The global mini articulating loader market is experiencing robust growth, driven by rising demand for compact, versatile equipment across construction, landscaping, and agricultural sectors. According to Mordor Intelligence, the Compact Loader Market — which includes mini articulating loaders — was valued at USD 8.12 billion in 2023 and is projected to grow at a CAGR of 5.8% from 2024 to 2029. This growth is fueled by increasing urbanization, infrastructure development, and the need for equipment capable of operating in confined spaces with high efficiency. Technological advancements such as improved hydraulics, enhanced fuel efficiency, and integration of smart controls are further accelerating adoption. As demand intensifies, leading manufacturers are focusing on innovation, durability, and machine versatility to capture a competitive edge. In this evolving landscape, the top 10 mini articulating loader manufacturers stand out for their product performance, global reach, and engineering excellence.

Top 10 Mini Articulating Loader Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Miniloaders.com

Domain Est. 2004 | Founded: 1997

Website: miniloaders.com

Key Highlights: Our Intrepid™ mini articulating loaders are built by Belgian manufacturer Knikmops, a family-owned company building high-quality wheel-loaders since 1997….

#2 Articulated loader

Domain Est. 1993

Website: manitou.com

Key Highlights: Check out the full range of Manitou articulated loaders: wheel loaders, compact and articulated loaders, front loaders, site loaders ……

#3 Gehl

Domain Est. 1995

Website: gehl.com

Key Highlights: We proudly design, build, test and manufacture machines that WORKS LIKE YOU. Dating back to 1859, GEHL has been deeply rooted in agriculture….

#4 Vermeer Mini Articulated Loaders

Domain Est. 1996

Website: vermeer.com

Key Highlights: Vermeer articulated loaders are designed to be highly maneuverable and versatile for your landscaping needs. Learn more about these mini compact loaders ……

#5 Articulated AVANT loaders

Domain Est. 1997

Website: avanttecno.com

Key Highlights: Today, Avant manufactures over 200 different attachments suitable for countless applications and we continue developing them with our customers….

#6 Compact Wheel Loaders

Domain Est. 1997

Website: bobcat.com

Key Highlights: Bobcat compact wheel loaders deliver performance, comfort and versatility to power through tough jobs. View photos, compare specs, and see models….

#7 ML22X Small Articulated Loader

Domain Est. 1997

Website: construction.newholland.com

Key Highlights: Introducing the ML22X – New Holland’s first electric Small Articulated Loader. This ultra compact machine carries zero emissions to safely operate indoors ……

#8 Multione

Domain Est. 2002

Website: multione.com

Key Highlights: Multione. Your top partner on mini-loaders. MultiOne is a leading Italian company in the design and production of compact machines and multifunctional loaders….

#9 Cast Group

Domain Est. 2008

Website: cast-group.it

Key Highlights: We manufacture small and medium-sized articulated and skid steer mini loaders that can help you with all your work!…

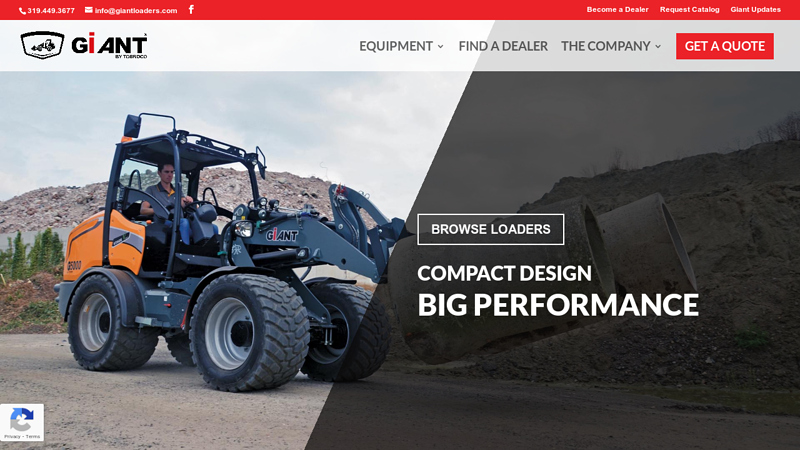

#10 Giant Loaders

Domain Est. 2019

Website: giantloaders.com

Key Highlights: Versatile and durable mini wheel loaders and compact loaders purpose built for construction, ag, snow removal and the tree care industries….

Expert Sourcing Insights for Mini Articulating Loader

H2: 2026 Market Trends for Mini Articulating Loaders

The mini articulating loader (MAL) market is poised for significant evolution by 2026, driven by technological innovation, shifting labor dynamics, and growing demand across diverse end-use sectors. These compact, highly maneuverable machines are increasingly favored in construction, landscaping, agriculture, and municipal applications due to their versatility in tight spaces and ability to handle a wide range of attachments.

One of the dominant trends shaping the 2026 outlook is the accelerating integration of electrification and hybrid power systems. As environmental regulations tighten—especially in North America and Europe—equipment manufacturers are prioritizing the development of electric mini articulating loaders to meet emissions standards and appeal to sustainability-focused contractors. Battery technology improvements are expected to enhance runtime and reduce charging times, making electric models more viable for full-day operations.

Automation and smart technology are also gaining traction. By 2026, an increasing number of MALs will feature telematics, remote monitoring, and predictive maintenance capabilities. These digital tools allow fleet managers to track machine utilization, optimize performance, and reduce downtime. Some advanced models may begin incorporating semi-autonomous functions, such as automated attachment changes or path guidance, particularly in controlled environments like indoor construction or warehouse logistics.

Another key trend is the expansion of the attachment ecosystem. Manufacturers are investing in modular designs that support quick-connect systems for hundreds of attachments—from augers and brooms to forks and snowblowers. This versatility enhances return on investment for owners, especially in multi-application businesses, and expands market reach into niche applications such as vineyard maintenance and urban infrastructure repair.

Geographically, North America and Western Europe will continue to lead adoption due to high construction activity, mature rental markets, and strong regulatory support for cleaner machinery. Meanwhile, Asia-Pacific, particularly China and India, is expected to see robust growth as urbanization and infrastructure investment accelerate, creating new demand for compact, agile equipment suited to congested job sites.

Finally, the rental and subscription-based equipment model is expected to grow in popularity by 2026. Smaller contractors and DIY users are increasingly turning to rental services to access advanced MALs without the upfront capital cost. Equipment-as-a-Service (EaaS) offerings, which bundle maintenance and upgrades, are likely to reshape how mini articulating loaders are consumed, especially among tech-savvy users.

In summary, the 2026 mini articulating loader market will be defined by electrification, digital integration, enhanced versatility, and evolving ownership models, positioning these machines as indispensable tools in modern worksite operations.

Common Pitfalls When Sourcing a Mini Articulating Loader (Quality, IP)

Sourcing a mini articulating loader can be a cost-effective solution for tight spaces and versatile material handling. However, buyers often encounter several pitfalls—particularly related to quality and ingress protection (IP) ratings—that can compromise performance, safety, and longevity. Being aware of these issues helps ensure a reliable and durable investment.

1. Overlooking Build Quality and Material Durability

One of the most common mistakes is selecting a mini articulating loader based solely on price or appearance, without evaluating the actual build quality. Low-cost models may use inferior steel, thin welds, or substandard hydraulics, leading to premature wear or structural failure.

- Thin-gauge frames may flex under load, reducing precision and safety.

- Poor welding increases the risk of cracks and breakdowns.

- Low-quality hydraulic components can leak or fail under pressure.

Always inspect for robust construction, reputable manufacturers, and third-party certifications.

2. Ignoring Ingress Protection (IP) Ratings

The IP rating indicates how well the loader’s electrical and mechanical components are protected against dust and water. In harsh environments (e.g., construction sites, farms, or wet conditions), overlooking IP ratings can lead to:

- Electrical failures due to moisture ingress.

- Sensor malfunctions from dust accumulation.

- Corrosion in control units or wiring.

Ensure the loader meets at least IP65 (dust-tight and protected against water jets) for outdoor or industrial use. Lower ratings like IP54 may not suffice in demanding conditions.

3. Assuming All “Compact” Loaders Are Suitable for Tight Spaces

While marketed as mini or compact, some models still require significant clearance. Buyers often fail to verify turning radius, overall dimensions, and lift path—leading to inefficiencies in confined areas.

- Measure access points and operating zones before committing.

- Verify zero-radius turning or near-true articulation capabilities.

4. Skimping on After-Sales Support and Spare Parts Availability

Even high-quality loaders require maintenance. Sourcing from manufacturers or suppliers with poor customer support or limited spare parts can result in extended downtime.

- Confirm availability of common replacement parts (hoses, seals, filters).

- Check for local service networks or technical support.

5. Misjudging Load Capacity and Stability

Some mini loaders advertise high lift capacities but may become unstable when fully extended or on uneven terrain. Always verify:

- Rated operating capacity (ROC) under real-world conditions.

- Stability on slopes and with attachments.

- Center of gravity changes when lifting at full height.

6. Neglecting Compatibility with Attachments

Mini articulating loaders are valued for their versatility. However, not all quick-attach systems are universal.

- Confirm compatibility with common attachments (buckets, augers, brooms).

- Check if the hydraulic flow rate supports high-demand tools.

Conclusion

To avoid these pitfalls, prioritize quality construction, verify IP ratings for your operating environment, and partner with reputable suppliers who offer strong support and transparent specifications. Investing time upfront ensures a durable, safe, and efficient mini articulating loader that meets your operational needs.

Logistics & Compliance Guide for Mini Articulating Loader

Product Overview

The Mini Articulating Loader (MAL) is a compact, versatile machine designed for maneuverability in confined spaces. It combines lifting, digging, and material handling capabilities, making it ideal for construction, landscaping, and agricultural applications. Proper logistics planning and regulatory compliance are essential for safe and legal operation and transport.

Transportation & Handling

Ensure the MAL is securely transported using a flatbed trailer or lowboy with appropriate tie-down points. Use rated straps or chains (minimum 4-point securement) to prevent shifting during transit. Verify that the machine is turned off, keys removed, and attachments are lowered and secured. Confirm weight and dimensions comply with road transport regulations in your region.

Weight & Dimensions

- Operating Weight: Typically 3,000–5,000 lbs (1,360–2,268 kg)

- Length (with bucket): Approx. 10–12 ft (3–3.7 m)

- Width: Approx. 5–6 ft (1.5–1.8 m)

- Height (bucket up): Up to 10 ft (3 m)

Verify local transport laws for width, height, and weight restrictions. Oversized loads may require permits or pilot vehicles.

Import & Export Compliance

When shipping internationally, ensure compliance with customs regulations:

– Provide accurate HS (Harmonized System) code (e.g., 8429.52 for self-propelled bulldozers, graders, and similar machinery).

– Include a commercial invoice, packing list, and bill of lading.

– Confirm CE marking (for EU), EPA and CARB emission compliance (for USA), or other regional certifications.

– Address potential import duties, VAT, and local safety standards.

Emissions & Environmental Regulations

The MAL must meet applicable emission standards:

– United States: EPA Tier 4 Final compliance for diesel engines.

– European Union: Stage V emission standards.

– California: Additional CARB certification may be required.

Ensure emission labels are visible and documentation is available for inspection.

Operator Certification & Safety

- Operators must be trained and certified per OSHA (29 CFR 1926.600/602) in the U.S. or equivalent local regulations.

- Conduct pre-operational inspections (fluids, tires, hydraulic systems, lights).

- Use seat belts, and maintain safe distances from drop-offs, trenches, and overhead obstacles.

- Follow lockout/tagout (LOTO) procedures during maintenance.

Noise & Vibration Compliance

Ensure the MAL meets noise emission standards (e.g., ISO 6395 for earth-moving machinery). Typical sound pressure levels should not exceed 80–85 dB(A) at the operator’s position. Provide hearing protection if operating in enclosed or prolonged noisy environments.

Regional Compliance Considerations

- North America: Comply with ANSI/SAE Z245.1 safety standards for mobile equipment.

- European Union: Adhere to Machinery Directive 2006/42/EC; CE marking mandatory.

- Australia/NZ: Meet AS/NZS 474.1 standards for safety of earth-moving machinery.

- Other Regions: Consult local machinery safety and environmental regulations.

Documentation & Record Keeping

Maintain the following:

– Operator’s manual and parts catalog

– Proof of emissions certification

– Maintenance logs

– Training and certification records

– Transport permits (if applicable)

Retain records for a minimum of 5 years or per local requirements.

Final Inspection & Delivery

Before deployment:

– Inspect for transport damage.

– Confirm all compliance labels are intact.

– Test all functions (steering, hydraulics, lights, alarms).

– Verify that safety decals and warnings are legible and properly placed.

Adhering to this guide ensures safe, legal, and efficient use of the Mini Articulating Loader across various operational and regulatory environments.

Conclusion: Sourcing a Mini Articulating Loader

After a comprehensive evaluation of market options, supplier capabilities, cost considerations, and operational requirements, sourcing a mini articulating loader proves to be a strategic investment to enhance productivity, versatility, and efficiency in confined or challenging work environments. These compact machines offer superior maneuverability, 360-degree swing capabilities, and the ability to perform multiple tasks with the use of various attachments, making them ideal for landscaping, construction, agriculture, and industrial applications.

Key factors such as reliability, after-sales support, warranty terms, and total cost of ownership were critical in the decision-making process. Selecting a reputable supplier with a proven track record, accessible service network, and strong operator training programs ensures long-term equipment performance and minimizes downtime.

In conclusion, procuring a mini articulating loader aligns with our operational goals of improving job site efficiency and reducing manual labor. By choosing a model that balances performance, durability, and cost-effectiveness, we position our operations for greater agility and competitiveness. The next steps involve finalizing the supplier agreement, scheduling delivery, and implementing operator training to ensure safe and optimal use.