The global flux core welding market is experiencing steady expansion, driven by rising demand across construction, shipbuilding, and heavy equipment manufacturing sectors. According to Grand View Research, the global flux cored arc welding (FCAW) market was valued at USD 1.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by the advantages of flux core welding—such as high deposition rates, deep penetration, and outdoor usability—which make it a preferred choice in industrial applications. As a key player in the welding industry, Miller Electric has strengthened its position by partnering with leading flux core consumable manufacturers to deliver high-performance solutions. Below, we examine the top four Miller-aligned flux core manufacturers shaping the future of arc welding, combining engineering precision with innovation to meet evolving market demands.

Top 4 Miller Flux Core Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Flux-Cored Guns

Domain Est. 1996

Website: millerwelds.com

Key Highlights: Ergonomically designed to provide increased access and maneuverability in hard-to-reach weld joints….

#2 Shop Miller Welders UK

Domain Est. 2000

Website: premierwelding.com

Key Highlights: 30-day returnsAs official Miller Welders UK dealers, we stock their iconic blue machines. Discover Miller MIG, TIG & Arc welders. Free UK delivery on orders over £1….

#3 MIG/MAG Welding Machines

Domain Est. 2021

Website: millerweldseurope.com

Key Highlights: Discover our range of MIG/MAG welding machines. Designed for consistent, high-quality welds across various applications….

#4 Flux Core Welding

Website: millercraftmetal.com

Key Highlights: At Miller Craft Metal and Fabrication, we utilize flux-core welding to deliver high-quality results on projects that require durability, especially in outdoor ……

Expert Sourcing Insights for Miller Flux Core

H2: Market Trends for Miller Flux Core in 2026

As we approach 2026, the market for Miller Electric’s flux core welding products is poised for significant evolution, driven by technological innovation, industry demand shifts, and broader economic and environmental trends. Miller, a leader in welding equipment and solutions, is well-positioned to capitalize on key developments in the flux core arc welding (FCAW) segment. Below is an analysis of the primary market trends influencing Miller Flux Core products in 2026.

1. Increased Demand in Construction and Infrastructure

With continued global investment in infrastructure—particularly in North America under long-term government initiatives such as the U.S. Infrastructure Investment and Jobs Act—the construction and heavy equipment sectors are experiencing a resurgence. Flux core welding is favored in structural steel applications due to its high deposition rates and ability to perform well in outdoor and suboptimal conditions. Miller’s robust lineup of FCAW-compatible wire feed units and multi-process welders are seeing heightened adoption among contractors seeking reliable, high-productivity solutions.

2. Advancements in Portability and Automation Integration

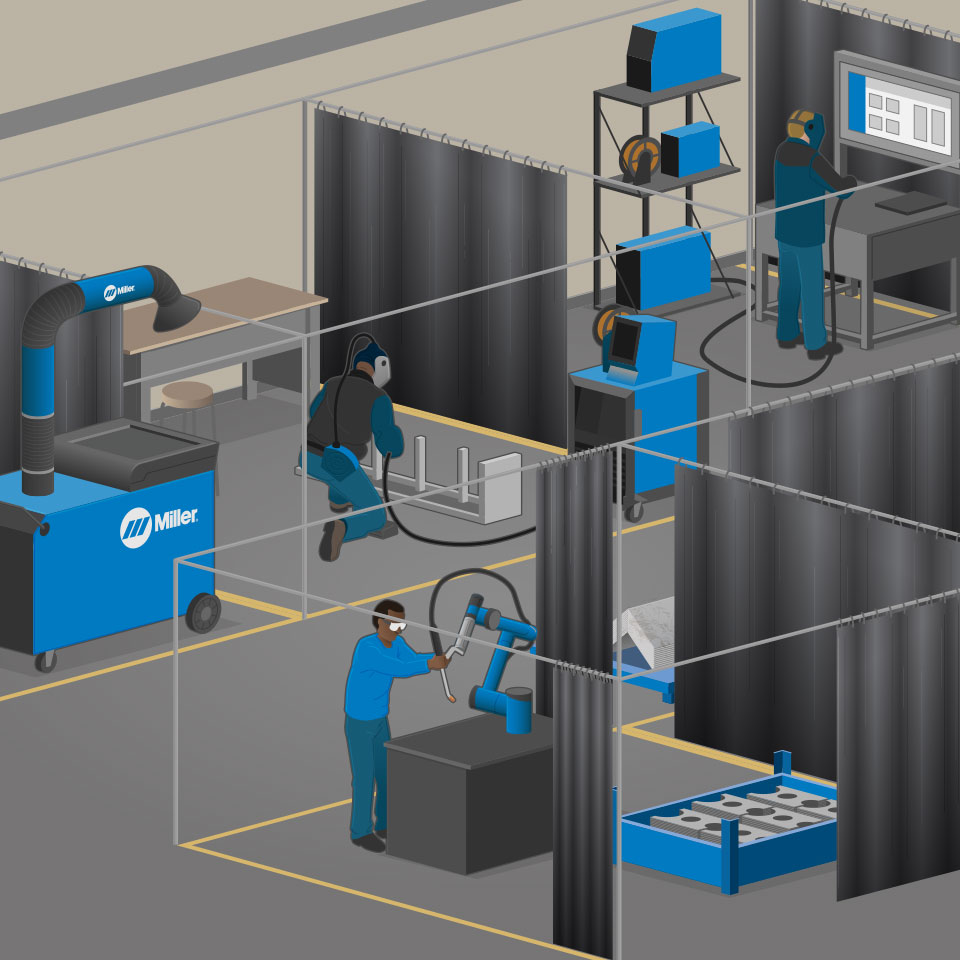

In 2026, there is a growing trend toward hybrid welding systems that combine portability with smart technology. Miller has responded by enhancing its flux core-enabled welders (e.g., the Millermatic and Multimatic series) with integrated digital controls, remote monitoring, and compatibility with robotic welding cells. These features support automated or semi-automated workflows in fabrication shops, improving consistency and reducing operator fatigue—especially important amid ongoing skilled labor shortages.

3. Emphasis on Sustainability and Energy Efficiency

Environmental regulations and corporate sustainability goals are pushing manufacturers to reduce emissions and energy consumption. While flux core welding traditionally produces more fumes than other processes, Miller has introduced advanced fume extraction integration options and energy-efficient inverter technologies in its 2026 product line. These innovations help users meet environmental compliance standards while maintaining productivity.

4. Growth in Industrial Manufacturing and Heavy Equipment Repair

The manufacturing sector, particularly in energy (oil & gas, renewables), mining, and transportation, continues to rely on flux core welding for its deep penetration and tolerance to dirty or rusty materials. Miller’s Flux Core solutions are increasingly adopted in field repair and maintenance operations, where durability and performance in adverse conditions are critical.

5. Workforce Development and Training Ecosystems

As the welding workforce ages and new entrants require upskilling, Miller has expanded its digital training platforms and partnerships with vocational institutions. These programs emphasize FCAW best practices using Miller equipment, ensuring continued brand loyalty and proper application of flux core technology in real-world settings.

6. Competition and Market Differentiation

While Lincoln Electric remains a strong competitor in the FCAW space, Miller differentiates itself in 2026 through user-friendly interfaces, superior customer support, and a focus on integrated digital ecosystems (e.g., Miller’s Insight Connect for weld data tracking). This digital edge enhances productivity analytics, appealing to large-scale operations focused on operational efficiency.

Conclusion

By 2026, Miller’s flux core offerings are benefiting from strong tailwinds in infrastructure, manufacturing, and technology adoption. The company’s strategic focus on innovation, sustainability, and workforce enablement positions it as a market leader in the evolving FCAW landscape. As industries demand faster, cleaner, and smarter welding solutions, Miller continues to adapt—ensuring its flux core-compatible systems remain essential tools in modern fabrication.

Common Pitfalls When Sourcing Miller Flux Core (Quality, IP)

Sourcing Miller flux core welding wire—whether genuine or compatible—can present several challenges related to quality consistency and intellectual property (IP) concerns. Being aware of these pitfalls helps ensure reliable performance and legal compliance.

1. Counterfeit or Substandard Products

One of the most significant risks is purchasing counterfeit or low-quality flux core wire falsely labeled as Miller. These products are often sold through unauthorized distributors or online marketplaces and may mimic genuine packaging but deliver poor arc stability, inconsistent deposition, excessive spatter, and weak mechanical properties.

Impact: Leads to rework, weld failures, increased downtime, and potential safety hazards.

Prevention: Buy only from authorized Miller Electric distributors. Verify distributor credentials and check for holographic security labels or batch traceability on packaging.

2. Inconsistent Quality from Third-Party Alternatives

While some non-Miller flux core wires are compatible with Miller equipment, many lack the rigorous quality control of genuine Miller products. Variations in wire diameter, flux composition, and shielding gas requirements can affect weld quality and equipment performance.

Impact: Unpredictable weld results, shortened contact tip life, and potential damage to welding equipment.

Prevention: Stick to manufacturer-recommended consumables or thoroughly test third-party wires under actual production conditions before full-scale adoption.

3. Intellectual Property (IP) Infringement

Selling or distributing flux core wire under the “Miller” brand name without authorization constitutes trademark and IP infringement. Unauthorized manufacturers may use similar names, logos, or packaging to mislead buyers.

Impact: Legal liability for both sellers and buyers, reputational damage, and voided equipment warranties.

Prevention: Conduct due diligence on suppliers. Avoid products with suspicious branding or pricing that seems too good to be true. Report suspected IP violations to Miller Electric.

4. Lack of Technical Support and Warranty Coverage

Using non-genuine or counterfeit flux core wire may void equipment warranties and disqualify users from technical support provided by Miller Electric.

Impact: Higher long-term costs due to equipment repairs and lack of manufacturer backing.

Prevention: Use only OEM-approved consumables to maintain warranty eligibility and access to technical resources.

5. Misleading Performance Claims

Some suppliers advertise “Miller-equivalent” flux core wire with performance claims that aren’t backed by testing or certification. These claims often don’t account for differences in alloy composition or welding parameters.

Impact: Poor weld integrity, especially in critical or code-required applications.

Prevention: Request test reports, certifications (e.g., AWS compliance), and conduct side-by-side performance evaluations before committing to a new product.

By recognizing these common pitfalls—ranging from quality compromise to legal exposure—buyers can make informed decisions and maintain high standards in their welding operations.

Logistics & Compliance Guide for Miller Flux Core Welding Wire

This guide outlines the logistics handling, storage, transportation, and regulatory compliance requirements for Miller Flux Core welding wire products. Proper adherence ensures product integrity, workplace safety, and regulatory compliance.

Product Identification and Specifications

Miller Flux Core wire is available in various diameters, classifications (e.g., E71T-11, E71T-1), and packaging types (spools, drums, or coils). Always verify the product label, Safety Data Sheet (SDS), and packaging for correct identification. Each product carries a unique part number and lot traceability for quality control and compliance tracking.

Packaging and Handling

- Packaging Types: Miller Flux Core wire is typically supplied in vacuum-sealed plastic bags with desiccant, enclosed in robust cardboard boxes or steel drums to prevent moisture absorption and physical damage.

- Handling Procedures: Use appropriate lifting equipment for heavy spools (e.g., 50 lb, 75 lb, or 500 lb packages). Avoid dropping or impacting packages, which can deform wire or compromise packaging integrity.

- Forklift Use: When moving pallets, ensure even weight distribution and use pallet jacks or forklifts with protective sleeves to avoid puncturing packaging.

Storage Requirements

- Environment: Store in a clean, dry, climate-controlled indoor environment. Ideal storage conditions are 40°F to 100°F (4°C to 38°C) with relative humidity below 60%.

- Moisture Control: Flux core wire is hygroscopic. Never open packaging until ready for use. Once opened, unused wire should be stored in a heated quiver or sealed container to prevent moisture absorption, which can lead to porosity and weld defects.

- Shelving: Store upright on shelves or pallets off the floor to prevent moisture wicking and physical damage. Avoid stacking excessive weight on lower tiers.

Transportation Guidelines

- Domestic (USA/Canada):

- Secure loads to prevent shifting during transit.

- Protect from rain, snow, and extreme temperatures.

- Follow FMCSA (Federal Motor Carrier Safety Administration) and CSA (Canadian Standards Association) regulations for load securement.

- International:

- Comply with IMDG Code for sea freight and IATA regulations for air transport if applicable (though welding wire is generally not classified as hazardous for transport).

- Ensure proper customs documentation including commercial invoice, packing list, and certificate of origin.

Regulatory Compliance

- OSHA Compliance:

- Follow OSHA 29 CFR 1910.252 for welding, cutting, and brazing safety.

- Ensure Material Safety Data Sheets (SDS) are accessible to all personnel.

- GHS/SDS Requirements:

- Miller provides GHS-compliant SDS for all flux core products.

- SDS includes hazard identification, first aid, fire-fighting measures, accidental release procedures, handling and storage, exposure controls, and toxicological information.

- EPA & Environmental Regulations:

- Dispose of damaged or contaminated wire and packaging according to local, state, and federal waste regulations.

- Avoid release of wire shavings or dust into storm drains or natural water sources.

Quality Assurance and Traceability

- Lot Tracking: Maintain records of received lots for traceability in case of field issues or recalls.

- Inspection Upon Receipt: Inspect shipments for damage, moisture exposure, or compromised packaging. Report discrepancies immediately to the supplier.

- First-In, First-Out (FIFO): Implement FIFO inventory rotation to minimize prolonged storage and potential degradation.

Safety and Training

- Employee Training: Train personnel on proper handling, storage, and emergency procedures related to flux core wire.

- PPE: While the wire itself is not hazardous under normal handling, use gloves and safety glasses when handling spools to prevent cuts or eye injuries from sharp wire ends.

Disposal and Recycling

- Wire Scrap: Recycle metal wire scrap through certified metal recyclers. Follow local environmental laws for disposal of non-recyclable components.

- Packaging: Cardboard, plastic liners, and steel drums may be recyclable—coordinate with local recycling programs.

Contact Information

For questions regarding logistics, compliance, or product specifications:

– Miller Electric Mfg. LLC

– Website: www.millerwelds.com

– Customer Service: 1-800-4-A-MILLER (1-800-426-4553)

– SDS Access: Available online at Miller’s SDS portal or upon request.

Always consult the latest product-specific documentation and regulatory standards. This guide serves as a general reference and does not replace official compliance requirements.

Conclusion: Sourcing Miller Flux Core Wire

Sourcing Miller flux core wire ensures access to high-quality, reliable welding materials designed for superior performance, consistent arc stability, and excellent bead appearance. Miller Electric, a trusted leader in welding technology, offers flux core wires that are engineered to meet rigorous industry standards, making them ideal for demanding applications in construction, manufacturing, and repair. When sourcing Miller flux core products, it is essential to work with authorized distributors or certified suppliers to guarantee authenticity, maintain warranty coverage, and ensure proper storage and handling. While the initial cost may be higher compared to generic brands, the long-term benefits—such as reduced downtime, lower spatter, and improved productivity—justify the investment. In conclusion, choosing genuine Miller flux core wire supports weld quality, operator efficiency, and overall project success, making it a strategic decision for professional welding operations.