The global welding equipment market is experiencing steady growth, driven by increasing demand from key industries such as construction, automotive, and manufacturing. According to Mordor Intelligence, the market is projected to grow at a CAGR of approximately 5.2% from 2024 to 2029, with arc welding equipment remaining a dominant segment due to its reliability and efficiency in metal fabrication. As one of the most popular entry-level MIG welders, the Miller Millermatic 140 Auto-Set has become a benchmark for performance and ease of use, fueling demand for compatible components, accessories, and manufacturing expertise. While Miller Electric maintains proprietary control over the original design, several manufacturers have emerged as leading suppliers of compatible parts, aftermarket enhancements, and support systems that align with the Millermatic 140’s specifications. These companies play a crucial role in extending the welder’s lifecycle, improving serviceability, and supporting the growing base of small-to-mid-sized operations relying on this trusted model. Below are the top five manufacturers contributing to the ecosystem surrounding the Miller Millermatic 140 Auto-Set, evaluated based on product quality, market presence, innovation, and customer support.

Top 5 Miller Millermatic 140 Auto Set Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

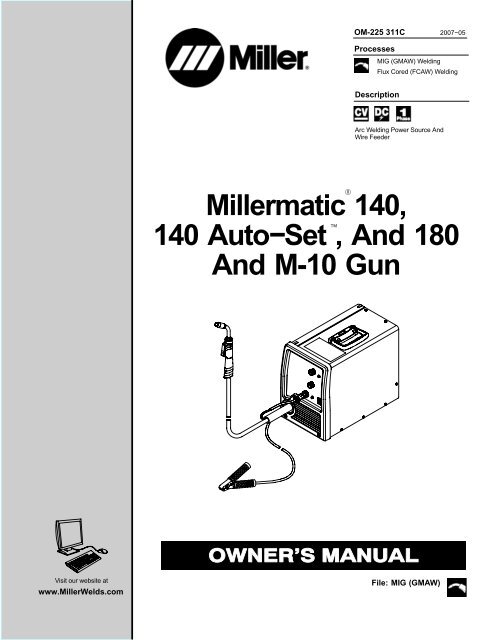

#1 Auto-Set™

Domain Est. 1996

Website: millerwelds.com

Key Highlights: Auto-Set™. Auto-Set™ control is a breakthrough control feature that automatically sets your welder to the proper parameters.Missing: 140 manufacturer…

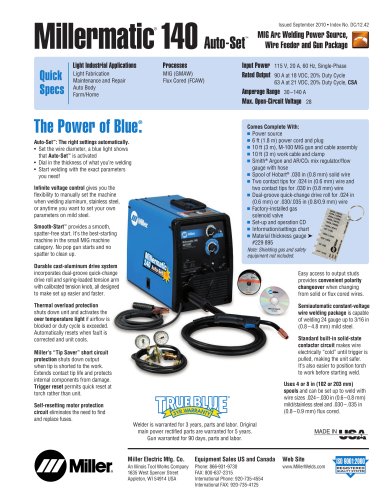

#2 Millermatic® 140 Auto

Domain Est. 1999

Website: pdf.directindustry.com

Key Highlights: The Millermatic 140 Auto-Set offers all the benefits of a standard MIG machine, but adds Auto-Set to eliminate the guesswork….

#3 Miller Millermatic 140 MIG Pkg with Auto

Domain Est. 2005

Website: weldingsuppliesfromioc.com

Key Highlights: This item is no longer available from Miller. The Millermatic 140 has now been replaced by the Millermatic 142 MIG Welder….

#4 Miller Electric

Domain Est. 2017

Website: millerserviceparts.com

Key Highlights: Free delivery over $85 30-day returns…

#5 Miller Genuine Parts 169716 Contact Tip Adapter Millermatic 140 …

Domain Est. 2019

Website: magicnailspaparma.com

Key Highlights: In stock Rating 5.0 (83) Miller Genuine Parts 169716 Contact Tip Adapter Millermatic 140 180 DVI Passport ; Used $19.80 (tax included) New Arrivals and Restocks Number in stock: …

Expert Sourcing Insights for Miller Millermatic 140 Auto Set

H2: 2026 Market Trends for the Miller Millermatic 140 Auto Set

As we approach 2026, the market for entry-level MIG welders like the Miller Millermatic 140 Auto Set is being shaped by several key trends in manufacturing, fabrication, and DIY sectors. This analysis explores the evolving demand, competitive landscape, technological advancements, and consumer expectations influencing the position and performance of the Millermatic 140 Auto Set in the coming years.

-

Rising Demand in DIY and Small-Scale Fabrication

The do-it-yourself (DIY) movement continues to expand, with more hobbyists, home garage welders, and small business owners investing in reliable, user-friendly welding equipment. The Millermatic 140 Auto Set, known for its Auto-Set feature that automatically adjusts voltage and wire feed speed, remains highly attractive to novice welders. As online tutorials, maker communities, and vocational training programs grow, demand for intuitive machines like the Millermatic 140 is expected to increase through 2026. -

Competition from Low-Cost Alternatives

While Miller Electric maintains a strong reputation for durability and performance, lower-cost brands from Asia and private-label welders sold through major retailers are gaining market share. These alternatives often mimic the ease-of-use features of the Auto Set system but at a reduced price point. To maintain its edge, Miller may need to emphasize its superior build quality, warranty support, and availability of service networks—key differentiators in a competitive landscape. -

Emphasis on Energy Efficiency and Sustainability

By 2026, energy efficiency and environmental considerations are becoming more influential in industrial equipment purchasing decisions. Although the Millermatic 140 is not a high-consumption machine, future market expectations may push manufacturers to incorporate more energy-saving technologies and recyclable components. Miller’s commitment to sustainable manufacturing practices could enhance brand loyalty and appeal to eco-conscious buyers. -

Integration with Digital Tools and Smart Features

While the Millermatic 140 Auto Set is not a “smart” welder, evolving expectations for digital connectivity—such as app-based diagnostics, usage tracking, or firmware updates—may begin influencing even entry-level equipment. Although Miller is unlikely to overhaul the Auto Set into a connected device by 2026, the company might explore optional digital accessories or companion tools to enhance user experience without compromising the unit’s simplicity. -

Supply Chain and Manufacturing Resilience

Post-pandemic supply chain adjustments continue to affect production and pricing. Miller’s U.S.-based manufacturing provides a strategic advantage in terms of reliability and lead times, especially as regionalization of supply chains becomes a priority. This localization supports faster distribution and after-sales service, reinforcing the value proposition of American-made equipment like the Millermatic 140 in the North American market. -

Training and Education Sector Adoption

Technical schools, community colleges, and vocational training centers are increasingly standardizing their welding curricula around user-friendly, dependable machines. The Auto Set feature makes the Millermatic 140 ideal for classroom environments where students have varying skill levels. As workforce development initiatives expand in 2026, institutional procurement could represent a steady stream of demand.

Conclusion

The Miller Millermatic 140 Auto Set is well-positioned to remain a top choice in the entry-level MIG welding segment through 2026, thanks to its ease of use, brand reputation, and reliability. However, Miller must navigate growing price competition and shifting consumer expectations around digital integration and sustainability. By reinforcing its strengths in support, durability, and accessibility, the Millermatic 140 can continue to lead in both hobbyist and light industrial markets.

Common Pitfalls When Sourcing a Miller Millermatic 140 Auto Set (Quality & Intellectual Property)

Sourcing a Miller Millermatic 140 Auto Set, especially outside authorized channels or from third-party sellers, carries significant risks related to both product quality and intellectual property (IP) infringement. Being aware of these pitfalls is crucial to avoid financial loss, safety hazards, and legal complications.

Counterfeit or Clone Units Masquerading as Genuine

One of the most prevalent risks is encountering counterfeit or unauthorized replica welders labeled as “Miller Millermatic 140 Auto Set.” These units often mimic the branding, color scheme, and model name but are manufactured by third parties without Miller Electric’s quality control or engineering standards. These clones may use subpar components (transformers, wiring, cooling systems) leading to unreliable performance, overheating, or premature failure. The “Auto-Set” feature—a key selling point relying on precise internal circuitry—may not function correctly or at all in counterfeit models.

Unauthorized Resellers and Grey Market Goods

Purchasing from unauthorized dealers, including some online marketplaces or liquidators, increases the risk of receiving grey market units. These may be intended for different regions (e.g., export models not compliant with U.S. electrical or safety standards), lack proper warranty coverage, or have been tampered with. Miller does not support warranty claims on units sold through unauthorized channels, leaving buyers without recourse if defects arise. Additionally, these sellers may not provide genuine user manuals or safety documentation.

Intellectual Property Infringement

Using or distributing counterfeit Miller welders constitutes a violation of intellectual property rights, including trademarks and design patents. Miller Electric actively protects its brand and proprietary technology. Buyers of counterfeit units may inadvertently support IP theft and, in rare cases, face legal scrutiny—especially if the units are used commercially and found to be infringing. Furthermore, these clones often bear fake certification marks (such as CE or UL), misleading consumers about safety compliance.

Compromised Safety and Regulatory Compliance

Genuine Miller welders undergo rigorous testing to meet safety standards (e.g., UL, CSA). Counterfeit or cloned Millermatic 140 units frequently bypass these certifications. This increases the risk of electrical shock, fire hazards, or arc flash incidents due to inadequate insulation, poor grounding, or faulty internal design. Using non-compliant equipment can also violate OSHA regulations in professional settings, exposing users or employers to liability.

Lack of Technical Support and Spare Parts

Even if a non-genuine unit functions initially, long-term support is nearly impossible. Miller will not provide technical assistance, firmware updates, or replacement parts for counterfeit models. Sourcing compatible components becomes difficult and expensive, often rendering the welder unusable once a critical part fails. Genuine Auto-Set circuit boards or contact tips are engineered specifically for Miller machines and may not integrate properly with clones.

Misleading Marketing and False Claims

Unscrupulous sellers often use terms like “compatible with Miller,” “inspired by,” or “Millermatic style” to imply authenticity without directly claiming the product is genuine. This misleading marketing exploits consumer trust in the Miller brand. Always verify the seller’s authorization status through Miller’s official website and inspect product documentation carefully before purchasing.

Conclusion

To avoid these pitfalls, always purchase Miller Millermatic 140 Auto Set units from authorized Miller dealers. Verify the product’s serial number with Miller customer service, inspect for official certification labels, and ensure full warranty coverage is provided. Investing in a genuine unit protects not only your wallet but also your safety and legal standing.

Logistics & Compliance Guide for Miller Millermatic 140 Auto Set

Package Contents and Inspection

Upon receiving the Miller Millermatic 140 Auto Set, verify the following items are included:

– Millermatic 140 Auto Set Welder

– Spool of .023″ Miller SuperClean™ Flux-Cored Wire (8-inch spool, 2 lb)

– Millerless Plus™ MIG Gun (10 ft)

– Work Cable with Clamp (8 ft)

– Gas Regulator/Flowmeter (if using MIG mode with shielding gas)

– Power Input Cable with NEMA 6-50P Plug

– User Manual and Safety Guidelines

– Auto-Set Technology Quick Reference Guide

Inspect packaging for damage. If damaged, document and report immediately to the carrier and supplier.

Shipping and Handling

- Weight: Approximately 44 lbs (20 kg)

- Dimensions (packed): 18.5″ L × 10″ W × 13″ H (47 × 25.4 × 33 cm)

- Use proper lifting techniques; unit is portable but should be handled with care.

- Store in a dry, temperature-controlled environment (–20°F to 120°F / –29°C to 49°C recommended).

- Avoid exposure to moisture, dust, and corrosive atmospheres during transit and storage.

Power Requirements and Electrical Compliance

- Input Voltage: 230V single-phase

- Plug Type: NEMA 6-50P (50A, 250V)

- Circuit Requirement: Minimum 50-amp dedicated circuit with appropriate overcurrent protection

- Compliance Standards:

- UL 1598 (Standard for Safety of Luminaires)

- CSA C22.2 No. 60974-1 (Arc Welding Equipment)

- Meets OSHA 29 CFR 1910.254 (Welding, Cutting, and Brazing)

- Complies with FCC Part 18 for electromagnetic interference (EMI)

Ensure proper grounding of the unit and workpiece in accordance with local electrical codes (NEC Article 630 in the U.S.).

Regulatory Compliance and Certifications

- Safety Certification: Certified by UL (Underwriters Laboratories) and CSA (Canadian Standards Association)

- EMC Compliance: Complies with CE (Europe), UKCA (UK), and FCC (U.S.) for electromagnetic compatibility

- RoHS Compliance: Contains no restricted hazardous substances per EU Directive 2011/65/EU

- WEEE Directive: Product falls under category 3 (Monitoring and Control Instruments); dispose of through approved electronic waste channels

Product bears the following marks: UL, CSA, CE, UKCA, and FCC.

Import/Export and International Logistics

- HS Code: 8515.21.00 (Arc-welding machines)

- Country of Origin: United States

- Documentation Required for Export:

- Commercial invoice

- Packing list

- Certificate of Origin

- FCC Declaration of Conformity

- RoHS Compliance Statement

Verify compliance with destination country’s electrical and safety standards. Use licensed freight forwarders familiar with industrial equipment regulations.

Installation and Site Preparation

- Provide adequate ventilation when welding indoors (follow ANSI Z87.1 and OSHA ventilation standards).

- Maintain minimum 3 ft (1 m) clearance around the unit for airflow.

- Install on a stable, level surface; avoid locations with high vibration or moving traffic.

- Use only Miller-approved accessories and consumables to maintain compliance and warranty.

Operator Safety and Training Compliance

- All operators must be trained in:

- Safe welding practices (AWS Z49.1: Safety in Welding, Cutting, and Allied Processes)

- Proper PPE usage (helmet, gloves, flame-resistant clothing, respiratory protection if needed)

- Emergency shutdown procedures

- Conduct regular equipment inspections per manufacturer guidelines.

- Post appropriate warning signs in welding areas (e.g., “Danger – Arc Radiation,” “Fire Hazard”).

Warranty and Technical Support

- Warranty: 3-year limited warranty on parts and labor (U.S. and Canada); international terms may vary

- Support: Contact Miller Electric at 1-800-4-A-MILLER (1-800-426-4553) or visit www.millerwelds.com

- Register your product online to activate warranty and receive compliance updates

Keep original purchase documentation and user manual for warranty claims.

Disposal and End-of-Life Compliance

- Do not dispose of in regular trash.

- Recycle electronic components through certified e-waste recyclers.

- Follow local, state, and federal regulations for disposal of electronic equipment.

- Contact Miller Electric or local authorities for guidance on proper decommissioning.

In conclusion, sourcing the Miller Millermatic 140 Auto-Set MIG welder requires careful consideration of several key factors to ensure reliability, value, and long-term performance. This user-friendly, lightweight welder is ideal for DIY enthusiasts, hobbyists, and contractors seeking a portable and efficient solution for thin to medium-duty welding applications. When sourcing the unit, it’s essential to purchase from authorized dealers or reputable suppliers to guarantee authenticity, access to warranty coverage, and manufacturer support. Comparing prices across trusted retailers—both online and local—can help secure a competitive deal, while also ensuring you receive genuine accessories and technical support. Additionally, verifying product specifications, warranty terms, and post-purchase service options will contribute to a successful acquisition. By sourcing the Miller Millermatic 140 Auto-Set through proper channels, buyers can confidently invest in a durable, high-performing welder known for its Auto-Set feature that simplifies setup and enhances ease of use.