The global V8 engine market is experiencing steady demand, particularly within the high-performance automotive and marine sectors. According to Mordor Intelligence, the internal combustion engine (ICE) market—which includes V8 configurations—is projected to grow at a CAGR of approximately 3.5% from 2023 to 2028, driven by continued demand in niche automotive, off-road, and specialty marine applications despite broader industry shifts toward electrification. V8 engines remain a preferred choice for their power density, torque output, and reliability in premium and performance-oriented segments. As of 2023, North America holds a significant share of V8 engine production, supported by a strong heritage in muscle cars, trucks, and recreational marine vehicles. This enduring demand has fostered a competitive landscape of specialized motorblock manufacturers capable of producing durable, high-tolerance V8 engine blocks. Below is a data-informed overview of the top nine motorblock V8 manufacturers leading innovation, scale, and engineering excellence in this sector.

Top 9 Motorblok V8 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Direct Connection

Domain Est. 2004

Website: dcperformance.com

Key Highlights: Dodge Power Brokers – Certified performance dealers factory trained to handle all of your performance sales, service and Direct Connection factory-tuned ……

#2 Cosworth Enabling Greatness for 65 Years

Domain Est. 1995

Website: cosworth.com

Key Highlights: For 65 years we’ve been at the forefront of vehicle innovation, delivering cutting-edge vehicle propulsion, electrification, data and control systems the world ……

#3 Scania V8 Trucks

Domain Est. 1996

Website: scania.com

Key Highlights: The Scania V8 is tailored for your specific needs and built to improve your total operating economy. Making it the perfect investment to drive your business ……

#4 Dodge HEMI

Domain Est. 1996

Website: dodge.com

Key Highlights: The Supercharged 6.2L HEMI® V8 is the most powerful of the legendary engines and is found under the hood of some of the most impressive performance vehicles in ……

#5 Griffith V8

Domain Est. 1996

Website: tvr.co.uk

Key Highlights: The all new TVR features a 5.0 litre Ford V8 powerplant with custom clutch, flywheel, ECU, dry-sump and other enhancements, together with a 6-Speed manual ……

#6 Judd Power

Domain Est. 2002

Website: juddpower.com

Key Highlights: An independent engineering company specialising in the design, development and manufacture of high performance racing engines and components….

#7 Hennessey Performance

Domain Est. 2002

Website: hennesseyperformance.com

Key Highlights: Hennessey Performance is home to the largest lineup of late-model high-performance sports cars, muscle cars, supercars, trucks & SUVs….

#8 Arash Motor Company

Domain Est. 2006

Website: arashcars.com

Key Highlights: AFX-R Our purest petrol sports car – high piston speed V8 engine. · AFX-8 Our new generation V8 petrol engine sportscar · AFX – I am speed – Our first lightweight ……

#9 3L Engineering

Domain Est. 2017

Website: 3lengineeringanddesign.com

Key Highlights: Build your dream V8 Beetle with bespoke engineering and design in South Africa. Handcrafted, high-performance vehicles tailored to your vision….

Expert Sourcing Insights for Motorblok V8

H2: Market Trends for Motorblok V8 in 2026

As the automotive industry evolves rapidly toward electrification, sustainability, and digital integration, the market for high-performance internal combustion engine (ICE) components such as the Motorblok V8 faces both challenges and niche opportunities in 2026. Below is an analysis of key market trends shaping the outlook for Motorblok V8 during this period.

1. Decline in Mass Market ICE Adoption

By 2026, global automakers are accelerating their transition to electric vehicles (EVs), driven by regulatory mandates (e.g., EU’s 2035 ICE ban, U.S. CAFE standards), consumer demand, and falling battery costs. As a result, mainstream vehicle platforms are increasingly EV-focused, reducing OEM demand for traditional V8 engine blocks. This trend limits broad commercial applications for Motorblok V8 in new passenger vehicles.

2. Growth in Niche and Enthusiast Markets

Despite declining ICE usage, a resilient niche market persists among performance enthusiasts, classic car restorers, and specialty manufacturers. The Motorblok V8 is likely to find sustained demand in:

– High-end custom builds and muscle car restomods

– Low-volume sports and supercar production (e.g., boutique automakers)

– Aftermarket performance upgrades where reliability and power output are prioritized

This segment values the visceral experience, sound, and mechanical authenticity of V8 engines—qualities that EVs do not replicate.

3. Increased Focus on Hybrid V8 Applications

Some premium automakers (e.g., Ferrari, Porsche, BMW M) are integrating V8 engines into high-performance hybrid systems. In this context, Motorblok V8 could benefit from demand in hybrid powertrains where ICE components are optimized for efficiency and combined with electric boost. Lightweight, durable engine blocks with potential for thermal and fuel efficiency enhancements will be in demand.

4. Sustainability and Alternative Fuels

In response to emissions regulations, there is growing interest in running legacy ICE platforms on carbon-neutral fuels (e.g., e-fuels, biofuels). The Motorblok V8 may be positioned as “future-proof” if marketed as compatible with renewable fuels. Manufacturers and tuners may retrofit or design V8 systems specifically for e-fuel use, extending the engine’s viability in eco-conscious performance circles.

5. Technological Enhancements and Smart Integration

Modern engine blocks are incorporating smart sensors, advanced cooling channels, and modular designs for better performance monitoring and integration with vehicle electronics. Motorblok V8 could differentiate itself by offering:

– Embedded telemetry for real-time diagnostics

– 3D-printed or composite elements to reduce weight

– Compatibility with digital engine management systems

These features cater to tech-savvy tuners and OEMs in high-performance sectors.

6. Regional Market Variations

Regulatory and cultural differences will shape regional demand:

– North America: Strong aftermarket and muscle car culture support V8 demand.

– Europe: Stricter emissions rules suppress use, but niche collectors and racers maintain interest.

– Middle East and Asia: Luxury and performance vehicle markets (e.g., UAE, Japan) continue to value V8 engines in high-end and modified vehicles.

7. Supply Chain and Manufacturing Innovation

By 2026, advanced materials (e.g., high-strength aluminum alloys, recycled composites) and manufacturing techniques (e.g., precision casting, AI-driven quality control) will improve the performance-to-weight ratio and sustainability of engine blocks. Motorblok V8 could leverage these to offer lighter, more durable products aligned with modern engineering standards.

Conclusion

While the broader automotive shift to electrification constrains the widespread use of V8 engine blocks, the Motorblok V8 is poised to thrive in specialized, high-value segments in 2026. Success will depend on strategic positioning in performance, hybrid integration, and sustainability narratives. Embracing innovation, alternative fuels, and digital capabilities will be key to maintaining relevance in an increasingly electrified world.

Common Pitfalls Sourcing Motorblok V8 (Quality, IP)

Sourcing a Motorblok V8 engine—whether for restoration, performance tuning, or industrial use—can present several challenges, particularly concerning quality assurance and intellectual property (IP) rights. Being aware of these pitfalls is crucial to avoid legal, operational, and safety issues.

1. Inconsistent Quality Standards

One of the most significant risks when sourcing a Motorblok V8 is inconsistent manufacturing quality, especially when dealing with third-party or non-OEM suppliers. Some units may not meet original specifications in terms of materials, machining precision, or durability. This can lead to premature engine failure, increased maintenance costs, and safety hazards. Buyers should verify certifications, conduct inspections, and request performance test data before procurement.

2. Counterfeit or Replica Parts

Due to the popularity of V8 engines, counterfeit or replica Motorblok V8 units are prevalent in unregulated markets. These replicas often mimic genuine designs but use inferior materials and workmanship. Using such components can compromise engine performance and void warranties. It’s essential to source from authorized distributors and validate authenticity through documentation and traceability.

3. Intellectual Property Infringement

The design and engineering of V8 engines like the Motorblok V8 may be protected under patents, trademarks, or copyrights. Sourcing from manufacturers that replicate these designs without proper licensing can expose buyers to legal liability for IP infringement. Always confirm that the supplier holds the necessary rights or licenses to produce and sell the engine.

4. Lack of Technical Support and Documentation

Many alternative suppliers fail to provide comprehensive technical documentation, service manuals, or engineering support. This absence can hinder proper installation, maintenance, and troubleshooting. Ensure that any Motorblok V8 sourced comes with full technical specifications, compliance statements, and access to manufacturer support.

5. Unclear Supply Chain Origins

Engines sourced through intermediaries or gray market channels may have unclear or unverifiable origins. This opacity increases the risk of receiving stolen, salvaged, or non-compliant units. Conduct due diligence on the supplier’s supply chain and demand transparency in sourcing and manufacturing processes.

6. Non-Compliance with Regional Regulations

Depending on the region, engines must comply with emissions, noise, and safety standards (e.g., EPA, Euro norms). Some Motorblok V8 variants may not meet local regulations, especially if modified or produced without oversight. Verify compliance before purchase to avoid legal penalties or operational restrictions.

By addressing these pitfalls proactively—through supplier vetting, legal checks, and quality validation—buyers can mitigate risks and ensure reliable, lawful acquisition of Motorblok V8 engines.

Logistics & Compliance Guide for Motorblok V8

This guide outlines the essential logistics and compliance procedures for the handling, transportation, storage, and regulatory adherence related to the Motorblok V8 engine assembly. Adherence to these guidelines ensures operational efficiency, legal compliance, and product integrity throughout the supply chain.

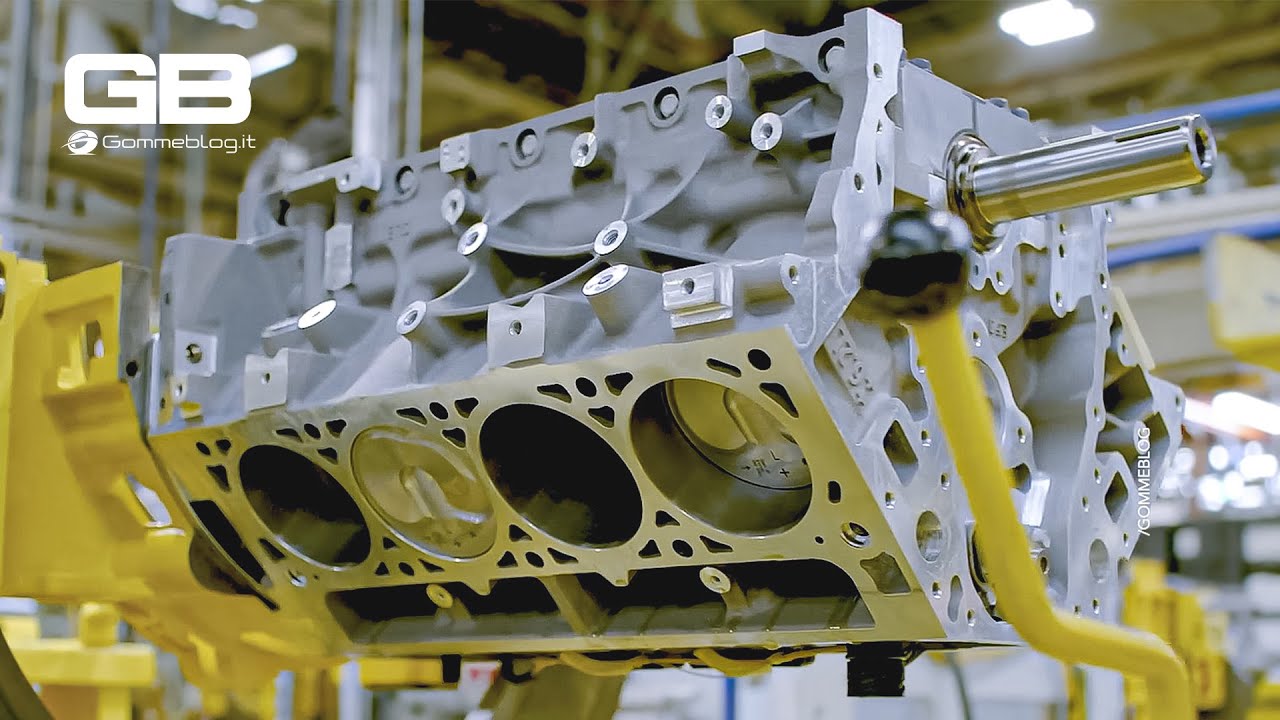

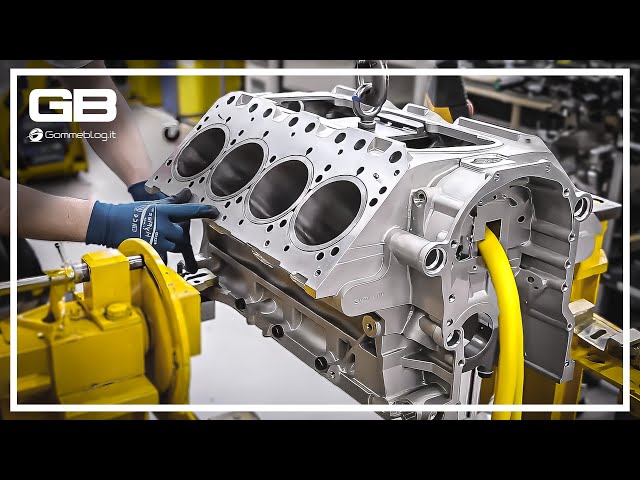

Overview of Motorblok V8

The Motorblok V8 is a high-performance internal combustion engine designed for use in automotive and industrial applications. Due to its weight, dimensions, and technical specifications, specific logistics protocols and compliance requirements apply during its distribution and handling.

Packaging and Labeling Requirements

All Motorblok V8 units must be shipped in manufacturer-approved packaging designed to prevent mechanical shock, moisture exposure, and contamination. Each package must include:

- Clearly visible product identification: “Motorblok V8 – Engine Assembly”

- Serial number and batch tracking label

- Weight and dimensional markings (L x W x H in cm and kg)

- “Fragile,” “This Side Up,” and “Do Not Stack” hazard indicators

- Compliance labels: CE marking (if applicable), RoHS, and REACH declarations

Ensure all labels are durable and resistant to environmental conditions during transit.

Transportation Guidelines

Motorblok V8 engines are classified as heavy industrial goods. Transportation must comply with the following:

- Use of palletized freight with secure strapping or crating

- Maximum stacking: one engine per pallet unless using reinforced stacking frames

- Use of forklifts or engine hoists with minimum 1.5-ton lifting capacity for loading/unloading

- Temperature-controlled transport recommended in extreme climates (below -10°C or above 50°C)

- Prohibition of air freight for standard shipments due to weight and IATA hazardous material classification (oil residue)

Ground and sea freight are preferred. Notify carriers in advance of oversized load requirements if applicable.

Storage Conditions

Store Motorblok V8 units in a dry, indoor environment meeting these standards:

- Temperature range: 5°C to 35°C

- Relative humidity: below 70%, non-condensing

- Minimum 30 cm clearance from walls and floors

- Protection from dust, vibration, and chemical exposure

- Horizontal storage only, on approved engine stands or pallets

Inventory rotation follows FIFO (First In, First Out) principles. Conduct monthly visual inspections for corrosion or packaging integrity.

Regulatory Compliance

Ensure full compliance with regional and international regulations:

- EU Compliance: Adhere to EU Directive 2000/53/EC (End-of-Life Vehicles) and 2011/65/EU (RoHS). Provide Declaration of Conformity (DoC) with each shipment.

- US Compliance: Comply with EPA emission standards (as applicable for complete engine systems) and DOT handling regulations for heavy cargo.

- REACH (EU): Confirm absence of Substances of Very High Concern (SVHC) above threshold levels.

- Export Controls: Verify ECCN classification; Motorblok V8 may fall under dual-use regulations depending on performance specs. Use ECCN 8410.90.00 unless otherwise specified.

Maintain up-to-date technical documentation, safety data sheets (SDS) for residual lubricants, and export compliance records.

Handling and Safety Protocols

Personnel must follow safety procedures when handling Motorblok V8:

- Wear appropriate PPE: steel-toed boots, gloves, and lifting aids

- Use mechanical assistance for all movements; manual lifting prohibited

- Confirm secure attachment before hoisting

- Keep work area clear and marked for heavy equipment operations

- Follow site-specific safety management systems (e.g., OSHA, ISO 45001)

Documentation and Traceability

Maintain the following documents for each Motorblok V8 unit:

- Bill of Lading (BOL)

- Packing List

- Certificate of Conformity

- Serial Number Log

- Shipping Manifest with destination and consignee details

- Customs documentation (e.g., Commercial Invoice, HS Code 8407.33)

Digital traceability via ERP or warehouse management system (WMS) is required for full audit trail.

Returns and Reverse Logistics

Defective or recalled Motorblok V8 units must be returned using the original packaging or equivalent protection. Coordinate returns through authorized service centers. Include a Return Material Authorization (RMA) number and failure description. All returned engines undergo compliance inspection before processing.

Environmental and Disposal Compliance

At end-of-life, Motorblok V8 engines must be processed in accordance with local environmental regulations:

- Drain all fluids (oil, coolant) using certified waste handling procedures

- Recycle metal components via licensed facilities

- Document disposal in compliance with WEEE (if applicable) and local hazardous waste laws

Never dispose of engines in landfills or via unapproved methods.

Summary

Proper logistics and compliance management for the Motorblok V8 ensures safety, regulatory adherence, and customer satisfaction. All stakeholders — manufacturers, distributors, carriers, and installers — must follow this guide to maintain product integrity and legal conformity. Regular training and audits are recommended to ensure ongoing compliance.

Conclusion for Sourcing a V8 Motor Block

In conclusion, sourcing a V8 motor block requires careful consideration of several key factors including compatibility, condition, availability, and cost. Whether for restoration, performance modification, or replacement purposes, selecting the right engine block involves thorough research into OEM specifications, supplier reliability, and verification of core components such as bore, stroke, material (cast iron or aluminum), and design generation.

Sourcing options—such as new from manufacturers, used from salvage yards, or remanufactured units—each offer distinct advantages in terms of cost and reliability. Additionally, evaluating logistical aspects like shipping, import regulations (if sourcing internationally), and required certifications ensures a smooth procurement process.

Ultimately, prioritizing quality, authenticity, and long-term suitability will help ensure that the sourced V8 motor block meets performance goals and delivers lasting value. A well-informed sourcing strategy minimizes downtime and maintenance risks, making it a critical step in any engine build or repair project.