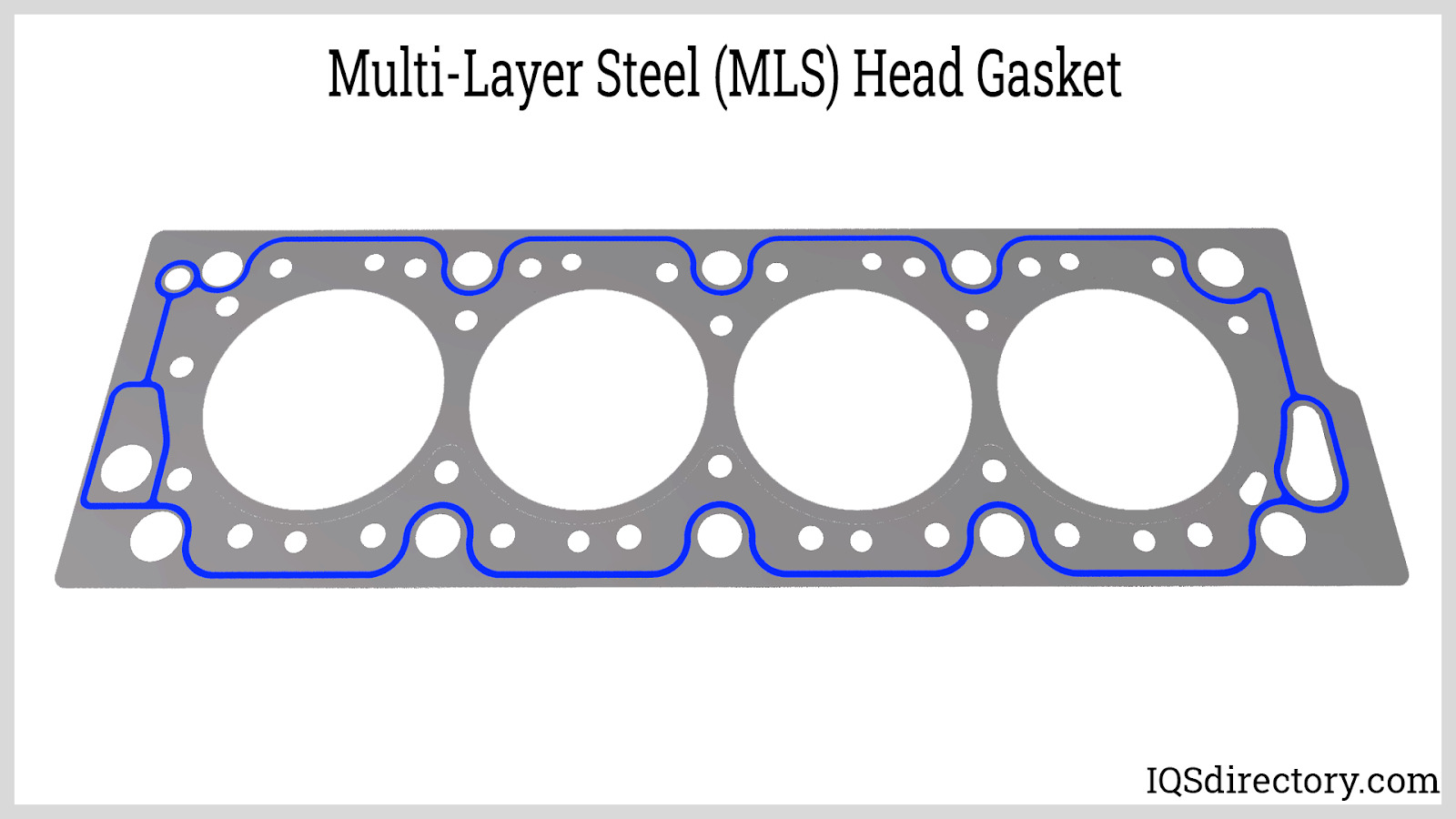

The global automotive head gasket market is experiencing robust growth, driven by rising vehicle production, stringent emissions regulations, and increasing demand for durable engine components. According to Grand View Research, the global engine gasket market size was valued at USD 6.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A key factor fueling this growth is the increasing adoption of multi-layer steel (MLS) head gaskets, which offer superior thermal conductivity, enhanced sealing performance, and greater durability under high combustion pressures—critical for modern turbocharged and downsized engines. As OEMs and aftermarket suppliers prioritize reliability and efficiency, the demand for high-performance MLS head gaskets continues to rise. This trend has led to a competitive manufacturing landscape, with a select group of global players leading innovation and volume production. Below, we examine the top nine multi-layer steel head gasket manufacturers shaping the future of engine sealing technology.

Top 9 Multi Layer Steel Head Gasket Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Multilayer Racing Head Gasket

Website: athena.eu

Key Highlights: In stock $24.99 deliverySpecifically designed to deal with increasingly high cylinder pressures and temperatures, Athena’s multilayer gaskets are fitted by many car manufacturers ….

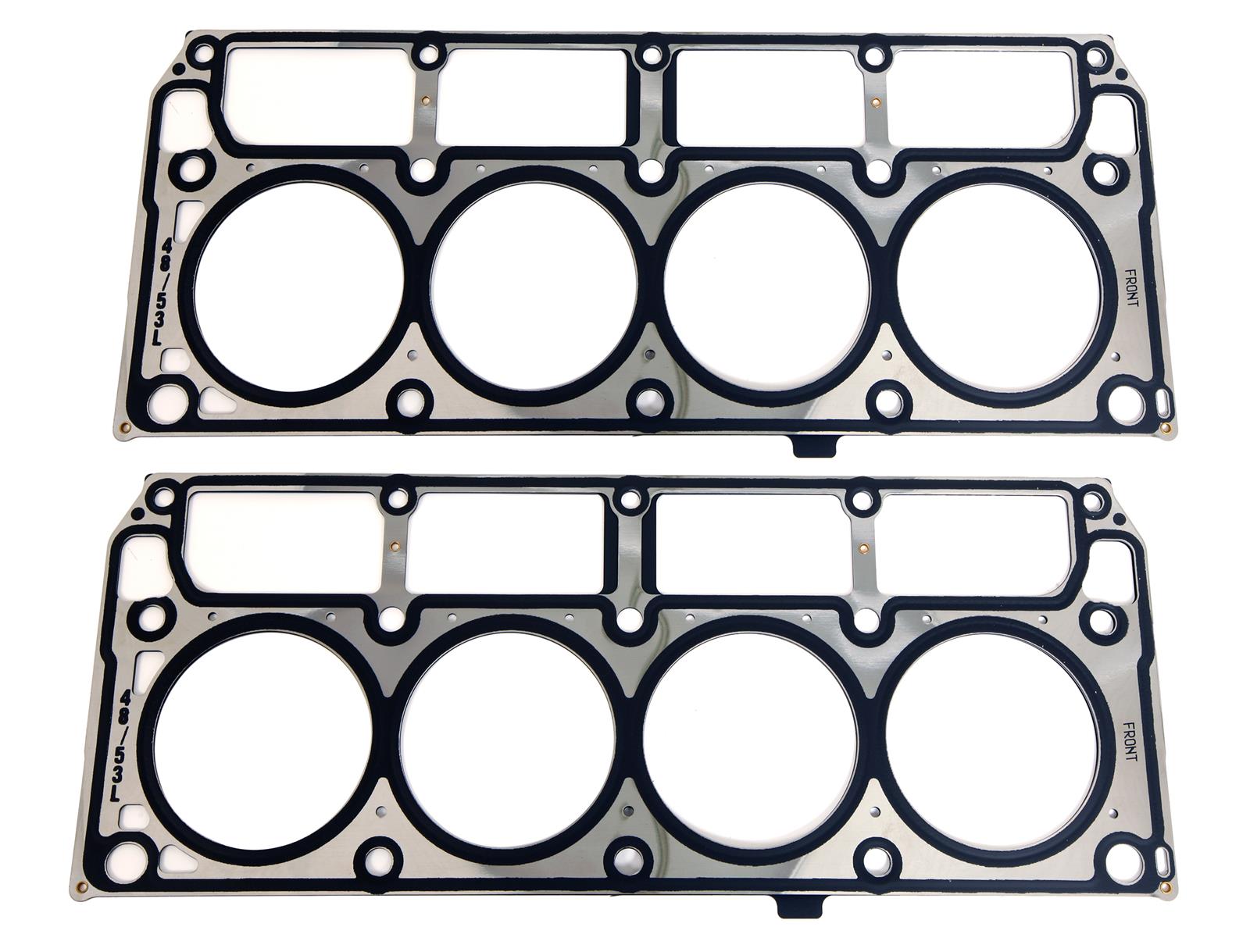

#2 Mr. Gasket 3130G Mr. Gasket MLS Head Gasket

Domain Est. 1995

Website: holley.com

Key Highlights: Free delivery over $149 90-day returnsOur unique Multi-Layered steel head gasket embossment formation process optimizes the embossment radius, reduces stress points, enhances gaske…

#3 Head Gaskets

Domain Est. 1996

Website: cometic.com

Key Highlights: Our Multi-Layer Steel gaskets are comprised of multiple embossed layers of both proprietary high temperature coated and uncoated stainless steel….

#4 MLS Head Gaskets & Head Gaskets

Domain Est. 1998

Website: felpro.com

Key Highlights: Fel-Pro head gaskets set the standard for a superior seal. Depend on PermaTorque® MLS head gaskets, PermaTorque® and PermaTorque® SD gaskets for your repair ……

#5 Multi

Domain Est. 1998

Website: reinz.com

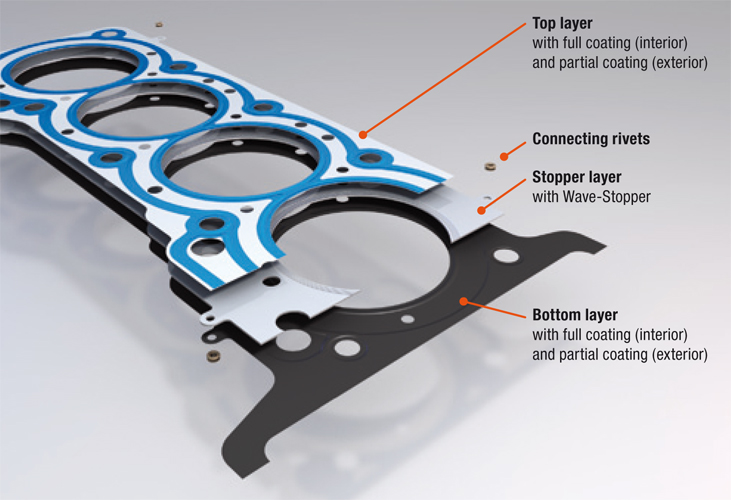

Key Highlights: Dana designs and manufactures multi-layer steel (MLS) cylinder-head gaskets consisting of two to five layers of stainless and/or carbon steel. They are designed ……

#6 Gaskets

Domain Est. 2000

Website: mahle-aftermarket.com

Key Highlights: All gaskets are not created equal – MAHLE® gaskets prove it every day. Head and intake manifold gasket materials. Multi-Layered Steel (MLS) Head & Manifold ……

#7 Head Gaskets

Domain Est. 2016

Website: victorreinz.us

Key Highlights: Multi-layer steel (MLS) head gaskets from Victor Reinz are manufactured using multiple layers of embossed stainless steel. Embossed beads and stoppers increase ……

#8 Cylinder

Domain Est. 2019

Website: elring.us

Key Highlights: Elring can supply gaskets of all types – metal layer, metal-elastomer and metal-soft material – individually matched to the requirements of each particular ……

#9 Metaloflex™ Cylinder

Website: elringklinger.de

Key Highlights: Metaloflex™ cylinder-head gaskets from ElringKlinger consist of beaded, elastomer-coated spring steel layers (single or multi-layer). The modular design ……

Expert Sourcing Insights for Multi Layer Steel Head Gasket

2026 Market Trends for Multi-Layer Steel (MLS) Head Gaskets

The Multi-Layer Steel (MLS) head gasket market is poised for significant evolution by 2026, driven by stringent emissions regulations, the rise of electrification, and continuous advancements in internal combustion engine (ICE) technology. While facing long-term pressure from electrification, MLS gaskets remain critical for high-performance and efficient ICE applications, with specific trends shaping their market trajectory.

Rising Demand Driven by High-Performance and Downsized Engines

The proliferation of turbocharged, downsized gasoline engines and high-efficiency diesel engines—especially in light-duty vehicles and performance segments—continues to boost demand for MLS head gaskets. These engines operate under higher cylinder pressures and thermal loads, where the superior sealing capabilities, resilience, and durability of MLS gaskets outperform traditional composite designs. By 2026, OEMs are expected to increasingly rely on MLS gaskets to meet performance and reliability standards in premium and performance-oriented vehicles.

Stringent Emissions and Fuel Efficiency Regulations as Key Drivers

Global regulatory frameworks such as Euro 7 (EU), Bharat Stage VII (India), and increasingly strict CAFE standards (USA) are compelling automakers to optimize engine efficiency. This includes higher compression ratios and advanced combustion technologies, which elevate stress on cylinder head seals. MLS gaskets, with their ability to maintain seal integrity under extreme conditions, are becoming essential components in compliance strategies. Their role in minimizing blow-by and ensuring consistent combustion efficiency directly supports emissions reduction goals.

Impact of Electrification: A Dual-Effect Market

While the growth of battery electric vehicles (BEVs) reduces the overall ICE vehicle footprint, the MLS head gasket market is not in immediate decline. By 2026, hybrid electric vehicles (HEVs) and plug-in hybrids (PHEVs) are expected to constitute a growing segment of the automotive market. These vehicles still utilize high-efficiency ICEs—often turbocharged and downsized—where MLS gaskets are preferred. Additionally, commercial vehicles, heavy-duty trucks, and niche performance segments will continue to depend on advanced ICEs, sustaining demand for MLS technology.

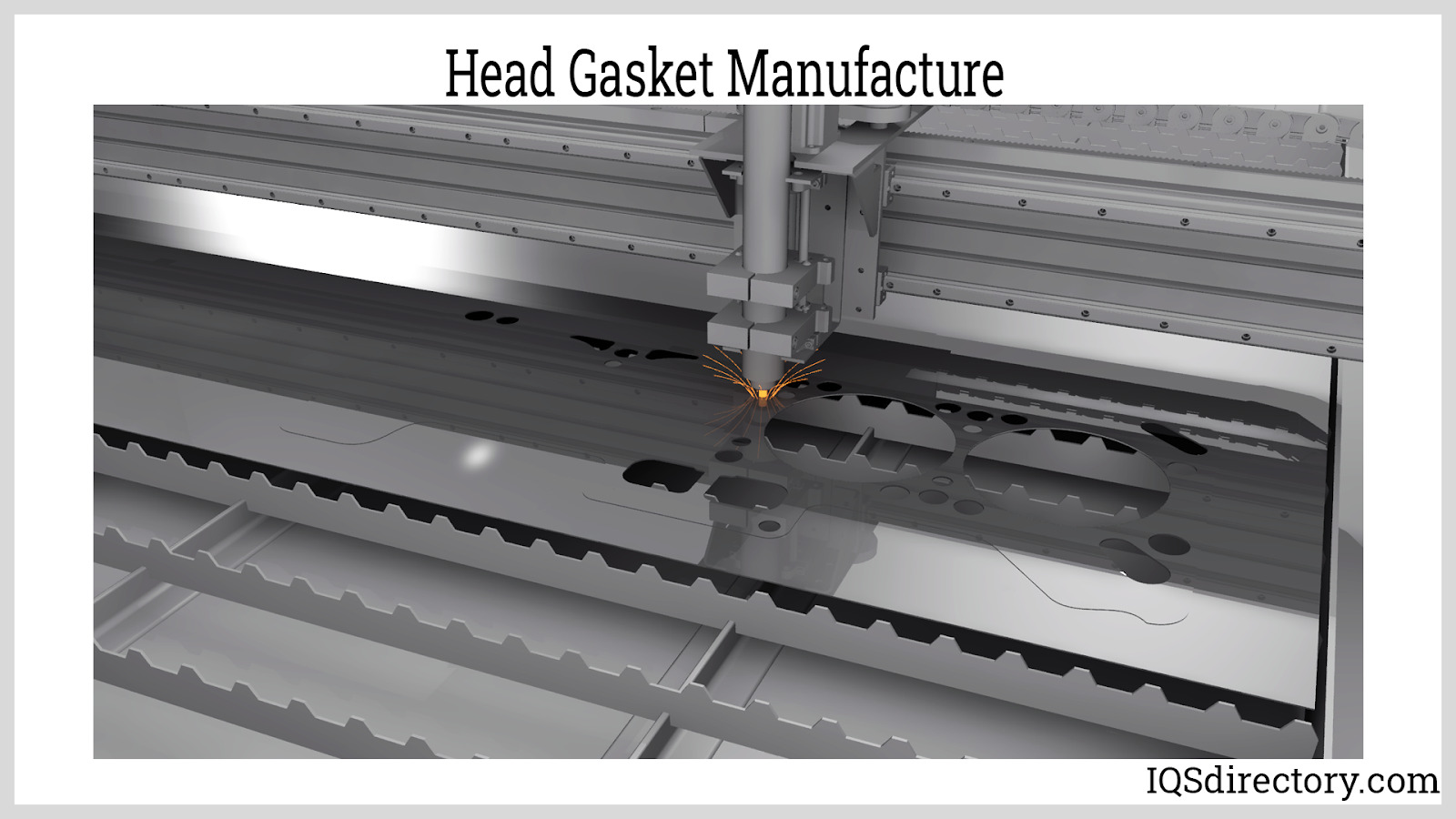

Innovation in Materials and Manufacturing Processes

To meet evolving performance requirements, gasket manufacturers are investing in advanced materials and precision manufacturing. Trends include the use of specialized elastomer coatings (e.g., Viton or graphite-based) for improved corrosion resistance and oil sealing, and the adoption of laser welding and automated stamping for tighter tolerances. By 2026, smart manufacturing and Industry 4.0 integration are expected to enhance quality control and customization capabilities, allowing faster adaptation to OEM-specific engine designs.

Regional Market Dynamics and Supply Chain Shifts

Asia-Pacific, particularly China and India, will remain key growth regions due to expanding automotive production and increasing demand for fuel-efficient vehicles. However, geopolitical factors and supply chain resilience concerns are prompting OEMs and suppliers to diversify manufacturing bases. Nearshoring and regionalization trends may lead to increased MLS gasket production in North America and Eastern Europe by 2026, reducing dependence on single-source suppliers.

Aftermarket Growth Supported by Vehicle Longevity

As vehicle lifespans extend and maintenance costs rise, the aftermarket for high-quality replacement gaskets is expanding. Consumers and repair shops increasingly opt for OEM-equivalent MLS gaskets due to their reliability and longevity. By 2026, the global aftermarket for MLS head gaskets is projected to grow steadily, supported by aging vehicle fleets and the complexity of modern engine repairs.

In conclusion, while the long-term outlook for ICE components faces challenges from electrification, the 2026 market for Multi-Layer Steel head gaskets is characterized by resilience and adaptation. Driven by performance demands, regulatory pressures, and hybridization, MLS gaskets will remain a vital technology in the global automotive landscape, particularly in high-efficiency and performance engine applications.

Common Pitfalls When Sourcing Multi-Layer Steel (MLS) Head Gaskets

Sourcing high-quality Multi-Layer Steel (MLS) head gaskets is critical for engine performance and longevity. However, several pitfalls related to quality and intellectual property (IP) can lead to component failure, warranty issues, and reputational damage. Being aware of these risks is essential for procurement professionals, engine rebuilders, and OEMs.

Quality-Related Pitfalls

- Inconsistent Material Sourcing: Using substandard or inconsistent steel grades for the shim layers or embossing can lead to premature failure. Lower-quality materials may lack the necessary tensile strength, corrosion resistance, or heat tolerance, resulting in blowouts or leaks under high cylinder pressures and temperatures.

- Poor Surface Coating Application: The anti-friction and sealing coating (typically Viton, rubber, or polymer-based) is vital. Inadequate coating thickness, uneven application, or use of inferior coating materials can compromise the gasket’s ability to seal effectively and survive multiple heat cycles, leading to head gasket failure.

- Inaccurate Embossing and Layer Alignment: Precision in the embossing profile (which provides spring load and seals combustion chambers, coolant, and oil passages) and perfect alignment of the multiple steel layers is paramount. Poor tooling or manufacturing tolerances result in weak sealing areas, uneven compression, and potential combustion gas leakage.

- Insufficient Quality Control (QC) and Testing: Suppliers lacking rigorous QC processes (e.g., dimensional checks, coating adhesion tests, pressure testing) may ship gaskets with undetected flaws. Relying solely on visual inspection without functional testing increases the risk of field failures.

- Lack of Application-Specific Engineering: Treating MLS gaskets as generic components rather than engineered solutions for specific engine designs (considering bore size, head bolt pattern, clamping force, and operating conditions) leads to incorrect specifications and inadequate performance.

Intellectual Property (IP)-Related Pitfalls

- Sourcing Counterfeit or “Pattern” Gaskets: Purchasing gaskets from unauthorized suppliers that replicate genuine OEM or premium aftermarket designs infringes on design patents and trademarks. These “pattern” parts often use inferior materials and processes, significantly increasing the risk of failure and voiding engine warranties.

- Unverified Supplier Claims: Accepting supplier claims of “OEM equivalent,” “direct replacement,” or “meets OEM specs” without independent verification or proper documentation (e.g., material certifications, test reports) is risky. Such claims may be misleading or unsubstantiated, potentially masking IP infringement or quality issues.

- Lack of Traceability and Documentation: Failing to obtain and maintain documentation proving the gasket’s origin, material certifications, and compliance with relevant standards makes it difficult to verify IP legitimacy and quality, especially in the event of a failure investigation or warranty claim.

- Engaging with Suppliers in IP-Risky Jurisdictions: Sourcing from regions known for lax IP enforcement increases the likelihood of receiving counterfeit or infringing products, even if the supplier presents themselves as legitimate.

- Ignoring Licensing Agreements: For businesses manufacturing or distributing gaskets, failing to secure proper licensing from patent holders (e.g., for specific MLS design technologies) exposes them to legal action for patent infringement and potential financial penalties.

Logistics & Compliance Guide for Multi-Layer Steel (MLS) Head Gaskets

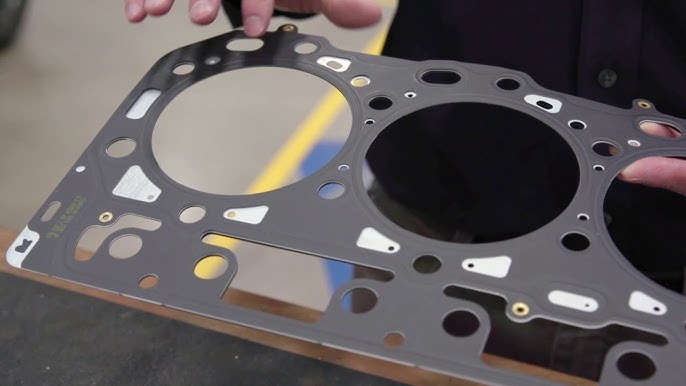

Product Overview and Classification

Multi-Layer Steel (MLS) head gaskets are precision-engineered components used in internal combustion engines to seal the combustion chamber, coolant passages, and oil galleries between the engine block and cylinder head. Constructed from multiple thin layers of stainless steel, often with elastomeric or Viton® coatings for enhanced sealing, MLS gaskets offer superior durability, heat resistance, and resilience under high pressure. Proper classification is essential for accurate logistics and compliance handling.

HS Code (Harmonized System Code):

The most relevant HS Code for MLS head gaskets is typically 8708.29.50, which falls under:

– Chapter 87: Vehicles and associated parts

– Heading 8708: Parts and accessories of motor vehicles

– Subheading 8708.29: Engine parts, not elsewhere specified

– 8708.29.50: Gaskets and similar joints for internal combustion engines

Note: HS code classification may vary by country. Confirm with local customs authorities or a licensed customs broker before shipment.

Packaging and Handling Requirements

Appropriate packaging ensures product integrity during transit and supports efficient inventory management.

- Primary Packaging: Each MLS head gasket should be individually wrapped in anti-corrosion paper (e.g., VCI – Vapor Corrosion Inhibitor) and sealed in a moisture-resistant plastic sleeve or vacuum-sealed bag.

- Secondary Packaging: Gaskets should be grouped in sturdy corrugated cardboard boxes with internal dividers to prevent movement. Boxes must be clearly labeled with product code, part number, quantity, and handling instructions (e.g., “Fragile,” “Do Not Stack,” “Keep Dry”).

- Palletization: Pallets must be constructed from ISPM 15-compliant wood (heat-treated or fumigated) for international shipments. Secure boxes using stretch wrap or strapping, ensuring load stability. Maximum pallet height: 1.8 meters (6 ft).

- Handling: Use mechanical lifting equipment (e.g., forklifts) when moving loaded pallets. Avoid dropping or impact, as deformation can compromise gasket performance.

Transportation and Storage Conditions

Maintaining optimal conditions throughout the supply chain preserves gasket functionality.

- Temperature Range: Store and transport between 5°C and 40°C (41°F to 104°F). Avoid exposure to extreme heat or freezing conditions.

- Humidity Control: Relative humidity should not exceed 60% to prevent moisture absorption and potential corrosion of steel layers.

- Light Exposure: Keep packaging away from direct sunlight or UV radiation, which may degrade elastomeric coatings.

- Ventilation: Store in dry, well-ventilated areas. Do not place directly on concrete floors; use pallets or racks to avoid moisture wicking.

Regulatory and Compliance Considerations

Ensure adherence to international, national, and environmental regulations.

- REACH (EU Regulation): Confirm that all materials (including coatings) comply with REACH (Registration, Evaluation, Authorization and Restriction of Chemicals). No restricted substances (e.g., SVHCs) above 0.1% w/w.

- RoHS (EU Directive 2011/65/EU): Although primarily for electrical equipment, verify that no lead, mercury, cadmium, or other listed substances are present, especially in coatings or plating.

- TSCA (USA): Comply with the Toxic Substances Control Act; ensure all chemicals used in manufacturing are listed or exempt.

- Country-Specific Labeling: Include bilingual labeling (e.g., English and local language) for non-English speaking markets. Labels must display:

- Part number and product name

- Manufacturer name and address

- Country of origin

- HS code and net weight

- Lot or batch number for traceability

- Export Controls: Verify if the product is subject to export restrictions (e.g., EAR – Export Administration Regulations). Generally, MLS gaskets are not controlled, but confirm with legal counsel for destination-specific rules.

Documentation for International Shipments

Accurate documentation prevents delays at customs.

- Commercial Invoice: Must include detailed product description, unit price, total value, currency, buyer/seller information, Incoterms® (e.g., FOB, EXW, DDP), and HS code.

- Packing List: Itemize contents per box and pallet, including dimensions, gross/net weight, and total shipment volume.

- Certificate of Origin: Required for preferential tariff treatment under trade agreements (e.g., USMCA, EU-UK TCA). May need notarization.

- Material Safety Data Sheet (MSDS/SDS): Provide if requested, especially for coated gaskets containing chemical sealants.

- Bill of Lading / Air Waybill: Ensure correct consignee, notify party, and freight details.

Quality and Traceability Standards

Maintain compliance with automotive quality management systems.

- ISO 901:2015 (Quality Management) and IATF 16949:2016 (Automotive Quality) are recommended for manufacturers and distributors.

- Implement batch/lot tracking to enable recalls if necessary. Record serial numbers, production date, and inspection data.

- Conduct periodic audits of packaging, storage, and shipping practices to ensure adherence to standards.

Disposal and Environmental Responsibility

At end-of-life, MLS gaskets should be handled responsibly.

- Recyclability: Stainless steel layers are fully recyclable. Remove any non-metallic coatings before recycling.

- Waste Disposal: Follow local regulations for industrial waste. Do not incinerate coated gaskets without proper emissions controls.

- Environmental Claims: Avoid unsubstantiated “eco-friendly” claims unless verified through lifecycle assessments.

Summary and Best Practices

Ensure all logistics personnel are trained on proper handling, storage, and documentation procedures. Regularly review compliance requirements with legal and customs experts, especially when entering new markets. Maintain a documented chain of custody from manufacturing to delivery to support traceability and customer confidence.

In conclusion, sourcing a multi-layer steel (MLS) head gasket requires careful consideration of several key factors to ensure optimal engine performance, reliability, and longevity. It is essential to select a high-quality gasket from a reputable manufacturer that meets or exceeds OEM specifications. Compatibility with the specific engine make, model, and operating conditions—especially in high-performance, turbocharged, or modified engines—is critical due to the demanding thermal and mechanical loads involved.

MLS head gaskets offer superior durability, resilience, and sealing capabilities compared to conventional gaskets, making them ideal for modern and high-stress applications. Attention must also be paid to proper installation procedures, including the use of correct torque specifications, surface finish requirements, and approved assembly lubricants, as even the best gasket can fail if not installed correctly.

Ultimately, investing in a premium multi-layer steel head gasket and ensuring proper sourcing and installation not only prevents costly leaks and engine damage but also enhances overall engine efficiency and reliability. A thorough vetting process of suppliers, combined with technical due diligence, will result in a successful and long-lasting repair or build.