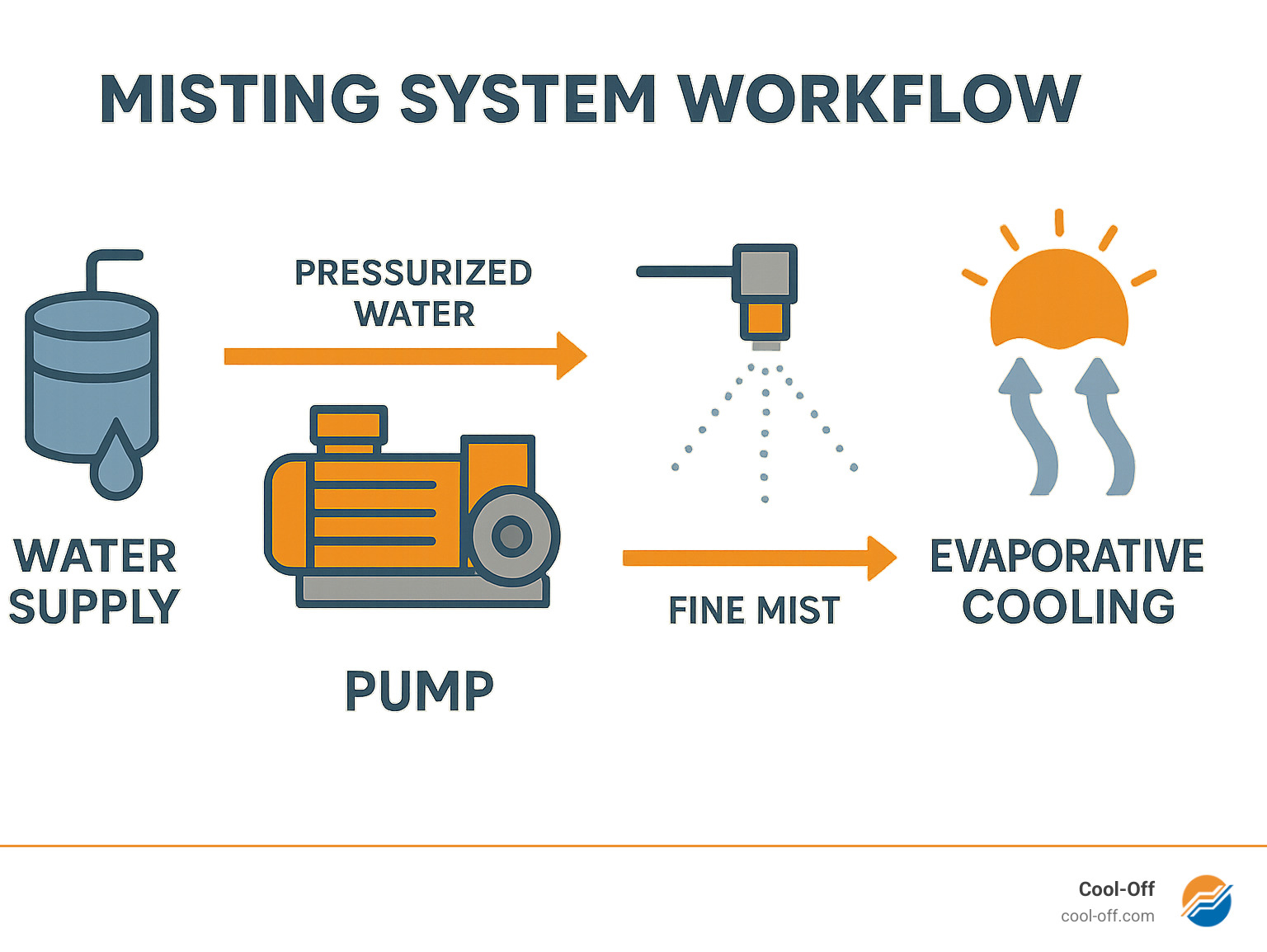

The global misting pump market is experiencing steady growth, driven by rising demand across agricultural, industrial, and residential cooling applications. According to a report by Mordor Intelligence, the misting system market—which includes key components such as misting pumps—is projected to grow at a CAGR of over 7.2% from 2023 to 2028. Similarly, Grand View Research estimates that the global evaporative cooling systems market, a major end-user segment for misting pumps, will expand at a CAGR of 7.8% from 2023 to 2030, fueled by increasing energy efficiency concerns and climate-related cooling needs. This growth trajectory is further supported by technological advancements in high-pressure pump designs and the expansion of smart irrigation systems. As demand surges, manufacturers are focusing on durability, energy efficiency, and precision engineering. In this competitive landscape, nine key players have emerged as leaders in innovation, reliability, and global reach—shaping the future of misting pump technology.

Top 9 Misting Pump Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Misting Systems & Misting Fans by Leading US Manufacturer

Domain Est. 1998 | Founded: 1994

Website: mistcool.com

Key Highlights: Made in America! We offer the highest quality we can at the best price available. The industry’s leading USA misting systems manufacturer since 1994….

#2 Misting and Humidity Systems

Domain Est. 1999

Website: corriganmist.com

Key Highlights: A market leading manufacturer of humidification and water filtration technologies. Jack’s core principle of designing and manufacturing reliable solutions….

#3 MistCooling Systems

Domain Est. 2002

Website: mistcooling.com

Key Highlights: Explore our range of DIY misting kits, powerful misting fans, and durable high-pressure pumps and nozzles, engineered for both residential and industrial spaces ……

#4 [PDF] Misting, Cooling and Fogging Products

Domain Est. 1997

Website: catpumps.com

Key Highlights: Humidity/Moisture Control Misting systems are used to maintain proper moisture and/or consistent humidity. They eliminate static electricity, suspend airborne ……

#5 Fog and Misting Systems for Humidity, Dust & Odor Control

Domain Est. 2001

Website: fogco.com

Key Highlights: Fogco manufactures the industry’s most powerful high-pressure misting systems designed to solve your toughest environmental challenges….

#6 MistAmerica

Domain Est. 2001

Website: mistamerica.com

Key Highlights: MistAmerica offers the highest quality outdoor misting systems, patio misters, fans, and more. Discover outdoor cooling systems, trusted for over 30 years….

#7 AeroMist

Domain Est. 2001

Website: aeromist.com

Key Highlights: AeroMist: Cool down in Phoenix with high-pressure misting systems! Shop misting kits, fans & pumps for patios & warehouses. Fast AZ shipping!…

#8 What’s New

Domain Est. 2004

Website: naturalfog.com

Key Highlights: Natural Fog Company not only designs and manufactures mist and fog nozzle, fitting, but also offers accessories for high and low pressure mist and fog system….

#9 Mist Pump

Domain Est. 2005

Website: wulipump.com

Key Highlights: WuLi Pump specializes in high-pressure mist pumps for cooling, fogging, humidification, agriculture, and odor control systems….

Expert Sourcing Insights for Misting Pump

H2: 2026 Market Trends for Misting Pumps

The global misting pump market is poised for notable transformation and growth by 2026, driven by technological innovation, rising demand for energy-efficient cooling solutions, and expanding applications across residential, commercial, and industrial sectors. Key market trends shaping the misting pump industry in 2026 include:

-

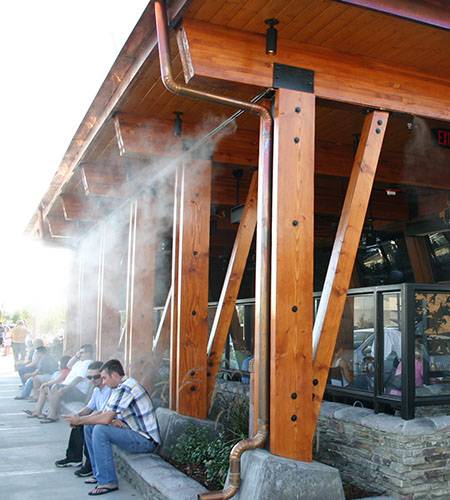

Increased Demand in Residential and Hospitality Sectors

Urbanization and rising temperatures due to climate change are boosting demand for outdoor comfort solutions. Misting pumps are increasingly integrated into patios, gardens, and outdoor dining areas in homes and hotels. The post-pandemic emphasis on outdoor living and al fresco experiences continues to fuel adoption, particularly in warm climates across North America, the Middle East, and Southeast Asia. -

Adoption of Smart and IoT-Enabled Misting Systems

By 2026, smart misting pumps equipped with sensors, Wi-Fi connectivity, and mobile app control are becoming mainstream. These systems allow users to regulate mist output, schedule operations, and monitor ambient conditions remotely. Integration with smart home ecosystems (such as Google Home and Amazon Alexa) enhances convenience and energy efficiency, making smart misting systems a growing segment. -

Focus on Energy Efficiency and Sustainability

Manufacturers are prioritizing low-energy consumption designs and eco-friendly materials. High-pressure misting pumps with variable frequency drives (VFDs) optimize power usage, reducing operational costs and environmental impact. Water conservation features, such as timer controls and humidity sensors, align with global sustainability goals and appeal to environmentally conscious consumers. -

Growth in Agricultural and Industrial Applications

Beyond cooling, misting pumps are being adopted in precision agriculture for greenhouse climate control, livestock cooling, and dust suppression. In industrial settings, they are used in construction sites, warehouses, and mining operations to manage temperature and airborne particles. These applications are expected to grow, particularly in emerging economies investing in infrastructure and agri-tech. -

Technological Advancements in Pump Design

Innovations such as ceramic plungers, corrosion-resistant materials, and modular designs are improving pump durability and maintenance cycles. Compact, quiet-operation models are gaining traction in noise-sensitive environments like resorts and urban spaces. These enhancements support longer product lifecycles and lower total cost of ownership. -

Expansion of E-Commerce and Direct-to-Consumer Sales

Online retail platforms have become a dominant channel for misting pump distribution. By 2026, brands are leveraging e-commerce with detailed product specifications, customer reviews, and bundled accessories to drive sales. DIY installation kits and video tutorials are lowering barriers to entry for consumers. -

Regional Market Dynamics

The Asia-Pacific region is emerging as a high-growth market due to rapid urbanization, rising disposable incomes, and increasing awareness of comfort technologies. Meanwhile, North America and Europe remain key markets, with strong demand driven by renovation activities and stringent energy regulations.

In summary, the 2026 misting pump market is characterized by smart integration, sustainability, and diversification across sectors. Companies that invest in innovation, digital connectivity, and eco-conscious design are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Misting Pumps (Quality, IP)

Sourcing misting pumps for applications such as cooling systems, humidification, or agricultural use requires careful attention to both quality and Ingress Protection (IP) ratings. Overlooking critical aspects can lead to premature failure, poor performance, safety hazards, and increased maintenance costs. Below are the key pitfalls to avoid:

1. Ignoring IP Rating Requirements

One of the most frequent mistakes is selecting a misting pump without verifying the appropriate Ingress Protection (IP) rating for the operating environment. Misting systems are often installed in outdoor, humid, or dusty areas where water and debris can easily compromise internal components.

- Pitfall: Choosing a pump with a low IP rating (e.g., IP44) for outdoor or high-moisture environments.

- Risk: Water or dust ingress can cause motor failure, electrical shorts, or corrosion.

- Best Practice: Always match the IP rating to the environment. For outdoor use, select pumps rated at least IP65 (dust-tight and protected against water jets). For fully exposed installations, IP67 or higher may be required.

2. Prioritizing Price Over Build Quality

Opting for the cheapest available misting pump often leads to short-term savings but long-term problems.

- Pitfall: Choosing pumps made with inferior materials (e.g., plastic housings, low-grade seals, or weak motors).

- Risk: Reduced lifespan, frequent breakdowns, leaks, and inconsistent pressure output.

- Best Practice: Evaluate material quality—look for stainless steel or reinforced polymer housings, ceramic plungers, and high-quality seals. Consider the warranty and brand reputation as indicators of durability.

3. Overlooking Pump Pressure and Flow Specifications

Misting systems require precise pressure (typically 50–100 bar) to create a fine mist. Using a pump that doesn’t meet these requirements results in poor performance.

- Pitfall: Selecting a pump based on horsepower alone without verifying pressure (PSI/Bar) and flow rate (LPM/GPM).

- Risk: Inadequate atomization—resulting in dripping nozzles instead of a fine mist—or excessive strain on the pump leading to overheating.

- Best Practice: Match the pump’s performance curve to your system’s nozzle requirements and total flow demand. Always include a pressure gauge and regulator.

4. Neglecting Motor and Seal Quality

The motor and seals are critical to long-term reliability, especially in continuous-duty applications.

- Pitfall: Accepting vague specifications or uncertified motors without checking insulation class (e.g., Class F) or seal type (e.g., mechanical vs. lip seals).

- Risk: Motor burnout in high-temperature environments or seal leakage causing water damage and contamination.

- Best Practice: Choose pumps with sealed, thermally protected motors and high-quality mechanical seals designed for constant operation and water exposure.

5. Failing to Verify Compliance and Certifications

Especially in commercial or industrial settings, regulatory compliance is essential.

- Pitfall: Sourcing pumps without CE, RoHS, or UL certification, particularly from unknown suppliers or marketplaces.

- Risk: Safety hazards, non-compliance with local regulations, and voided insurance in case of failure.

- Best Practice: Request certification documents and verify compliance with regional electrical and safety standards.

6. Underestimating the Importance of After-Sales Support

Even high-quality pumps may require maintenance or replacement parts over time.

- Pitfall: Procuring from suppliers with no local service, limited spare parts availability, or poor technical support.

- Risk: Extended downtime and difficulty troubleshooting or repairing the system.

- Best Practice: Choose suppliers or manufacturers with accessible customer support, available spare parts (e.g., seals, plungers, check valves), and clear service documentation.

7. Not Considering Noise Levels and Vibration

Misting pumps, especially high-pressure models, can generate significant noise and vibration.

- Pitfall: Installing a pump in a noise-sensitive area without evaluating decibel (dB) ratings or vibration dampening.

- Risk: Annoyance in residential or public spaces, structural fatigue over time.

- Best Practice: Opt for pumps with low-noise motors and rubber mounting feet. Consider installing the pump on a vibration-absorbing base or in an enclosed, insulated housing.

By avoiding these common pitfalls, buyers can ensure reliable, efficient, and long-lasting performance from their misting pump systems. Always conduct thorough due diligence on specifications, certifications, and supplier credibility before finalizing procurement.

Logistics & Compliance Guide for Misting Pump

Product Classification and Documentation

Ensure accurate classification of the misting pump for international shipping and customs compliance. Misting pumps are typically categorized under HS (Harmonized System) codes related to mechanical appliances or fluid handling equipment. A common classification is HS Code 8413.70 – “Pumps for liquids, whether or not fitted with a measuring device.” Confirm the exact code with your local customs authority, as variations may apply based on motor type, capacity, and intended use (e.g., agricultural, commercial cooling, or industrial).

Required documentation includes:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Product Specifications Sheet

– Safety Data Sheet (SDS), if applicable (e.g., for units with lubricants or chemical-resistant components)

Maintain a technical file with compliance certifications and product test reports for audit readiness.

Import/Export Regulations

Adhere to import and export regulations based on destination and origin countries. Key considerations include:

– Export Controls: Verify if the misting pump contains components subject to dual-use or technology export restrictions (e.g., high-pressure motors or electronic controllers). Check against regulations such as the U.S. EAR (Export Administration Regulations) or EU Dual-Use Regulation.

– Import Duties and Taxes: Research applicable tariffs, VAT, or GST in the destination country. Some countries offer reduced rates for energy-efficient or agricultural equipment.

– Restricted Destinations: Confirm that the destination country does not restrict imports of mechanical pumps or related components due to trade sanctions or environmental policies.

Engage a licensed customs broker to ensure accurate declaration and timely clearance.

Electrical and Safety Compliance

Misting pumps with electrical components must meet regional safety standards:

– North America: Comply with UL/CSA standards (e.g., UL 499 for heating appliances if integrated, or UL 1017 for commercial refrigeration if used in cooling systems). Ensure adherence to NEC (National Electrical Code) for installation.

– European Union: CE marking is mandatory. Conform to directives such as:

– Low Voltage Directive (LVD) 2014/35/EU

– Electromagnetic Compatibility (EMC) Directive 2014/30/EU

– RoHS Directive 2011/65/EU (restriction of hazardous substances)

– Other Regions: Check local requirements (e.g., UKCA in the UK, CCC in China, PSE in Japan).

Provide multilingual user manuals that include safety warnings, installation instructions, and maintenance protocols.

Packaging and Shipping Requirements

Use robust, environmentally appropriate packaging to prevent damage during transit:

– Secure the pump with anti-vibration materials (e.g., foam inserts or bubble wrap).

– Waterproof packaging if shipping to humid or outdoor environments.

– Clearly label packages with:

– Product name and model

– Handling symbols (e.g., “Fragile,” “This Side Up”)

– Weight and dimensions

– Compliance markings (e.g., CE, UL)

Choose shipping partners experienced in handling mechanical equipment. Consider freight class and insurance based on value and fragility.

Environmental and Sustainability Standards

Comply with environmental regulations affecting production and distribution:

– REACH (EU): Declare substances of very high concern (SVHC) in materials used (e.g., plastics, seals).

– WEEE (EU): Provide take-back or recycling information if the pump includes electronic components.

– Energy Efficiency: Where applicable, comply with energy performance standards (e.g., EU Ecodesign Directive) for motor-driven units.

Optimize logistics to reduce carbon footprint—consolidate shipments, use sea freight over air when possible, and select eco-friendly packaging materials.

After-Sales and Warranty Compliance

Establish a compliance-support structure for post-sale obligations:

– Register products with national databases if required (e.g., energy labeling in EU).

– Offer multilingual customer support and warranty service per regional consumer laws (e.g., 2-year warranty under EU Consumer Rights Directive).

– Maintain records of shipped units for recalls or compliance audits.

Ensure spare parts availability aligns with statutory product lifecycle requirements in key markets.

Conclusion for Sourcing a Misting Pump:

After evaluating various suppliers, product specifications, costs, and performance requirements, it is clear that sourcing a high-quality misting pump requires a balanced approach that considers reliability, efficiency, and long-term value. Key factors such as pump pressure, flow rate, material durability, warranty, and customer support play a critical role in ensuring optimal performance and longevity in applications ranging from agriculture and cooling systems to sanitation and humidification.

Based on comparative analysis, sourcing from reputable manufacturers with proven track records in delivering consistent performance and technical support is recommended. Additionally, prioritizing energy-efficient models with low maintenance requirements can result in significant cost savings over time. It is also advisable to consider suppliers offering customization options and responsive after-sales service to address future needs or challenges.

In conclusion, a strategic sourcing decision—grounded in thorough research, testing, and supplier evaluation—will ensure the acquisition of a reliable and efficient misting pump that meets operational demands while maximizing return on investment.

![[PDF] Misting, Cooling and Fogging Products](https://www.sohoinchina.com/wp-content/uploads/2026/01/pdf-misting-cooling-and-fogging-products-506.jpg)