The global motor roller market is experiencing robust growth, driven by increasing automation across industrial and logistics sectors. According to a report by Mordor Intelligence, the global conveyor system market—which includes motor rollers—was valued at USD 5.8 billion in 2023 and is projected to grow at a CAGR of over 6.2% from 2024 to 2029. This expansion is fueled by rising demand for energy-efficient, low-maintenance conveying solutions in e-commerce, manufacturing, and airport baggage handling systems. As motor rollers offer compact integration and superior control compared to traditional roller drives, manufacturers are investing heavily in intelligent and modular designs. With the Asia Pacific region emerging as a key growth hub due to rapid industrialization and warehouse modernization, the competitive landscape is evolving. Based on market presence, innovation, and technological advancement, the following nine companies stand out as leading motor roller manufacturers shaping the future of automated material handling.

Top 9 Motor Roller Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 TrueDrive™ Motorized Drive Rollers

Domain Est. 1996

Website: johnsonelectric.com

Key Highlights: Johnson Electric has re-imagined motorized drive roller (MDR) technology from the ground up with exclusive Dynamic Zone Control™ (DZC™)….

#2 HIWIN

Domain Est. 1996

Website: hiwin.com

Key Highlights: We are the first manufacturer of linear motion and motion control products in the world that has both ISO-9001 and ISO-14001 certifications….

#3 SIMU

Domain Est. 1997

Website: simu.com

Key Highlights: SIMU designs, manufactures and markets motors and control systems based on the best market standards for professionals around the world….

#4 Increase productivity with the motor driven roller from Lenze

Domain Est. 1996

Website: lenze.com

Key Highlights: Discover our high-quality motor driven rollers for efficient material handling. Find out more now and receive a non-binding offer!…

#5

Domain Est. 2001

Website: itohdenki.com

Key Highlights: Each Itoh Denki motor driven roller is customizable and can fit virtually any application’s needs. totes being conveyed on Itoh Denki motor driven rollers….

#6 Who Is Pulseroller

Domain Est. 2008

Website: pulseroller.com

Key Highlights: PULSEROLLER is the brand name for a family of 24 volt DC, motorized drive roller products and controls. The PULSEROLLER brand consists of a variety of motor ……

#7 Motorized roller conveyor for heavy loads

Domain Est. 2011

Website: prodex-online.com

Key Highlights: Our heavy duty conveyors can be used for conveying to the storage area, manufacturing, production line, order picking, packaging and shipping….

#8 LEESON Brand

Domain Est. 2021

Website: regalrexnord.com

Key Highlights: The LEESON band spans thousands of alternating current (AC) and direct current (DC) motors, gearmotors, washdown and variable-speed control solutions….

#9 GCS

Domain Est. 2023

Website: gcsroller.com

Key Highlights: Global Conveyor Supplies Company Limited (GCS), formerly known as RKM, specializes in manufacturing conveyor rollers and related accessories….

Expert Sourcing Insights for Motor Roller

H2 2026 Market Trends for Motor Rollers

As we approach the second half of 2026, the global motor roller market is experiencing a period of dynamic transformation, driven by technological innovation, sustainability mandates, and shifting industrial demands. Here’s a comprehensive analysis of the key trends shaping the market:

1. Accelerated Electrification and Energy Efficiency

- Dominance of IE4 and IE5 Motors: Regulatory pressure and rising energy costs are accelerating the adoption of ultra-premium efficiency (IE4) and super-premium efficiency (IE5) motors in motor rollers. OEMs are increasingly integrating these high-efficiency motors to meet stringent global standards (e.g., EU Ecodesign, U.S. DOE rules).

- Growth in Permanent Magnet Synchronous Motors (PMSM): PMSM-based motor rollers are gaining traction due to their superior power density, efficiency, and controllability. This trend is particularly strong in automated logistics and food processing industries.

- Integration with Variable Frequency Drives (VFDs): Demand is rising for motor rollers with built-in or compatible VFDs, enabling precise speed control and dynamic response in smart conveyor systems, reducing energy consumption by up to 50% in variable-load applications.

2. Smart and Connected Motor Rollers

- IoT-Enabled Predictive Maintenance: Motor rollers equipped with embedded sensors (temperature, vibration, current) are becoming standard in Industry 4.0 environments. Real-time data transmission to cloud platforms enables predictive maintenance, reducing downtime and extending equipment life.

- Digital Twins and System Integration: Leading manufacturers are offering digital twin capabilities, allowing simulation, optimization, and remote monitoring of conveyor systems. Seamless integration with MES and ERP systems is a competitive differentiator.

- Plug-and-Produce Functionality: Advancements in communication protocols (e.g., IO-Link, OPC UA) enable faster commissioning and reconfiguration of motor roller lines, supporting flexible manufacturing and agile logistics.

3. Sustainability and Circular Economy Focus

- Lightweight and Recyclable Materials: OEMs are adopting aluminum housings and recyclable polymers to reduce weight and environmental impact. End-of-life recyclability is becoming a procurement criterion for environmentally conscious industries.

- Low-Noise and Eco-Design: With growing emphasis on workplace ergonomics, low-noise motor rollers (<60 dB) are in demand, especially in distribution centers and cleanrooms. Eco-design certifications (e.g., ISO 14001) influence purchasing decisions.

- Modular and Repairable Designs: To support circular economy goals, manufacturers are shifting toward modular architectures that allow easy replacement of bearings, seals, or electronics, extending product lifecycle.

4. Regional Market Dynamics

- Asia-Pacific Growth Surge: China, India, and Southeast Asia are leading in market expansion, fueled by e-commerce logistics, food & beverage automation, and government smart manufacturing initiatives.

- Europe’s Regulatory Leadership: The EU continues to drive innovation through strict efficiency and sustainability regulations, making it a testbed for next-gen motor roller technologies.

- North America’s Automation Push: High labor costs and supply chain resilience efforts are accelerating the adoption of automated material handling systems, boosting motor roller demand in warehousing and parcel sorting.

5. Competitive Landscape and Innovation

- Consolidation and Partnerships: Strategic mergers and technology partnerships (e.g., motor roller manufacturers with automation software firms) are increasing to offer integrated solutions.

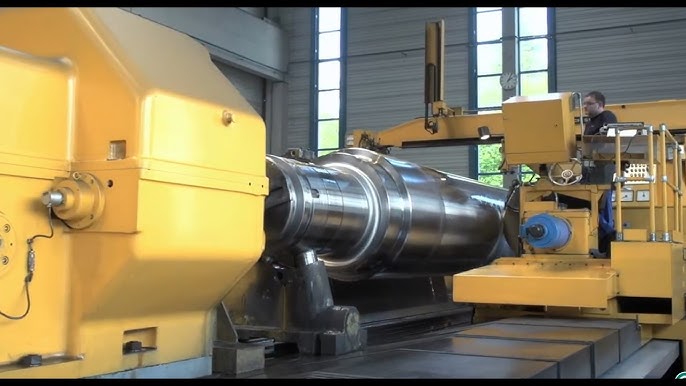

- Customization and Application-Specific Designs: Demand is rising for application-tailored motor rollers—such as washdown-rated models for food processing or heavy-duty versions for automotive assembly lines.

- Price Pressure and Value Engineering: While premium features grow, cost-sensitive markets are driving innovation in value-engineered models without compromising reliability.

Conclusion

By H2 2026, the motor roller market is defined by a convergence of intelligence, efficiency, and sustainability. Success will depend on manufacturers’ ability to deliver connected, energy-optimized, and environmentally responsible solutions tailored to evolving industrial automation needs. Companies investing in digital integration, advanced materials, and modular design are best positioned to lead in this competitive landscape.

Common Pitfalls Sourcing Motor Rollers (Quality, IP)

Sourcing motor rollers—especially for applications requiring specific quality standards or Ingress Protection (IP) ratings—can present several challenges. Overlooking these pitfalls can lead to performance issues, premature failure, safety hazards, and increased total cost of ownership.

Poor Quality Control and Inconsistent Manufacturing

One of the most frequent issues when sourcing motor rollers, particularly from low-cost suppliers, is inconsistent quality control. Components such as bearings, seals, motor windings, and shafts may vary in material quality and precision. This inconsistency can result in premature wear, misalignment, noise, and reduced service life. Lack of standardized testing procedures or documentation further complicates quality verification.

Misrepresentation of IP Ratings

Many suppliers claim high IP ratings (e.g., IP55, IP65, IP67), but these claims are often unverified or based on incomplete testing. In reality, the motor roller may only meet the rating under ideal lab conditions or for the motor housing alone—not the entire roller assembly, including shaft seals, end caps, and cable entries. Using rollers with falsely advertised IP ratings in harsh environments (e.g., washdown, dusty, or outdoor settings) can lead to moisture or particulate ingress, resulting in motor failure or safety risks.

Inadequate Sealing and Shaft Protection

Even with a correctly rated motor housing, the shaft entry point is a common weak link. Poorly designed or low-quality shaft seals can degrade quickly under continuous rotation or exposure to chemicals and water. Suppliers may overlook dynamic sealing performance, leading to leaks and contamination of internal components. This pitfall is especially critical in food processing, packaging, and outdoor conveyor applications.

Substandard Motor Components

Motor rollers often use integrated AC or DC motors, and cost-cutting may lead to undersized windings, low-grade magnets, or inadequate thermal protection. This results in overheating, reduced efficiency, and shortened operational life. Additionally, motors may lack proper certification (e.g., CE, UL) or use counterfeit components, posing safety and compliance risks.

Lack of Traceability and Documentation

Reputable suppliers provide detailed technical documentation, including material certifications, test reports, and compliance statements. However, many motor roller sources—especially in unregulated markets—offer little to no traceability. This absence makes it difficult to validate claims, ensure regulatory compliance, or conduct root-cause analysis in case of failure.

Incompatible Duty Cycles and Load Ratings

Some motor rollers are marketed for heavy-duty use but are not designed for continuous operation or high radial/axial loads. Selecting a roller based solely on dimensions or price, without verifying load capacity, duty cycle, and thermal performance, can result in rapid mechanical or electrical failure, especially in demanding industrial environments.

Insufficient Testing for Real-World Conditions

Suppliers may test motor rollers under optimal, short-term conditions that don’t reflect actual operating environments. For example, a roller may pass a brief water spray test (IP65) but fail under prolonged exposure or high-pressure washdown. Without real-world simulation or third-party validation, performance in the field can fall drastically short of expectations.

Conclusion

To mitigate these pitfalls, buyers should prioritize suppliers with verifiable quality certifications, demand full technical documentation, and, where possible, conduct on-site audits or third-party testing. Clearly defining application requirements—including environmental conditions, load demands, and required IP ratings—helps ensure the selected motor rollers deliver long-term reliability and safety.

Logistics & Compliance Guide for Motor Roller

Overview

This guide outlines the essential logistics and compliance considerations for the transportation, handling, and regulatory adherence related to Motor Rollers—motorized cargo transport units used in material handling, particularly in warehouses, distribution centers, and logistics facilities. Adhering to these guidelines ensures operational efficiency, safety, and legal compliance.

Regulatory Compliance

Motor Rollers must comply with national and international regulations governing industrial equipment, electrical systems, and workplace safety. Key compliance areas include:

Electrical Safety Standards

- Ensure all Motor Rollers meet IEC 60204-1 (Safety of Machinery – Electrical Equipment of Machines).

- Verify compliance with regional electrical codes (e.g., NEC in the U.S., CE marking in the EU).

- Regular inspection and certification of wiring, motors, and control systems.

Machinery Safety Regulations

- Comply with ISO 13849 (Safety of Machinery – Safety-Related Parts of Control Systems).

- Implement emergency stop mechanisms, guarding, and overload protection.

- Adhere to ANSI B20.1 (Safety Standard for Conveyors and Related Equipment) in North America.

Workplace Safety (OSHA/EU-OSHA)

- Follow lockout/tagout (LOTO) procedures during maintenance.

- Provide clear safety signage and operator training.

- Ensure compliance with ergonomic and noise exposure limits.

Transportation & Shipping

Proper handling during transit is critical to prevent damage and ensure safe delivery.

Packaging Requirements

- Use robust wooden crates or heavy-duty pallets with corner protectors.

- Secure all moving parts and cover electrical components to prevent moisture ingress.

- Include shock and tilt indicators for sensitive models.

Freight Classification

- Classify Motor Rollers under HTS Code 8428.90 (Other Conveyors and Elevators) for international shipments.

- Confirm correct UN classification if batteries are included (e.g., UN3480 for lithium-ion).

- Declare weight, dimensions, and hazardous components (if any) on shipping documentation.

Mode-Specific Guidelines

- Air Freight: Prohibited or restricted if equipped with lithium batteries unless compliant with IATA Dangerous Goods Regulations.

- Ocean Freight: Use moisture-resistant packaging; consider container desiccants.

- Overland Transport: Secure units with straps and avoid stacking unless designed for it.

Import & Export Compliance

Cross-border movement of Motor Rollers requires adherence to customs and trade regulations.

Documentation

- Commercial invoice with detailed product description, value, and country of origin.

- Packing list specifying quantity, weight, and dimensions.

- Certificate of Conformity (CE, UL, or other applicable standards).

- Bill of Lading or Air Waybill.

Tariff & Duties

- Research applicable import tariffs based on destination country and HTS code.

- Leverage Free Trade Agreements (e.g., USMCA, RCEP) where eligible.

- Account for VAT, GST, or other local taxes.

Restricted Components

- Declare any dual-use technologies or controlled materials.

- Verify compliance with export control regulations (e.g., EAR in the U.S., EU Dual-Use Regulation).

Installation & On-Site Handling

Safe deployment ensures long-term performance and compliance.

Site Preparation

- Verify floor load capacity and power supply compatibility (voltage, phase, frequency).

- Ensure adequate clearance and ventilation around units.

Commissioning

- Perform initial safety checks and functional testing.

- Calibrate sensors and speed controls per manufacturer specifications.

- Document installation and obtain sign-off from a qualified technician.

Maintenance & Recordkeeping

Ongoing compliance depends on disciplined maintenance.

Scheduled Maintenance

- Follow manufacturer-recommended service intervals.

- Inspect belts, motors, bearings, and electrical connections regularly.

- Maintain logs for audits and warranty claims.

Regulatory Documentation

- Keep records of safety inspections, repairs, and operator training.

- Retain compliance certificates for at least seven years (or as required locally).

Environmental & Disposal Compliance

End-of-life handling must follow environmental regulations.

Waste Electrical Equipment (WEEE)

- Recycle Motor Rollers in accordance with WEEE Directive (EU) or equivalent.

- Partner with certified e-waste recyclers.

Battery Disposal

- Handle and dispose of onboard batteries per local hazardous waste rules.

- Never landfill lithium or lead-acid batteries.

Conclusion

Adhering to this Logistics & Compliance Guide ensures Motor Rollers are transported, installed, operated, and disposed of safely and legally. Regular audits, staff training, and staying updated on regulatory changes are key to maintaining compliance across the equipment lifecycle.

Conclusion for Sourcing Motor Rollers

After a comprehensive evaluation of potential suppliers, technical specifications, cost structures, and quality standards, it is concluded that sourcing motor rollers requires a strategic balance between performance, reliability, and cost-efficiency. Selecting the right supplier involves not only assessing upfront pricing but also considering long-term factors such as product durability, energy efficiency, after-sales support, and compliance with industry standards.

Partnering with suppliers who demonstrate proven expertise in motorized roller manufacturing, offer customizable solutions, and provide certifications (such as ISO, CE, or IP ratings) ensures compatibility with specific application requirements, such as conveyor systems in logistics, industrial automation, or material handling.

Additionally, establishing strong supply chain partnerships with reliable lead times and responsive technical support minimizes downtime and enhances operational continuity. It is recommended to conduct pilot testing with shortlisted suppliers before large-scale procurement to validate performance under real-world conditions.

In summary, a well-structured sourcing strategy for motor rollers—grounded in technical due diligence, total cost of ownership analysis, and supplier reliability—will deliver optimal operational efficiency and long-term value for the organization.