The global miniature solenoid valve market is experiencing robust growth, driven by increasing demand across industries such as medical devices, automation, automotive, and industrial machinery. According to a 2023 report by Mordor Intelligence, the global solenoid valve market is projected to grow at a CAGR of 6.8% from 2023 to 2028, with miniature variants gaining prominence due to their compact design, energy efficiency, and precision control capabilities. Grand View Research further supports this trend, estimating the solenoid valve market to surpass USD 11.5 billion by 2030, fueled by advancements in smart manufacturing and the miniaturization of fluid control systems. As industries continue to prioritize space-saving and high-performance components, miniature solenoid valves have become critical enablers of innovation. This growing demand has spurred intense competition and technological refinement among manufacturers worldwide. Below, we highlight the top 10 miniature solenoid valve manufacturers shaping this evolving landscape through engineering excellence, product reliability, and strategic market reach.

Top 10 Miniature Solenoid Valve Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Miniature Solenoid Valve

Domain Est. 1995

Website: gemssensors.com

Key Highlights: The AG Series valves are ideal for general purpose applications up to 1,000 psi (69 bar) such as medical, food processing, automotive and industrial ……

#2 Discover Festo Solenoid Valves

Domain Est. 1997

Website: festo.com

Key Highlights: Explore Festo’s solenoid valves for reliable pneumatic control, featuring compact designs and IP65 protection. Discover our industrial solutions today!…

#3 Solenoid Valves

Domain Est. 2006

Website: solenoidsolutionsinc.com

Key Highlights: Solenoid Solutions offers miniature, subminiature, high capacity and low wattage or low power solenoid valves. Below are descriptions and diagrams of 2-way ……

#4 Miniature Valves

Domain Est. 1995

Website: discreteautomation.emerson.com

Key Highlights: We provide a wide range of general service and highly customizable miniature valves with exceptional service lifetimes. They can function well when working ……

#5 Solenoid Valves

Domain Est. 1995

Website: ph.parker.com

Key Highlights: We can supply a superior array of solenoid valve solutions, covering a wide selection of function and material types. Our solenoid valve family of products ……

#6 Air Cylinders, Solenoid Valves and Pneumatics

Domain Est. 1995

Website: smcusa.com

Key Highlights: LPV series is a 2-port solenoid normally closed or normally open pinch valve for fluid control. The LPV series pinch valve also comes with a u-shaped tube slot ……

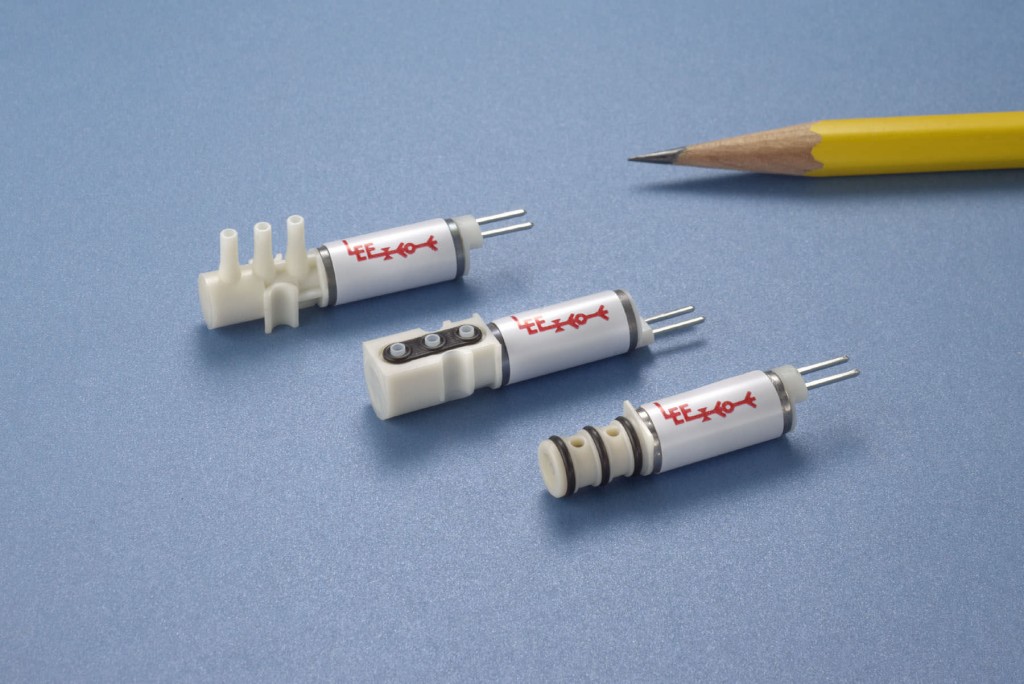

#7 Miniature Solenoid Valves

Domain Est. 1996

Website: theleeco.com

Key Highlights: Reliable 2-way and 3-way miniature solenoid valves for air or liquid applications ranging from low power medical diagnostics to high pressure hydraulics….

#8 Miniature Solenoid Valves

Domain Est. 1996

Website: marotta.com

Key Highlights: Marotta Controls’ miniature solenoid valves deliver high performance in demanding applications. Click to learn more about our product line….

#9 Custom Solenoids and Valve Solutions

Domain Est. 1999

Website: tlxtech.com

Key Highlights: Miniature Solenoid Air Valve. This example of an ultra small solenoid air valve is suitable for a variety of low pressure applications….

#10 Miniature Solenoid Valves

Domain Est. 2004

Website: ipolymer.com

Key Highlights: Our iPolymer Miniature Solenoid Valves are electromechanically operated valves available with a 2-Way or 3-Way design….

Expert Sourcing Insights for Miniature Solenoid Valve

2026 Market Trends for Miniature Solenoid Valves: Key Drivers and Projections

The miniature solenoid valve market is poised for significant growth and transformation by 2026, driven by advancing technologies, evolving industrial demands, and emerging applications. Here are the critical trends shaping the landscape:

H2: Rising Demand in Medical and Life Sciences Applications

The healthcare and life sciences sector remains the primary growth engine for miniature solenoid valves. By 2026, increasing miniaturization of medical devices—such as portable diagnostic equipment, wearable drug delivery systems, dialysis machines, and lab-on-a-chip systems—will necessitate compact, reliable, and precisely controllable fluid handling components. The demand for valves with biocompatible materials (e.g., PEEK, medical-grade stainless steel), low power consumption, and high cycle life will intensify. Additionally, the expansion of point-of-care testing and home healthcare solutions will further fuel adoption, driving innovation in valve design for safety, sterility, and ease of integration.

H2: Advancements in Automation and Industry 4.0 Integration

The global push toward smart manufacturing and Industry 4.0 is accelerating the adoption of miniature solenoid valves in automated systems. These valves are critical in robotics, precision fluid dispensing, pneumatic control, and sensor-actuator networks. By 2026, integration with IoT platforms and digital twins will become standard, requiring valves with embedded sensors for real-time monitoring of pressure, flow, temperature, and valve status. Demand for digital communication protocols (e.g., IO-Link, Modbus) will grow, enabling predictive maintenance, remote diagnostics, and seamless connectivity within smart factories.

H2: Growth in Electric Vehicles and Battery Manufacturing

The electric vehicle (EV) revolution is creating new opportunities for miniature solenoid valves in thermal management systems, battery cooling circuits, and fuel cell applications. As EV production scales through 2026, manufacturers will require valves that are compact, corrosion-resistant, and capable of operating in harsh environments. Similarly, in battery manufacturing, precision fluid control during electrolyte filling and cell formation processes demands highly reliable miniature valves, supporting market expansion in the energy storage sector.

H2: Emphasis on Energy Efficiency and Miniaturization

With global focus on sustainability and energy conservation, valve manufacturers are prioritizing low-power designs and energy-efficient actuation mechanisms. By 2026, expect widespread adoption of latching solenoid valves that consume power only during switching, significantly reducing energy usage in battery-operated and portable devices. Concurrently, ongoing miniaturization trends—enabled by advanced materials and micro-machining techniques—will allow valves to fit into increasingly compact systems without sacrificing performance or durability.

H2: Regional Market Shifts and Supply Chain Resilience

Asia-Pacific, particularly China, Japan, and South Korea, will continue to dominate both production and consumption due to strong electronics, automotive, and medical device manufacturing. However, geopolitical factors and supply chain disruptions may drive diversification, with increased investment in regional manufacturing hubs in North America and Europe. By 2026, companies will prioritize supply chain resilience, leading to localized production and strategic partnerships to mitigate risks and ensure component availability.

In summary, the 2026 miniature solenoid valve market will be defined by innovation in medical technology, integration with smart systems, expansion into green energy applications, and a relentless focus on efficiency and reliability—positioning the industry for sustained, high-value growth.

Common Pitfalls When Sourcing Miniature Solenoid Valves (Quality & IP Rating)

Sourcing miniature solenoid valves requires careful attention to both quality and Ingress Protection (IP) ratings to ensure reliable performance and longevity in the intended application. Overlooking key factors can lead to premature failure, safety hazards, or system downtime. Below are common pitfalls to avoid:

1. Prioritizing Cost Over Quality

One of the most frequent mistakes is selecting the lowest-cost option without evaluating build quality. Cheap valves may use inferior materials (e.g., low-grade seals, weak coil insulation, or non-corrosion-resistant bodies), leading to:

- Shorter operational lifespan

- Leakage due to seal degradation

- Coil burnout under continuous duty

- Inconsistent response times

Always assess the manufacturer’s reputation, material specifications, and certifications (e.g., ISO, RoHS) rather than focusing solely on price.

2. Misinterpreting or Overlooking IP Ratings

The IP (Ingress Protection) rating defines a valve’s resistance to dust and moisture. A common pitfall is assuming a higher IP rating is always necessary—or conversely, selecting a valve with inadequate protection.

- Too Low IP Rating: Using an IP65 valve in a washdown environment (requiring IP67/IP69K) can result in water ingress, short circuits, or corrosion.

- Over-Specifying: Choosing IP69K for a dry, indoor application increases cost unnecessarily and may limit valve size or availability.

Always match the IP rating to the actual environmental conditions (e.g., humidity, water jets, dust levels) as defined by IEC 60529.

3. Assuming All “Miniature” Valves Are Interchangeable

Miniature solenoid valves vary widely in dimensions, port sizes, and mounting configurations. Sourcing a valve without verifying:

- Exact footprint and installation space

- Port thread type (e.g., NPT, G, M)

- Flow path orientation (in-line, 90°)

- Voltage and power compatibility

…can lead to fitment issues or performance mismatches in the system.

4. Neglecting Media Compatibility

Many buyers focus only on electrical and mechanical specs while ignoring fluid compatibility. Using a valve with incompatible seals (e.g., NBR with aggressive solvents) or body material (e.g., brass with ammonia) can cause:

- Swelling or degradation of seals

- Corrosion of internal components

- Blockages or contamination

Always verify the valve’s wetted materials against the media being controlled, including any additives or impurities.

5. Overlooking Duty Cycle and Thermal Management

Miniature solenoid valves are often used in high-frequency applications. A common mistake is selecting a valve rated only for intermittent duty (e.g., 10%) for continuous operation. This leads to:

- Coil overheating

- Reduced magnetic force

- Premature coil failure

Ensure the valve’s duty cycle and thermal class (e.g., Class F insulation) match the application’s operational demands.

6. Inadequate Validation of Supplier Claims

Some suppliers may list inflated or unverified IP ratings or performance specs. Always request:

- Third-party test reports

- Sample testing under real-world conditions

- References or case studies

Avoid vendors who cannot provide documentation or technical support.

By addressing these pitfalls early in the sourcing process, you can ensure the selected miniature solenoid valve delivers reliable, long-term performance in its intended environment.

Logistics & Compliance Guide for Miniature Solenoid Valves

This guide provides essential information for the safe, efficient, and compliant handling, transportation, storage, and regulatory adherence related to miniature solenoid valves throughout the supply chain.

Product Classification & Identification

Miniature solenoid valves are electromechanical devices used to control the flow of fluids (liquids or gases) in compact systems. Typically constructed from brass, stainless steel, or engineered plastics with copper windings, these valves are classified under:

– HS Code (Harmonized System): 8537.10 (Electrical apparatus for switching or protecting electrical circuits… for a voltage ≤ 1,000 V) or 8481.80 (Valves of other kinds, for pipes, boiler shells, tanks, vats or the like), depending on function and design.

– UN Number: Not typically hazardous; no UN number required unless containing pressurized components (verify per configuration).

– Proper Shipping Name: “Non-hazardous machinery parts” or “Electromechanical components” (non-regulated).

Packaging Requirements

Ensure miniature solenoid valves are protected against mechanical shock, moisture, and electrostatic discharge (ESD):

– Use anti-static packaging (e.g., pink poly bags or conductive foam) for ESD-sensitive components.

– Secure valves in rigid inner packaging (e.g., blister packs or molded trays) to prevent movement.

– Outer packaging must be strong corrugated cardboard boxes with adequate cushioning (foam inserts, bubble wrap).

– Seal packages to prevent dust and moisture ingress.

– Label packages clearly with product name, part number, quantity, and handling symbols (e.g., “Fragile,” “This Side Up”).

Storage Conditions

Store valves in a controlled indoor environment to maintain performance and shelf life:

– Temperature: 5°C to 40°C (41°F to 104°F)

– Relative Humidity: 30% to 70% (non-condensing)

– Environment: Clean, dry, and free of corrosive gases or dust.

– Position: Store in original packaging, upright if specified by manufacturer.

– Shelf Life: Typically 2–5 years; verify with manufacturer datasheet. Avoid long-term storage near magnetic fields or strong EMI sources.

Transportation Guidelines

- Modes: Suitable for air, sea, and ground freight (non-hazardous classification facilitates shipment).

- Handling: Avoid dropping, stacking beyond recommended limits, or exposure to extreme temperatures.

- Documentation: Include commercial invoice, packing list, and bill of lading. For international shipments, ensure accurate HS code declaration.

- Special Considerations: If valves contain small magnets or rare-earth materials, comply with carrier-specific rules (e.g., IATA for air freight regarding magnetic fields).

Regulatory Compliance

Ensure adherence to international and regional regulations:

– RoHS (EU Directive 2011/65/EU): Compliant with restrictions on hazardous substances (Pb, Cd, Hg, etc.). Confirm via supplier declaration.

– REACH (EC 1907/2006): No SVHCs (Substances of Very High Concern) above threshold levels. Supplier SDS available upon request.

– WEEE (2012/19/EU): Mark products with crossed-out wheeled bin symbol if applicable; ensure end-of-life take-back compliance.

– CE Marking: Required for EU market; confirms conformity with relevant directives (e.g., EMC, LVD).

– UKCA Marking: Required for UK market (post-Brexit); similar requirements to CE.

– FCC (USA): Electromagnetic compatibility compliance may be required if integrated into devices (verify based on end-use).

– China RoHS: Labeling required if containing restricted substances.

Export Controls

- EAR99 (U.S. Export Administration Regulations): Most miniature solenoid valves fall under EAR99 (low-risk, non-controlled items).

- ITAR/USML: Not applicable unless designed for defense or aerospace applications.

- Dual-Use Considerations: Verify if valves are intended for use in regulated industries (e.g., nuclear, chemical processing) which may trigger export licensing.

Documentation & Traceability

Maintain full traceability through:

– Batch/lot numbers on packaging and labels.

– Certificate of Conformity (CoC) for RoHS, REACH, and CE/UKCA.

– Material Declaration (e.g., IPC-1752 standard).

– Product datasheets and technical specifications.

– Importers must retain compliance documentation for a minimum of 10 years (EU requirement).

End-of-Life & Environmental Responsibility

- Do not dispose of in regular waste.

- Follow WEEE or local e-waste regulations for recycling.

- Partner with certified electronic waste recyclers.

- Inform customers of proper disposal channels.

Summary

Miniature solenoid valves are generally low-risk for logistics and compliance when properly packaged and documented. Key focus areas include ESD protection, environmental storage, accurate HS coding, and adherence to RoHS, REACH, and regional marking requirements (CE/UKCA). Always consult manufacturer specifications and update compliance status regularly to reflect regulatory changes.

Conclusion on Sourcing Miniature Solenoid Valves

After a thorough evaluation of potential suppliers, technical specifications, and cost considerations, it is evident that sourcing miniature solenoid valves requires a balanced approach that prioritizes reliability, performance, and long-term value. Key factors such as size compatibility, operating voltage, flow rate, pressure rating, media compatibility, and durability must align with the application requirements to ensure optimal functionality.

Multiple suppliers from both domestic and international markets offer competitive products, with Asian manufacturers often providing cost-effective solutions, while European and North American suppliers tend to emphasize high precision and certifications for demanding industries such as medical, laboratory automation, and aerospace.

For high-reliability applications, partnering with suppliers possessing ISO certifications, robust quality control processes, and proven technical support is recommended. Additionally, considering sample testing, minimum order quantities, lead times, and after-sales service is essential to mitigate risks and ensure supply chain continuity.

In conclusion, the most effective sourcing strategy involves identifying 2–3 pre-qualified suppliers capable of meeting technical and quality standards, followed by pilot procurement and performance assessment. This approach ensures a scalable, reliable supply of miniature solenoid valves that support product performance and operational efficiency.