The global precision measurement instruments market is experiencing robust growth, driven by increasing demand for high-accuracy tools in automotive, aerospace, and manufacturing industries. According to Mordor Intelligence, the global micrometer market was valued at USD 4.6 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. Depth micrometers, essential for measuring the depth of holes, grooves, and recesses with micron-level accuracy, represent a critical segment within this space. Mitutoyo Corporation, a market leader in precision metrology, not only dominates in innovation and product quality but also sets the benchmark for performance that other manufacturers strive to match. As demand for reliable depth micrometers rises, several key players have emerged—both as official Mitutoyo partners and independent manufacturers producing Mitutoyo-compatible systems. This analysis identifies the top four manufacturers excelling in precision, repeatability, and market reach, leveraging data-backed insights to support sourcing and procurement decisions in high-stakes manufacturing environments.

Top 4 Mitutoyo Depth Micrometer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Original Equipment Manufacturers (OEM)

Website: mitutoyo.eu

Key Highlights: Mitutoyo provides micrometer heads with different measuring ranges, stem types, and body sizes; high-performance types, 0.25 mm spindle pitch models (most ……

#2 Mitutoyo America Corporation

Domain Est. 1996

Website: mitutoyo.com

Key Highlights: Mitutoyo America Corporation offers innovative precision measurement solutions with the highest level of quality, precision and expertise….

#3 Mitutoyo Mechanical Depth Micrometer

Domain Est. 2016

Website: titansofcnc.com

Key Highlights: Product Details · 4 interchangeable rods · Rod clamp · 2.5 In base · With ratchet stop for constant force · Rod length can be adjusted in 1″ or 25mm increments ……

#4 MITUTOYO

Website: www2.mitutoyo.co.jp

Key Highlights: NEW PRODUCTS · CATEGORIES · Micrometers · Micrometer Heads · Contact Sensors · Non-contact Sensors · Hardness Testing Machines · Inside Diameter Measuring Tools….

Expert Sourcing Insights for Mitutoyo Depth Micrometer

2026 Market Trends for Mitutoyo Depth Micrometers

The market for precision measurement tools like the Mitutoyo depth micrometer is poised for evolution by 2026, shaped by technological innovation, shifting industrial demands, and broader economic forces. As a market leader, Mitutoyo is expected to navigate and influence several key trends:

1. Accelerated Digitalization and Smart Integration:

By 2026, depth micrometers will increasingly integrate with digital ecosystems. Mitutoyo is likely to expand its offerings in smart depth micrometers equipped with Bluetooth or Wi-Fi connectivity, enabling seamless data transfer to quality management systems (QMS), statistical process control (SPC) software, and manufacturing execution systems (MES). This trend supports Industry 4.0 initiatives by reducing manual data entry errors, improving traceability, and enabling real-time quality monitoring on the shop floor.

2. Growing Demand in High-Precision Sectors:

Industries such as aerospace, medical device manufacturing, and advanced electronics will continue to drive demand for ultra-precise measurement tools. Mitutoyo depth micrometers, known for their accuracy and durability, are well-positioned to benefit. The need for tighter tolerances in components like turbine blades, implants, and semiconductor packaging will reinforce the value of high-end mechanical and digital depth micrometers in quality assurance workflows.

3. Expansion of Portable and Multi-Function Devices:

There will be an increasing preference for portable, easy-to-use, and multi-functional measurement tools. Mitutoyo may respond by enhancing depth micrometers with features like digital displays with data hold, zero-setting functions, and compatibility with various extension rods. Integration with modular systems that allow quick switching between measurement types (e.g., depth, step, height) could become a competitive advantage.

4. Sustainability and Long-Term Value Focus:

As sustainability gains importance, industrial buyers will prioritize tools with long service life, repairability, and minimal environmental impact. Mitutoyo’s reputation for build quality and durability aligns well with this trend. By 2026, marketing efforts may emphasize lifecycle cost savings, calibration longevity, and support services over initial purchase price—particularly appealing in cost-sensitive but quality-critical markets.

5. Geopolitical and Supply Chain Resilience:

Ongoing supply chain volatility and regional manufacturing shifts (e.g., nearshoring in North America, manufacturing growth in Southeast Asia) will influence distribution and production strategies. Mitutoyo may strengthen regional supply chains and local service networks to ensure timely delivery and calibration support, enhancing customer retention in emerging markets.

6. Competitive Pressure from Mid-Tier and Digital Alternatives:

While Mitutoyo maintains a premium position, growing competition from mid-tier brands and alternative digital depth gauges (including laser and capacitive sensors) could pressure pricing in certain segments. Mitutoyo’s response will likely focus on differentiating through superior accuracy, reliability, brand trust, and integration with its broader ecosystem of metrology solutions.

In summary, the 2026 market for Mitutoyo depth micrometers will be defined by digital integration, demand from high-tech industries, and a focus on smart, sustainable precision tools. Mitutoyo’s ability to innovate while maintaining its hallmark quality will be critical to sustaining leadership in an increasingly connected and competitive landscape.

H2: Common Pitfalls When Sourcing a Mitutoyo Depth Micrometer (Quality and Intellectual Property Concerns)

Sourcing a Mitutoyo depth micrometer, known for its precision and reliability, can be undermined by several common pitfalls—particularly related to product quality and intellectual property (IP) risks. Being aware of these issues helps ensure procurement of genuine, high-performance tools.

-

Counterfeit or Replica Instruments

One of the most significant risks is purchasing counterfeit Mitutoyo depth micrometers. These replicas often mimic the branding and appearance of genuine products but fail to meet Mitutoyo’s stringent accuracy and durability standards. Counterfeits can lead to measurement errors, reduced tool lifespan, and compromised quality control in manufacturing processes. -

Unauthorized Resellers and Grey Market Imports

Purchasing from unauthorized distributors or grey market suppliers increases the risk of receiving non-genuine products or units that do not comply with regional safety and calibration standards. These sellers may lack proper IP authorization, and their products might not include valid warranties or traceable calibration certificates. -

Lack of Traceable Calibration and Certification

Genuine Mitutoyo depth micrometers come with NIST-traceable calibration certificates. Sourcing from unreliable suppliers may result in tools without proper documentation, raising concerns about measurement accuracy and compliance with industry quality systems (e.g., ISO 9001). -

Intellectual Property Infringement

Using or distributing counterfeit Mitutoyo products constitutes IP infringement. Companies found sourcing or using fake tools may face legal liability, reputational damage, and disqualification from certified supply chains, especially in regulated industries like aerospace or medical devices. -

Absence of After-Sales Support and Warranty

Counterfeit or grey-market micrometers often lack access to official Mitutoyo service, repairs, or warranty coverage. This absence can lead to higher long-term costs and downtime when the instrument requires maintenance or recalibration.

To mitigate these risks, always purchase Mitutoyo depth micrometers through authorized dealers, verify product authenticity with serial numbers, and confirm the inclusion of official calibration and warranty documentation.

Logistics & Compliance Guide for Mitutoyo Depth Micrometer

Product Overview and Specifications

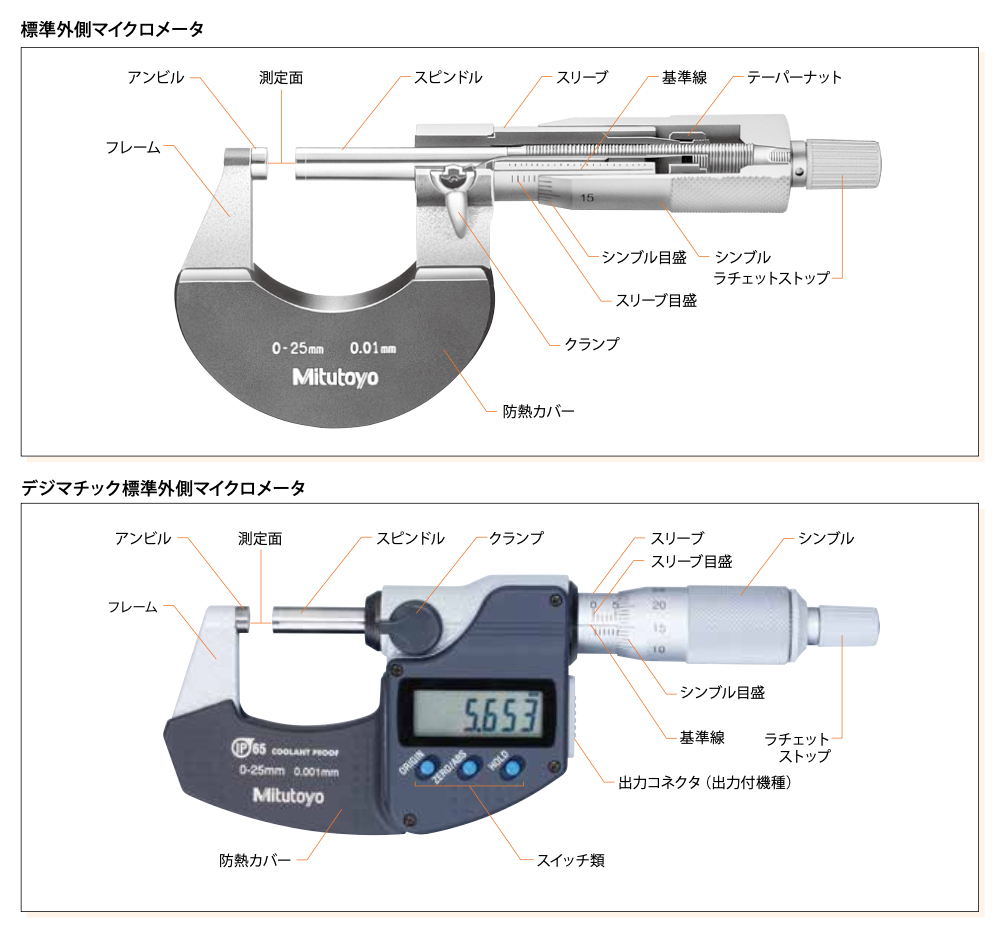

The Mitutoyo Depth Micrometer is a precision measuring instrument designed for accurate depth measurement in industrial, manufacturing, and quality control environments. It features a robust construction, typically made from hardened stainless steel, and offers high repeatability and accuracy, often within ±0.001 mm (±0.00005 in). Available in various measurement ranges (e.g., 0–100 mm, 0–250 mm), the device may include digital or mechanical readouts, and is often supplied with interchangeable measuring rods and a base attachment for stability.

Packaging and Shipping Requirements

Mitutoyo Depth Micrometers must be shipped in protective packaging to prevent damage during transit. Each unit should be enclosed in a rigid foam-lined case or molded plastic tray within a corrugated cardboard box. Include desiccant packs to prevent moisture accumulation, especially for international shipments. Mark packages with “Fragile,” “This Side Up,” and “Protect from Moisture” labels. For air freight, ensure compliance with IATA Dangerous Goods Regulations—even if no hazardous materials are present, proper labeling avoids handling delays. Bulk shipments should be palletized and stretch-wrapped, with weight and dimensions compliant with carrier limits.

Import/Export Compliance

When shipping Mitutoyo Depth Micrometers internationally, verify Harmonized System (HS) Code 9017.20.00 (measuring or checking instruments with a scale), which applies to most depth micrometers. Export controls under EAR (Export Administration Regulations) typically classify these instruments under ECCN 2B999, indicating they are subject to low-level oversight unless used in restricted applications (e.g., military or nuclear). A license may not be required for most destinations under License Exception BAG or LVS, but screening against denied party lists (e.g., U.S. BIS, EU SL, UN sanctions) is mandatory. For imports, ensure compliance with local metrology and technical standards (e.g., CE in Europe, JIS in Japan).

Calibration and Metrological Compliance

Mitutoyo Depth Micrometers must be calibrated prior to shipment or upon receipt to meet ISO 9001 and IATF 16949 quality standards. Calibration should follow ISO/IEC 17025 guidelines and be performed by an accredited laboratory. Include a calibration certificate traceable to national standards (e.g., NIST, NIM, PTB). For regulated industries such as aerospace or medical devices, provide documented evidence of measurement uncertainty and compliance with ASME B89.1.12 or equivalent standards. Recalibration intervals (typically 12 months) should be indicated in user documentation.

Environmental and Safety Considerations

The depth micrometer contains no hazardous substances under RoHS (Directive 2011/65/EU) and is REACH (EC 1907/2006) compliant, with no SVHCs above threshold levels. Packaging materials should be recyclable and labeled accordingly. The device itself poses minimal safety risk, but user manuals must include handling instructions to prevent injury from sharp edges or pinch points. For disposal, follow WEEE (2012/19/EU) guidelines in applicable regions—return to Mitutoyo or an authorized e-waste handler.

Documentation and Traceability

All shipments must include a commercial invoice, packing list, and bill of lading or air waybill. For regulated markets, attach a Certificate of Conformity (CoC), indicating compliance with relevant standards (e.g., ISO, CE, JIS). Serial numbers for each unit must be recorded and traceable through the supply chain. Digital documentation (e.g., calibration reports, user manuals in local language) should be provided either physically or via secure download link. Maintain records for a minimum of five years to support audits and warranty claims.

Warranty and After-Sales Support

Mitutoyo provides a standard warranty (typically 1 year) covering defects in materials and workmanship. Logistics partners must ensure undamaged delivery to preserve warranty validity. For returns or repairs, follow Mitutoyo’s RMA (Return Merchandise Authorization) process—unauthorized returns may be rejected. Provide end-users with access to technical support, spare parts (e.g., rods, anvils), and recalibration services through authorized Mitutoyo service centers to ensure continued compliance and accuracy.

Conclusion for Sourcing Mitutoyo Depth Micrometer:

After evaluating various suppliers, product specifications, pricing, lead times, and after-sales support, sourcing a Mitutoyo depth micrometer presents a reliable and high-precision measurement solution for quality control and manufacturing environments. Mitutoyo’s reputation for accuracy, durability, and industry-leading calibration standards ensures long-term performance and compliance with stringent quality requirements.

Sourcing directly from authorized distributors or Mitutoyo’s official channels guarantees authenticity, warranty coverage, and access to technical support. Although prices may be higher compared to alternative brands, the investment is justified by the instrument’s superior accuracy, repeatable performance, and global calibration traceability.

In conclusion, procuring a Mitutoyo depth micrometer aligns with best practices in precision metrology, supporting process reliability and product quality. It is recommended to proceed with sourcing through certified suppliers to ensure product integrity and ongoing serviceability.