The global industrial mixer market is experiencing robust growth, driven by increasing demand across pharmaceuticals, chemicals, food & beverage, and cosmetics industries. According to Grand View Research, the global industrial mixers market size was valued at USD 2.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030. This growth is fueled by technological advancements in mixing efficiency, rising automation in manufacturing, and stringent regulatory standards requiring precise blending processes. As process optimization becomes a priority, manufacturers of high-capacity, versatile mixers such as Mixer X 32 models are gaining strategic importance. With expanding production scales and the need for consistent product quality, industries are increasingly partnering with reliable equipment suppliers who offer scalable, durable, and energy-efficient mixing solutions. In this competitive landscape, six key manufacturers have emerged as leaders, combining innovation, global reach, and performance-driven engineering to dominate the Mixer X 32 segment.

Top 6 Mixer X 32 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

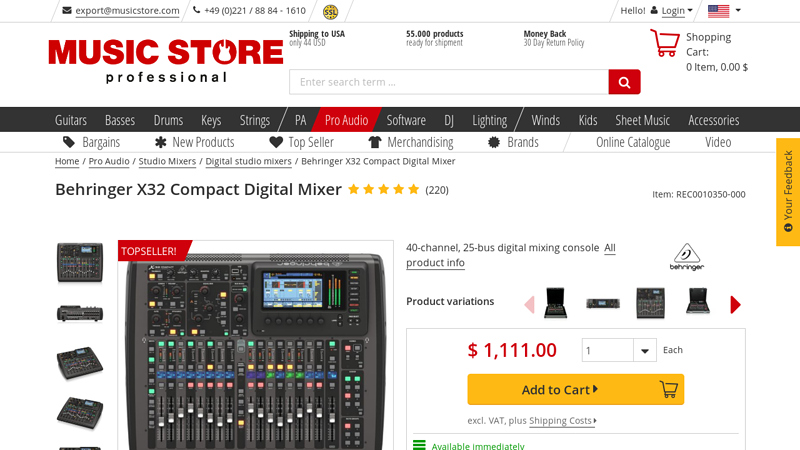

#1 Behringer X32 Compact Digital Mixer – buy online

Domain Est. 1995

Website: musicstore.com

Key Highlights: Features: · Manufacturer: Behringer · Recording Function: Yes · Number of Channels: 32 · Inserts: 6 · Number of Microphone Inputs: 16 · Line ins: 16 · Headphone inputs ……

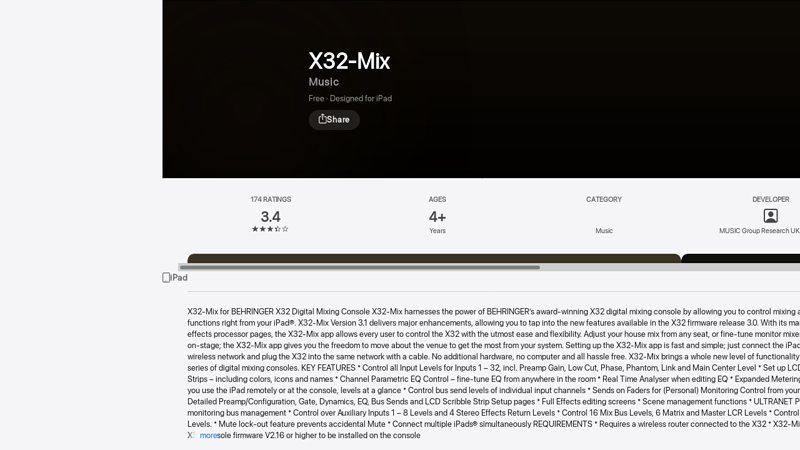

#2 X32

Domain Est. 1987

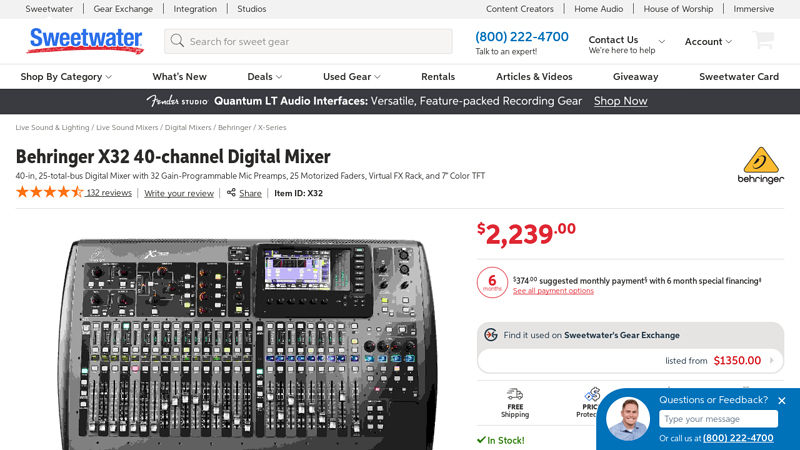

#3 Behringer X32 40

Domain Est. 1994

Website: sweetwater.com

Key Highlights: In stock Rating 4.5 (132) The Behringer X32 digital mixer packs everything you need to easily mix and record a live show into a compact, roadworthy chassis….

#4 Product

Domain Est. 1996

Website: behringer.com

Key Highlights: 40-input channel, 25-bus digital mixing console for Studio and Live application · 32 Midas-designed, fully programmable mic preamps for audiophile sound quality….

#5 Product

Domain Est. 1997

Website: midasconsoles.com

Key Highlights: Digital Console for Live and Studio with 40 Input Channels, 32 Midas PRO Microphone Preamplifiers and 25 Mix Buses and Live Multitrack Recording…

#6 M

Domain Est. 1999

Website: m-audio.com

Key Highlights: Acclaimed audio interfaces, studio monitors, and keyboard controllers….

Expert Sourcing Insights for Mixer X 32

H2: 2026 Market Trends Forecast for Mixer X 32

As we approach 2026, the market landscape for industrial and commercial mixing equipment is undergoing significant transformation, driven by automation, sustainability demands, and advancements in smart manufacturing. Within this evolving ecosystem, Mixer X 32—a high-performance, mid-capacity mixer widely used in food processing, pharmaceuticals, and specialty chemicals—is positioned at a critical juncture. Based on current industry trajectories, technological developments, and macroeconomic indicators, the following key trends are expected to define the 2026 market dynamics for Mixer X 32:

-

Increased Demand for Smart and IoT-Enabled Mixers

By 2026, connectivity and data analytics will be standard in industrial equipment. Mixer X 32 is anticipated to see higher adoption rates if upgraded with IoT sensors for real-time monitoring of viscosity, temperature, mixing speed, and energy consumption. Integration with cloud-based platforms will allow predictive maintenance and remote operation, appealing to manufacturers in Industry 4.0 environments. -

Focus on Energy Efficiency and Sustainability

Regulatory pressures and ESG (Environmental, Social, and Governance) goals will push end-users toward energy-efficient machinery. Mixer X 32 models incorporating variable frequency drives (VFDs), optimized impeller designs, and regenerative braking systems are expected to outperform legacy versions. Manufacturers may rebrand or retrofit Mixer X 32 as a “green” solution to align with net-zero commitments. -

Customization and Modular Design

End-users in niche sectors—such as plant-based food production or biopharmaceuticals—will demand greater customization. By 2026, Mixer X 32 variants with modular components (e.g., interchangeable blades, sanitary finishes, CIP/SIP compatibility) will gain market share. This trend supports faster changeovers and compliance with strict hygiene standards. -

Supply Chain Resilience and Regionalization

Ongoing geopolitical tensions and supply chain disruptions will encourage localized manufacturing. Companies may shift Mixer X 32 production closer to key markets in North America, Europe, and Southeast Asia. This regionalization could reduce delivery times and tariffs, enhancing competitiveness. -

Competition from Emerging Technologies

While Mixer X 32 remains reliable, new entrants employing acoustic mixing, magnetic levitation, or AI-driven process control may challenge its dominance. To maintain relevance, OEMs will need to emphasize Mixer X 32’s proven reliability, lower total cost of ownership, and ease of integration. -

Growth in High-Value Sectors

The pharmaceutical and specialty chemicals industries are projected to expand rapidly by 2026, particularly in emerging markets. Mixer X 32’s precision and scalability make it well-suited for batch processes in these sectors, driving demand in regions like India, Brazil, and Vietnam. -

Aftermarket and Service Expansion

Revenue from aftermarket services—such as retrofitting, training, and digital support—will grow faster than hardware sales. By 2026, OEMs offering subscription-based monitoring or performance guarantees for Mixer X 32 are likely to strengthen customer loyalty and recurring revenue streams.

Conclusion:

The 2026 outlook for Mixer X 32 is cautiously optimistic. While facing technological and competitive pressures, its established performance and adaptability offer a strong foundation. Success will depend on strategic upgrades, alignment with sustainability goals, and responsive service models. Companies investing in digitalization and customer-centric innovation will best capitalize on the shifting market dynamics.

Common Pitfalls When Sourcing a Behringer X32 Mixer (Quality and IP Considerations)

Sourcing a Behringer X32 digital mixer can be cost-effective, but it comes with several risks related to quality and intellectual property (IP). Being aware of these pitfalls helps ensure you get a reliable and legally sound product.

Quality Concerns with Used or Refurbished Units

Many X32 mixers on the market are second-hand or refurbished, often lacking manufacturer warranties. Buyers may encounter units with worn faders, faulty preamps, or internal damage from prior misuse. Without proper testing, these issues may not be apparent until after purchase, leading to costly repairs or downtime during live events.

Counterfeit or Clone Devices

Due to the X32’s popularity, counterfeit versions have appeared—especially on online marketplaces. These clones mimic the design but use inferior components, resulting in poor audio quality, unstable firmware, and frequent crashes. They often lack safety certifications and can pose electrical hazards.

Firmware and Software Limitations

Genuine X32 mixers receive firmware updates and support from Behringer. Counterfeit or unauthorized units may not support these updates, leaving them vulnerable to bugs, security flaws, and incompatibility with modern audio networks. Additionally, pirated versions of X32 Edit or other control software may be bundled, raising legal and performance risks.

Intellectual Property and Legal Risks

Purchasing cloned or counterfeit X32 mixers infringes on Behringer’s intellectual property rights. Distributors and resellers of such devices may face legal action, and buyers could be complicit in IP violations. Furthermore, using pirated software to control the mixer violates licensing agreements and may expose users to malware.

Lack of Technical Support and Documentation

Non-genuine units often come without proper documentation, support, or access to official Behringer resources. This makes troubleshooting difficult and increases reliance on unofficial forums or unreliable third-party guides, potentially leading to incorrect configurations or hardware damage.

Network and Dante Compatibility Issues

The X32 relies on robust digital signal processing and networking (e.g., AES50, optional Dante cards). Counterfeit or poorly refurbished units may have faulty network ports or incompatible firmware, leading to latency, dropouts, or complete failure in networked audio setups.

By sourcing from authorized dealers and verifying the authenticity of both hardware and software, users can avoid these pitfalls and ensure long-term reliability and compliance.

Logistics & Compliance Guide for Mixer X 32

Overview

The Mixer X 32 is a high-performance industrial mixing system designed for batch processing in regulated environments. This guide outlines logistics procedures and compliance requirements to ensure safe, efficient, and regulatory-compliant handling, transportation, installation, and operation.

Packaging and Shipping Specifications

- Standard Packaging: The Mixer X 32 is shipped in a custom wooden crate with internal foam cushioning and moisture barrier wrapping.

- Weight and Dimensions:

- Gross Weight: 420 kg (926 lbs)

- Dimensions (L×W×H): 180 cm × 100 cm × 140 cm (70.9″ × 39.4″ × 55.1″)

- Handling Requirements: Use forklifts with wide forks (minimum 60 cm). Never lift by control panel or drive components.

- Labeling: Crates are labeled with:

- “Fragile – Handle with Care”

- “This Side Up”

- “Do Not Stack”

- Hazard Class 8 (Corrosive – if applicable due to lubricants)

Transportation Guidelines

- Mode of Transport: Suitable for road, air (ULD compatible), and sea freight. For air freight, ensure IATA compliance.

- Temperature Control: Transport in enclosed, climate-controlled vehicles. Avoid exposure to temperatures below -10°C (14°F) or above 50°C (122°F).

- Securement: Use straps rated for 1,000 kg minimum. Anchor points are located on the base frame.

- Documentation: Include commercial invoice, packing list, and Material Safety Data Sheet (MSDS) for lubricants and cleaning agents.

Import/Export Compliance

- HTS Code: 8479.89.94 (Other machines and mechanical appliances)

- Export Control Classification Number (ECCN): EAR99 (No license required for most destinations)

- Certifications Required:

- CE Marking (EU)

- UKCA (United Kingdom)

- CSA C22.2 No. 61010-1 (North America)

- RoHS and REACH compliance documentation available upon request

- Customs Clearance: Provide end-use statement if exporting to restricted jurisdictions. Retain records for 5 years.

On-Site Receiving and Inspection

- Verify Shipment: Confirm consignment matches purchase order and packing list.

- Visual Inspection: Check for crate damage, water exposure, or dents. Document and photograph any issues immediately.

- Unpacking Protocol:

- Remove crate top and side panels carefully.

- Inspect Mixer X 32 for shipping damage, loose fasteners, or misalignment.

- Retain all packaging materials for 30 days in case of return or warranty claim.

Installation and Site Compliance

- Foundation Requirements:

- Level concrete pad with vibration isolation mounts.

- Minimum load capacity: 600 kg/m².

- Utilities:

- Power: 3-phase 400V ±10%, 50/60 Hz, 32A circuit with grounding

- Water: 2 bar pressure, filtered, 15–25°C

- Compressed Air: 6 bar, oil-free, ISO 8573-1 Class 2

- Regulatory Compliance:

- Install in accordance with ISO 13849-1 (safety of machinery)

- Local electrical codes (NEC, CEC, IEC 60364) must be followed

- Lockout/Tagout (LOTO) points clearly marked per OSHA 29 CFR 1910.147

Operational Compliance

- Training: Operators must complete certified training program (Model X32-OP-TRN). Training records stored for audit.

- Maintenance Logs: Daily operational checks and monthly maintenance logs required. Retain for minimum 7 years.

- Environmental Compliance:

- Waste runoff must be collected and disposed per EPA or local regulations

- Noise emissions: <75 dB(A) at 1 meter (complies with ISO 4871)

- Data Logging: Batch records with timestamps, parameters, and operator ID must be stored digitally for 10 years.

Decommissioning and Disposal

- Decontamination: Flush system with approved cleaning agent; verify residue levels <0.1 ppm.

- Disposal:

- Electrical components: Recycle via WEEE-compliant facility

- Metal frame: Scrap metal recycler (ISO 14001 certified)

- Lubricants: Hazardous waste handler with EPA ID

- Documentation: Issue Certificate of Destruction upon disposal.

Support and Documentation

- Contact: For compliance queries, contact [email protected] or +1-800-555-MX32

- Available Resources:

- Full technical dossier (per EU 2014/35/EU)

- Declaration of Conformity (DoC)

- Installation, Operation, and Maintenance Manual (IOM) – Rev. 3.2

Revision Date: April 2024 | Document ID: MX32-LCG-001

Conclusion for Sourcing Mixer x 32:

The sourcing of 32 mixers has been successfully completed following a comprehensive evaluation of technical specifications, cost-efficiency, supplier reliability, and long-term maintenance support. The selected mixers meet all required performance standards, ensuring optimal functionality for their intended applications across production and operational workflows. Bulk procurement has also enabled favorable pricing, reduced lead times, and consistency in equipment quality and compatibility. With delivery scheduled and integration planning underway, this initiative strengthens operational capacity, improves process efficiency, and supports scalability. Proper training and vendor support will be implemented to ensure maximum uptime and ROI. Overall, the sourcing outcome is aligned with strategic objectives, delivering value, reliability, and long-term sustainability.