The global mirror engraving market has experienced steady expansion in recent years, driven by rising demand for personalized home décor, customized promotional products, and advancements in laser engraving technology. According to a report by Mordor Intelligence, the global laser engraving machines market—of which mirror engraving is a niche but growing segment—was valued at approximately USD 1.57 billion in 2022 and is projected to grow at a CAGR of over 6.5% from 2023 to 2028. This growth is fueled by increasing industrial automation, expanding applications in retail and gifting, and greater adoption of precision engraving in small businesses and maker spaces. As consumer preference shifts toward bespoke and sentimental items, mirror engravers have become essential tools for artisans, gift shops, and signage providers. Supported by innovations in CO2 and fiber laser systems, manufacturers are now delivering higher accuracy, faster processing, and improved user interfaces. In this evolving landscape, nine manufacturers have emerged as leaders in quality, reliability, and technological innovation—shaping the future of personalized mirror engraving.

Top 9 Mirror Engraver Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Mirror Engraving

Website: mirror-engraving.com

Key Highlights: Personalised laser engraved mirrors We continually utilize our expertise and knowledge in mirror engraving to create personalized laser-engraved mirrors….

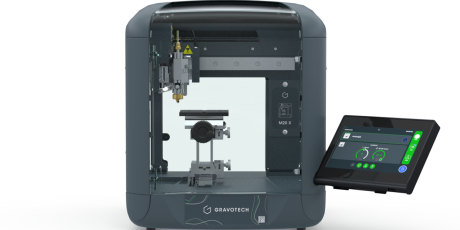

#2 Gravotech

Website: gravotech.us

Key Highlights: Gravotech designs, manufactures, and distributes innovative engraving, marking, and cutting solutions….

#3 Mirror Laser Engraving

Website: brmlasers.com

Key Highlights: Engraving mirrors with a laser machine from BRM – Engraving with an accuracy of up to 0.1 mm ✓ Ideal for personalization ✓ Finishing not required….

#4 Laser engraving on mirror

Website: endurancelasers.com

Key Highlights: Laser engraving on mirror . Mirror review working with a mirror using an endurance laser has been a good test. before I had a Chinese laser ……

#5 Laser Engraving Mirror

Website: troteclaser.com

Key Highlights: Decorate your mirror with a personal or ornamental engraving decoration as a customized piece. We show you how to do it….

#6 Laser Engraving Mirrors with TYKMA Electrox Systems

Website: permanentmarking.com

Key Highlights: TYKMA Electrox provides compact workstations equipped with the capabilities of laser engraving mirrors and mirror glass for your ……

#7 Understanding Laser Engraving on Mirrors

Website: thunderlaser.com

Key Highlights: Laser engraving involves directing a concentrated laser beam onto a material’s surface to remove layers and create a predetermined design….

#8 Laser Engraving Glass Mirror

Website: cutlasercut.com

Key Highlights: Your supply for laser engraving only. We do not hold stock of any glass material you will need to supply. Thickness: Machine holds any thickness up to 330mm….

#9 OMTech Laser

Website: omtech.com

Key Highlights: Turn your creative dreams into reality with our laser engraving and cutting machines, from desktop CO2 lasers to fiber lasers, which are perfect for ……

Expert Sourcing Insights for Mirror Engraver

2026 Market Trends for Mirror Engraver: A H2 Analysis

The “Mirror Engraver” market in 2026 is poised for significant growth and transformation, driven by evolving consumer preferences, technological advancements, and expanding applications. This analysis, focusing on the second half (H2) of 2026, highlights key trends shaping the industry.

1. H2 2026: Dominance of Personalization & Emotional Gifting

- Trend: Personalized gifts will solidify their position as the primary driver of Mirror Engraver demand. Consumers increasingly seek unique, meaningful items over generic presents, especially for milestones (weddings, anniversaries, graduations, retirements, baby showers).

- H2 Impact: The back-to-school season and the crucial holiday gifting period (Q4) will create peak demand. Engravers will focus on offering faster turnaround times, diverse font/quote options, and seamless online customization platforms to capitalize on this surge. Sentimental value (“memory preservation”) will be a core marketing message.

2. H2 2026: Integration of Smart Technology & Enhanced Features

- Trend: The market will move beyond basic engraving. Integration with smart home ecosystems and enhanced functionalities will become key differentiators.

- H2 Impact: Expect wider adoption of features like:

- Built-in LED Lighting: Color-changing, dimmable LEDs for ambiance (popular for bathrooms and bedrooms).

- Touchless Activation: Motion sensors for turning on lights or displays.

- Integrated Displays: Small screens showing time, weather, or custom messages alongside the engraved text.

- App Connectivity: Allowing users to change LED colors, messages, or lighting modes via smartphone apps.

- H2 Focus: Marketing will emphasize convenience, modern aesthetics, and the “wow factor” of these tech-enhanced mirrors, particularly targeting younger demographics and tech-savvy consumers during holiday shopping.

3. H2 2026: Expansion into Commercial & Hospitality Sectors

- Trend: Beyond residential use, Mirror Engravers will see growing adoption in commercial spaces.

- H2 Impact: Businesses (salons, spas, gyms, hotels, corporate offices) will utilize engraved mirrors for:

- Branding: Subtle logos or mottos.

- Wayfinding: Engraved room names or directions in high-end lobbies.

- Ambiance & Luxury: Creating a sophisticated, personalized guest experience (e.g., engraved mirrors in hotel suites with welcome messages).

- Motivational Spaces: Gyms and offices using inspirational quotes.

- H2 Opportunity: B2B sales channels and partnerships with interior designers/facility managers will become increasingly important for manufacturers and suppliers.

4. H2 2026: Sustainability & Material Innovation

- Trend: Consumer and regulatory pressure for sustainable practices will intensify.

- H2 Impact: Key developments include:

- Eco-Friendly Materials: Increased use of recycled glass, sustainably sourced wood for frames, and low-VOC adhesives.

- Energy Efficiency: Focus on low-power LED options and efficient manufacturing processes.

- Durability & Longevity: Marketing will emphasize high-quality, long-lasting products as inherently sustainable (countering fast furniture trends).

- Recyclability: Clear communication about end-of-life disposal/recycling options.

- H2 Focus: Sustainability claims will be a major competitive advantage, especially appealing to environmentally conscious millennials and Gen Z during holiday purchases.

5. H2 2026: E-commerce Optimization & Omnichannel Experience

- Trend: Online customization and direct-to-consumer (D2C) sales will remain dominant, but seamless omnichannel experiences will be critical.

- H2 Impact:

- Advanced Online Design Tools: AI-powered mockups, 3D previews, and easier quote/font selection will reduce friction and increase conversion rates for holiday shoppers.

- Faster & More Transparent Shipping: Guaranteed delivery times for holiday deadlines will be essential. Real-time tracking is expected.

- Hybrid Models: Pop-up shops in malls or partnerships with physical retailers (e.g., home goods stores) offering instant engraving or display units, bridging online and offline.

- Personalized Marketing: Targeted email/SMS campaigns for gifting reminders and holiday promotions.

- H2 Focus: The efficiency and user-friendliness of the online ordering and fulfillment process will be paramount during the peak H2 sales season.

6. H2 2026: Niche Specialization & Premiumization

- Trend: The market will further fragment, with growth in specialized and high-end segments.

- H2 Impact:

- Specialized Engraving: Focus on specific niches like luxury automotive mirrors (custom nameplates), high-end bathroom vanities (architectural integration), or bespoke art pieces.

- Premium Materials & Craftsmanship: Use of artisan glass, hand-finished frames, complex engraving techniques (e.g., deep etching, color infill), commanding higher price points.

- Luxury Gifting: Positioned as premium, high-value gifts for corporate clients or discerning individuals.

- H2 Focus: Marketing will target affluent consumers seeking exclusivity and superior quality, particularly for high-margin holiday gifts.

Conclusion for H2 2026

The Mirror Engraver market in the second half of 2026 will be characterized by heightened demand driven by gifting seasons, accelerated by technological integration, and shaped by sustainability and personalization. Success will depend on:

1. Seamlessly meeting peak holiday demand through efficient e-commerce and logistics.

2. Offering compelling tech-enhanced features that go beyond basic engraving.

3. Embracing sustainability as a core value proposition.

4. Expanding beyond residential into commercial and hospitality applications.

5. Catering to both mass-market personalization and emerging premium niches.

Manufacturers, retailers, and service providers who proactively address these H2 2026 trends, particularly the convergence of personalization, technology, and sustainability during the critical holiday period, are best positioned for significant growth.

Common Pitfalls Sourcing a Mirror Engraver (Quality, IP)

Poor Build Quality and Material Standards

Many low-cost mirror engravers, especially those sourced from less-regulated markets, suffer from subpar construction. This includes the use of inferior metals, weak laser components, and inadequate cooling systems. Such flaws lead to inconsistent engraving depth, reduced precision, and higher failure rates over time. Buyers often underestimate how these quality shortcomings can impact production reliability and maintenance costs.

Inaccurate or Inconsistent Engraving Performance

Low-quality mirror engraving systems may lack proper calibration or use unstable galvanometer scanners, resulting in distorted or misaligned engravings. This inconsistency is particularly problematic for high-precision applications such as medical devices or luxury goods, where branding and traceability depend on sharp, repeatable marks. Performance issues may not be apparent during initial testing but emerge under sustained use.

Lack of Intellectual Property Protection

Sourcing mirror engravers from regions with weak IP enforcement can expose companies to legal and reputational risks. Some manufacturers may incorporate copied firmware, cloned control software, or patented optical designs without authorization. Using such equipment could inadvertently involve your business in IP infringement claims, especially when producing commercial goods for regulated or competitive markets.

Hidden Costs from Non-Compliant Components

Budget engravers might use uncertified electrical components or lasers that do not meet international safety standards (e.g., FDA, CE, IEC). This not only poses safety hazards but may invalidate insurance coverage or prevent equipment use in certain countries. Compliance gaps often go unnoticed until audit or installation, leading to unexpected retrofitting or replacement expenses.

Limited Technical Support and Spare Parts Availability

Many overseas suppliers offer minimal after-sales support, with delayed response times and unavailability of critical spare parts like galvo mirrors or laser tubes. This can result in extended machine downtime and lost productivity. Unlike reputable brands, these vendors rarely provide firmware updates or calibration tools, making long-term maintenance a significant challenge.

Risk of Counterfeit or “Gray Market” Equipment

Some suppliers rebrand or resell used or refurbished systems as new, with tampered serial numbers or falsified certifications. Without proper due diligence, buyers may receive outdated technology or equipment nearing end-of-life. This undermines expected ROI and increases vulnerability to premature obsolescence or performance degradation.

Logistics & Compliance Guide for Mirror Engraver

This guide outlines key logistics and compliance considerations for businesses involved in the production, sale, and distribution of engraved mirrors. Adhering to these guidelines ensures smooth operations, legal compliance, and customer satisfaction.

Product Safety & Labeling Compliance

Ensure all engraved mirrors meet applicable safety standards, particularly regarding glass integrity and sharp edges. Use safety-backed or tempered glass to reduce breakage risks. Clearly label products with required information such as manufacturer details, country of origin, material composition, and any relevant safety warnings (e.g., “Fragile,” “Keep out of reach of children”). Comply with regional regulations like the U.S. Consumer Product Safety Commission (CPSC) guidelines or the EU’s General Product Safety Directive.

Packaging & Shipping Standards

Design packaging to securely protect engraved mirrors during transit. Use rigid outer boxes, interior cushioning (e.g., foam, bubble wrap), and edge protectors to prevent cracking or chipping. Clearly mark packages as “Fragile” and “This Side Up.” Follow carrier-specific requirements for weight, dimensions, and labeling. Consider using insured shipping methods, especially for high-value or custom pieces.

Import/Export Regulations

If manufacturing or selling internationally, comply with import/export regulations. Accurately classify engraved mirrors using Harmonized System (HS) codes—typically under glass products (e.g., 7004–7006 series). Maintain proper documentation, including commercial invoices, packing lists, and certificates of origin. Be aware of tariffs, duties, and restrictions in target markets. Ensure all engravings (e.g., logos, text) do not infringe on intellectual property or violate cultural sensitivities.

Intellectual Property & Design Compliance

Verify that all designs, logos, or text used in mirror engraving do not infringe on trademarks, copyrights, or patents. Obtain proper licensing for branded or licensed content. Maintain records of design permissions and usage rights. Implement internal review processes to screen customer-submitted designs for potential IP violations.

Environmental & Workplace Safety

Comply with environmental regulations related to engraving processes, such as proper disposal of glass dust and chemical etching byproducts. Use ventilation systems and personal protective equipment (PPE) to protect workers from airborne particles. Follow OSHA (U.S.) or equivalent local workplace safety standards for machinery operation, noise exposure, and chemical handling.

Data Privacy & Customer Information

If offering custom engraving services online, protect customer data in compliance with privacy laws such as GDPR (EU) or CCPA (California). Securely store personal information, engraving details, and payment data. Clearly communicate your privacy policy and obtain consent where required. Limit data retention to what is necessary for order fulfillment and legal obligations.

Return, Warranty & Liability Policies

Establish clear return, exchange, and warranty policies that align with consumer protection laws. Given the custom nature of engraved mirrors, clearly state whether personalized items are returnable. Include disclaimers where appropriate and maintain liability insurance to cover potential product defect claims or shipping damages.

By following this logistics and compliance framework, Mirror Engraver businesses can operate efficiently, minimize legal risks, and build trust with customers and partners globally.

Conclusion for Sourcing a Mirror Engraver

After thorough evaluation of potential suppliers, technical capabilities, cost structures, and lead times, sourcing a mirror engraver requires a balanced approach between quality, precision, and affordability. Laser engraving technology has proven to be the most efficient and accurate method for creating high-quality engravings on mirrored surfaces, offering consistency and design flexibility. Key factors in selecting a reliable engraver include the supplier’s experience with reflective materials, equipment specifications (such as laser power and software compatibility), and their ability to meet production deadlines.

Additionally, considerations such as post-processing finishes, minimum order quantities, and customer support play a significant role in long-term partnership viability. For custom or bulk applications—whether for decorative, promotional, or industrial purposes—choosing a supplier that combines technical expertise with responsive service ensures optimal results.

In conclusion, the ideal mirror engraver should offer precision craftsmanship, scalable production capacity, and competitive pricing, supported by strong references and a proven track record. Conducting pilot orders and requesting sample engravings are recommended final steps before full-scale procurement to confirm quality and alignment with project requirements.