards.

2. Shift Toward Higher-Grade Multimode Fibers (OM5)

There is a growing shift from OM3 and OM4 to OM5 (wideband multimode fiber) due to its ability to support short-wave wavelength division multiplexing (SWDM). OM5 enables multiple data streams over a single fiber using different wavelengths, improving efficiency and future-proofing infrastructure. By 2026, OM5 adoption is expected to accelerate, especially in environments requiring scalable, high-density connectivity.

3. Competition and Coexistence with Single-Mode Fiber

While single-mode fiber (SMF) dominates long-haul and telecom applications, MMF continues to hold a strong position in short-distance applications (<500 meters), such as intra-data center links and local area networks (LANs). The lower cost of MMF transceivers and installation makes it an attractive option for enterprise and campus networks. However, the line between MMF and SMF applications is blurring, with SMF encroaching on MMF territory due to falling transceiver prices. The market will likely see a hybrid approach, with MMF maintaining dominance in cost-sensitive, short-reach scenarios.

4. Impact of 5G and Edge Computing

The rollout of 5G networks and the growth of edge computing are creating new opportunities for multimode fiber in distributed network architectures. While fronthaul and backhaul primarily rely on single-mode fiber, MMF is being deployed in edge data centers and localized network hubs where distances are short and cost efficiency is critical. This trend is expected to boost MMF demand in telecommunications and industrial IoT applications.

5. Regional Market Dynamics

North America and Europe will continue to lead in MMF adoption, driven by advanced data center ecosystems and enterprise network modernization. The Asia-Pacific region, particularly China, India, and Southeast Asia, is anticipated to witness the highest growth due to rapid digitalization, government investments in broadband infrastructure, and expanding cloud services.

6. Sustainability and Green Data Centers

Sustainability initiatives are influencing fiber optic cable design and deployment. Manufacturers are focusing on producing low-smoke zero-halogen (LSZH) and recyclable jacketing materials for MMF cables. Energy-efficient data centers are also favoring MMF for its lower power consumption compared to copper and certain active optical solutions.

7. Technological Innovation and Standardization

Ongoing developments in multimode fiber technology—such as enhanced modal bandwidth and improved compatibility with emerging optical interfaces—are being supported by standards bodies like ISO/IEC and TIA. By 2026, new standards may emerge to support 800G and 1.6T Ethernet over multimode fiber using advanced modulation techniques, further extending the lifecycle of MMF in high-performance environments.

Conclusion

In 2026, the multimode fiber optic cable market will remain robust, particularly in data center and enterprise networking segments. While facing competition from single-mode fiber and wireless technologies, MMF’s cost advantages, ease of deployment, and ongoing technological enhancements will ensure its relevance. The convergence of AI, edge computing, and green infrastructure will shape demand, positioning OM5 and next-generation MMF solutions as critical enablers of high-speed, energy-efficient connectivity.

Common Pitfalls When Sourcing Multimode Fiber Optic Cable (Quality, IP)

Sourcing multimode fiber optic cable requires careful consideration to ensure network performance, longevity, and compliance with industry standards. Overlooking key factors can lead to significant issues related to quality, reliability, and intellectual property (IP) protection. Below are common pitfalls to avoid:

Overlooking Fiber Grade and Specifications

One of the most frequent mistakes is failing to verify the fiber’s grade (e.g., OM3, OM4, OM5) and ensuring it meets the required standards (TIA/EIA-492 or ISO/IEC 11801). Using lower-grade cable than needed can severely limit bandwidth and transmission distance, especially in high-speed applications like 40G or 100G Ethernet. Always confirm specifications with test reports and ensure compatibility with existing infrastructure.

Ignoring Manufacturer Credentials and Reputation

Procuring fiber from unknown or unverified suppliers increases the risk of counterfeit or substandard products. These may use inferior glass, poor jacketing materials, or inaccurate labeling, leading to high attenuation and early failure. Always source from reputable manufacturers with verifiable certifications (e.g., UL, ETL, RoHS) and traceable production histories.

Falling for Counterfeit or Rebranded Products

The fiber optic market is vulnerable to counterfeit cables that mimic genuine products. These may bear fake logos, serial numbers, or packaging. Counterfeits often underperform and can pose safety hazards. Conduct due diligence by verifying batch numbers, using manufacturer authentication tools, and purchasing through authorized distributors.

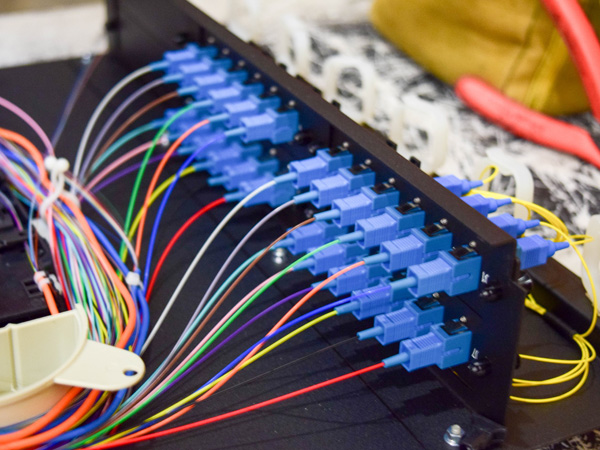

Skipping Certification and Test Documentation

Reliable multimode fiber should come with detailed test results, including insertion loss, bandwidth (modal dispersion), and length verification. Skipping this step means accepting unverified performance. Demand full certification documentation (e.g., OFNP/OFNR test reports) for each batch to ensure compliance and support warranty claims.

Neglecting Intellectual Property (IP) and Licensing Issues

Some high-performance multimode fibers (e.g., laser-optimized OM3/OM4) incorporate proprietary designs protected by patents. Using cables that infringe on these IP rights—even unknowingly—can expose buyers to legal risks, especially in regulated or enterprise environments. Ensure suppliers are authorized to manufacture and sell the specific fiber type and provide proof of licensing if applicable.

Compromising on Jacketing and Fire Ratings

Selecting the wrong cable jacket (e.g., using OFNR instead of OFNP in plenum spaces) violates fire safety codes and poses serious hazards. Different environments require specific fire ratings (OFNP, OFNR, LSZH). Always match the cable type to the installation environment to meet building codes and safety standards.

Underestimating Installation and Environmental Factors

Low-quality cables may not withstand bending, crushing, or temperature fluctuations, leading to signal loss or breakage during or after installation. Ensure cables meet mechanical specifications for the intended use, especially in harsh environments or high-density patching scenarios.

By avoiding these pitfalls, organizations can ensure they source reliable, standards-compliant multimode fiber optic cable that supports current and future network demands while protecting against legal and performance risks.

Logistics & Compliance Guide for Multimode Fiber Optic Cable

Overview

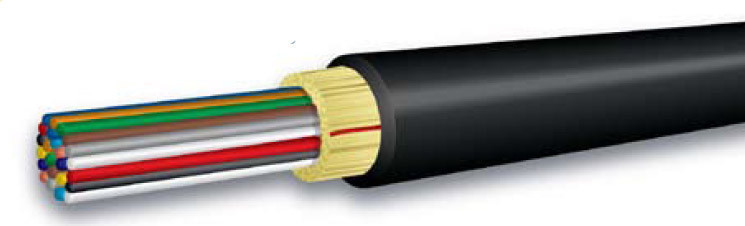

Multimode fiber optic cables are essential for high-speed data transmission over short to medium distances, commonly used in data centers, enterprise networks, and telecommunications infrastructure. Ensuring compliant and efficient logistics for these sensitive components requires adherence to technical, regulatory, and handling standards. This guide outlines best practices for the transportation, storage, import/export, and regulatory compliance of multimode fiber optic cables.

Packaging & Handling

- Protective Packaging: Cables must be shipped on reels or spools, enclosed in sturdy, moisture-resistant packaging to prevent kinking, crushing, or exposure to environmental contaminants.

- Labeling: Clearly label packages with “Fragile,” “This Side Up,” and product specifications (e.g., OM3/OM4/OM5, length, core size). Include handling instructions and part numbers.

- Bend Radius Compliance: During handling and transport, ensure the minimum bend radius (typically 10–15 times the cable diameter) is maintained to prevent signal loss or permanent damage.

- Static Protection: Use anti-static materials where applicable, especially for cables with sensitive connectors or terminations.

Storage Conditions

- Environment: Store cables in a dry, temperature-controlled environment (5°C to 35°C recommended). Avoid exposure to direct sunlight, humidity, and corrosive chemicals.

- Positioning: Keep reels upright on pallets or racks. Do not stack reels excessively to avoid compression damage.

- Shelf Life: Monitor shelf life; while fiber itself is durable, jackets and strength members may degrade over time in suboptimal conditions.

Transportation

- Mode Selection: Multimode cables can be shipped via air, sea, or ground freight depending on urgency and volume. Air freight is preferred for time-sensitive deliveries.

- Shock & Vibration Mitigation: Use cushioning and secure fastening in transit to minimize vibration and impact, especially during long-haul or international shipping.

- Temperature Control: For extreme climates, use climate-controlled containers to prevent jacket brittleness or moisture ingress.

Regulatory Compliance

- RoHS (Restriction of Hazardous Substances): Ensure cables comply with RoHS directives (EU, China, etc.), limiting substances like lead, mercury, and cadmium.

- REACH (EU Regulation): Confirm compliance with REACH regulations concerning chemical safety.

- UL & ETL Certification: In North America, cables should carry UL or ETL listings for fire safety and performance (e.g., OFNR, OFNP ratings).

- NEC (National Electrical Code): Adhere to NEC Article 770 for installation and fire ratings, especially for plenum (OFNP) or riser (OFNR) cable types.

International Trade & Documentation

- HS Code Classification: Use the correct Harmonized System (HS) code. Common codes:

- 8544.70 — Optical fiber cables (may vary by region and composition).

- Export Controls: For dual-use technologies, verify no ITAR or EAR restrictions apply (typically not applicable to standard multimode cables, but confirm with manufacturer).

- Customs Documentation: Include commercial invoice, packing list, bill of lading, and certificates of origin. Specify technical details: fiber type (e.g., 50/125 µm), category (OM3, OM4), and length.

- CE Marking: Required for sale within the European Economic Area, certifying conformity with health, safety, and environmental standards.

Environmental & Safety Standards

- Fire Safety Ratings: Ensure cables meet required fire resistance standards:

- OFNP (Plenum): For air-handling spaces; low smoke and flame spread.

- OFNR (Riser): For vertical shafts between floors.

- LSZH (Low Smoke Zero Halogen): Preferred in confined or public spaces for reduced toxic emissions during combustion.

- Recycling & Disposal: Follow local e-waste regulations for end-of-life disposal or recycling. Fiber optic cables are recyclable, particularly glass and metal components.

Quality Assurance & Traceability

- Manufacturer Certification: Source cables from ISO 9001-certified suppliers. Request test reports (e.g., insertion loss, bandwidth).

- Batch Traceability: Maintain records of lot numbers, production dates, and compliance documentation for audit and warranty purposes.

Conclusion

Effective logistics and compliance management for multimode fiber optic cables ensure product integrity, regulatory adherence, and customer satisfaction. By following standardized handling, storage, and documentation practices, organizations can minimize risk, avoid customs delays, and support reliable network deployments globally. Regular updates to regulatory requirements and international standards are recommended to maintain compliance.

Conclusion for Sourcing Multimode Fiber Optic Cable:

In conclusion, sourcing multimode fiber optic cable requires a strategic approach that balances performance requirements, cost efficiency, and future scalability. Multimode fiber remains a cost-effective and reliable solution for short to medium-distance data transmission, particularly in data centers, enterprise networks, and local area networks (LANs). When selecting a supplier and cable type, it is essential to consider factors such as fiber grade (OM3, OM4, or OM5), bandwidth needs, compatibility with existing infrastructure, and adherence to industry standards (e.g., TIA/EIA and ISO/IEC).

Prioritizing reputable vendors who offer high-quality, tested, and certified products ensures reliability and minimizes signal loss and downtime. Additionally, evaluating total cost of ownership—including installation, maintenance, and potential upgrades—can lead to more informed procurement decisions. As network demands continue to grow, sourcing OM4 or OM5 fibers with laser-optimized performance provides a future-ready foundation for evolving bandwidth requirements.

Ultimately, a well-considered sourcing strategy for multimode fiber optic cable supports robust network performance, scalability, and long-term operational efficiency.