The global motorcycle alternator market is experiencing steady growth, driven by rising motorcycle production, increasing demand for reliable power systems in two-wheelers, and advancements in engine electrification. According to Mordor Intelligence, the motorcycle market is projected to grow at a CAGR of over 5% from 2024 to 2029, directly influencing the demand for critical components like alternators. As motorcycles become more feature-rich—with integrated electronics, LED lighting, and advanced ignition systems—the need for efficient and durable alternators has intensified. This growth, combined with expansion in emerging markets across Asia-Pacific and Latin America, has intensified competition among component suppliers. In this evolving landscape, a select group of manufacturers have emerged as leaders, combining technological innovation, quality production, and global reach. Based on market presence, technical capability, and customer partnerships, here are the top 9 motorbike alternator manufacturers shaping the industry today.

Top 9 Motorbike Alternator Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

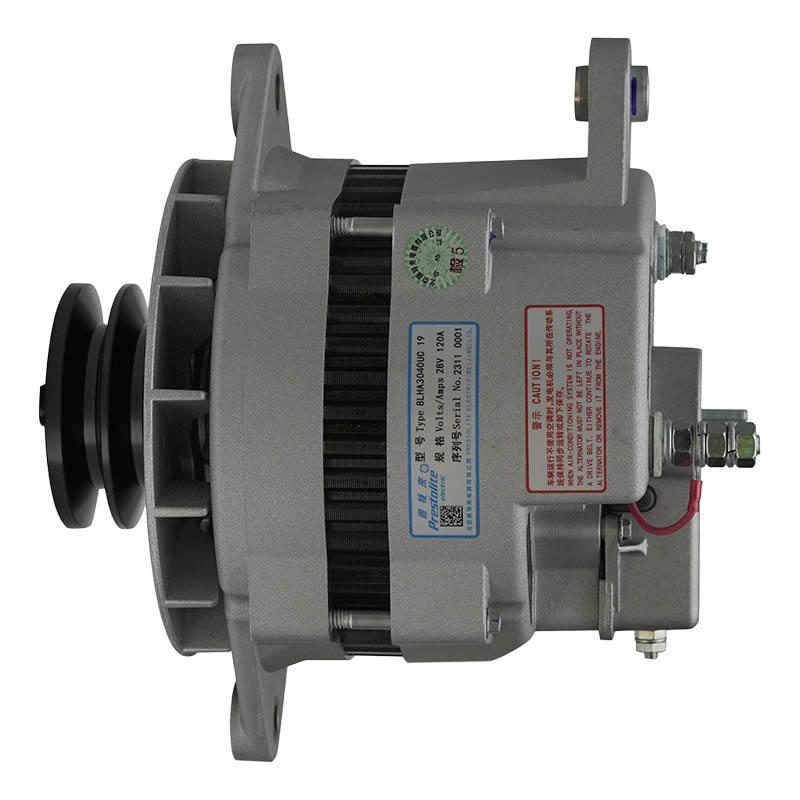

#1 Prestolite Electric

Domain Est. 1996

Website: prestolite.com

Key Highlights: A leading global manufacturer of alternators, starters, electrical equipment and new-energy solutions for a comprehensive range of vehicle applications….

#2 Starters and Alternators

Domain Est. 2004 | Founded: 1913

Website: boschautoparts.com

Key Highlights: 100% New: Manufactured from 100% new materials. Bosch has been a major supplier of new alternators to Original Equipment vehicle manufacturers since 1913….

#3 12317701566

Domain Est. 2017

Website: shopbmwmotorcycles.com

Key Highlights: In stock Rating 5.0 1 · $34.95 deliveryOrder Your OEM Alternator (12317701566) For Your 2008-2026 BMW-Motorrad Vehicle From The Official BMW Motorrad Parts Store!…

#4 Powermaster

Domain Est. 1997

Website: powermastermotorsports.com

Key Highlights: Powermaster Has New Contact Info! Catalog. site last updated 2.07.11. PH: 630-957-4019. © 2011 Powermaster Motorsports. All rights reserved….

#5 Aftermarket Motorsport Parts & Kits Superstore

Domain Est. 2002

Website: ricksmotorsportelectrics.com

Key Highlights: Rick’s Motorsport Electrics offers a full parts line of motorsport charging and starting systems & electrical ignition components for Asian and European street ……

#6 High Output Alternator (12v)

Domain Est. 2002

#7 SEG Automotive

Domain Est. 2017 | Founded: 1913

Website: seg-automotive.com

Key Highlights: We develop & produce high-quality powertrain components for passenger cars & commercial vehicles worldwide – since 1913. ▻Learn more!…

#8 Motorcycle Products

Website: mitsuba.co.jp

Key Highlights: We have released a number of products including AC generators, ACG starters, fuel pump modules, LED blinker light systems, and various relays….

#9 DENSO’s high

Website: denso-am.eu

Key Highlights: DENSO alternators convert mechanical power into electrical energy that supplies various loads in the vehicle system….

Expert Sourcing Insights for Motorbike Alternator

H2: Projected 2026 Market Trends for Motorbike Alternators

The motorbike alternator market in 2026 is expected to be shaped by significant technological evolution, shifting consumer demands, and broader industry trends. Here’s a detailed analysis of the key trends anticipated to influence the sector:

1. Increased Integration with Smart and Connected Systems

By 2026, motorbike alternators will increasingly be designed to support advanced electronics and IoT integration. Modern motorcycles are incorporating more digital features—such as TFT displays, GPS navigation, ride-by-wire systems, and telematics. This necessitates alternators with higher output efficiency and stable voltage regulation. Alternator designs will likely integrate smart monitoring capabilities, enabling real-time diagnostics and predictive maintenance through connectivity with onboard ECUs.

2. Growth in Electric and Hybrid Motorbike Development

While alternators are inherently part of internal combustion engine (ICE) systems, the rise of electric motorcycles may indirectly influence alternator design. In hybrid motorbikes (e.g., range extenders), alternators may be repurposed or redesigned as part of the auxiliary power generation system. Although full-electric bikes eliminate traditional alternators, demand for high-efficiency energy recovery systems could inspire alternator-like regenerative technologies adapted for hybrid applications.

3. Demand for Lightweight and Compact Designs

As motorbike manufacturers prioritize fuel efficiency, performance, and agile design, there will be growing demand for alternators that are lighter and more compact. Advances in materials—such as high-strength alloys and improved magnetic components—will enable manufacturers to reduce alternator weight without sacrificing output. This trend supports the broader industry shift toward miniaturization and component integration.

4. Focus on Energy Efficiency and Thermal Management

With stricter emissions regulations and consumer expectations for better fuel economy, alternators will need to operate more efficiently under varied load conditions. Innovations in rotor-stator design, improved cooling mechanisms, and the use of rare-earth magnets will enhance energy conversion efficiency. Additionally, better thermal management will be crucial to maintaining reliability, especially in high-performance and adventure touring bikes.

5. Expansion in Emerging Markets

Asia-Pacific (especially India, Indonesia, and Vietnam) and parts of Africa and Latin America will remain key growth regions for motorbike sales. These markets favor affordable, durable motorcycles, which will sustain demand for cost-effective, reliable alternators. Localized manufacturing and supply chain development will enable OEMs and aftermarket players to meet this demand efficiently, driving volume growth in the alternator segment.

6. Rise of the Aftermarket and Customization

The global aftermarket for motorbike parts is expanding as riders modify and maintain older models. In 2026, the alternator aftermarket will benefit from demand for high-output upgrades, especially among enthusiasts and long-distance tourers. Custom alternators offering improved charging performance for auxiliary lights, heated gear, or audio systems will gain popularity, supported by e-commerce platforms and specialized retailers.

7. Sustainability and Circular Economy Considerations

Environmental regulations and consumer awareness will push manufacturers toward sustainable production practices. Alternator producers may adopt recyclable materials, reduce hazardous substances, and implement remanufacturing programs. Rebuilt or remanufactured alternators could gain market share as cost- and eco-friendly alternatives, particularly in mature markets with aging vehicle fleets.

Conclusion

By 2026, the motorbike alternator market will be characterized by innovation driven by electrification trends, digital integration, and efficiency demands. While traditional ICE motorcycles will continue to dominate globally—especially in developing regions—alternator technology will evolve to support smarter, lighter, and more efficient power generation. Stakeholders must adapt to these dynamics by investing in R&D, expanding in high-growth regions, and aligning with sustainability goals to remain competitive.

Common Pitfalls When Sourcing a Motorbike Alternator (Quality and IP)

Sourcing a motorbike alternator involves several potential pitfalls, particularly concerning quality assurance and intellectual property (IP) rights. Being aware of these issues can help avoid operational failures, legal complications, and financial losses.

Poor Quality Components

One of the most frequent issues when sourcing motorbike alternators is receiving substandard or counterfeit parts. Low-quality alternators often use inferior materials such as low-grade copper windings, weak bearings, and subpar voltage regulators. These components may lead to premature failure, inconsistent charging, or even damage to the bike’s electrical system. Buyers should verify certifications, request sample testing, and evaluate supplier track records to mitigate this risk.

Lack of IP Compliance

Another critical pitfall is the unintentional procurement of alternators that infringe on intellectual property rights. Many reputable manufacturers hold patents or trademarks on specific alternator designs, particularly for OEM models. Sourcing from suppliers who produce unlicensed copies can expose buyers to legal liability, seizure of goods, or reputational damage. Always confirm that the supplier has proper licensing or is producing generic, non-infringing versions.

Inadequate IP Protection in Contracts

Even when dealing with legitimate suppliers, failure to address IP ownership and usage rights in procurement contracts can lead to disputes. For example, if a custom alternator design is developed during the sourcing process, unclear terms may result in ownership ambiguity. Drafting comprehensive agreements that define IP rights, usage limitations, and confidentiality is essential.

Inconsistent Performance Specifications

Some suppliers may advertise alternators with specifications that do not match actual performance. This misrepresentation can stem from inaccurate labeling or deliberate exaggeration. To avoid this, demand third-party test reports, conduct independent evaluations, and compare technical data sheets with known OEM standards.

Supply Chain Transparency Issues

A lack of visibility into the supply chain increases the risk of receiving alternators from unauthorized or unqualified subcontractors. This opacity can compromise both quality and IP integrity. Insist on supply chain disclosures and conduct audits where possible to ensure alignment with your standards.

By addressing these pitfalls proactively—through due diligence, legal safeguards, and technical validation—sourcing professionals can secure reliable, compliant motorbike alternators that meet performance and regulatory requirements.

Logistics & Compliance Guide for Motorbike Alternator

Overview

A motorbike alternator is a critical component of a motorcycle’s electrical system, responsible for charging the battery and powering electrical systems while the engine runs. When shipping or importing/exporting motorbike alternators, proper logistics planning and adherence to compliance regulations are essential to ensure smooth transportation, avoid delays, and remain legally compliant across jurisdictions.

Classification & Harmonized System (HS) Code

Motorbike alternators are typically classified under the Harmonized System (HS) for international trade. The most commonly used HS code is:

- 8511.50 – “Magneto dynamos and generators, of a type used in motor vehicles”

Note: Specific country variations may exist. Always verify the correct HS code with the destination country’s customs authority, as misclassification can lead to fines or shipment delays.

Packaging & Handling Requirements

Proper packaging ensures product integrity during transit:

- Use sturdy, corrugated cardboard boxes with internal cushioning (foam inserts or bubble wrap).

- Protect electrical connectors with caps or tape to prevent damage.

- Clearly label packages with product details, part numbers, and handling instructions (e.g., “Fragile,” “Do Not Stack”).

- Avoid magnetic materials near the alternator to prevent interference with internal components.

Shipping & Transportation

- Mode of Transport: Alternators can be shipped via air, sea, or land freight depending on volume, urgency, and cost.

- Temperature & Humidity: Store and transport in dry, temperature-controlled environments to prevent corrosion.

- Marking & Labeling: Include shipping marks, destination address, weight, and handling symbols per carrier requirements.

- Documentation: Prepare commercial invoice, packing list, bill of lading/air waybill, and any required export declarations.

Export Controls & Restrictions

- Most motorbike alternators are not subject to strict export controls. However, if components include rare earth magnets or dual-use technologies, check for ITAR (International Traffic in Arms Regulations) or EAR (Export Administration Regulations) restrictions, especially when shipping to embargoed countries.

- Confirm compliance with the destination country’s import regulations on automotive electrical parts.

Import Compliance

- Duties & Taxes: Duties vary by country. Use the correct HS code to determine applicable tariff rates.

- Certifications: Some countries may require CE marking (Europe), EAC certification (Eurasian Economic Union), or other regional conformity marks.

- Electromagnetic Compatibility (EMC): In the EU, alternators may fall under EMC Directive 2014/30/EU. Ensure compliance if the product is sold as a standalone component.

- RoHS Compliance: In regions like the EU, alternators must comply with the Restriction of Hazardous Substances (RoHS) directive, limiting lead, cadmium, mercury, and other substances.

Environmental & Safety Regulations

- Waste Electrical and Electronic Equipment (WEEE): If selling in the EU, producers may need to register under WEEE and provide take-back options.

- Battery & Chemical Content: While alternators themselves don’t contain batteries, ensure any accompanying items (e.g., lubricants) meet hazardous materials regulations for transport (e.g., IATA, IMDG).

Aftermarket vs. OEM Considerations

- Aftermarket alternators may face stricter scrutiny depending on local regulations. Some countries require certification that aftermarket parts meet original equipment standards.

- Clearly document whether the alternator is OEM (Original Equipment Manufacturer) or aftermarket.

Record Keeping & Traceability

- Maintain records of shipments, certifications, test reports, and compliance documentation for at least 5–7 years, depending on jurisdiction.

- Implement serial or batch tracking for recalls or warranty claims.

Conclusion

Shipping motorbike alternators globally requires attention to proper classification, packaging, and adherence to international trade and safety regulations. By following this guide, businesses can ensure efficient logistics operations and minimize compliance risks in domestic and international markets. Always consult with local customs brokers or legal experts for country-specific requirements.

Conclusion for Sourcing a Motorbike Alternator:

Sourcing a motorbike alternator requires careful consideration of compatibility, quality, cost, and reliability. It is essential to match the alternator specifications precisely with the make, model, and engine requirements of the motorcycle to ensure optimal performance and longevity. Whether opting for original equipment manufacturer (OEM) parts or reputable aftermarket alternatives, verifying product authenticity and supplier credibility is crucial to avoid substandard components. Additionally, evaluating warranty options, availability of technical support, and ease of installation can significantly influence the decision-making process. In conclusion, a well-researched sourcing strategy that balances cost-efficiency with performance and reliability will lead to improved electrical system functionality and contribute to the overall dependability and safety of the motorbike.