The global ladder manufacturing market is experiencing steady growth, driven by rising construction activities, increasing demand for maintenance and safety equipment across industrial and residential sectors, and stringent workplace safety regulations. According to Mordor Intelligence, the global ladder market was valued at approximately USD 3.8 billion in 2023 and is projected to grow at a CAGR of over 4.5% during the forecast period from 2024 to 2029. This growth is further supported by innovations in lightweight, durable materials—such as fiberglass and aerospace-grade aluminum—and the expansion of e-commerce channels facilitating easier access to specialized equipment. As demand for reliable, ergonomically designed moving ladders rises in logistics, warehousing, and facility management, manufacturers are focusing on safety compliance, modular designs, and load capacity enhancements. In this competitive landscape, a select group of companies are leading the way through technological advancements, global distribution networks, and a strong commitment to quality—making them stand out among the top 10 moving ladder manufacturers worldwide.

Top 10 Moving Ladder Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

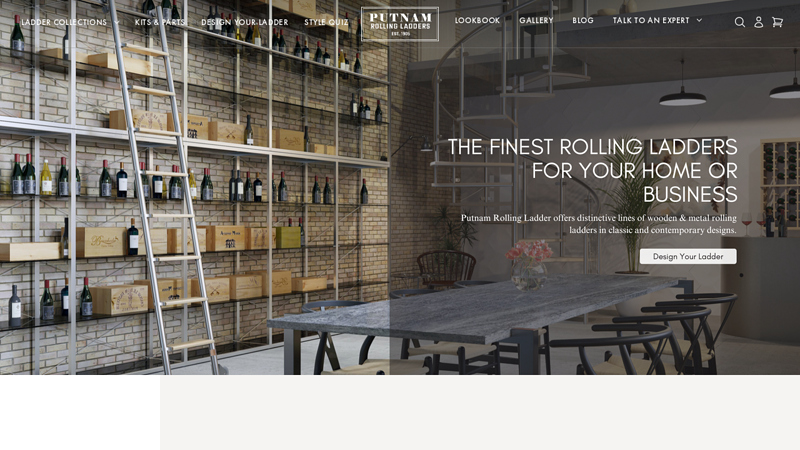

#1 Putnam Rolling Ladder Co.

Domain Est. 1996

Website: putnamrollingladder.com

Key Highlights: Putnam Rolling Ladder Co., Inc. manufactures custom rolling ladders for libraries, commercial, and residential use….

#2 Industrial Ladders – Prefabricated, Modular Metal Stairs

Domain Est. 2010

Website: erectastep.com

Key Highlights: ErectaStep’s industrial metal ladders and access platforms are modular, lightweight and easy to install. No special tools needed, in stock and ready to ……

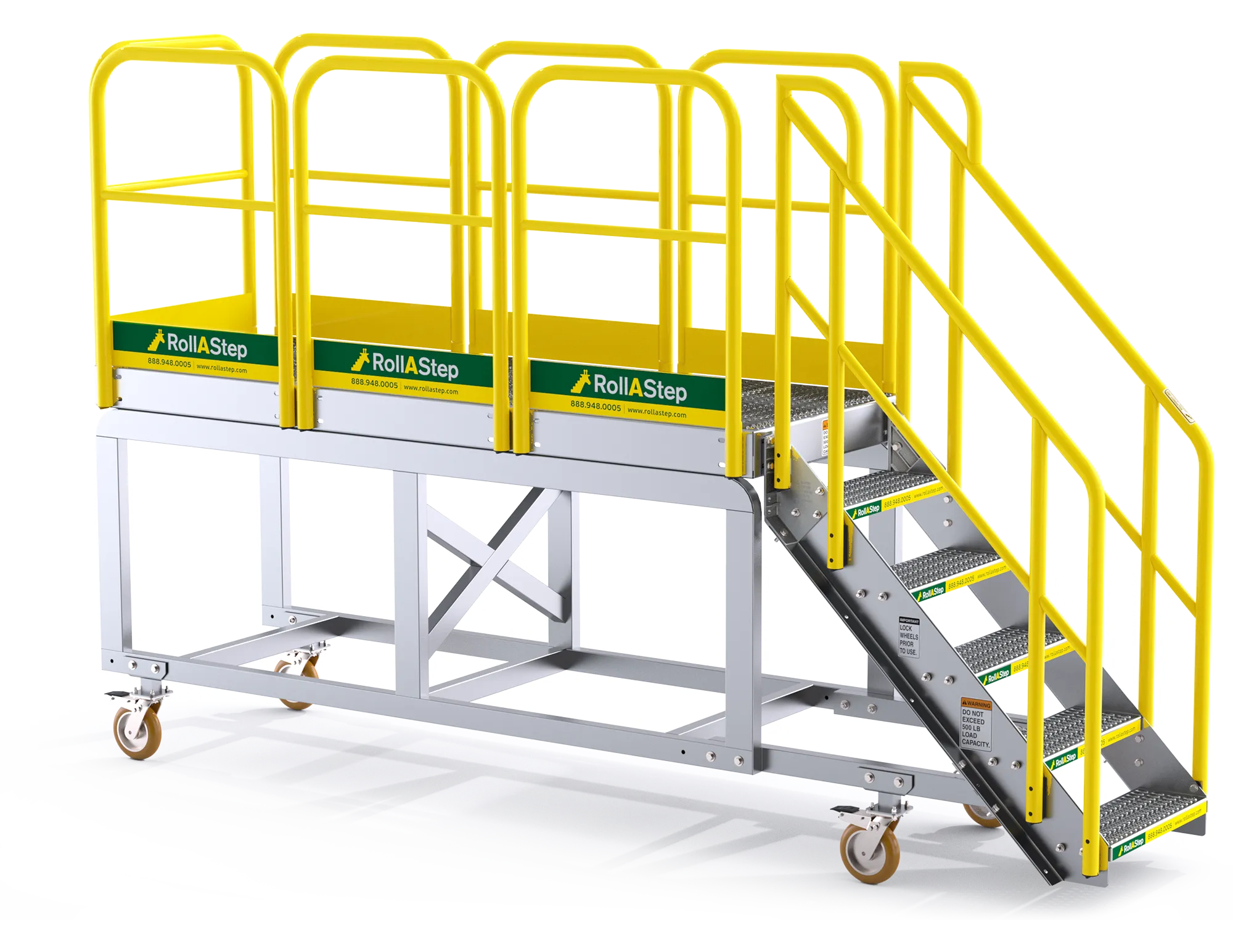

#3 RollaStep

Domain Est. 2011

Website: rollastep.com

Key Highlights: Mobile, pre-fabricated, in stock, ready-to-ship rolling stairs, industrial work platform, and portable ladders with the stability of fixed stairs….

#4 Metal Rolling Ladders

Domain Est. 1996

Website: cotterman.com

Key Highlights: R2C ready to climb. 450 lb. load rating. 59° climb angle. All welded const. Learn More. Metal Rolling Ladders. R2C ready to climb. 450 lb. load rating….

#5 Shop Major Brand Ladders, Scaffolding

Domain Est. 1996

Website: sunsetladder.com

Key Highlights: Shop or rent step ladders, extension ladders, platform ladders, attic ladders, cage & wall ladders, rolling ladders, crossover bridges, and work platforms….

#6 Leveler Adjustable Leg Ladder

Domain Est. 1996

#7 Compare

Domain Est. 1996

Website: wernerco.com

Key Highlights: From builders aluminium step ladders, shock-resistant fibreglass, multi-purpose ladders and extension ladders to roof ladders and ladder accessories….

#8 Ballymore Safety Products

Domain Est. 1997

Website: ballymore.com

Key Highlights: The ProLine rolling safety ladder is the most versitile heavy-duty rolling ladder in the industry. It has an extra heavy duty 1000 lb. capacity! Shop Now ……

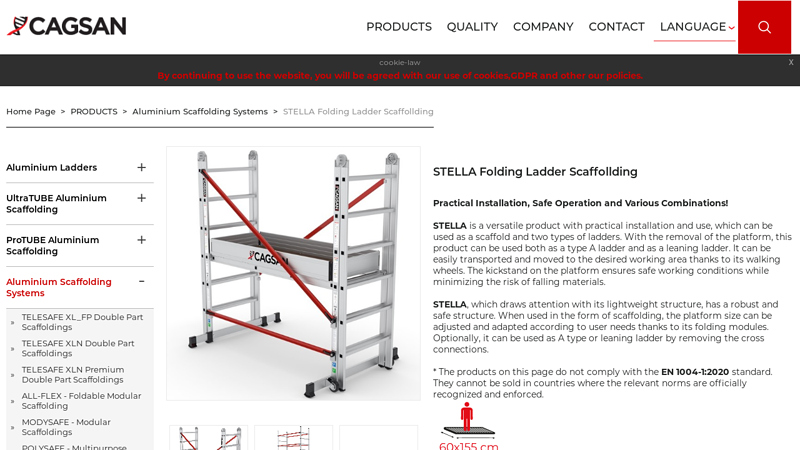

#9 STELLA Folding Ladder Scaffollding

Domain Est. 2002

Website: cagsanmerdiven.com

Key Highlights: STELLA is a versatile product with practical installation and use, which can be used as a scaffold and two types of ladders….

#10 Modern Interior Ladder Systems

Domain Est. 2010

Website: bartelsdoors.com

Key Highlights: Modern Interior Leaning Ladders, by MWE, offer the ability to instantly reach higher shelves and cabinets without any rail installation….

Expert Sourcing Insights for Moving Ladder

H2: 2026 Market Trends for Moving Ladder

The global market for moving ladders—specialized tools used in furniture moving, logistics, and home relocation services—is poised for notable transformation by 2026. Driven by shifts in urbanization, consumer behavior, and advancements in material science and smart technology, several key trends are expected to shape the industry.

-

Rising Demand in Urban and E-Commerce Logistics

As urban populations continue to grow and e-commerce expands, the need for efficient home delivery and furniture assembly services is increasing. Moving ladders are essential tools in last-mile logistics, especially for bulky items. By 2026, service providers are expected to invest in lightweight, modular moving ladders to improve delivery speed and worker safety in dense city environments. -

Growth in DIY and Self-Moving Services

The popularity of do-it-yourself (DIY) moving solutions, fueled by cost-conscious consumers and platforms like U-Haul, PODS, and peer-to-peer rental apps, is boosting demand for user-friendly moving ladders. Innovations such as foldable designs, non-slip grips, and easy assembly will be critical differentiators in this consumer-driven segment. -

Adoption of Lightweight and Durable Materials

Manufacturers are transitioning from traditional steel to advanced composites and aerospace-grade aluminum alloys. These materials reduce weight without sacrificing strength, improving portability and reducing user fatigue. By 2026, eco-conscious materials and recyclable components are expected to become standard, aligning with broader sustainability trends. -

Integration of Smart Technology

Smart moving ladders equipped with load sensors, anti-tip mechanisms, and ergonomic feedback systems are emerging. While still in early stages, these innovations are expected to gain traction in professional moving companies by 2026, enhancing safety compliance and reducing workplace injuries. -

Expansion in Rental and Shared Equipment Models

Equipment rental platforms are gaining momentum, especially in developed markets. Moving ladders are increasingly being offered as part of rental kits for temporary use. This shift supports circular economy principles and reduces ownership costs for occasional users. -

Regional Market Diversification

While North America and Western Europe remain dominant markets due to high mobility rates and mature logistics sectors, growth in Asia-Pacific—particularly in China and India—is accelerating. Rising middle-class populations and urban relocations are creating new opportunities for moving ladder manufacturers and distributors.

In summary, by 2026, the moving ladder market will be shaped by innovation in design, materials, and service models, with an emphasis on safety, sustainability, and convenience across both consumer and professional segments.

Common Pitfalls When Sourcing Moving Ladders (Quality and Intellectual Property)

Sourcing moving ladders—mechanical or automated systems designed to transport personnel and materials vertically and horizontally in industrial or construction settings—can present significant challenges, particularly concerning product quality and intellectual property (IP) risks. Failing to address these issues can lead to safety hazards, operational inefficiencies, legal disputes, and reputational damage. Below are key pitfalls to avoid.

Poor Quality Standards and Safety Compliance

One of the most critical risks in sourcing moving ladders is receiving substandard products that fail to meet required safety and performance standards. Many suppliers, especially in regions with less stringent manufacturing oversight, may cut corners on materials, welding, load-bearing components, or control systems. This compromises operator safety and increases the likelihood of mechanical failure, downtime, and costly repairs. Always verify that suppliers adhere to recognized certifications such as ISO 9001 (quality management), CE marking (European safety), or ANSI/ASME standards.

Lack of Third-Party Testing and Validation

Moving ladders often operate in high-risk environments, making rigorous performance testing essential. A common pitfall is relying solely on supplier-provided test data without independent verification. Without third-party validation of load capacity, cycle testing, or electrical safety, buyers may unknowingly procure equipment that underperforms or poses safety risks. Insist on access to certified test reports and consider on-site performance audits before finalizing procurement.

Inadequate Design Documentation and Reverse Engineering Risks

When sourcing from overseas or lesser-known manufacturers, buyers may receive incomplete or inaccurate technical documentation, including CAD files, wiring diagrams, and maintenance manuals. This not only complicates installation and servicing but may also indicate that the product is a reverse-engineered version of a patented design. Poor documentation often correlates with IP infringement, especially if the ladder’s design closely resembles a proprietary system protected by patents.

Intellectual Property Infringement

A major legal hazard in sourcing moving ladders is unknowingly purchasing equipment that violates existing patents or design rights. Some manufacturers replicate patented features—such as unique drive mechanisms, safety interlocks, or modular rail systems—without authorization. If your company imports or uses such equipment, you could face cease-and-desist orders, customs seizures, or even litigation. Conduct due diligence by reviewing patent databases and requiring suppliers to provide IP indemnification in contracts.

Hidden Costs from Frequent Maintenance and Downtime

Low initial pricing can be deceptive. Inferior moving ladders often suffer from premature wear, unreliable automation, or poor integration with existing systems, resulting in higher total cost of ownership. Frequent breakdowns lead to operational delays and increased maintenance expenses. Evaluate total lifecycle costs rather than focusing solely on purchase price, and request performance data from existing customers.

Insufficient Warranty and After-Sales Support

Many suppliers offer limited or ambiguous warranty terms, particularly when sourcing internationally. If a moving ladder fails after installation, lack of responsive technical support or spare parts availability can severely disrupt operations. Ensure that contracts clearly define warranty coverage, response times, and access to service technicians. Prefer suppliers with local support networks or global service partnerships.

Conclusion

Sourcing moving ladders requires careful evaluation beyond cost and delivery timelines. Prioritize suppliers with verifiable quality certifications, transparent design practices, and strong IP compliance. Conduct thorough due diligence, demand comprehensive documentation, and include protective clauses in procurement agreements to mitigate risks related to both quality and intellectual property.

Logistics & Compliance Guide for Moving a Ladder

Proper handling, transportation, and compliance when moving a ladder are essential for safety, legal adherence, and equipment longevity. This guide outlines best practices for logistics and compliance when transporting ladders, whether for personal use or within a professional setting.

Assess Ladder Type and Dimensions

Before moving a ladder, identify its type (step, extension, platform, etc.) and measure its length, width, and weight. This information determines the appropriate transport method, securing requirements, and any need for permits (e.g., for oversized loads). Always consult the manufacturer’s guidelines for handling recommendations.

Use Proper Packaging and Protection

Protect the ladder from damage during transit by using padding on rails and rungs. Foam tubing, moving blankets, or custom ladder sleeves help prevent scratches, dents, and structural compromise. Covering the ladder also safeguards vehicles and other cargo from sharp edges.

Secure Ladder for Transport

When transporting on a vehicle (truck, van, or car roof rack), the ladder must be firmly secured. Use ratchet straps, nylon tie-downs, or ladder clamps to fasten both ends and midpoints. Ensure the ladder does not extend beyond the vehicle’s rear by more than 4 feet (per U.S. DOT regulations), and mark any overhanging portion with a red flag or reflective tape.

Comply with Transportation Regulations

Adhere to local, state, and federal transportation laws. In the U.S., the Department of Transportation (DOT) governs load securement under FMCSA guidelines. Commercial operators must ensure ladder loads meet weight distribution and securement standards. For international moves, verify compliance with regional regulations (e.g., ADR in Europe).

Follow Safe Handling Procedures

Train personnel on proper lifting techniques to prevent injury. Use team lifting for heavy or long ladders, and utilize dollies or ladder carts where possible. Avoid carrying ladders near power lines or in high-wind conditions. Always maintain three points of contact when moving or positioning an extension ladder.

Maintain Documentation and Inspections

Keep records of ladder maintenance, inspection logs, and compliance training. Regularly inspect ladders for damage (cracks, bent rungs, worn feet) before and after transport. Remove damaged ladders from service immediately and tag them for repair or disposal.

Special Considerations for Commercial Use

For businesses, ensure all ladder transport activities align with OSHA standards (29 CFR 1910.23 and 1926.1053). Provide employees with safety training, and conduct periodic audits of transport practices. Use labeled ladder racks or compartments in service vehicles to prevent shifting during transit.

Environmental and Storage Compliance

Store transported ladders in a dry, secure area away from direct sunlight and corrosive substances. When moving ladders through environmentally sensitive areas (e.g., construction sites near waterways), prevent contamination from cleaning solvents or coatings. Dispose of damaged ladders in accordance with local waste regulations.

By following this logistics and compliance guide, individuals and organizations can ensure the safe, legal, and efficient movement of ladders while minimizing risks to people, property, and equipment.

Conclusion for Sourcing a Moving Ladder

In conclusion, sourcing a moving ladder requires careful consideration of quality, durability, safety features, and cost-effectiveness. After evaluating various suppliers, materials, and design options, it is evident that selecting a reliable and ergonomically designed moving ladder significantly enhances efficiency and safety during relocation tasks. Prioritizing reputable suppliers with proven track records ensures long-term value and reduces the risk of equipment failure. Additionally, factoring in portability, weight capacity, and ease of storage will meet both operational needs and user requirements. Ultimately, a well-sourced moving ladder contributes to smoother logistics operations, improved worker safety, and greater overall productivity.