The global milking equipment market is experiencing steady growth, driven by increasing demand for automation in dairy farming, rising milk production, and a shift toward large-scale commercial dairy operations. According to Grand View Research, the global milking machines market size was valued at USD 2.1 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is fueled by technological advancements such as robotic milking systems, increased labor costs, and the need for enhanced milk hygiene and cow comfort. As dairy farms worldwide adopt more efficient and scalable solutions, the role of leading milking machine manufacturers becomes increasingly critical. These companies are not only investing in innovation but also expanding their global footprint to meet regional demands. Based on market presence, technological capabilities, and production scale, the following are the top 10 milking machine manufacturers shaping the future of modern dairying.

Top 10 Milking Machine Men Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

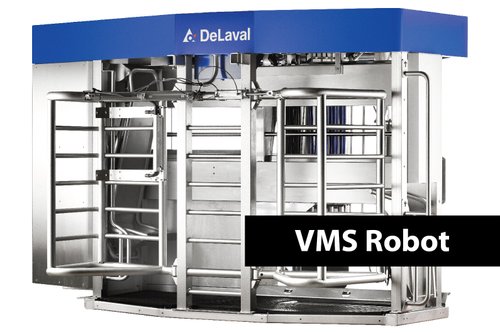

#1 DeLaval

Domain Est. 1998

Website: delaval.com

Key Highlights: DeLaval provides integrated solutions designed to improve dairy producers’ production, animal welfare and overall quality of life….

#2 Milking Machine Manufacturer

Domain Est. 2022

Website: godhanmilkingmachine.com

Key Highlights: A top milking machine manufacturer, we focus on creating high-caliber devices that satisfy the demands of dairy farmers….

#3 Bright farming is yours by choice

Domain Est. 1996

Website: lely.com

Key Highlights: Lely, an international family business, offers innovative dairy farming solutions—from milking to cleaning. We help farmers organize smart, efficient farms….

#4 Sezer Agriculture and Milking Technologies

Domain Est. 1999 | Founded: 1978

Website: en.sezermac.com

Key Highlights: Since 1978, we bring quality to the farms! View in details, newproducts, electronic pulsator, SEP-B / with card 24V, undefined, MINI-1 (20 Lt.), mobile milking ……

#5 J.Delgado

Domain Est. 2000

Website: j-delgado.com

Key Highlights: One of the largest companies dedicated to the manufacture and installation of milking parlours. We also manufacture spares adaptable to other brands….

#6 Capralite Milking Machine and Silverline Hoof Trimmer

Domain Est. 2003

#7 History

Domain Est. 2003

Website: surgemilker.com

Key Highlights: In 1916 Babson Brothers began manufacturing and selling The Pine Tree Milking Machine – an upright floor pail designed like many others of that time. While the ……

#8 Milkplan

Domain Est. 2007

Website: milkplan.com

Key Highlights: Milkplan designs and manufactures premium dairy equipment for milk cooling, milking parlours, and farm equipment – trusted in 100+ countries worldwide….

#9 Lely

Domain Est. 2015

Website: lelyna.com

Key Highlights: Lely Certified Pre-Owned robotic milking systems offer the legendary Lely performance you need, with the capital savings you want and peace of mind you deserve….

#10 Milk Barn LLC

Website: gomilkbarn.com

Key Highlights: Supplying service, supplies, and solutions for milking, feeding, cow comfort, and manure handling! Contact us to learn how we can help your dairy farm with ……

Expert Sourcing Insights for Milking Machine Men

H2: 2026 Market Trends for Milking Machine Manufacturers

The global market for milking machine manufacturers is poised for transformative growth and innovation by 2026, driven by advancements in agricultural technology, rising demand for dairy efficiency, and sustainability imperatives. Key trends shaping the industry include:

-

Increased Automation and Smart Technology Integration

By 2026, milking machine manufacturers are expected to heavily invest in fully automated and robotic milking systems (AMS). These systems utilize IoT sensors, AI-driven analytics, and real-time monitoring to optimize udder health, milk yield, and animal welfare. Integration with farm management software allows seamless data transfer, enabling predictive maintenance and precision dairy farming. -

Growth in Robotic Milking Systems

The adoption of robotic milking systems is accelerating, particularly in North America, Western Europe, and parts of Asia-Pacific. These systems reduce labor costs and improve milking frequency and cow comfort. Manufacturers are focusing on scalable, modular designs to cater to both large commercial farms and small-to-mid-sized operations. -

Sustainability and Energy Efficiency

Environmental concerns are pushing manufacturers to develop energy-efficient and low-carbon-footprint milking equipment. Innovations include regenerative braking in robotic units, solar-powered systems, and water-saving cleaning cycles. Compliance with stricter environmental regulations will be a key differentiator in competitive markets. -

Expansion in Emerging Markets

Countries in Southeast Asia, Africa, and Latin America are witnessing modernization of dairy infrastructure. As government initiatives support dairy farming mechanization, milking machine manufacturers are tailoring cost-effective, durable solutions for these regions, often through localized production and partnerships. -

Focus on Animal Welfare and Milk Quality

Consumer demand for high-quality, ethically produced milk is influencing design standards. Milking machines are being engineered with softer liners, optimized pulsation rates, and hygienic materials to minimize stress and mastitis risks. This aligns with global dairy quality certifications and traceability standards. -

Consolidation and Strategic Partnerships

The competitive landscape is seeing increased mergers and acquisitions among key players (e.g., DeLaval, Lely, GEA, and Fullwood Pakka). Collaborations with agri-tech startups are enabling faster innovation in data analytics, cloud-based monitoring, and AI-driven herd management tools. -

Digital Services and Subscription Models

Beyond hardware, manufacturers are shifting toward service-oriented business models. Remote diagnostics, predictive maintenance subscriptions, and performance analytics platforms are becoming integral offerings, enhancing customer retention and recurring revenue.

In summary, by 2026, milking machine manufacturers will be at the nexus of agritech and sustainability, with innovation centered on automation, data intelligence, and global accessibility. Companies that adapt to regional needs and embrace digital transformation will lead the market.

Common Pitfalls When Sourcing Milking Machine Components (Quality, IP)

Sourcing milking machine components—often colloquially referred to as “milking machine men” though more accurately described as parts, systems, or suppliers—requires careful attention to avoid critical issues related to quality and intellectual property (IP). Overlooking these areas can lead to operational failures, legal disputes, and reputational damage. Below are the most common pitfalls to watch for.

Poor Component Quality and Performance

One of the primary risks in sourcing milking machine parts is receiving substandard components that fail to meet industry performance and safety standards. Low-quality materials or poor manufacturing can lead to frequent breakdowns, contamination risks, and reduced milk yield. Components such as pulsators, liners, and vacuum pumps must meet strict hygiene and durability requirements. Sourcing from unverified suppliers without proper certifications (e.g., ISO, CE, or 3A) increases the likelihood of receiving parts that degrade quickly or compromise animal health and milk quality.

Lack of Traceability and Documentation

Many suppliers in less-regulated markets fail to provide comprehensive documentation, including material certifications, test reports, or traceability records. This lack of transparency makes it difficult to verify the quality and origin of components. In regulated dairy industries, traceability is essential for compliance and food safety audits. Without proper documentation, businesses risk non-compliance with regional agricultural or food safety standards (e.g., FDA, EU regulations).

Intellectual Property Infringement

A significant and often overlooked risk is sourcing components that infringe on existing patents or trademarks. Some suppliers offer “compatible” or “OEM-style” parts that mimic branded products but may violate intellectual property rights. Using such parts can expose the buyer to legal action from original equipment manufacturers (OEMs), especially in markets with strong IP enforcement. This is particularly common with proprietary technologies such as automated milking systems or smart sensors.

Counterfeit or Replica Parts

Counterfeiting is prevalent in the agricultural machinery sector. Buyers may unknowingly purchase replica parts advertised as genuine or high-quality alternatives. These counterfeit components often lack reliability and can introduce serious safety hazards. Distinguishing between legitimate aftermarket parts and illegal copies requires due diligence, including supplier audits and verification of part authenticity through OEM channels.

Inadequate After-Sales Support and Warranty

Sourcing from low-cost suppliers may come with limited or non-existent technical support, warranties, or spare parts availability. When a critical milking system component fails, the absence of responsive support can result in prolonged downtime, affecting herd productivity and farm profitability. Reliable suppliers should offer technical assistance, repair services, and clear warranty terms.

Ignoring Compatibility and Integration Risks

Even high-quality components can cause issues if they are not fully compatible with existing milking systems. Differences in design, specifications, or communication protocols (especially in automated systems) can lead to integration failures. Buyers must ensure that sourced parts meet exact technical specifications and are tested for interoperability with their current infrastructure.

Conclusion

To mitigate these pitfalls, it’s essential to conduct thorough supplier vetting, demand full compliance documentation, verify IP status, and prioritize long-term reliability over initial cost savings. Partnering with reputable manufacturers and consulting legal experts on IP matters can protect both operational integrity and legal compliance in dairy farming operations.

Logistics & Compliance Guide for Milking Machine Maintenance Technicians

Overview

This guide outlines the essential logistics and regulatory compliance procedures for Milking Machine Maintenance Technicians (“Milking Machine Men”) to ensure safe, efficient, and legally compliant operations across dairy farms. Adherence to these protocols supports animal health, milk quality, and regulatory standards.

Equipment Transport & Inventory Management

- Vehicle Preparation: Maintain a clean, organized service vehicle equipped with necessary tools, spare parts (e.g., liners, hoses, gaskets), and safety gear.

- Inventory Tracking: Use a digital or physical log to track parts usage, stock levels, and expiration dates (e.g., lubricants, seals). Replenish supplies weekly.

- Cold Chain for Sensitive Components: Store temperature-sensitive parts (e.g., rubber components) in climate-controlled conditions to prevent degradation.

Regulatory Compliance Requirements

- Milk Safety Regulations: Comply with national and regional milk safety standards (e.g., FDA Pasteurized Milk Ordinance in the U.S., EU Milk Hygiene Regulations).

- Machine Performance Standards: Ensure all repairs and adjustments meet recognized performance benchmarks (e.g., vacuum levels, pulsation rates per ICAR guidelines).

- Recordkeeping: Maintain service logs including:

- Date and time of service

- Farm identification

- Equipment serviced (make, model, serial number)

- Work performed and parts replaced

- Post-service performance test results

On-Farm Protocols

- Biosecurity Measures:

- Disinfect boots and tools before and after entering barns.

- Use farm-provided coveralls or disposable suits where required.

- Avoid cross-contamination between herds.

- Coordination with Farm Staff: Communicate with farm managers to schedule service during low-traffic milking times and minimize disruption.

- Waste Disposal: Properly dispose of used parts, lubricants, and cleaning solutions in accordance with local environmental regulations. Recycle where possible.

Safety & Personal Protective Equipment (PPE)

- Required PPE: Wear gloves, safety glasses, steel-toed boots, and cut-resistant clothing when servicing equipment.

- Electrical Safety: De-energize and lockout electrical components before performing repairs.

- Chemical Handling: Follow SDS guidelines for cleaning agents and lubricants; store in labeled, sealed containers.

Documentation & Reporting

- Service Reports: Provide farms with a signed service report after each visit, including inspection findings and recommendations.

- Regulatory Submissions: Submit maintenance records to dairy cooperatives or regulatory bodies as required (e.g., annual certification audits).

- Non-Compliance Reporting: Report any recurring equipment failures or systemic issues to the manufacturer and relevant dairy authority.

Training & Certification

- Certification Maintenance: Hold valid certifications (e.g., from equipment manufacturers or agricultural extension programs).

- Continuing Education: Attend annual training on updated regulations, new technologies, and safety protocols.

- Onboard New Technicians: Follow a standardized training checklist to ensure compliance knowledge transfer.

Emergency Procedures

- Spill Response: Carry spill kits for oil or chemical leaks; follow farm-specific containment procedures.

- Equipment Failure: Notify farm manager immediately of critical failures; provide estimated downtime and repair timeline.

- Injury Protocol: Report any on-farm injuries per OSHA (or local equivalent) requirements and complete incident reports within 24 hours.

Conclusion

Strict adherence to logistics and compliance standards ensures the reliability of milking systems, protects milk quality, and upholds public health. Regular audits and technician accountability are vital for continued success in the field.

Conclusion for Sourcing Milking Machines:

Sourcing milking machines requires a thorough evaluation of various factors including the scale of the dairy operation, herd size, budget, required level of automation, and long-term maintenance needs. It is essential to select machines that ensure animal welfare, improve milk quality, and enhance operational efficiency. Conducting due diligence on suppliers, comparing different models and technologies (such as pipeline, parlor, or robotic systems), and considering after-sales service and spare parts availability are critical steps in the sourcing process. Additionally, compliance with hygiene standards and relevant regulations should not be overlooked. Ultimately, investing in the right milking machine system—tailored to the farm’s specific needs—can lead to increased productivity, reduced labor costs, and sustainable dairy farming practices.