The global polymer sealants market is experiencing steady expansion, driven by rising demand across construction, automotive, and industrial sectors. According to Grand View Research, the global sealants market size was valued at USD 9.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030. This growth is fueled by increasing infrastructure development, especially in emerging economies, and the growing adoption of high-performance, durable sealing solutions that offer resistance to moisture, temperature fluctuations, and environmental degradation. Mordor Intelligence also highlights a CAGR of approximately 5.2% during the forecast period of 2023–2028, underscoring the sustained momentum in material innovation and sustainable product development. As demand for MS (Modified Silane) polymer sealants rises—valued for their superior adhesion, flexibility, and low VOC emissions—the competitive landscape has intensified. These high-performance sealants are increasingly replacing traditional silicone and polyurethane-based products in high-end applications. Against this backdrop, the following nine manufacturers have emerged as leaders, combining technological expertise, global reach, and consistent product innovation to capture significant market share in the MS polymer sealant segment.

Top 9 Ms Polymer Sealant Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

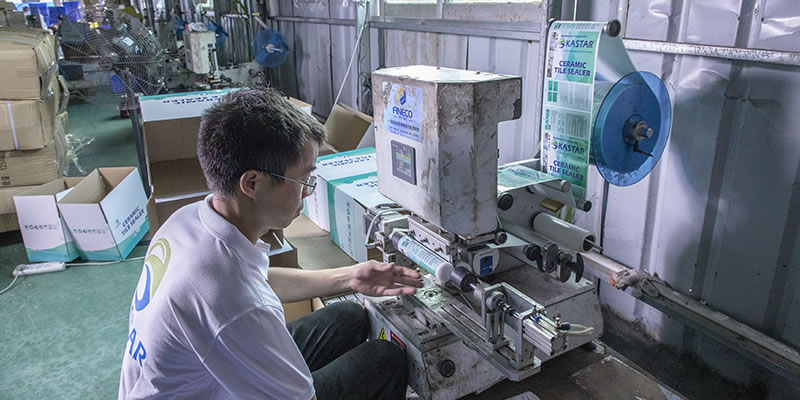

#1 MS Polymer Sealant Manufacturer

Domain Est. 2021 | Founded: 2002

Website: kastarsealant.com

Key Highlights: Since 2002, Kastar Adhesive Co., Ltd has been specialized in research and manufacturing of MS polymer sealant/adhesive. We provide One-Stop Solution Service ……

#2 OEM Ms Polymer Sealant Manufacturer and Supplier, Product

Domain Est. 2023

Website: chemsealant.com

Key Highlights: Get top-quality Ms Polymer Sealant directly from the OEM manufacturer and supplier. Our product is reliable and affordable – order now!…

#3 Kaneka MS Polymer

Domain Est. 2018

Website: kanekamspolymer.com

Key Highlights: High Performance Moisture Cure Sealants, Adhesives, and Coatings ; Applications. KANEKA MS POLYMER™ has performed successfully in various industrial applications ……

#4 MS Polymer Moisture Cure Adhesives and Sealants

Domain Est. 2020

Website: purchaseadhesives.com

Key Highlights: This new MS polymer adhesive and sealant technology provides water-tight sealing of joints, suitable for marine and boating environments….

#5 MS Polymer Sealant and Modified Silicone Leading Manufacturer

Domain Est. 2024

Website: tengyusealant.com

Key Highlights: It is a universal elastic sealant with a wide range of uses. It can be used indoors and outdoors and elastic sealing of various joints….

#6 MS Polymer

Website: gluecom.eu

Key Highlights: MS POLYMEER 1-component MS polymer-based sealant and light adhesive. Its primary use is to seal seams, overlaps, joints and cracks. € 9 ……

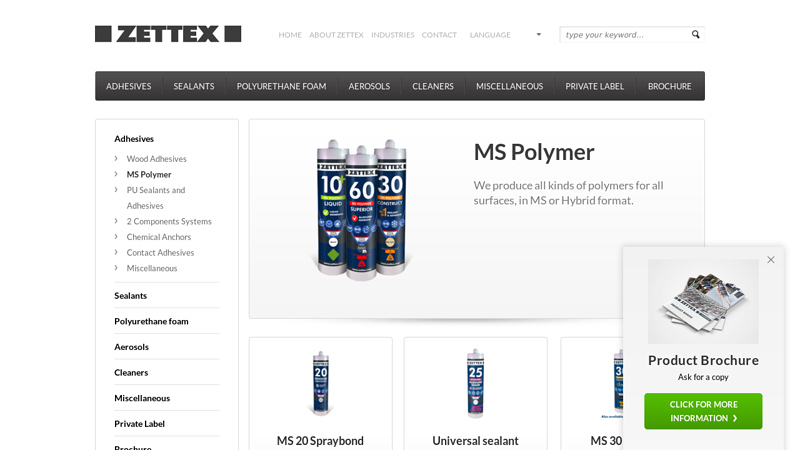

#7 MS Polymer

Domain Est. 2001

Website: zettex.com

Key Highlights: MS polymer spray for air-tight joints in construction and the automotive industry. Universal sealant. Zettex MS 25 Allround Sealer is suitable for use on all ……

#8 MS polymer adhesives for the transportation industry

Domain Est. 2002

Website: saba-adhesives.com

Key Highlights: MS polymer adhesives are used to create various elastic bonds and seals. Examples include bonding and sealing cabins, trailers, windows, side panels, interior ……

#9 MS Polymer Sealant & Adhesive

Domain Est. 2013

Website: therubbercompany.com

Key Highlights: Our MS Polymer Sealant is a high bond strength, single component joint sealant with high levels of elasticity. The easy applicator tube is easy to gun out….

Expert Sourcing Insights for Ms Polymer Sealant

H2: Market Trends for Ms Polymer Sealant in 2026

As we approach 2026, the global market for polymer-based sealants—specifically referencing “Ms Polymer Sealant” (commonly known as modified silane or silane-terminated polymer sealants)—is poised for significant growth and transformation, driven by evolving construction practices, environmental regulations, and material innovation. Below is an analysis of key market trends shaping the Ms Polymer Sealant industry in 2026:

1. Rising Demand in Construction and Infrastructure

The construction sector remains the largest consumer of Ms Polymer sealants, with increasing adoption in residential, commercial, and infrastructure projects. These sealants are favored for their superior adhesion to diverse substrates (metal, glass, concrete, and plastics), flexibility, and long-term durability. Urbanization in emerging economies—particularly in Asia-Pacific (China, India, Southeast Asia) and the Middle East—is fueling demand for high-performance sealants in curtain walls, prefabricated buildings, and modular construction, all of which benefit from the low-shrinkage and crack-resistant properties of Ms Polymer technology.

2. Shift Toward Sustainable and Low-VOC Products

Environmental regulations, such as REACH in Europe and EPA standards in North America, are pushing manufacturers to develop low-VOC (volatile organic compound) and solvent-free sealant solutions. Ms Polymer sealants are inherently low in VOCs and do not require isocyanates or solvents, making them a preferred choice for green building certifications like LEED and BREEAM. In 2026, eco-conscious construction and renovation projects are expected to accelerate the substitution of traditional silicone and polyurethane sealants with Ms Polymer alternatives.

3. Growth in Automotive and Industrial Applications

Beyond construction, the automotive industry is increasingly using Ms Polymer sealants for bonding and sealing in electric vehicles (EVs), where resistance to thermal cycling, vibration, and moisture is critical. Lightweighting trends and the need for improved cabin acoustics and energy efficiency are driving adoption. Additionally, industrial equipment, rail, and marine sectors are adopting these sealants for their durability and ease of application without primers.

4. Technological Advancements and Product Innovation

Leading chemical companies (e.g., Sika, Henkel, 3M, and Momentive) are investing in R&D to enhance cure speed, UV resistance, and paintability of Ms Polymer formulations. By 2026, smart sealants with self-healing properties or integrated sensors for structural health monitoring are beginning to emerge in niche markets, particularly in high-value infrastructure and aerospace applications.

5. Regional Market Expansion

Asia-Pacific is expected to dominate global demand in 2026, driven by rapid industrialization and government investment in smart cities and transportation networks. Europe maintains strong growth due to stringent environmental policies and retrofitting of aging buildings. North America sees steady demand, especially in the residential remodeling sector and hurricane-prone regions requiring resilient building materials.

6. Supply Chain and Raw Material Dynamics

The availability of silane-terminated prepolymers and specialty additives remains a critical factor. Geopolitical tensions and supply chain disruptions have prompted manufacturers to localize production and secure long-term feedstock agreements. Recycling and circular economy practices are also influencing R&D, with early-stage efforts to develop recyclable or bio-based Ms Polymer variants.

Conclusion

By 2026, Ms Polymer sealants are projected to capture a growing share of the global sealant market—estimated to exceed $15 billion for high-performance sealants—due to their environmental compatibility, versatility, and performance advantages. Companies that invest in sustainable innovation, regional expansion, and application-specific customization are best positioned to lead in this evolving landscape.

Common Pitfalls When Sourcing MS Polymer Sealant: Quality and Intellectual Property Risks

Sourcing MS (Modified Silane) polymer sealants can be complex, with significant risks related to product quality and intellectual property (IP) infringement. Being aware of these pitfalls is essential to ensure performance, compliance, and supply chain integrity.

Inconsistent or Substandard Quality

One of the most prevalent issues when sourcing MS polymer sealants—especially from low-cost or unverified suppliers—is inconsistent or substandard product quality. Many manufacturers claim to offer MS polymer technology, but the actual formulation may deviate significantly from genuine performance standards.

- Diluted or Non-Compliant Formulations: Some suppliers may reduce the concentration of active MS polymer resins or replace them with cheaper alternatives (e.g., hybrid polymers or polyurethanes), leading to inferior adhesion, durability, and weather resistance.

- Lack of Certification and Testing Data: Reputable MS polymer sealants are typically backed by third-party certifications (e.g., ISO, ASTM, CE) and extensive performance data. Suppliers may provide falsified or generic test reports that do not reflect the actual product batch.

- Inadequate Cure Performance: Poorly formulated sealants may exhibit slow cure rates, surface tackiness, or incomplete cross-linking, especially under variable temperature and humidity conditions.

To mitigate this, always request technical data sheets (TDS), safety data sheets (SDS), and independent test reports. Conduct pilot testing and batch validation before large-scale procurement.

Intellectual Property (IP) Infringement

MS polymer technology is a patented innovation originally developed by Kaneka Corporation and later licensed to select manufacturers (e.g., Sika, Momentive, Bostik). Sourcing sealants from unauthorized producers poses serious IP risks.

- Unauthorized Use of Proprietary Technology: Many generic “MS polymer” sealants on the market use formulations that mimic the technology but infringe on existing patents. Using such products may expose your company to legal liability, especially in regulated industries or international markets.

- Mislabeling and Greenwashing: Suppliers may falsely market their sealants as “Kaneka-based” or “true MS polymer” without proper licensing. This misrepresentation can damage your brand reputation and lead to contractual disputes.

- Supply Chain Vulnerability: Relying on IP-infringing products can result in sudden supply disruptions if legal action is taken against the supplier, leading to project delays and additional costs.

To avoid IP pitfalls, verify the supplier’s licensing status with Kaneka or the original patent holder. Request documentation confirming legitimate technology use and consider engaging legal counsel for high-volume or long-term contracts.

Conclusion

Sourcing MS polymer sealants requires due diligence to avoid quality inconsistencies and IP exposure. Prioritize suppliers with verifiable technical credentials, transparent manufacturing practices, and proper licensing. Investing time in supplier vetting reduces long-term risk and ensures reliable product performance.

Logistics & Compliance Guide for Ms Polymer Sealant

Product Overview

Ms Polymer Sealant is a high-performance, single-component adhesive and sealant based on modified silane polymer technology. It offers excellent adhesion to various substrates, high elasticity, UV resistance, and low VOC emissions. This guide outlines key logistics and compliance considerations for handling, transporting, storing, and disposing of the product in accordance with international and regional regulations.

Regulatory Classification

Ms Polymer Sealant is classified under the following regulatory frameworks:

– GHS (Globally Harmonized System): Not classified as hazardous under GHS criteria for health, physical, or environmental hazards.

– CLP Regulation (EU): Does not meet the criteria for classification as hazardous according to Regulation (EC) No 1272/2008.

– OSHA Hazard Communication Standard (29 CFR 1910.1200): Non-hazardous under U.S. OSHA guidelines.

– TSCA (Toxic Substances Control Act): All components are listed on the TSCA Inventory.

– REACH (EC 1907/2006): Registered and compliant; no SVHCs (Substances of Very High Concern) above threshold levels.

Safety Data Sheet (SDS) Management

An up-to-date Safety Data Sheet compliant with ISO 11014 and regional requirements (e.g., EU Annex II, ANSI Z400.1) must be available:

– For all distribution channels.

– In the local language of the destination country.

– Accessible to emergency responders, warehouse personnel, and end users.

Ensure SDS revision control and distribution upon any formulation or regulatory change.

Packaging & Labeling Requirements

- Primary Packaging: Supplied in moisture-resistant cartridges (plastic or aluminum) sealed with a foil closure.

- Secondary Packaging: Cartons designed to prevent damage during transport; quantity per master case as per shipping regulations.

- Labeling: Each unit must display:

- Product name and batch/lot number

- Net weight/volume

- Manufacturer name, address, and contact information

- GHS-compliant label (if applicable)

- “Keep out of reach of children” and “Use only in well-ventilated areas”

- CE mark (for EU market) or equivalent regional conformity marking

Storage Conditions

Store Ms Polymer Sealant under the following conditions to maintain product integrity:

– Temperature: 5°C to 25°C (41°F to 77°F)

– Environment: Dry, cool area away from direct sunlight and heat sources

– Shelf Life: Typically 12 months from date of manufacture when unopened and stored properly

– Orientation: Store vertically to prevent deformation and leakage

Transportation Guidelines

Ms Polymer Sealant is generally not regulated as a dangerous good for transport under:

– IMDG Code (Maritime): Not subject to classification as hazardous marine pollutant

– IATA DGR (Air): Not restricted for air transport

– ADR/RID (Road/Rail in Europe): Not classified as hazardous

– 49 CFR (U.S. DOT): Not regulated as hazardous material

Despite non-hazardous status, packages must be:

– Securely packed to prevent leakage or damage

– Labeled with proper shipping name, UN number (if applicable), and handling instructions

– Accompanied by a commercial invoice and SDS when crossing international borders

Import & Export Compliance

Ensure compliance with destination country requirements:

– Customs Documentation: Accurate HS code (e.g., 3506.91 for adhesives) and country of origin declaration

– Import Permits: Verify if required (e.g., in China, India, or Brazil)

– Language Requirements: Product labels and SDS in official language(s) of destination

– EPA/Customs Border Protection (U.S.): No TSCA certification required for non-TSCA regulated chemicals; verify import notification if applicable

Environmental, Health & Safety (EHS) Considerations

- Handling: Use gloves and eye protection during prolonged contact. Avoid inhalation of vapors in confined spaces.

- Spill Management: Wipe up spills with absorbent material; do not flush into drains. Dispose of contaminated material as non-hazardous waste.

- Ventilation: Use in well-ventilated areas; local exhaust recommended for large-scale applications.

- Disposal: Follow local regulations. Empty containers may be disposed of as non-hazardous solid waste. Do not incinerate unless in approved facilities.

Regulatory Monitoring & Updates

Assign responsibility for ongoing regulatory monitoring:

– Track changes in GHS, REACH, CLP, and other relevant regulations

– Review and update SDS annually or upon formulation change

– Subscribe to regulatory intelligence services for global market updates

Training & Documentation

Provide training for all personnel involved in logistics and handling:

– SDS interpretation

– Proper storage and handling procedures

– Emergency response protocols

Maintain records of training, SDS revisions, shipping documents, and compliance audits for a minimum of 5 years.

Emergency Response

In case of exposure or incident:

– Inhalation: Move to fresh air; seek medical attention if irritation persists

– Skin Contact: Wash with soap and water; remove contaminated clothing

– Eye Contact: Rinse thoroughly with water for at least 15 minutes; consult a physician

– Ingestion: Do not induce vomiting; seek immediate medical help

Emergency contact: Manufacturer’s 24/7 hotline – [Insert Contact Information]

Conclusion

Ms Polymer Sealant is a compliant, non-hazardous product suitable for global distribution when handled according to this guide. Adherence to logistics and regulatory requirements ensures safety, avoids shipment delays, and supports environmental responsibility. Always consult the latest SDS and local authorities for jurisdiction-specific rules.

Conclusion for Sourcing MS Polymer Sealant:

In conclusion, sourcing MS polymer sealant requires a strategic approach that balances quality, cost, reliability, and technical performance. These advanced sealants offer superior adhesion, flexibility, UV resistance, and durability compared to traditional silicone or polyurethane alternatives, making them ideal for diverse applications in construction, automotive, and industrial sectors.

To ensure optimal results, it is essential to partner with reputable suppliers or manufacturers who provide certified, high-performance products and comprehensive technical support. Factors such as curing time, substrate compatibility, environmental conditions, and regulatory compliance (e.g., VOC emissions) must be carefully evaluated during the selection process.

Additionally, consolidating supply chains, negotiating long-term agreements, and conducting regular supplier audits can enhance cost-efficiency and supply continuity. As demand for sustainable and high-performance building materials continues to rise, investing in premium MS polymer sealants not only improves project outcomes but also strengthens a company’s competitive edge.

Ultimately, successful sourcing hinges on due diligence, ongoing market evaluation, and a focus on long-term value rather than upfront cost savings alone.