The global laser welding equipment market is experiencing robust growth, driven by increasing demand for precision manufacturing across automotive, aerospace, and medical device industries. According to a report by Mordor Intelligence, the laser welding market was valued at USD 3.8 billion in 2023 and is projected to grow at a CAGR of over 7.5% through 2029. This expansion is fueled by advancements in fiber laser technology and a growing shift toward automation in industrial processes. Within this competitive landscape, Miller Electric—a long-standing leader in welding solutions—does not manufacture standalone laser welders. However, several prominent manufacturers have emerged as top suppliers of laser welding systems often compared to or integrated alongside conventional Miller brand equipment in industrial settings. These companies combine high-power laser performance, intelligent controls, and scalable solutions to meet evolving production demands. Below are the top four manufacturers producing advanced laser welders comparable in reliability and innovation to Miller’s reputation in arc welding, based on market presence, product capability, and pricing competitiveness.

Top 4 Miller Laser Welder Price Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Engine-Driven Welders and Machines

Website: millerwelds.com

Key Highlights: View and compare engine-driven welders from Miller. Models are available in diesel, gasoline or LP and for a variety of industries. Learn more!…

#2 Revolutionizing Welding

Website: bakersgas.com

Key Highlights: The Miller OptX™ 2kW Handheld Laser Welder embodies this spirit, offering welders a seamless blend of ease of use, speed, and precision….

#3 252 Miller Welders & Kits for sale from $1112.00

Website: weldersupply.com

Key Highlights: Free delivery over $300Quality Miller TIG and Stick welding packages and kits available with fast shipping from Welders Supply….

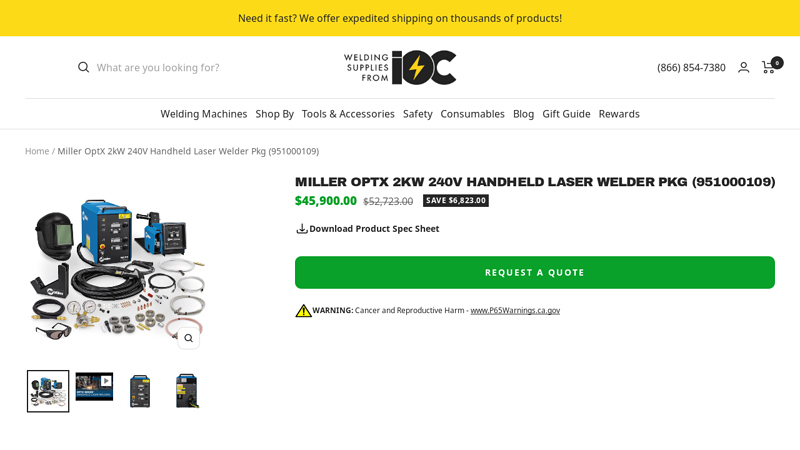

#4 Miller OptX 2kW 240V Handheld Laser Welder Pkg (951000109)

Website: weldingsuppliesfromioc.com

Key Highlights: Miller OptX 2kW 240V Handheld Laser Welder Pkg (951000109). Sale price$45,900.00 Regular price$52,723.00. Save $6,823.00. Split your purchase into installments ……

Expert Sourcing Insights for Miller Laser Welder Price

H2: Projected 2026 Market Trends for Miller Laser Welder Prices

As the global manufacturing and metal fabrication industries continue to evolve, laser welding technology is becoming increasingly integral to high-precision production processes. Miller Electric, a leading name in welding equipment, is expected to see notable shifts in the pricing of its laser welders by 2026. These changes will be influenced by technological advancements, supply chain dynamics, competitive pressures, and growing industrial demand.

-

Technological Innovation and Product Differentiation

By 2026, Miller is anticipated to release next-generation laser welders featuring enhanced automation, improved energy efficiency, and better integration with Industry 4.0 systems (such as IoT-enabled diagnostics and cloud-based monitoring). These advanced features are likely to drive an upward pressure on prices for premium models. Consumers seeking higher accuracy, faster welding speeds, and reduced heat distortion will pay a premium, especially in aerospace, automotive, and medical device manufacturing sectors. -

Increased Competition and Market Expansion

The laser welding market is becoming more competitive, with key players like IPG Photonics, TRUMPF, and Amada expanding their footholds. To maintain market share, Miller may adopt a tiered pricing strategy—offering entry-level laser welders at more competitive prices while preserving higher margins on advanced systems. This could result in a wider price range across the Miller product line, making laser technology more accessible to small and medium-sized enterprises (SMEs). -

Supply Chain and Raw Material Costs

Global supply chain stability, particularly for critical components like fiber lasers, optics, and rare-earth materials, will influence pricing. Ongoing geopolitical tensions and fluctuations in semiconductor availability could lead to cost volatility. If supply constraints persist into 2026, Miller may pass some of these costs onto consumers, resulting in moderate price increases—estimated between 3% and 6% annually, depending on model complexity. -

Regional Market Dynamics

In North America, where Miller holds strong brand recognition, pricing may remain relatively stable due to localized production and service networks. However, in emerging markets (e.g., Southeast Asia and Eastern Europe), Miller may adjust pricing strategies to compete with lower-cost alternatives, potentially subsidizing entry-level units to gain market penetration. -

Sustainability and Regulatory Factors

Environmental regulations promoting energy-efficient manufacturing could incentivize adoption of laser welding over traditional arc methods. Governments may introduce subsidies or tax incentives for businesses investing in green technologies. These factors could indirectly affect net pricing by reducing the total cost of ownership, thereby increasing demand and possibly stabilizing or even lowering long-term price growth.

Conclusion

By 2026, Miller laser welder prices are expected to reflect a balance between innovation-driven premiums and competitive market pressures. While high-end models will likely see price increases due to advanced features, broader market accessibility and strategic pricing could keep average price growth moderate—projected at 4–7% cumulatively from 2023 to 2026. End-users should anticipate greater value through performance and integration, even as upfront costs rise slightly.

Common Pitfalls When Sourcing Miller Laser Welder Prices (Quality, IP)

Sourcing Miller laser welders requires careful attention beyond just the initial price tag. Overlooking key factors related to quality and intellectual property (IP) can lead to significant long-term costs, operational risks, and legal complications. Here are common pitfalls to avoid:

Overlooking Build Quality and Component Authenticity

One of the most frequent mistakes is focusing solely on upfront cost while ignoring the actual build quality and authenticity of components. Counterfeit or low-tier suppliers may offer “Miller-priced” laser welders that use inferior materials, substandard optics, or non-genuine Miller parts. These units often fail prematurely under industrial use, leading to costly downtime, frequent repairs, and inconsistent weld quality. Always verify that the welder meets Miller’s published specifications and request documentation proving the authenticity of critical components.

Ignoring IP and Brand Licensing Issues

Another major pitfall is sourcing from suppliers who claim to sell Miller equipment but lack proper IP authorization. Some third-party vendors may use Miller’s branding or model names without licensing, selling rebranded or cloned systems that infringe on intellectual property rights. Purchasing such equipment can expose your company to legal liability, void warranties, and result in no access to official technical support or software updates. Ensure the supplier is an authorized Miller distributor with verifiable credentials.

Underestimating the Total Cost of Ownership

Focusing exclusively on the initial Miller laser welder price can be misleading. Inferior or unauthorized systems may have lower purchase prices but higher long-term costs due to increased maintenance, lower energy efficiency, and shorter lifespans. Genuine Miller systems are engineered for durability and performance, often resulting in lower total cost of ownership. Always conduct a lifecycle cost analysis, factoring in service, consumables, and productivity losses.

Skipping Verification of Warranty and Support

Unauthorized suppliers may offer limited or void warranties, leaving buyers without recourse if the system fails. Genuine Miller laser welders come with comprehensive manufacturer-backed warranties and access to trained technical support. Failing to confirm warranty terms and post-purchase support can leave operations vulnerable. Always verify that warranty coverage is valid and provided directly through Miller or an authorized service partner.

Assuming All “Miller-Compatible” Systems Are Equal

Some suppliers market systems as “Miller-compatible” or “Miller-integrated,” implying seamless performance. However, compatibility does not guarantee performance parity. Non-genuine systems may not integrate properly with Miller’s software or control systems, leading to reduced precision, safety risks, or compliance issues. Confirm full system integration and performance validation before purchase.

By avoiding these common pitfalls, buyers can ensure they invest in a high-quality, IP-compliant Miller laser welding solution that delivers reliable performance and long-term value.

Logistics & Compliance Guide for Miller Laser Welder Price

When evaluating the price of a Miller laser welder, it’s essential to consider not only the initial purchase cost but also the logistics and compliance factors that can significantly impact total ownership cost. Understanding these elements ensures smoother procurement, transportation, installation, and operation in accordance with local and international regulations.

Shipping and Transportation Considerations

The delivered cost of a Miller laser welder includes more than the manufacturer’s listed price. Shipping method (air, sea, or ground), distance, packaging requirements, and freight insurance all influence final expenses. Laser welding systems are often large, heavy, and sensitive to environmental conditions, requiring specialized crating and handling. International shipments may incur customs delays and require compliance with export/import regulations such as export licenses or ITAR (International Traffic in Arms Regulations) if applicable.

Import Duties and Tax Implications

Purchasing a Miller laser welder from outside your country may subject the transaction to import duties, value-added tax (VAT), or goods and services tax (GST). These fees vary by country and classification under the Harmonized System (HS) Code. For example, industrial laser machines often fall under HS Code 8515.21 or similar, which determines the applicable duty rate. Accurate classification and documentation (commercial invoice, packing list, certificate of origin) are vital to avoid customs delays and unexpected costs.

Regulatory Compliance for Laser Equipment

Laser welding systems are subject to stringent safety and emissions regulations. In the United States, the Food and Drug Administration (FDA) Center for Devices and Radiological Health (CDRH) regulates laser products under 21 CFR Part 1040.10 and 1040.11. This includes requirements for safety labeling, protective housings, interlocks, and emission compliance. Buyers must ensure the specific Miller laser welder model meets these standards and includes proper certification (e.g., FDA compliance letter, CDRH report).

International Safety and Certification Standards

For global operations, Miller laser welders must comply with regional safety certifications. Key standards include:

– CE Marking (European Union): Compliance with the Machinery Directive (2006/42/EC) and the EMC Directive (2014/30/EU), including EN 60825 for laser safety.

– UKCA Marking (United Kingdom): Post-Brexit equivalent to CE, required for products placed on the UK market.

– CSA/UL (Canada and USA): Electrical safety standards for industrial equipment.

– PSE (Japan): Required for electrical devices under the Japanese Electrical Appliance and Material Safety Law.

Ensure the model purchased includes necessary documentation and certifications for your region to avoid non-compliance penalties or installation delays.

Installation and Site Preparation Requirements

Delivery and installation of a Miller laser welder may involve site audits to verify facility readiness. Requirements often include:

– Adequate floor space and structural support

– Proper power supply (voltage, phase, grounding)

– Cooling systems or exhaust ventilation

– Safety enclosures and interlock integration

– Network connectivity for monitoring and diagnostics

Failure to meet these requirements can result in additional expenses or operational downtime, affecting the effective cost of ownership.

Warranty, Service, and Spare Parts Logistics

The published price of a Miller laser welder may not include extended warranty, on-site service plans, or initial spare parts. Consider the availability and lead time for replacement components, especially for optical or electronic parts subject to wear. For international buyers, assess whether Miller or an authorized distributor provides local technical support and service response times, as extended downtimes can increase operational costs.

Environmental and Disposal Regulations

End-of-life disposal of laser systems must comply with environmental regulations such as WEEE (Waste Electrical and Electronic Equipment) in the EU or EPA guidelines in the U.S. Laser components may contain hazardous materials (e.g., certain optics or batteries), requiring proper recycling procedures. Factor in potential disposal costs or take-back programs when evaluating long-term expenses.

Conclusion

The true cost of a Miller laser welder extends beyond the sticker price. Logistics—including shipping, import duties, and site preparation—and compliance with safety, regulatory, and environmental standards all contribute to the total investment. Proactively addressing these factors ensures a smooth acquisition process, regulatory adherence, and optimal return on investment.

Conclusion: Sourcing Miller Laser Welder Pricing

After evaluating various suppliers, distributors, and market channels, the pricing for Miller laser welders varies significantly based on model specifications, included features, region, and level of support (e.g., training, warranty, service). Generally, Miller laser welders are positioned in the premium segment of the market, reflecting their reputation for durability, advanced technology, and reliable after-sales support.

Key findings include:

- Entry-level models start around $15,000–$20,000, ideal for small workshops or light industrial use.

- Mid-range to high-end systems (e.g., Miller X-Steer or integrated robotic solutions) can range from $30,000 to over $60,000, depending on configuration.

- Additional costs such as delivery, installation, training, and extended warranties should be factored into the total investment.

- Authorized dealers often provide better pricing packages, including service agreements and financing options, compared to third-party resellers.

- Direct engagement with Miller Electric or certified distributors ensures authenticity, access to technical support, and compatibility with OEM parts.

In conclusion, while Miller laser welders represent a higher initial investment compared to some competitors, their long-term value—through reliability, productivity gains, and support—makes them a justified choice for businesses prioritizing quality and uptime. It is recommended to obtain detailed quotes from at least three authorized suppliers, evaluate total cost of ownership, and consider long-term service agreements when finalizing the purchase decision.